check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2527 of 3066

CHASSIS AND BODY MAINTENANCE

MA-35

C

D

E

F

G

H

I

J

K

MA

B

MA

CHASSIS AND BODY MAINTENANCEPFP:00100

Checking Exhaust SystemELS000B9

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage, chafing or deterioration.

Checking Clutch Fluid Level and LeaksELS000BA

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch SystemELS000BB

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

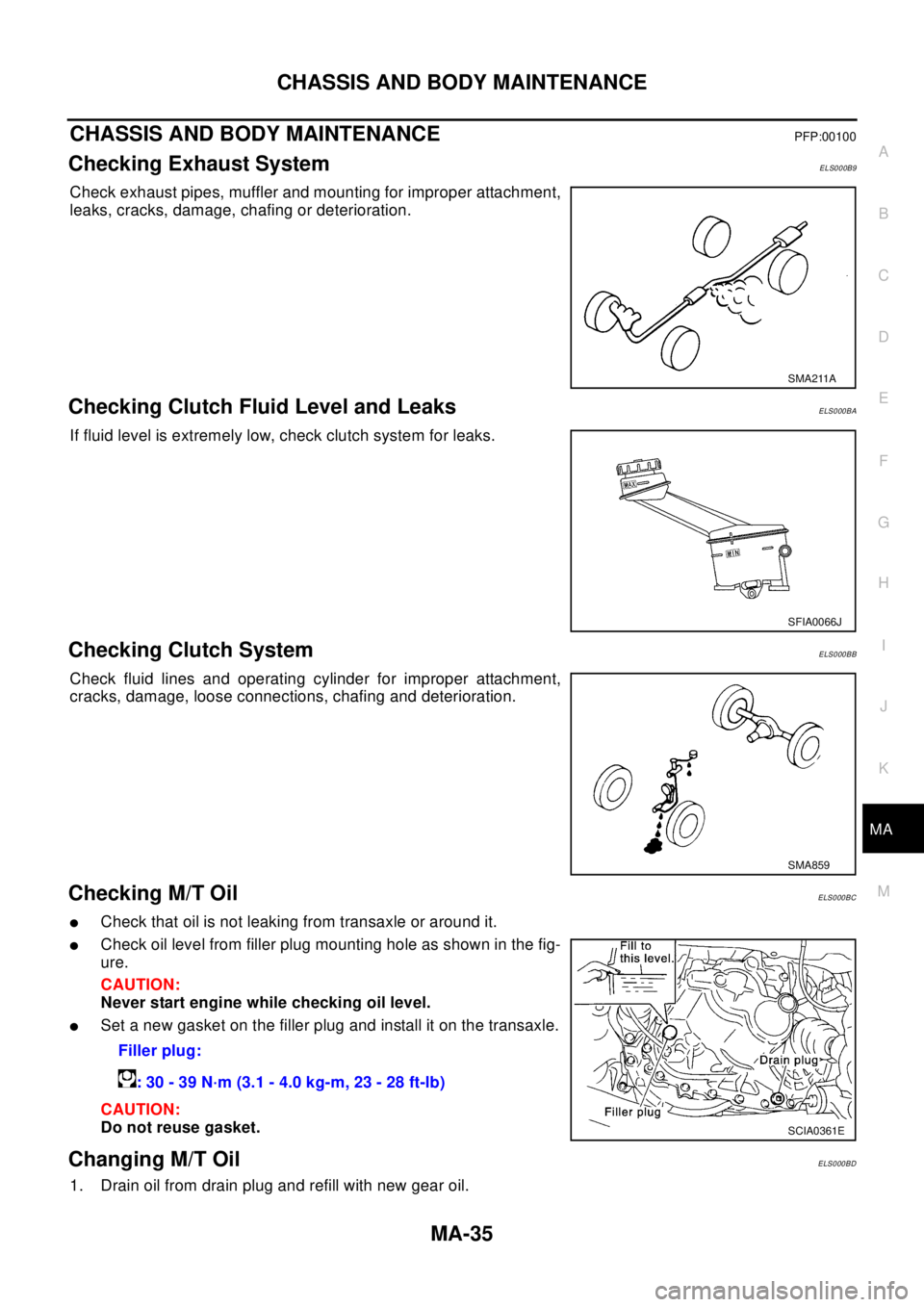

Checking M/T OilELS000BC

lCheck that oil is not leaking from transaxle or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Never start engine while checking oil level.

lSet a new gasket on the filler plug and install it on the transaxle.

CAUTION:

Do not reuse gasket.

Changing M/T OilELS000BD

1. Drain oil from drain plug and refill with new gear oil.

SMA211A

SFIA0066J

SMA859

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SCIA0361E

Page 2528 of 3066

MA-36

CHASSIS AND BODY MAINTENANCE

2. Check oil level.

CAUTION:

Do not reuse gasket.

