check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2278 of 3066

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-25

lVehicle vibration

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

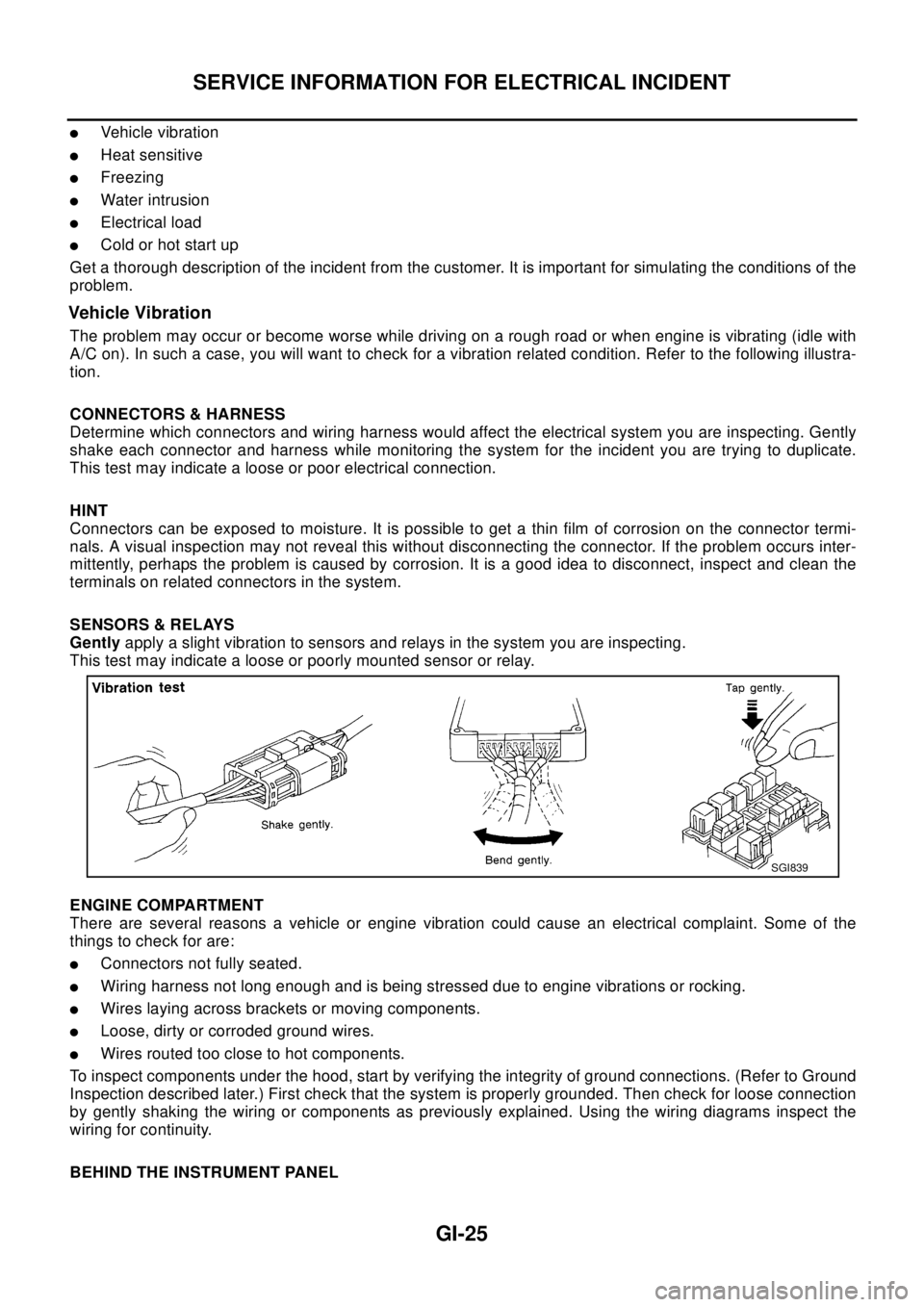

Vehicle Vibratio n

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

SGI839

Page 2288 of 3066

CONSULT-II CHECKING SYSTEM

GI-35

CONSULT-II CHECKING SYSTEMPFP:00000

DescriptionEAS000G8

lCONSULT-II is a hand-held type tester. When it is connected with a diagnostic connector equipped on the

vehicle side, it will communicate with the control unit equipped in the vehicle and then enable various

kinds of diagnostic tests.

lRefer to “CONSULT-II Software Operation Manual” for more information.

