key NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 9 of 3066

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT Line Pressure Test ............................................... 290

Road Test ............................................................. 291

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION ........................................................................ 308

Symptom Chart .................................................... 308

TCM Terminals and Reference Value ................... 347

CAN COMMUNICATION ........................................ 351

System Description .............................................. 351

TROUBLE DIAGNOSES FOR SYMPTOMS .......... 352

............................................................................. 352

1. O/D OFF Indicator Lamp Does Not Come On . 354

2. Engine Cannot Be Started In “P” and “N” Position. 355

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed .............................................. 356

4. In “N” Position, Vehicle Moves ......................... 356

5. Large Shock. “N”®“R” Position ...................... 358

6. Vehicle Does Not Creep Backward In “R” Position. 359

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ........................................................... 362

8. Vehicle Cannot Be Started From D

1................. 364

9. A/T Does Not Shift: D

1®D2Or Does Not Kick-

down: D

4®D2..................................................... 366

10. A/T Does Not Shift: D

2®D3......................... 368

11.A/TDoesNotShift:D

3®D4.......................... 371

12. A/T Does Not Perform Lock-up ...................... 374

13. A/T Does Not Hold Lock-up Condition ........... 375

14. Lock-up Is Not Released ................................ 376

15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3) ................................................ 377

16. Vehicle Does Not Start From D

1..................... 379

17. A/T Does Not Shift: D

4®D3, When Overdrive

Control Switch “ON”®“OFF” .............................. 380

18. A/T Does Not Shift: D

3®22, When Selector

Lever “D”®“2” Position ...................................... 380

19. A/T Does Not Shift: 2

2®11, When Selector

Lever “2”®“1” Position ....................................... 381

20. Vehicle Does Not Decelerate By Engine Brake. 381

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) ........................................ 382

ALL

MAIN POWER SUPPLY AND GROUND CIRCUIT. 389

Wiring Diagram — AT — MAIN ............................ 389

Diagnostic Procedure ........................................... 390

VEHICLE SPEED SENSOR·A/T (REVOLUTION

SENSOR) ................................................................ 392

Description ........................................................... 392

Wiring Diagram — AT — VSSA/T ........................ 394

Diagnostic Procedure ........................................... 395

DTC VEHICLE SPEED SENSOR MTR .................. 397

Description ........................................................... 397

Wiring Diagram — AT — VSSMTR ...................... 399

Diagnostic Procedure ........................................... 400

ACCELE RATOR PEDAL POSITION (APP) SEN-

SOR ........................................................................ 401

Description ........................................................... 401Wiring Diagram — AT — TPS ..............................403

Diagnostic Procedure ...........................................404

SHIFT SOLENOID VALVE A ..................................406

Description ............................................................406

Wiring Diagram — AT — SSV/A ...........................408

Diagnostic Procedure ...........................................409

Component Inspection ..........................................410

SHIFT SOLENOID VALVE B ..................................411

Description ............................................................411

Wiring Diagram — AT — SSV/B ...........................413

Diagnostic Procedure ...........................................414

Component Inspection ..........................................415

OVERRUN CLUTCH SOLENOID VALVE ...............416

Description ............................................................416

Wiring Diagram — AT — OVRCSV ......................418

Diagnostic Procedure ...........................................419

Component Inspection ..........................................420

TORQUE CONVERTER CLUTCH SOLENOID

VALVE .....................................................................421

Description ............................................................421

Wiring Diagram — AT — TCV ..............................423

Diagnostic Procedure ...........................................424

Component Inspection ..........................................425

BATT/FLUID TEMP SEN (A/T FLUID TEMP SEN-

SOR CIRCUIT AND TCM POWER SOURCE) .......426

Description ............................................................426

Wiring Diagram — AT — BA/FTS .........................428

Diagnostic Procedure ...........................................429

Component Inspection ..........................................431

ENGINE SPEED SIGNAL .......................................432

Description ............................................................432

Wiring Diagram — AT — ENGSS .........................433

Diagnostic Procedure ...........................................434

LINE PRESSURE SOLENOID VALVE ...................436

Description ............................................................436

Wiring Diagram — AT — LPSV ............................438

Diagnostic Procedure ...........................................439

Component Inspection ..........................................441

CAN CAMMUNICATION LINE ................................443

Description ............................................................443

On Board Diagnosis Logic ....................................443

Self-Diagnosis Code Confirmation Procedure ......443

Wiring Diagram — AT — CAN ..............................444

Diagnostic Procedure ...........................................445

A/T SHIFT LOCK SYSTEM ....................................446

Description ............................................................446

Shift Lock System Electrical Parts Location .........446

Wiring Diagram — SHIFT — ................................447

Diagnostic Procedure ...........................................448

KEY INTERLOCK CABLE ......................................452

Components .........................................................452

Removal ...............................................................452

Installation ............................................................453

ON-VEHICLE SERVICE ..........................................454

Control Valve Assembly and Accumulators ..........454

Control Cable Adjustment .....................................456

Park/Neutral Position (PNP) Switch Adjustment ..456

Page 13 of 3066

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

lAfter performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DURE”.