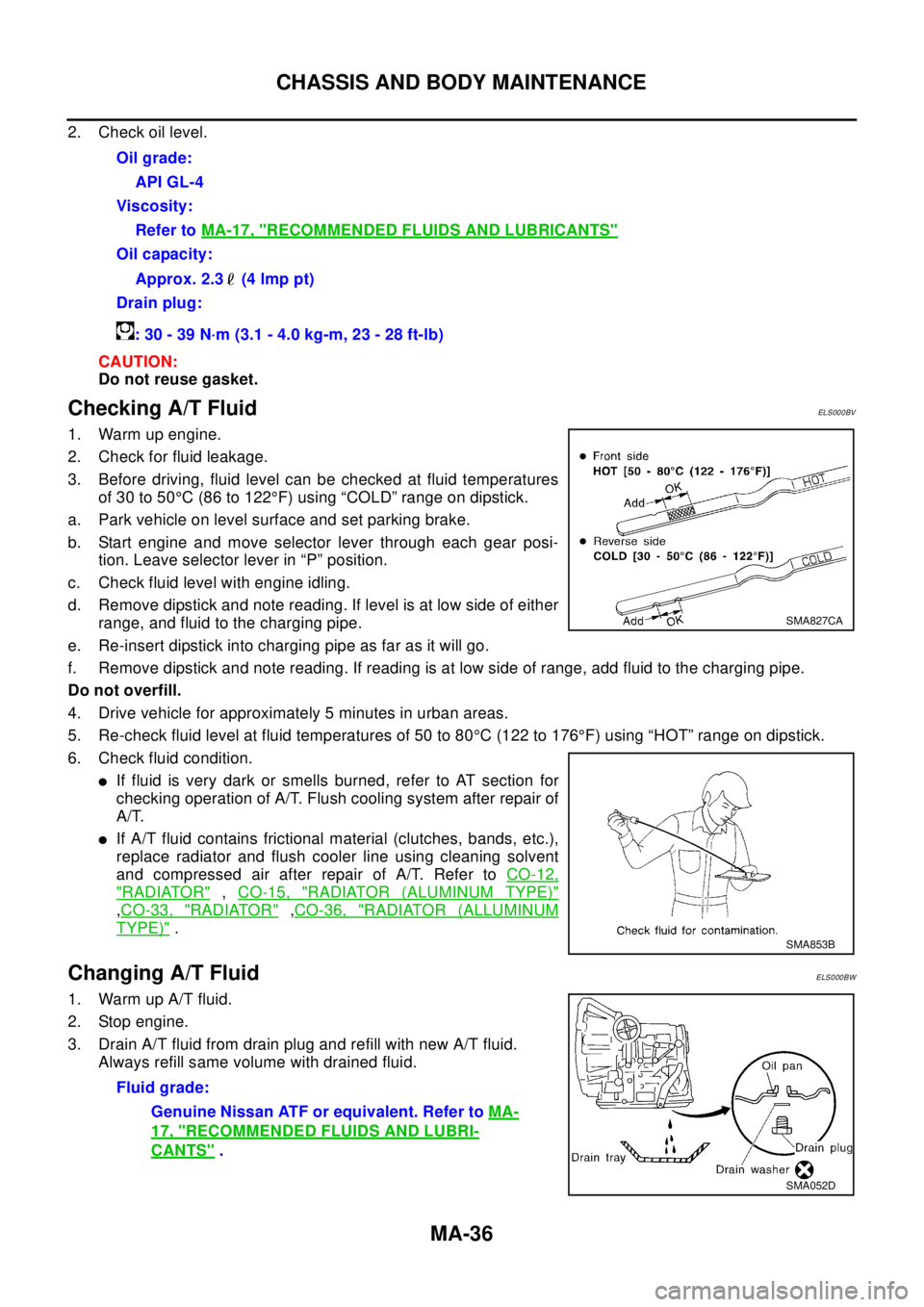

Checking A/T FluidELS000BV

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)"

,CO-33, "RADIATOR",CO-36, "RADIATOR (ALLUMINUM

TYPE)".

Changing A/T FluidELS000BW

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.Oil grade:

API GL-4

Viscosity:

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRICANTS"

Oil capacity:

Approx. 2.3 (4 lmp pt)

Drain plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

SMA052D

Page 2529 of 3066

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”. If fluid is still dirty, repeat steps 2 through 5.