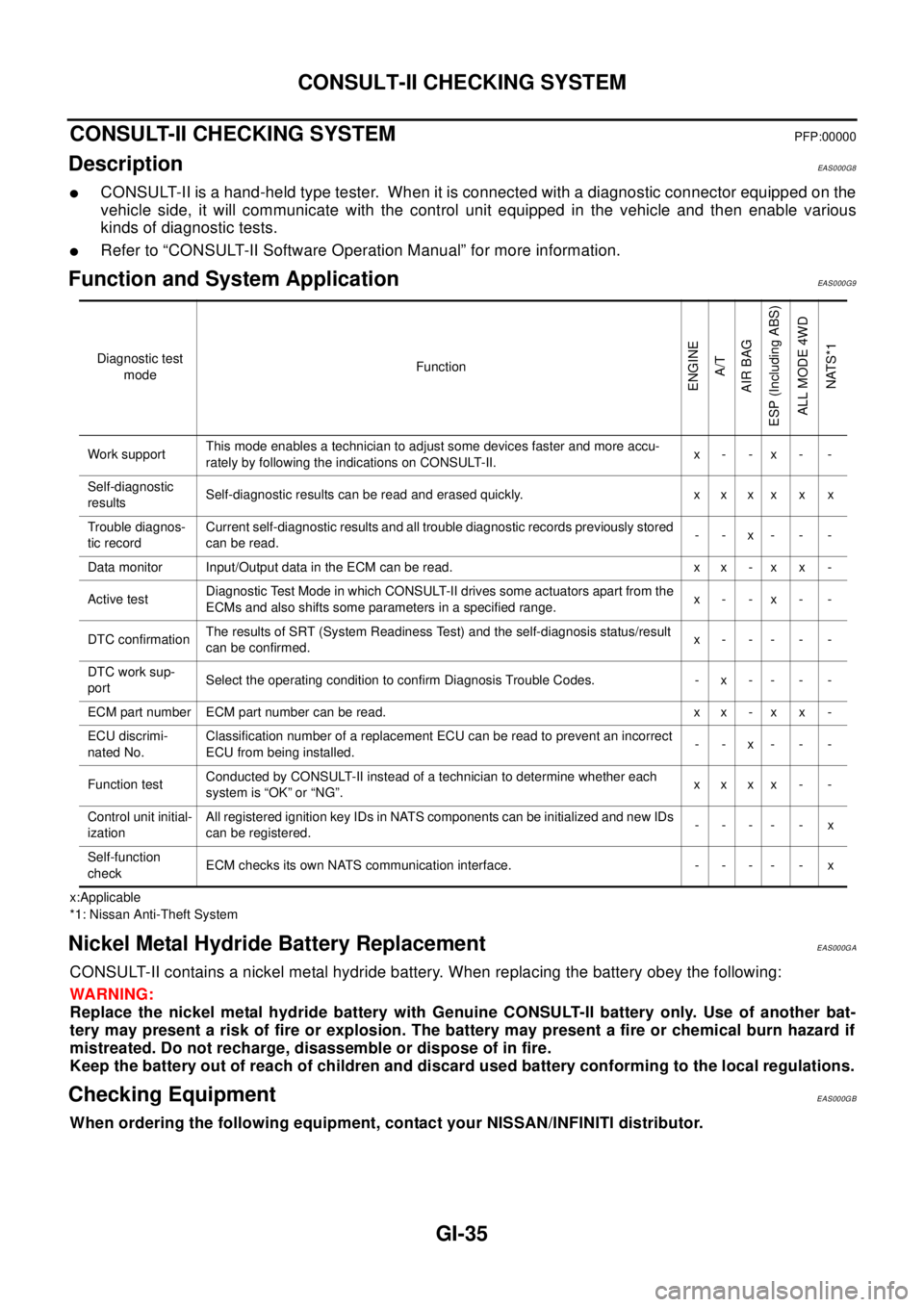

Function and System ApplicationEAS000G9

x:Applicable

*1: Nissan Anti-Theft System

Nickel Metal Hydride Battery ReplacementEAS000GA

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WA RN ING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if

mistreated. Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking EquipmentEAS000GB

When ordering the following equipment, contact your NISSAN/INFINITI distributor.