The DTC should not be displayed in the “DTC CONFIRMA-

TION PROCEDURE” if the repair is completed.

lBefore proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

lDisassembly should be done in a clean work area.

lUse lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transaxle.

lPlace disassembled parts in order for easier and proper assembly.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lGaskets, seals and O-rings should be replaced any time the transaxle is disassembled.

lIt is very important to perform functional tests whenever they are indicated.

lThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

lProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

lBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

lExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

lAfter overhaul, refill the transaxle with new ATF.

lWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

to “Changing A/T Fluid”,AT-13, "

A/T FLUID".

Service Notice or PrecautionsECS004Q3

FAI L-S AFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

When the ignition key is turned “ON” following Fail-Safe operation, O/D OFF indicator lamp blinks for about 8

seconds. Refer to SELF-DIAGNOSTIC PROCEDURE(WITHOUT CONSULT-II)",AT- 2 7 3 , "

Diagnostic Proce-

dure Without CONSULT-II"(EXCEPT FOR EURO-OBD) or "TCM Self-diagnostic Procedure(NO TOOLS)",

AT- 5 1 , "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)"(EURO-OBD).

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW”, refer toAT-284, "

Work Flow"(EXCEPT FOR Euro-OBD) orAT-61, "Work

Flow"(Euro-OBD).

The SELF-DIAGNOSIS results will be as follows:

lThe first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

lDuring the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

lExternal leaks in the hub weld area.

lConverter hub is scored or damaged.

lConverter pilot is broken, damaged or fits poorly into crankshaft.

lSteel particles are found after flushing the cooler and cooler lines.

lPump is damaged or steel particles are found in the converter.

SAT652J

Page 63 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-57

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

lWHAT..... Vehicle & A/T model

lWHEN..... Date, Frequencies

lWHE NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-57

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

lWHAT..... Vehicle & A/T model

lWHEN..... Date, Frequencies

lWHE](/img/5/57402/w960_57402-62.png)

TROUBLE DIAGNOSIS — INTRODUCTION

AT-57

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

lWHAT..... Vehicle & A/T model

lWHEN..... Date, Frequencies

lWHERE..... Road conditions

lHOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencyoContinuousoIntermittent ( times a day)

SymptomsoVehicle does not move. (oAny positionoParticular position)

oNo up-shift (o1st®2ndo2nd®3rdo3rd®O/D)

oNo down-shift (oO/D®3rdo3rd®2ndo2nd®1st)

oLockup malfunction

oShift point too high or too low.

oShift shock or slip (oN®DoLockupoAny drive position)

oNoise or vibration

oNo kickdown

oNo pattern select

oOthers

()

O/D OFF indicator lamp Blinks for about 8 seconds.

oContinuously litoNot lit

Malfunction indicator lamp (MIL)oContinuously litoNot lit

Page 286 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-280

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

lWHAT..... Vehicle & A/T model

lWHEN..... Date, Frequencies

lWHERE..... Road condit NISSAN X-TRAIL 2003 Electronic Repair Manual AT-280

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

lWHAT..... Vehicle & A/T model

lWHEN..... Date, Frequencies

lWHERE..... Road condit](/img/5/57402/w960_57402-285.png)

AT-280

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

lWHAT..... Vehicle & A/T model

lWHEN..... Date, Frequencies

lWHERE..... Road conditions

lHOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencyoContinuousoIntermittent ( times a day)

SymptomsoVehicle does not move. (oAny positionoParticular position)

oNo up-shift (o1st®2ndo2nd®3rdo3rd®O/D)

oNo down-shift (oO/D®3rdo3rd®2ndo2nd®1st)

oLockup malfunction

oShift point too high or too low.

oShift shock or slip (oN®DoLockupoAny drive position)

oNoise or vibration

oNo kickdown

oNo pattern select

oOthers

()

O/D OFF indicator lamp Blinks for about 8 seconds.

oContinuously litoNot lit

Page 452 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-446

[ALL]

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

DescriptionECS00405

lThe mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the sele NISSAN X-TRAIL 2003 Electronic Repair Manual AT-446

[ALL]

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

DescriptionECS00405

lThe mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the sele](/img/5/57402/w960_57402-451.png)

AT-446

[ALL]

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

DescriptionECS00405

lThe mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from “P” (parking) to any other posi-

tion unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from “P” to any other position.