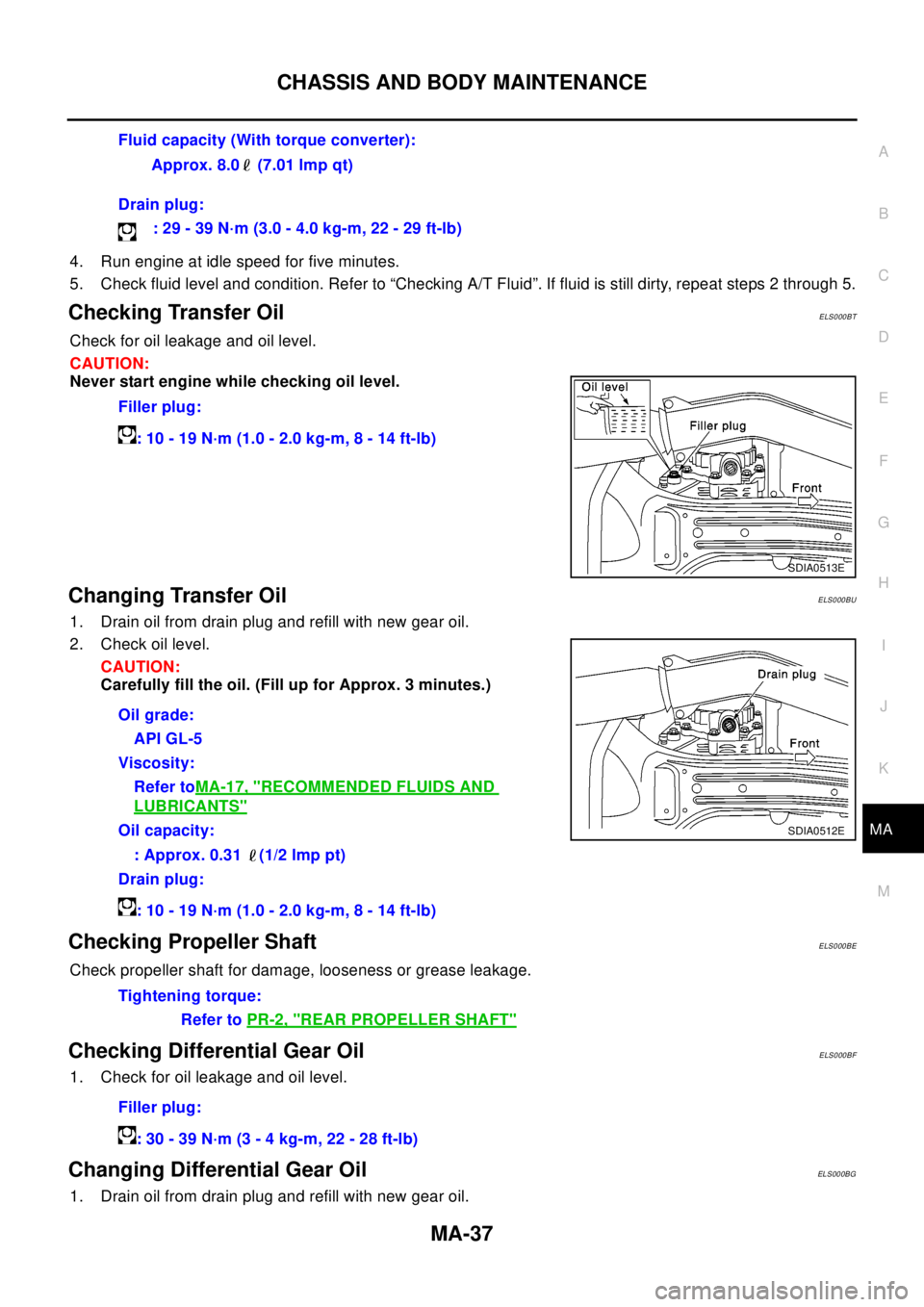

Checking Transfer OilELS000BT

Check for oil leakage and oil level.

CAUTION:

Never start engine while checking oil level.

Changing Transfer OilELS000BU

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

CAUTION:

Carefully fill the oil. (Fill up for Approx. 3 minutes.)

Checking Propeller ShaftELS000BE

Check propeller shaft for damage, looseness or grease leakage.

Checking Differential Gear OilELS000BF

1. Check for oil leakage and oil level.

Changing Differential Gear OilELS000BG

1. Drain oil from drain plug and refill with new gear oil.Fluid capacity (With torque converter):

Approx. 8.0 (7.01 lmp qt)

Drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

Filler plug:

:10-19N·m(1.0-2.0kg-m,8-14ft-lb)

SDIA0513E

Oil grade:

API GL-5

Viscosity:

Refer toMA-17, "

RECOMMENDED FLUIDS AND

LUBRICANTS"

Oil capacity:

: Approx. 0.31 (1/2 lmp pt)

Drain plug:

:10-19N·m(1.0-2.0kg-m,8-14ft-lb)SDIA0512E

Tightening torque:

Refer toPR-2, "

REAR PROPELLER SHAFT"

Filler plug:

:30-39N·m(3-4kg-m,22-28ft-lb)