Diagnostic test

modeFunction

ENGINE

A/T

AIR BAG

ESP (Including ABS)

ALL MODE 4WD

NATS*1

Work supportThis mode enables a technician to adjust some devices faster and more accu-

rately by following the indications on CONSULT-II.x- -x- -

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly. x x x x x x

Trouble diagnos-

tic recordCurrent self-diagnostic results and all trouble diagnostic records previously stored

can be read.--x- - -

Data monitor Input/Output data in the ECM can be read. x x - x x -

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from the

ECMs and also shifts some parameters in a specified range.x- -x- -

DTC confirmationThe results of SRT (System Readiness Test) and the self-diagnosis status/result

can be confirmed.x- -- - -

DTC work sup-

portSelect the operating condition to confirm Diagnosis Trouble Codes. - x - - - -

ECM part number ECM part number can be read. x x - x x -

ECU discrimi-

nated No.Classification number of a replacement ECU can be read to prevent an incorrect

ECU from being installed.--x- - -

Function testConducted by CONSULT-II instead of a technician to determine whether each

system is “OK” or “NG”.xxxx - -

Control unit initial-

izationAll registered ignition key IDs in NATS components can be initialized and new IDs

can be registered.---- - x

Self-function

checkECM checks its own NATS communication interface. - - - - - x

Page 2301 of 3066

GI-48

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2360 of 3066

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Brake fluid level and line check ...........................BR-9