The key cannot be removed unless the selector lever is placed in “P”.

lThe shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationECS00406

SCIA0781E

Page 454 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-448

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can b NISSAN X-TRAIL 2003 Electronic Repair Manual AT-448

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can b](/img/5/57402/w960_57402-453.png)

AT-448

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can be moved from “P” position with key in ON position and brake pedal released.

lSelector lever can be moved from “P” position when key is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to “P” position. It can be removed when

selector lever is set to any position except “P”.

1.CHECKKEYINTERLOCKCABLE

Check key interlock cable for damage.

OK or NG

OK >> GO TO 2

NG >> Repair key interlock cable. Refer toAT - 4 5 2 , "

KEY INTERLOCK CABLE".

2.CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK >> GO TO 3

NG >> Check selector lever. Refer toAT - 4 5 6 , "

Park/Neutral Position (PNP) Switch Adjustment".

3.CHECK POWER SOURCE

1. Turn ignition switch to “ON” position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

OK or NG

OK >> GO TO 4

NG >> Check the following items:

1. Harness for short or open between battery and stop

lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer toPG-2, "

POWER SUPPLY

ROUTING".) Voltage : Battery voltageSCIA0782E

Page 458 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

feren NISSAN X-TRAIL 2003 Electronic Repair Manual AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

feren](/img/5/57402/w960_57402-457.png)

AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

ference with adjacent parts.

lAfter installing key interlock cable to control device, make sure that casing cap and bracket are

firmly secured in their positions.

RemovalECS0040A

1. Unlock slider by squeezing lock tabs on slider from adjuster

holder and remove interlock rod from cable.

SAT996J

SAT853J

Page 459 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual KEY INTERLOCK CABLE

AT-453

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Remove lock plate from steering lock assembly and remove key

interlock cable.

InstallationECS0040B

1. Turn ignition key to lock position.

NISSAN X-TRAIL 2003 Electronic Repair Manual KEY INTERLOCK CABLE

AT-453

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Remove lock plate from steering lock assembly and remove key

interlock cable.

InstallationECS0040B

1. Turn ignition key to lock position.](/img/5/57402/w960_57402-458.png)

KEY INTERLOCK CABLE

AT-453

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

2. Remove lock plate from steering lock assembly and remove key

interlock cable.

InstallationECS0040B

1. Turn ignition key to lock position.

2. Set A/T selector lever to P position.

3. Set key interlock cable to steering lock assembly and install lock

plate.

4. Clamp cable to steering column and fix to control cable with

band.