Page 2533 of 3066

CHASSIS AND BODY MAINTENANCE

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

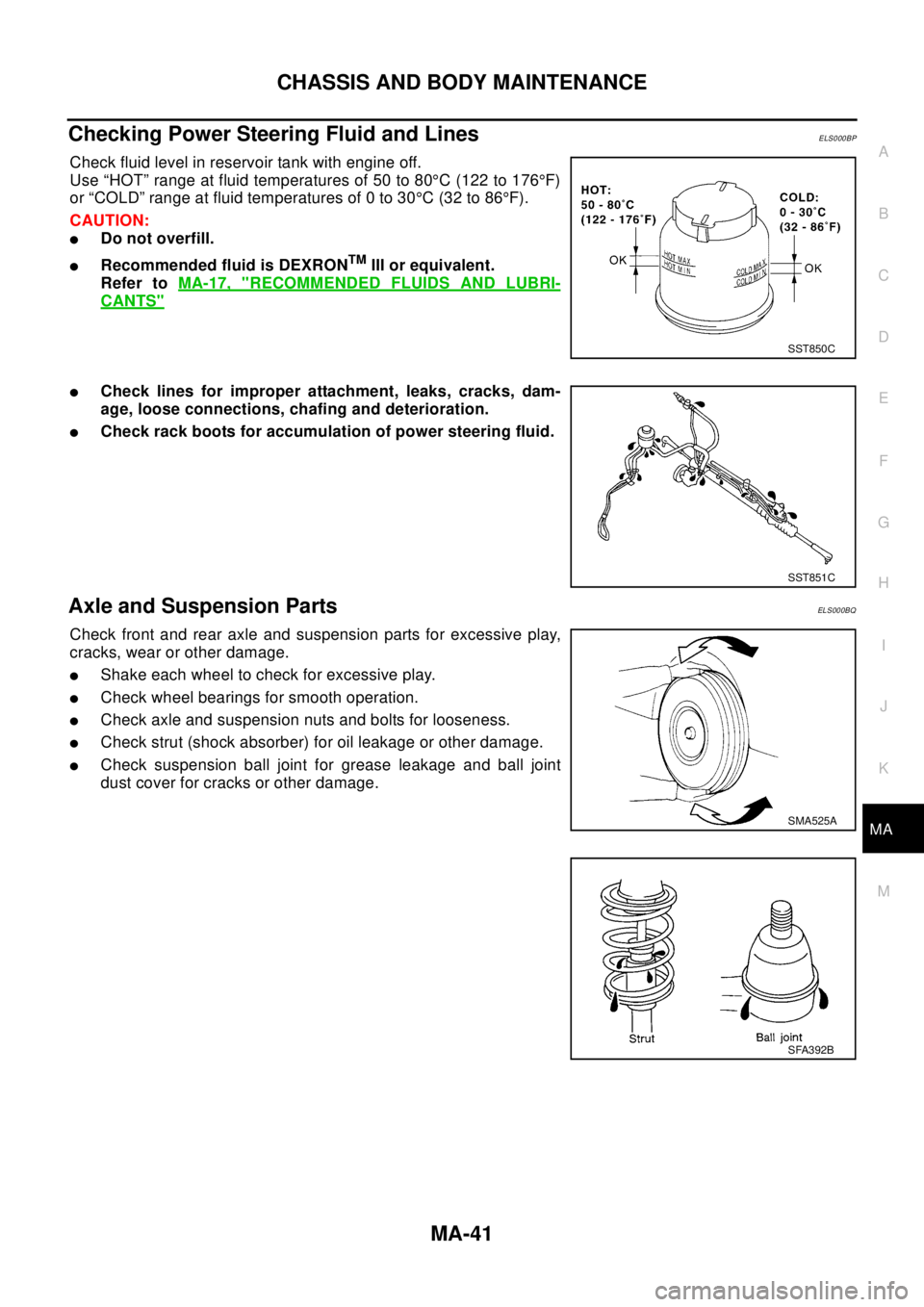

Checking Power Steering Fluid and LinesELS000BP

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80°C (122 to 176°F)

or “COLD” range at fluid temperatures of 0 to 30°C(32to86°F).

CAUTION:

lDo not overfill.

lRecommended fluid is DEXRONTMIII or equivalent.

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS"

lCheck lines for improper attachment, leaks, cracks, dam-

age, loose connections, chafing and deterioration.

lCheck rack boots for accumulation of power steering fluid.

Axle and Suspension PartsELS000BQ

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

lShake each wheel to check for excessive play.

lCheck wheel bearings for smooth operation.

lCheck axle and suspension nuts and bolts for looseness.

lCheck strut (shock absorber) for oil leakage or other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

SST850C

SST851C

SMA525A

SFA392B

Page 2534 of 3066

MA-42

CHASSIS AND BODY MAINTENANCE

Drive Shaft

ELS000CL

lCheck boot and drive shaft for cracks, wear, damage and

grease leakage.

Lubricating Locks, Hinges and Hood LatchesELS000BR

Checking Seat Belts, Buckles, Retractors, Anchors and AdjustersELS000BS

Checking Body CorrosionELS000C0

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PA R T S C O N TA C T

Waist moulding, windshield moulding, bumper, etc.

SFA108A

Front door Refer toBL-8, "DOOR".

Back door Refer toBL-60, "

BACK DOOR".

Page 2547 of 3066

M/T OIL

MT-11

D

E

F

G

H

I

J

K

L

MA

B

MT

M/T OILPFP:KLD20

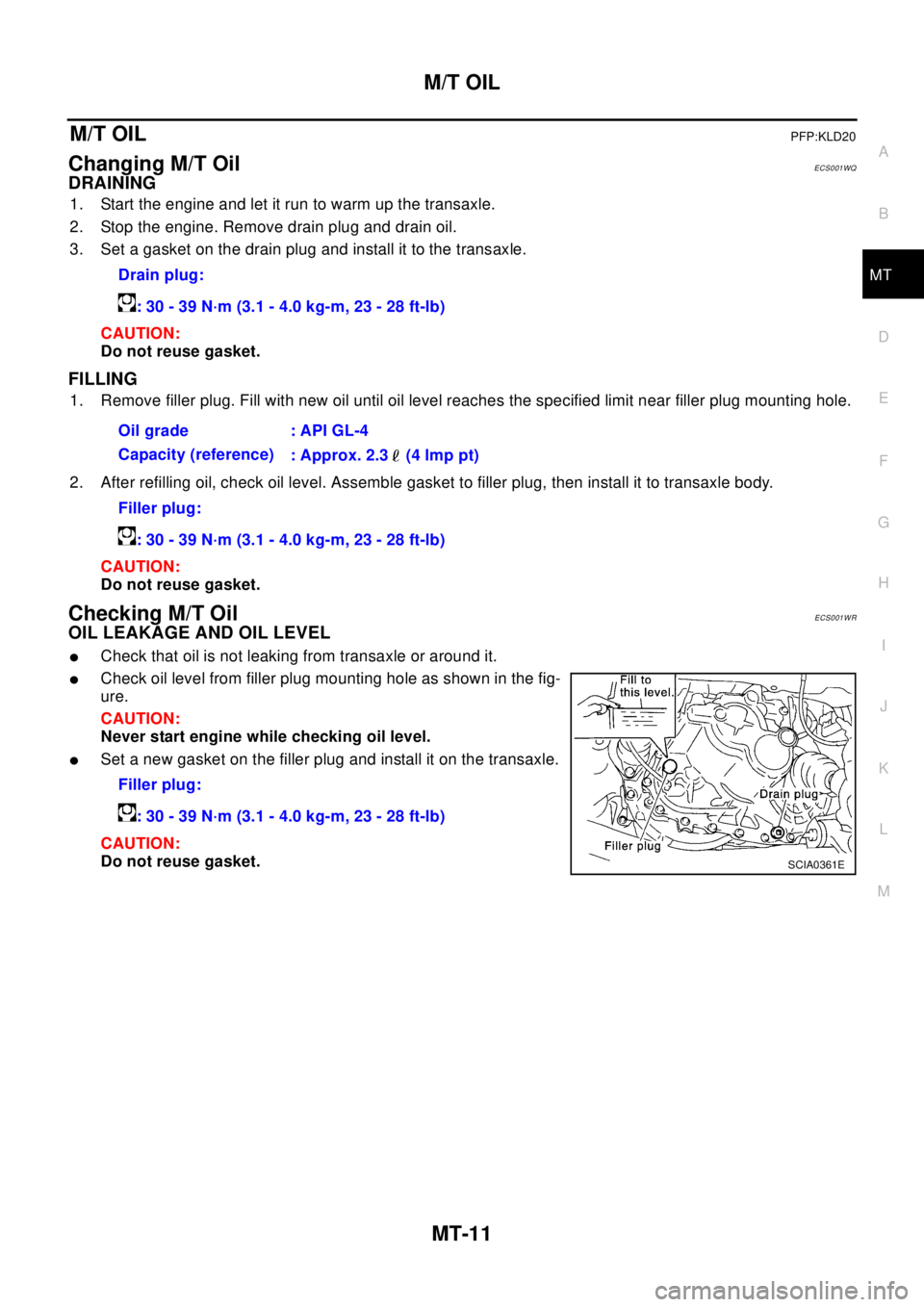

Changing M/T OilECS001WQ

DRAINING

1. Start the engine and let it run to warm up the transaxle.

2. Stop the engine. Remove drain plug and drain oil.

3. Set a gasket on the drain plug and install it to the transaxle.

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug. Fill with new oil until oil level reaches the specified limit near filler plug mounting hole.