Brake hydraulic line ...........................................BR-11

Brake inspection ................................................MA-39

Brake lines and cables inspection .....................MA-39

Brake master cylinder ........................................BR-13

Brake pedal .........................................................BR-6

Brake switch ........................EC-329,EC-562,EC-810

BRK/SW - Wiring diagram ...EC-330,EC-564,EC-811

Bulb specifications ..............................................LT-67

Bumper, front .........................................................EI-6

Bumper, rear ..........................................................EI-9

C

Camshaft inspection(QR20DE) .........................EM-38

Camshaft inspection(YD22DDTi) ....................EM-150

Camshaft position sensor (CMPS) ..................EC-739

Camshaft position sensor (PHASE) ..EC-223,EC-507

Camshaft(QR20DE) ..........................................EM-33

Camshaft(YD22DDTi) ......................................EM-149

CAN - Wiring diagramEC-115,EC-461,LAN-6,LAN-12

CAN (Controller Area Network) .........AT-129,AT-351,

LAN-3

,LAN-5,LAN-11

CAN Communication ..........................................TF-53

CAN communicationEC-28,EC-114,EC-393,EC-460,

AT-129

,AT-351,BRC-53,BRC-59,BRC-90,BRC-108,

LAN-3

,LAN-5,LAN-11

Canister-See EVAP canister .............EC-374,EC-649

CHARGE - Wiring diagram ................................SC-13

Charging system ................................................SC-12

Chassis and body maintenance ........................MA-35

CHIME - Wiring diagram .....................................DI-54

CIGAR - Wiring diagram ..................................WW-25

Cigarette lighter ...............................................WW-25

Circuit breaker ...................................................PG-12

CKPS - Wiring diagram ...................................EC-736

Clearance lamp ........................................LT-4,LT-40

Clock ...................................................................DI-60

CLOCK - Wiring diagram ....................................DI-60

Closed loop control ..............................EC-25,EC-390

Clutch cover .......................................................CL-15

Clutch disc .........................................................CL-15

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-5

Clutch release bearing .......................................CL-13

Clutch release mechanism ................................CL-13

Clutch withdrawal lever ......................................CL-13

CMPS - Wiring diagram ...................................EC-741

Coil spring (rear) ...............................................RSU-8

Collision diagnosis ...........................................SRS-46

Combination meter .....................................DI-4,DI-22

Combination switch ................................LT-24,LT-44

Common rail fuel pressure sensor ...................EC-723

Component Location (auto A/C) .........ATC-31,MTC-4

Compression pressure(QR20DE) ......................EM-52

Compression pressure(YD22DDTi) .................EM-173

Compressor clutch removal and installation ..ATC-129

Compressor special service tool ......................ATC-11