5. Insert interlock rod into adjuster holder.

6. Install casing cap to bracket.

7. Move slider in order to fix adjuster holder to interlock rod.

SAT854J

SAT854J

SAT804E

SAT805E

Page 629 of 3066

TROUBLE DIAGNOSIS

ATC-51

C

D

E

F

G

H

I

K

L

MA

B

AT C

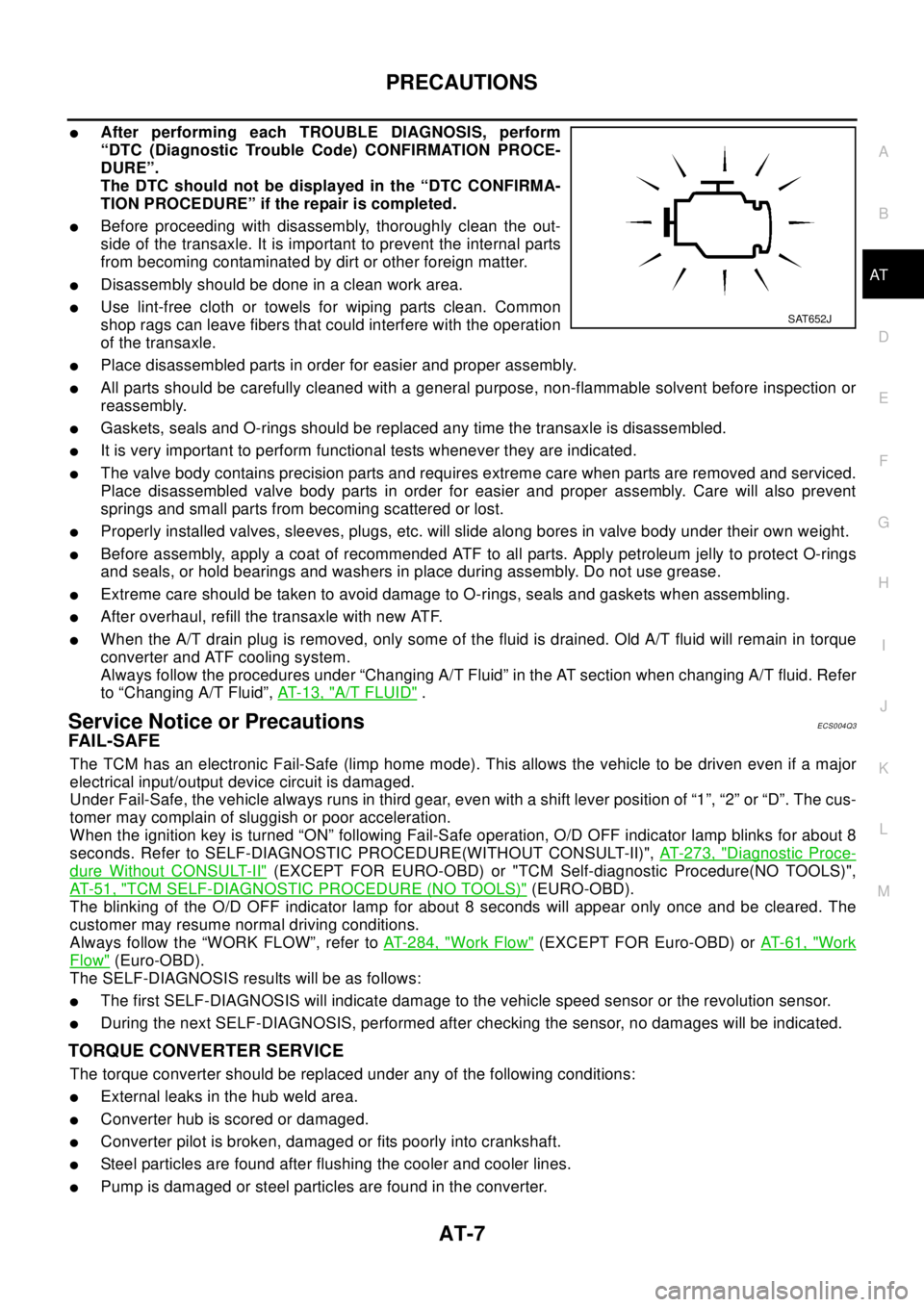

lPress the mode switch as desired.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION (FOR LHD MODELS)

When ignition key is turned from OFF to ON, inlet port can be set to AUTO or manual.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 5 mode.

lPress (fan) UP switch to set system in auxiliary mode.

lDisplay shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

lPress the recirculation (REC) switch as desired.

Operational CheckEJS001GY

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature 90°For32°C.

2. Press OFF switch.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous tempera-

ture.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for memory functionAT C - 9 2

.

If OK, continue with next check.

RJIA0040E

LED status of REC switch Setting status Setting changeover method

ON Manual REC status is memorized.

REC SW : ON

OFF AUTO control

Conditions :Engine running and at normal operating temperature

RJIA0496E

Page 726 of 3066

AV-4

AUDIO

Service Procedure

SPEED DEPENDENT VOLUME CONTROL

Description

If activated, the radio output volume will be automatically adjusted to compensate for increased driving noises

at higher driving speeds.

The radio receives a speed signal from the vehicle speed sensor (VSS) and selects the output volume.

PERSONAL AUDIO SETTINGS

Description

The radio is designed to store several settings (volume, bass, treble, preset stations and level of speed depen-

dent volume control) with every NATS ignition key used. Up to a maximum of 4 NATS keys can be registered.

During the communication mentioned under “Anti-Theft System”, the radio will recognize the used ignition key

and select the accompanying settings.