2. After refilling oil, check oil level. Assemble gasket to filler plug, then install it to transaxle body.

CAUTION:

Do not reuse gasket.

Checking M/T OilECS001WR

OIL LEAKAGE AND OIL LEVEL

lCheck that oil is not leaking from transaxle or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Never start engine while checking oil level.

lSet a new gasket on the filler plug and install it on the transaxle.

CAUTION:

Do not reuse gasket.Drain plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

Oil grade : API GL-4

Capacity (reference)

: Approx. 2.3 (4 lmp pt)

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SCIA0361E

Page 2553 of 3066

TRANSAXLE ASSEMBLY

MT-17

D

E

F

G

H

I

J

K

L

MA

B

MT

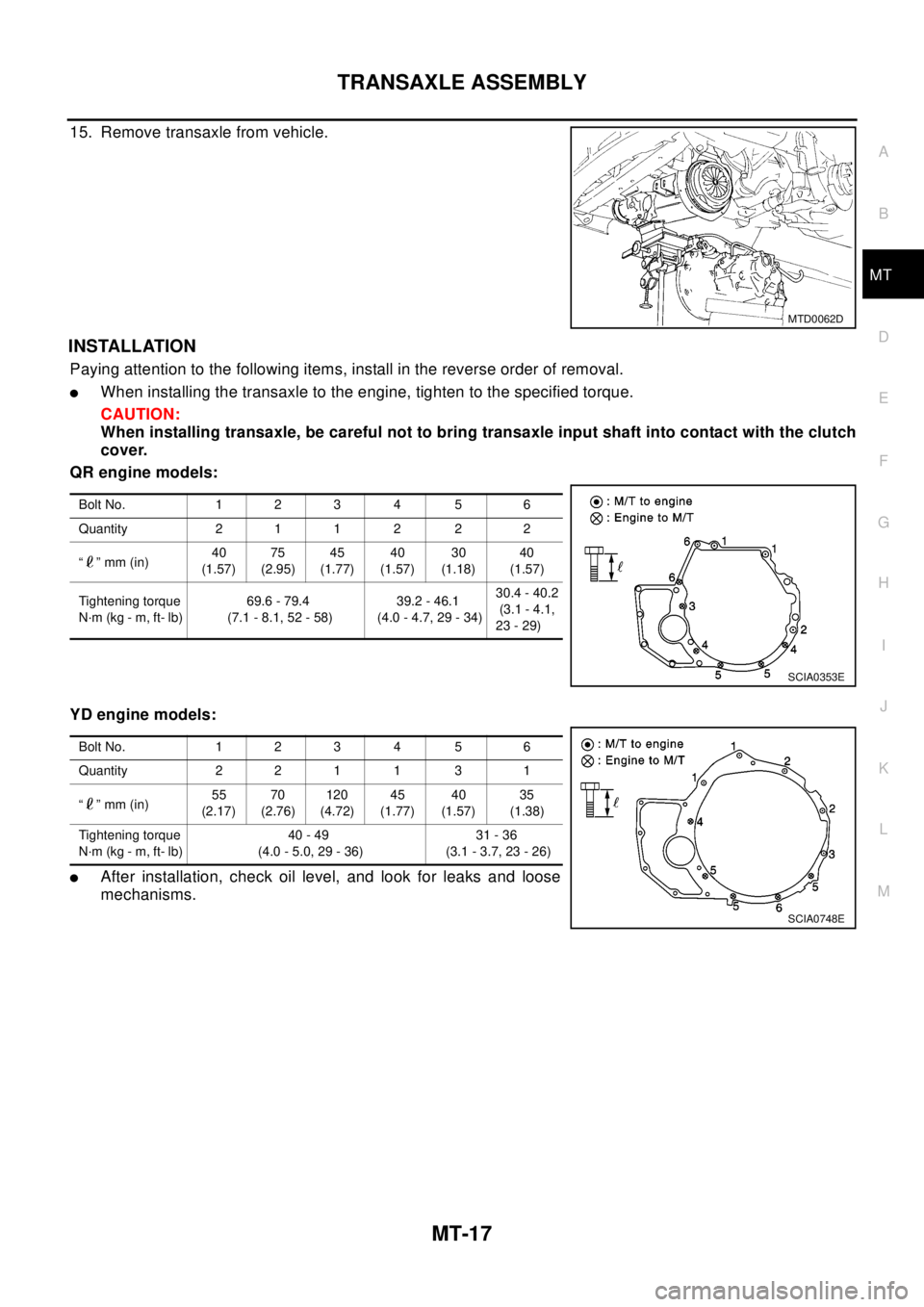

15. Remove transaxle from vehicle.

INSTALLATION

Paying attention to the following items, install in the reverse order of removal.

lWhen installing the transaxle to the engine, tighten to the specified torque.

CAUTION:

When installing transaxle, be careful not to bring transaxle input shaft into contact with the clutch

cover.

QR engine models:

YD engine models:

lAfter installation, check oil level, and look for leaks and loose

mechanisms.