Condenser .....................................................ATC-138

Connecting rod bearing clearance(QR20DE) ...EM-83

Connecting rod bearing clearance(YD22DDTi)EM-206

Connecting rod bushing clearance(QR20DE) ..EM-83

Connecting rod bushing clearance(YD22DDTi)EM-200

Connecting rod(QR20DE) .................................EM-82

Connecting rod(YD22DDTi) ..............EM-198,EM-202

Console box - See Instrument panel ..........IP-3,IP-10

CONSULT for engine ............EC-86,EC-434,EC-691

CONSUT for VDC ...........................................BRC-77

Control unit .....................................ATC-104,MTC-19

Control units (terminal arrangement) .................PG-73

Controller Area Network (CAN) ........AT-129,AT-351,

LAN-3

,LAN-5,LAN-11

Converter housing installation ...........AT-459,AT-556

COOL/F - Wiring diagram ...EC-315,EC-552,EC-763

Coolant mixture ratio .........................................MA-19

Coolant replacement(QR20DE) ........................MA-20

Coolant replacement(YD22DDTi) .....................MA-27

Cooling circuit (engine)(QR20DE) ......................CO-7

Cooling circuit (engine)(YD22DDTi) .................CO-28

Cooling fan control system(QR20DE) ...............CO-13

Cooling fan motor ..............................EC-324,EC-561

Cooling fan relay ................................EC-324,EC-561

Cooling fan(QR20DE) .......................................CO-13

Cooling fan(YD22DDTi) ....................................CO-34

Coupling sleeve (M/T) ...........................MT-19,MT-24

Cowl top ..............................................................EI-12

Cowl top cover ....................................................EI-12

Crankcase ventilation system ..........................EC-663

Crankcase ventilation system - See Positive crankcase

ventilation ...........................................EC-375

,EC-650

Crankshaft position sensor (POS) .....EC-217,EC-501

Crankshaft position sensor (TDC) ...................EC-734

Crankshaft(QR20DE) ........................................EM-65

Crankshaft(YD22DDTi) ...................................EM-200

CRFPS - Wiring diagram .................................EC-724

Cylinder block boring(QR20DE) .......................EM-86

Cylinder block boring(YD22DDTi) ...................EM-204

Cylinder block(QR20DE) ..................................EM-64

Cylinder block(YD22DDTi) ..............................EM-188

Cylinder head bolt tightening(QR20DE) ...........EM-54

Cylinder head bolt tightening(YD22DDTi) .......EM-175

Cylinder head gasket selection(YD22DDTi) ...EM-175

Cylinder head(QR20DE) ...................................EM-52

Cylinder head(YD22DDTi) ..............................EM-173

D

Data link connector ............................EC-371

,EC-646

Data link connector for Consult ...........EC-88,EC-435,

EC-691

Daytime light system .............................................LT-9

Daytime running light - See Daytime light systemLT-9

DEF - Wiring diagram .......................................GW-10

Desiccant Assembly .......................ATC-27,ATC-140

Diagnosis sensor unit .....................................SRS-39

Page 2362 of 3066

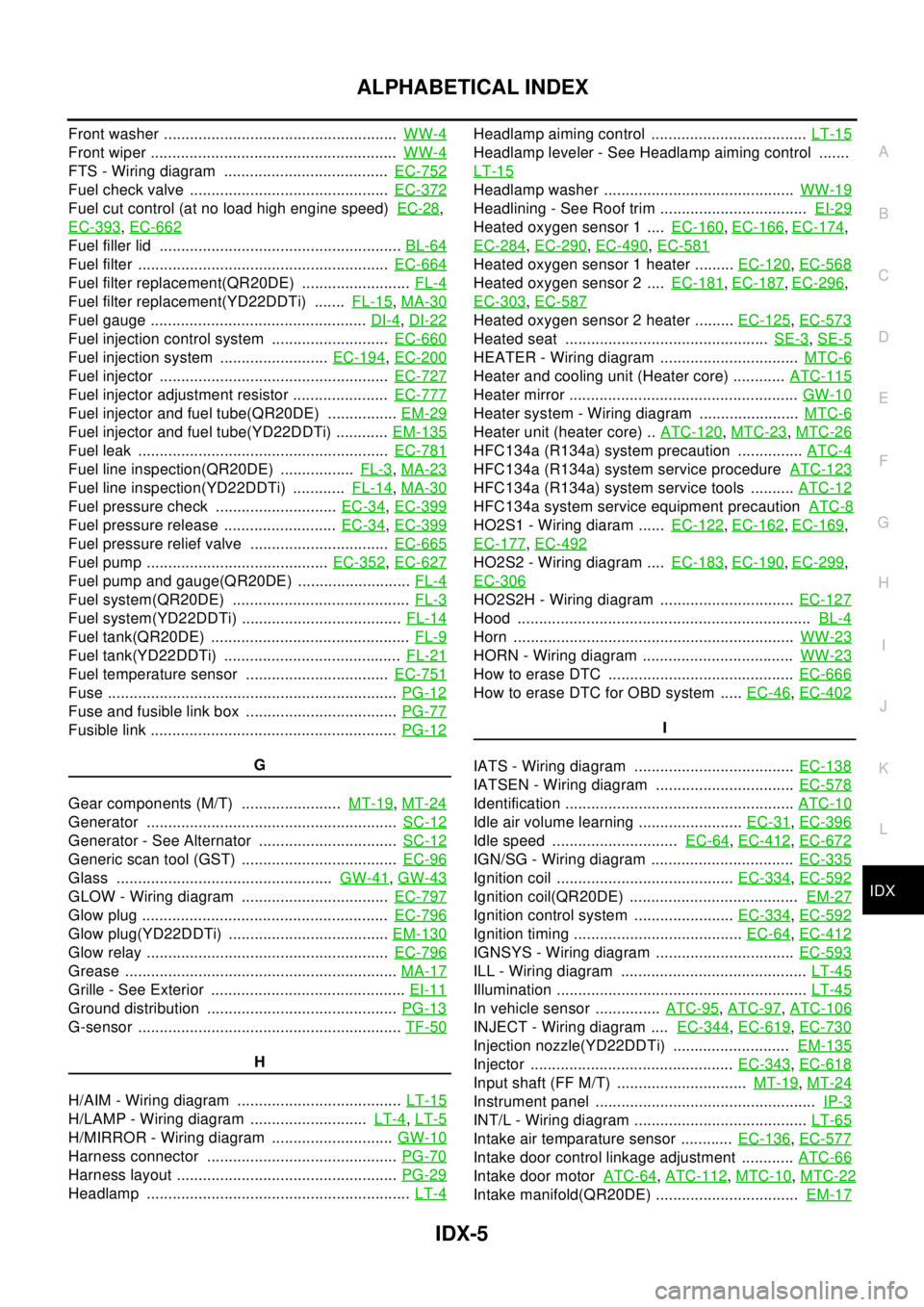

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FTS - Wiring diagram ......................................EC-752