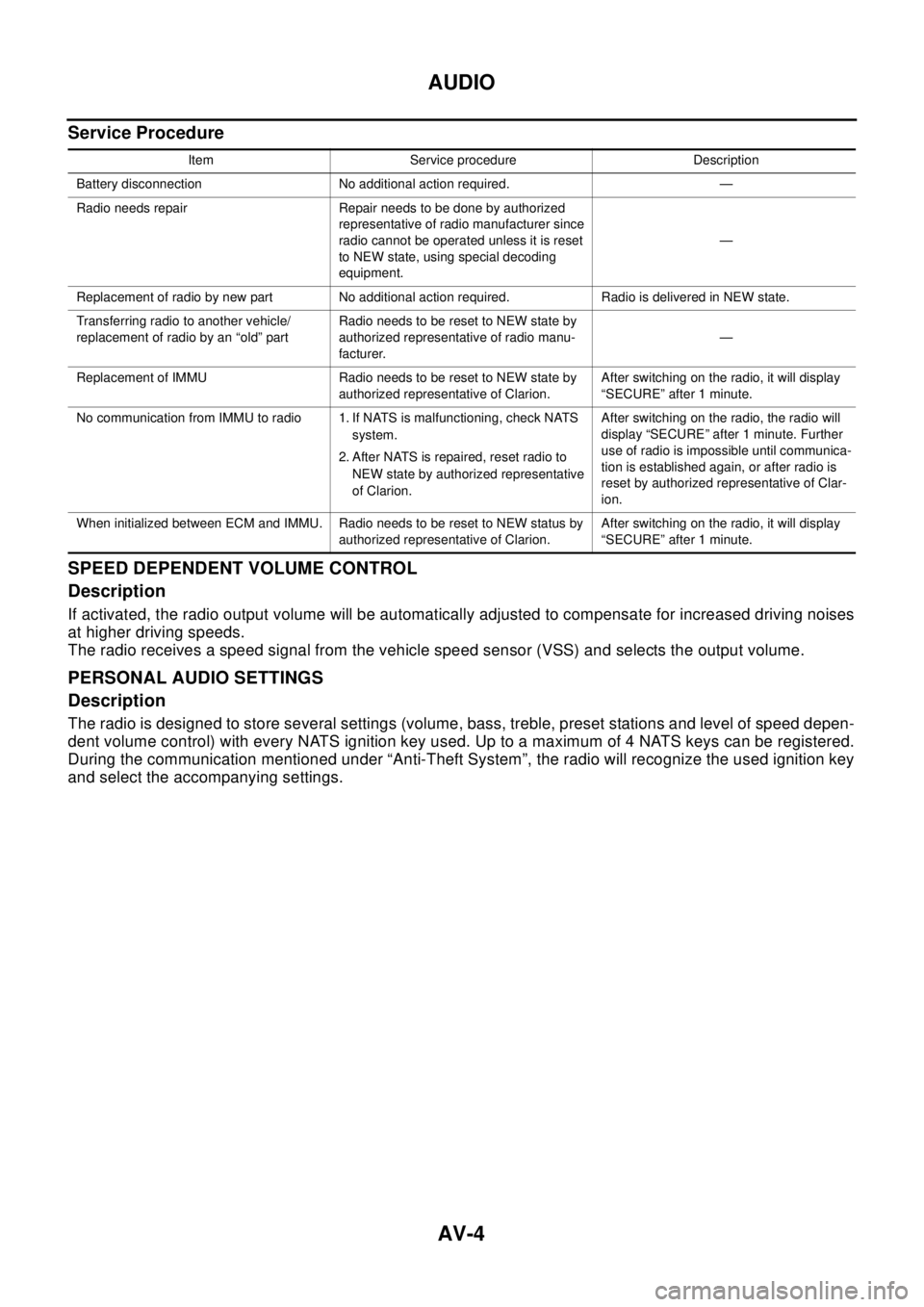

Item Service procedure Description

Battery disconnection No additional action required. —

Radio needs repair Repair needs to be done by authorized

representative of radio manufacturer since

radio cannot be operated unless it is reset

to NEW state, using special decoding

equipment.—

Replacement of radio by new part No additional action required. Radio is delivered in NEW state.

Transferring radio to another vehicle/

replacement of radio by an “old” partRadio needs to be reset to NEW state by

authorized representative of radio manu-

facturer.—

Replacement of IMMU Radio needs to be reset to NEW state by

authorized representative of Clarion.After switching on the radio, it will display

“SECURE” after 1 minute.

No communication from IMMU to radio 1. If NATS is malfunctioning, check NATS

system.

2. After NATS is repaired, reset radio to

NEW state by authorized representative

of Clarion.After switching on the radio, the radio will

display “SECURE” after 1 minute. Further

use of radio is impossible until communica-

tion is established again, or after radio is

reset by authorized representative of Clar-

ion.

When initialized between ECM and IMMU. Radio needs to be reset to NEW status by

authorized representative of Clarion.After switching on the radio, it will display

“SECURE” after 1 minute.