MTD0062D

Bolt No. 1 2 3 4 5 6

Quantity 2 1 1 2 2 2

“”mm(in)40

(1.57)75

(2.95)45

(1.77)40

(1.57)30

(1.18)40

(1.57)

Tightening torque

N·m (kg - m, ft- lb)69.6 - 79.4

(7.1 - 8.1, 52 - 58)39.2 - 46.1

(4.0 - 4.7, 29 - 34)30.4 - 40.2

(3.1 - 4.1,

23 - 29)

SCIA0353E

Bolt No. 1 2 3 4 5 6

Quantity 2 2 1 1 3 1

“”mm(in)55

(2.17)70

(2.76)120

(4.72)45

(1.77)40

(1.57)35

(1.38)

Tightening torque

N·m (kg - m, ft- lb)40 - 49

(4.0 - 5.0, 29 - 36)31 - 36

(3.1 - 3.7, 23 - 26)

SCIA0748E

Page 2643 of 3066

TROUBLE DIAGNOSIS

MTC-7

C

D

E

F

G

H

I

K

L

MA

B

MTC

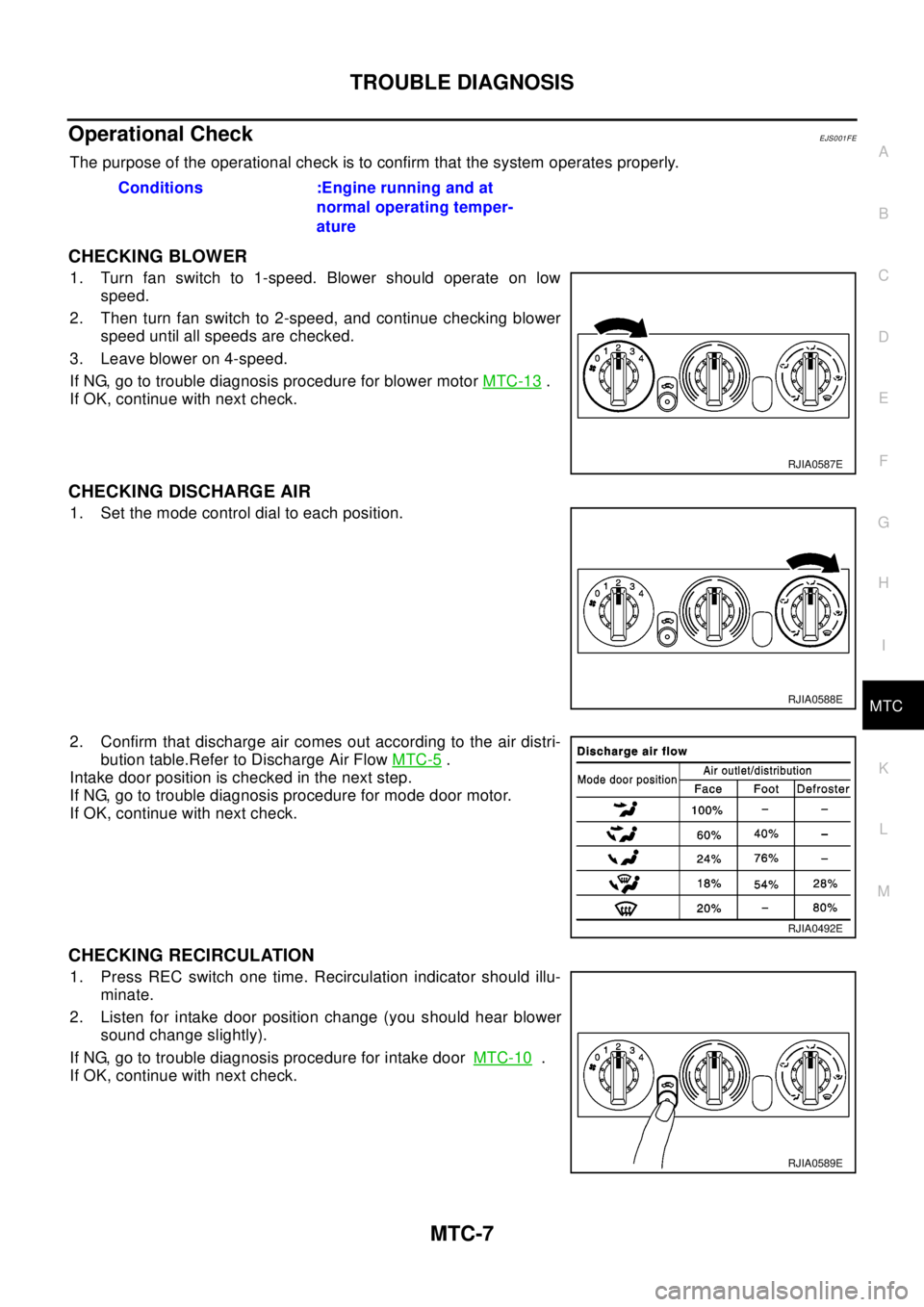

Operational CheckEJS001FE

The purpose of the operational check is to confirm that the system operates properly.

CHECKING BLOWER

1. Turn fan switch to 1-speed. Blower should operate on low

speed.

2. Then turn fan switch to 2-speed, and continue checking blower

speed until all speeds are checked.

3. Leave blower on 4-speed.

If NG, go to trouble diagnosis procedure for blower motorMTC-13

.

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Set the mode control dial to each position.

2. Confirm that discharge air comes out according to the air distri-

bution table.Refer to Discharge Air FlowMTC-5

.

Intake door position is checked in the next step.

If NG, go to trouble diagnosis procedure for mode door motor.

If OK, continue with next check.

CHECKING RECIRCULATION

1. Press REC switch one time. Recirculation indicator should illu-

minate.

2. Listen for intake door position change (you should hear blower

sound change slightly).

If NG, go to trouble diagnosis procedure for intake doorMTC-10

.