Fuel check valve ..............................................EC-372

Fuel cut control (at no load high engine speed)EC-28,

EC-393

,EC-662

Fuel filler lid ........................................................BL-64

Fuel filter ..........................................................EC-664

Fuel filter replacement(QR20DE) .........................FL-4

Fuel filter replacement(YD22DDTi) .......FL-15,MA-30

Fuel gauge ..................................................DI-4,DI-22

Fuel injection control system ...........................EC-660

Fuel injection system .........................EC-194,EC-200

Fuel injector .....................................................EC-727

Fuel injector adjustment resistor ......................EC-777

Fuel injector and fuel tube(QR20DE) ................EM-29

Fuel injector and fuel tube(YD22DDTi) ............EM-135

Fuel leak ..........................................................EC-781

Fuel line inspection(QR20DE) .................FL-3,MA-23

Fuel line inspection(YD22DDTi) ............FL-14,MA-30

Fuel pressure check ............................EC-34,EC-399

Fuel pressure release ..........................EC-34,EC-399

Fuel pressure relief valve ................................EC-665

Fuel pump ..........................................EC-352,EC-627

Fuel pump and gauge(QR20DE) ..........................FL-4

Fuel system(QR20DE) .........................................FL-3

Fuel system(YD22DDTi) .....................................FL-14

Fuel tank(QR20DE) ..............................................FL-9

Fuel tank(YD22DDTi) .........................................FL-21

Fuel temperature sensor .................................EC-751

Fuse ...................................................................PG-12

Fuse and fusible link box ...................................PG-77

Fusible link .........................................................PG-12

G

Gear components (M/T) .......................MT-19

,MT-24

Generator ..........................................................SC-12

Generator - See Alternator ................................SC-12

Generic scan tool (GST) ....................................EC-96

Glass ..................................................GW-41,GW-43

GLOW - Wiring diagram ..................................EC-797

Glow plug .........................................................EC-796

Glow plug(YD22DDTi) .....................................EM-130

Glow relay ........................................................EC-796

Grease ...............................................................MA-17

Grille - See Exterior .............................................EI-11

Ground distribution ............................................PG-13

G-sensor .............................................................TF-50

H

H/AIM - Wiring diagram ......................................LT-15

H/LAMP - Wiring diagram ...........................LT-4,LT-5

H/MIRROR - Wiring diagram ............................GW-10

Harness connector ............................................PG-70

Harness layout ...................................................PG-29

Headlamp .............................................................LT-4

Headlamp aiming control ....................................LT-15

Headlamp leveler - See Headlamp aiming control .......

LT-15

Headlamp washer ............................................WW-19

Headlining - See Roof trim ..................................EI-29

Heated oxygen sensor 1 ....EC-160,EC-166,EC-174,

EC-284

,EC-290,EC-490,EC-581

Heated oxygen sensor 1 heater .........EC-120,EC-568

Heated oxygen sensor 2 ....EC-181,EC-187,EC-296,

EC-303

,EC-587

Heated oxygen sensor 2 heater .........EC-125,EC-573

Heated seat ...............................................SE-3,SE-5

HEATER - Wiring diagram ................................MTC-6

Heater and cooling unit (Heater core) ............ATC-115

Heater mirror .....................................................GW-10

Heater system - Wiring diagram .......................MTC-6

Heater unit (heater core) ..ATC-120,MTC-23,MTC-26

HFC134a (R134a) system precaution ...............ATC-4

HFC134a (R134a) system service procedureATC-123

HFC134a (R134a) system service tools ..........ATC-12

HFC134a system service equipment precautionATC-8

HO2S1 - Wiring diaram ......EC-122,EC-162,EC-169,

EC-177

,EC-492

HO2S2 - Wiring diagram ....EC-183,EC-190,EC-299,

EC-306

HO2S2H - Wiring diagram ...............................EC-127

Hood ....................................................................BL-4

Horn .................................................................WW-23

HORN - Wiring diagram ...................................WW-23

How to erase DTC ...........................................EC-666

HowtoeraseDTCforOBDsystem .....EC-46,EC-402

I

IATS - Wiring diagram .....................................EC-138

IATSEN - Wiring diagram ................................EC-578

Identification .....................................................ATC-10

Idle air volume learning ........................EC-31,EC-396

Idle speed .............................EC-64,EC-412,EC-672

IGN/SG - Wiring diagram .................................EC-335

Ignition coil .........................................EC-334,EC-592

Ignition coil(QR20DE) .......................................EM-27

Ignition control system .......................EC-334,EC-592

Ignition timing .......................................EC-64,EC-412

IGNSYS - Wiring diagram ................................EC-593

ILL - Wiring diagram ...........................................LT-45

Illumination ..........................................................LT-45

In vehicle sensor ...............ATC-95,ATC-97,ATC-106

INJECT - Wiring diagram ....EC-344,EC-619,EC-730

Injection nozzle(YD22DDTi) ...........................EM-135

Injector ...............................................EC-343,EC-618

Input shaft (FF M/T) ..............................MT-19,MT-24

Instrument panel ...................................................IP-3

INT/L - Wiring diagram ........................................LT-65

Intake air temparature sensor ............EC-136,EC-577

Intake door control linkage adjustment ............ATC-66

Intake door motorATC-64,ATC-112,MTC-10,MTC-22

Intake manifold(QR20DE) .................................EM-17

Page 2383 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR A/T MODELS)

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002AG

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “A/T” displayed on NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR A/T MODELS)

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002AG

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “A/T” displayed on](/img/5/57402/w960_57402-2382.png)

CAN SYSTEM (FOR A/T MODELS)

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002AG

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “A/T” displayed on

CONSULT-II. Refer toEC-114, "

DTC U1000 CAN COMMUNICATION LINE"(WITH EURO-OBD) orEC-

460, "DTC U1000 CAN COMMUNICATION LINE"(WITHOUT EURO-OBD) for “ENGINE” and Refer to

AT-213, "

DTC U1000 CAN COMMUNICATION LINE"(EURO-OBD) orAT-443, "CAN CAMMUNICATION

LINE"(EXC.F/EURO-OBD) for “A/T”.