If OK, continue with next check.Conditions :Engine running and at

normal operating temper-

ature

RJIA0587E

RJIA0588E

RJIA0492E

RJIA0589E

Page 2654 of 3066

MTC-18

TROUBLE DIAGNOSIS

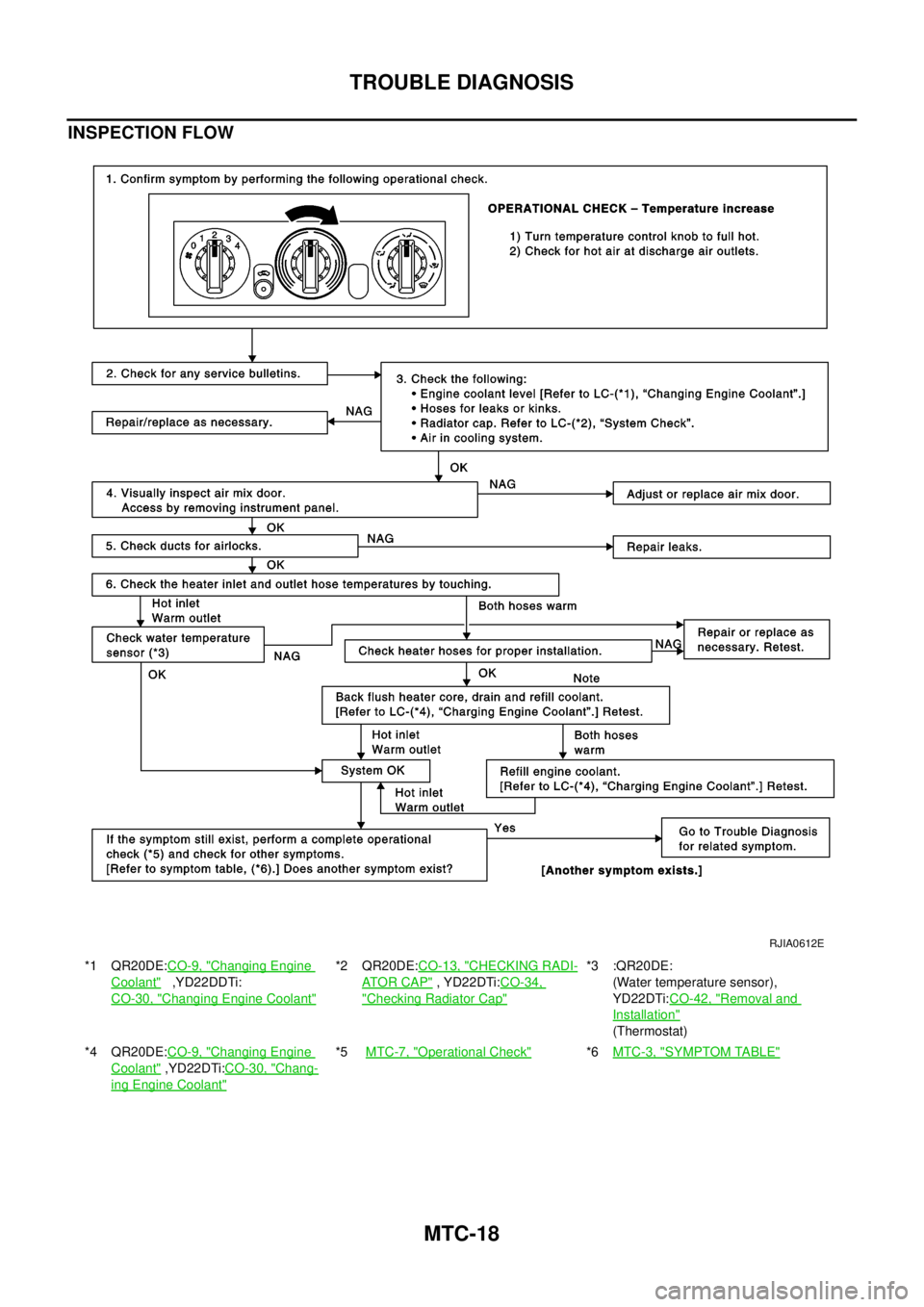

INSPECTION FLOW

*1 QR20DE:CO-9, "Changing Engine

Coolant",YD22DDTi:

CO-30, "

Changing Engine Coolant"

*2 QR20DE:CO-13, "CHECKING RADI-

AT O R C A P", YD22DTi:CO-34,

"Checking Radiator Cap"

*3 :QR20DE:

(Water temperature sensor),

YD22DTi:CO-42, "

Removal and

Installation"

(Thermostat)

*4 QR20DE:CO-9, "

Changing Engine

Coolant",YD22DTi:CO-30, "Chang-

ing Engine Coolant"

*5MTC-7, "Operational Check"*6MTC-3, "SYMPTOM TABLE"

RJIA0612E

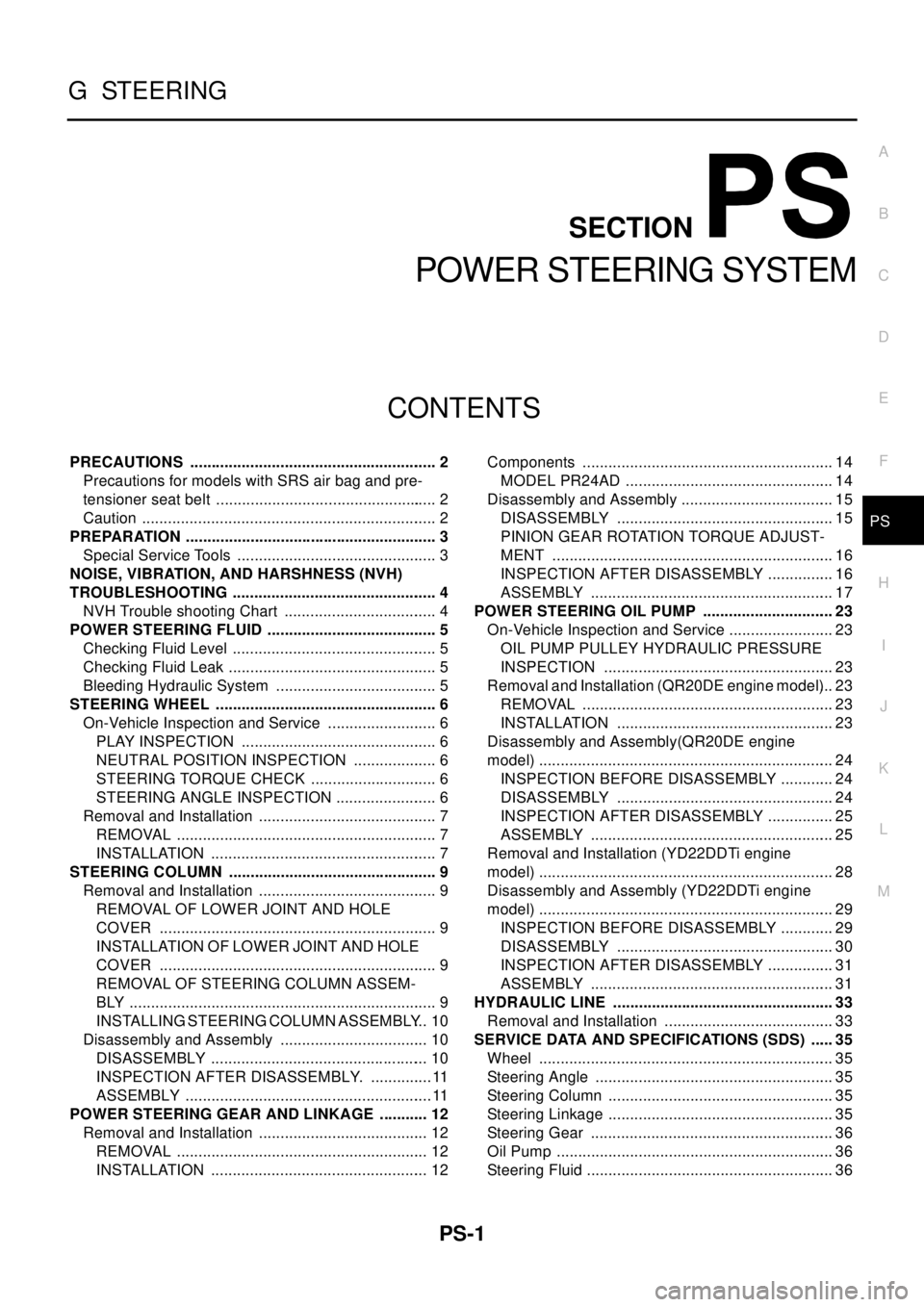

Page 2761 of 3066

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTION

A

B

PS

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for models with SRS air bag and pre-

tensioner seat belt .................................................... 2

Caution ..................................................................... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Trouble shooting Chart .................................... 4

POWER STEERING FLUID ........................................ 5

Checking Fluid Level ................................................ 5

Checking Fluid Leak ................................................. 5

Bleeding Hydraulic System ...................................... 5

STEERING WHEEL .................................................... 6

On-Vehicle Inspection and Service .......................... 6

PLAY INSPECTION .............................................. 6

NEUTRAL POSITION INSPECTION .................... 6

STEERING TORQUE CHECK .............................. 6

STEERING ANGLE INSPECTION ........................ 6

Removal and Installation .......................................... 7

REMOVAL ............................................................. 7

INSTALLATION ..................................................... 7

STEERING COLUMN ................................................. 9

Removal and Installation .......................................... 9

REMOVAL OF LOWER JOINT AND HOLE

COVER ................................................................. 9

INSTALLATION OF LOWER JOINT AND HOLE

COVER ................................................................. 9

REMOVAL OF STEERING COLUMN ASSEM-

BLY ........................................................................ 9

INSTALLING STEERING COLUMN ASSEMBLY... 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY. ...............11

ASSEMBLY ..........................................................11

POWER STEERING GEAR AND LINKAGE ............ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12Components ........................................................... 14

MODEL PR24AD ................................................. 14

Disassembly and Assembly .................................... 15

DISASSEMBLY ................................................... 15

PINION GEAR ROTATION TORQUE ADJUST-

MENT .................................................................. 16

INSPECTION AFTER DISASSEMBLY ................ 16

ASSEMBLY ......................................................... 17

POWER STEERING OIL PUMP ............................... 23

On-Vehicle Inspection and Service ......................... 23

OIL PUMP PULLEY HYDRAULIC PRESSURE

INSPECTION ...................................................... 23

Removal and Installation (QR20DE engine model)... 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 23

Disassembly and Assembly(QR20DE engine

model) ..................................................................... 24

INSPECTION BEFORE DISASSEMBLY ............. 24

DISASSEMBLY ................................................... 24

INSPECTION AFTER DISASSEMBLY ................ 25

ASSEMBLY ......................................................... 25

Removal and Installation (YD22DDTi engine

model) ..................................................................... 28

Disassembly and Assembly (YD22DDTi engine

model) ..................................................................... 29

INSPECTION BEFORE DISASSEMBLY ............. 29

DISASSEMBLY ................................................... 30

INSPECTION AFTER DISASSEMBLY ................ 31

ASSEMBLY ......................................................... 31

HYDRAULIC LINE .................................................... 33

Removal and Installation ........................................ 33

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

Wheel ..................................................................... 35

Steering Angle ........................................................ 35

Steering Column ..................................................... 35

Steering Linkage ..................................................... 35

Steering Gear ......................................................... 36

Oil Pump ................................................................. 36

Steering Fluid .......................................................... 36