2. Attach the printed sheet of “SELF-DIAG RESULTS” and “DATA MONITOR” onto the check sheet. Refer to

LAN-8, "

CHECK SHEET"

3. Based on the data monitor results, put “v” marks onto the items with “UNKWN” or “NG” in the check sheet

table. Refer toLAN-8, "

CHECK SHEET"

NOTE:

If “NG” is displayed on “CAN COMM” for the diagnosed control unit, replace the control unit.

4. According to the check sheet results (example), start inspection. Refer toLAN-9, "

CHECK SHEET

RESULTS (EXAMPLE)"

Page 2386 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-10

[CAN]

CANSYSTEM(FORA/TMODELS)

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals

33(B/W), 34 (L/R) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair h NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-10

[CAN]

CANSYSTEM(FORA/TMODELS)

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals

33(B/W), 34 (L/R) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair h](/img/5/57402/w960_57402-2385.png)

LAN-10

[CAN]

CANSYSTEM(FORA/TMODELS)

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals

33(B/W), 34 (L/R) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness between ECM and TCM.

4.ECM/TCM INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer toLAN-10, "

ECM/TCM INTERNAL CIRCUIT INSPECTION"

OK or NG

OK >> Reconnect all connectors to perform “SELF-DIAG RESULTS” and “DATA MONITOR” for

“ENGINE” and “A/T”. Refer toEC-114, "

DTC U1000 CAN COMMUNICATION LINE"(WITH

EURO-OBD) orEC-460, "

DTC U1000 CAN COMMUNICATION LINE"(WITHOUT EURO-OBD)

for “ENGINE” and Refer toAT-213, "

DTC U1000 CAN COMMUNICATION LINE"(EURO-OBD) or

AT-443, "

CAN CAMMUNICATION LINE"(EXC.F/EURO-OBD) for “A/T”.

NG >> Replace ECM and/or TCM.

Component InspectionEKS002AI

ECM/TCM INTERNAL CIRCUIT INSPECTION

lRemove ECM and TCM from vehicle.

lCheck resistance between ECM terminals 33 and 34.

lCheck resistance between TCM terminals 5 and 6.33(B/W) – ground : Continuity should not exist.

34(L/R) – ground : Continuity should not exist.

SKIA0889E

Unit Terminal Resistance value (W)

ECM 33–34

Approx. 108 - 132

TCM 5 – 6

PKIA0298E

Page 2389 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002FN

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL MODE 4WD”,

and NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002FN

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL MODE 4WD”,

and](/img/5/57402/w960_57402-2388.png)

CAN SYSTEM (FOR M/T MODELS)

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002FN

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL MODE 4WD”,

and “ABS” displayed on CONSULT-II. Refer toEC-114, "

DTC U1000 CAN COMMUNICATION LINE"

(WITH EURO-OBD) orEC-460, "DTC U1000 CAN COMMUNICATION LINE"(WITHOUT EURO-OBD)

for“ENGINE”andRefertoTF-53, "

CAN COMMUNICATION SYSTEM"for “ALL MODE 4WD”. Refer to

BRC-108, "

Inspection 15 CAN Communication Circuit, ESP/TCS/ABS Control Unit and Steering Angle

Sensor"for “ABS”.

2. Attach the printed sheet of “SELF-DIAG RESULTS” and “DATA MONITOR” onto the check sheet. Refer to

LAN-14, "

CHECK SHEET"

3. Based on the data monitor results, put “v” marks onto the items with “UNKWN” or “NG” in the check sheet

table. Refer toLAN-14, "

CHECK SHEET"

NOTE:

If “NG” is displayed on “CAN COMM” for the diagnosed control unit, replace the control unit.

4. According to the check sheet results (example), start inspection. Refer toLAN-15, "

CHECK SHEET

RESULTS (EXAMPLE)"

Page 2393 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-17

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect steering wheel angle sensor connector and harness connector M75.

2. Check continuity NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-17

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect steering wheel angle sensor connector and harness connector M75.

2. Check continuity](/img/5/57402/w960_57402-2392.png)

CAN SYSTEM (FOR M/T MODELS)

LAN-17

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect steering wheel angle sensor connector and harness connector M75.

2. Check continuity between steering wheel angle sensor harness

connector M81 terminals 4 (W), 5 (R) and harness connector

M75 terminals 8 (W), 19 (R).

OK or NG

OK >> GO TO 3.

NG >> Repair harness.

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect 4WD control unit connector.

2. Check continuity between harness connector E116 terminals

8(W), 19 (R) and 4WD control unit harness connector E122 ter-

minals 48 (W), 39 (R).

OK or NG

OK >> Reconnect all connectors to perform “SELF-DIAG

RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL

MODE 4WD”, and “ABS” displayed on CONSULT-II.

Refer toEC-114, "

DTC U1000 CAN COMMUNICATION

LINE"(WITH EURO-OBD) orEC-460, "DTC U1000

CAN COMMUNICATION LINE"(WITHOUT EURO-OBD) for “ENGINE” and Refer toTF-53,

"CAN COMMUNICATION SYSTEM"for “ALL MODE 4WD”. Refer toBRC-108, "Inspection 15

CAN Communication Circuit, ESP/TCS/ABS Control Unit and Steering Angle Sensor"for “ABS”.

NG >> Repair harness.

ECM Circuit CheckEKS002FQ

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check following terminals and connector for damage, bend and loose connection. (control module-side

and harness-side)

lECM.

lHarness connector F41.

lHarness connector M61.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.4(W) – 8(W) : Continuity should exist.

5(R) – 19(R) : Continuity should exist.

SKIA0928E

8(W) – 48(W) : Continuity should exist.

19(R) – 39(R) : Continuity should exist.

SKIA0929E

Page 2398 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-22

[CAN]

CAN SYSTEM (FOR M/T MODELS)

8.CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F43 termi-

nals 33 (W) and 34(R).

OK or NG

OK NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-22

[CAN]

CAN SYSTEM (FOR M/T MODELS)

8.CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F43 termi-

nals 33 (W) and 34(R).

OK or NG

OK](/img/5/57402/w960_57402-2397.png)

LAN-22

[CAN]

CAN SYSTEM (FOR M/T MODELS)

8.CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F43 termi-

nals 33 (W) and 34(R).

OK or NG

OK >> GO TO 9.

NG >> Repair harness between ECM and harness connector

F41.

9.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals 33

(W), 34 (R) and ground.

OK or NG

OK >> GO TO 10.

NG >> Repair harness between ECM and harness connector

F41.

10.ECM / ESP/TCS/ABS CONTROL UNIT INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer toLAN-22, "

ECM / ESP/TCS/ABS CONTROL UNIT INTERNAL CIR-

CUIT INSPECTION"

OK or NG

OK >> Reconnect all connectors to perform “SELF-DIAG RESULTS” and “DATA MONITOR” for

“ENGINE”, “ALL MODE 4WD”, and “ABS” displayed on CONSULT-II. Refer toEC-114, "

DTC

U1000 CAN COMMUNICATION LINE"(WITH EURO-OBD) orEC-460, "DTC U1000 CAN COM-

MUNICATION LINE"(WITHOUT EURO-OBD) for “ENGINE” and Refer toTF-53, "CAN COMMU-

NICATION SYSTEM"for “ALL MODE 4WD”. Refer toBRC-108, "Inspection 15 CAN

Communication Circuit, ESP/TCS/ABS Control Unit and Steering Angle Sensor"for “ABS”.

NG >> Replace ECM and/or ESP/TCS/ABS control unit.

Component InspectionEKS002FW

ECM / ESP/TCS/ABS CONTROL UNIT INTERNAL CIRCUIT INSPECTION

lRemove ECM and ESP/TCS/ABS control unit from vehicle.

lCheck resistance between ECM terminals 33 and 34.

lCheck resistance between ESP/TCS/ABS control unit terminals

61 and 63.33(W) – 34(R) : Continuity should not exist.

SKIA0888E

33(W) – ground : Continuity should not exist.

34(R) – ground : Continuity should not exist.

SKIA0889E

Unit Terminal Resistance value (W)

ECM 33 – 34

Approx. 108 - 132

ESP/TCS/ABS control unit 61 – 63

SKIA0933E