secure NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 5 of 3066

ACCELERATOR CONTROL SYSTEM

ACC-3

C

D

E

F

G

H

I

J

K

L

MA

ACC

lDo not adjust the adjusting screw (painted white) of the accelerator work unit. (YD22DDTi)

lWhen the harness connector of the accelerator sensor is disconnected, perform²Accelerator

Pedal Released Position Learning².Referto²Basic Service Procedure²in EC section.

INSTALLATION

Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck that the accelerator pedal moves smoothly within the whole operation range.

lCheck that the accelerator pedal securely returns to the original position.

lFor the electrical inspection of the accelerator pedal assembly, refer toEC-154, "DTC P0121 APP SEN-

SOR"(WITH EURO-OBD) andEC-484, "DTC P0121 APP SENSOR"(WITHOUT EURO-OBD).

(QR20DE)

lFor the electrical inspection of the accelerator work unit, refer toEC-715, "DTC P0120 ACCELERATOR

PEDAL POSITION SENSOR"andEC-783, "DTC P1510 ACCELERATOR PEDAL RELEASED POSI-

TION SWITCH".(YD22DDTi)

lCheck that the drum of the accelerator work unit can be fully opened. (YD22DDTi)

Page 11 of 3066

PRECAUTIONS

AT-5

D

E

F

G

H

I

J

K

L

MA

B

AT

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

ECS004Q0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WA RN ING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

Precautions for On Board Diagnostic (EURO-OBD) System of A/T and Engine —

Euro-OBD —

ECS004Q1

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch “OFF” and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MIL to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lBe sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Precautions For Trouble DiagnosisECS004VN

CAN SYSTEM

lDo not apply voltage of 7.0V or higher to the measurement terminals.

lUse the tester with its open terminal voltage being 7.0V or less.

Precautions For Harness RepairECS004VO

CAN SYSTEM

lSolder the repaired parts, and wrap with tape. [Frays of twisted

line must be within 110 mm (4.33 in)]

PKIA0306E

Page 458 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

feren NISSAN X-TRAIL 2003 Electronic Repair Manual AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

feren](/img/5/57402/w960_57402-457.png)

AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

ference with adjacent parts.

lAfter installing key interlock cable to control device, make sure that casing cap and bracket are

firmly secured in their positions.

RemovalECS0040A

1. Unlock slider by squeezing lock tabs on slider from adjuster

holder and remove interlock rod from cable.

SAT996J

SAT853J

Page 478 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-472

[ALL]

DISASSEMBLY

c. Remove thrust washer and bearing race from oil pump assem-

bly.

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pi NISSAN X-TRAIL 2003 Electronic Repair Manual AT-472

[ALL]

DISASSEMBLY

c. Remove thrust washer and bearing race from oil pump assem-

bly.

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pi](/img/5/57402/w960_57402-477.png)

AT-472

[ALL]

DISASSEMBLY

c. Remove thrust washer and bearing race from oil pump assem-

bly.

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pin.

lDo not reuse anchor end pin.

b. Remove brake band and strut from transmission case.

lTo prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

thefigureatleft.

Leave the clip in position after removing the brake band.

SAT013F

SAT014FA

SAT196F

SAT039D

Page 687 of 3066

BLOWER UNIT

ATC-109

C

D

E

F

G

H

I

K

L

MA

B

AT C

BLOWER UNITPFP:27200

Removal and InstallationEJS000UL

REMOVAL

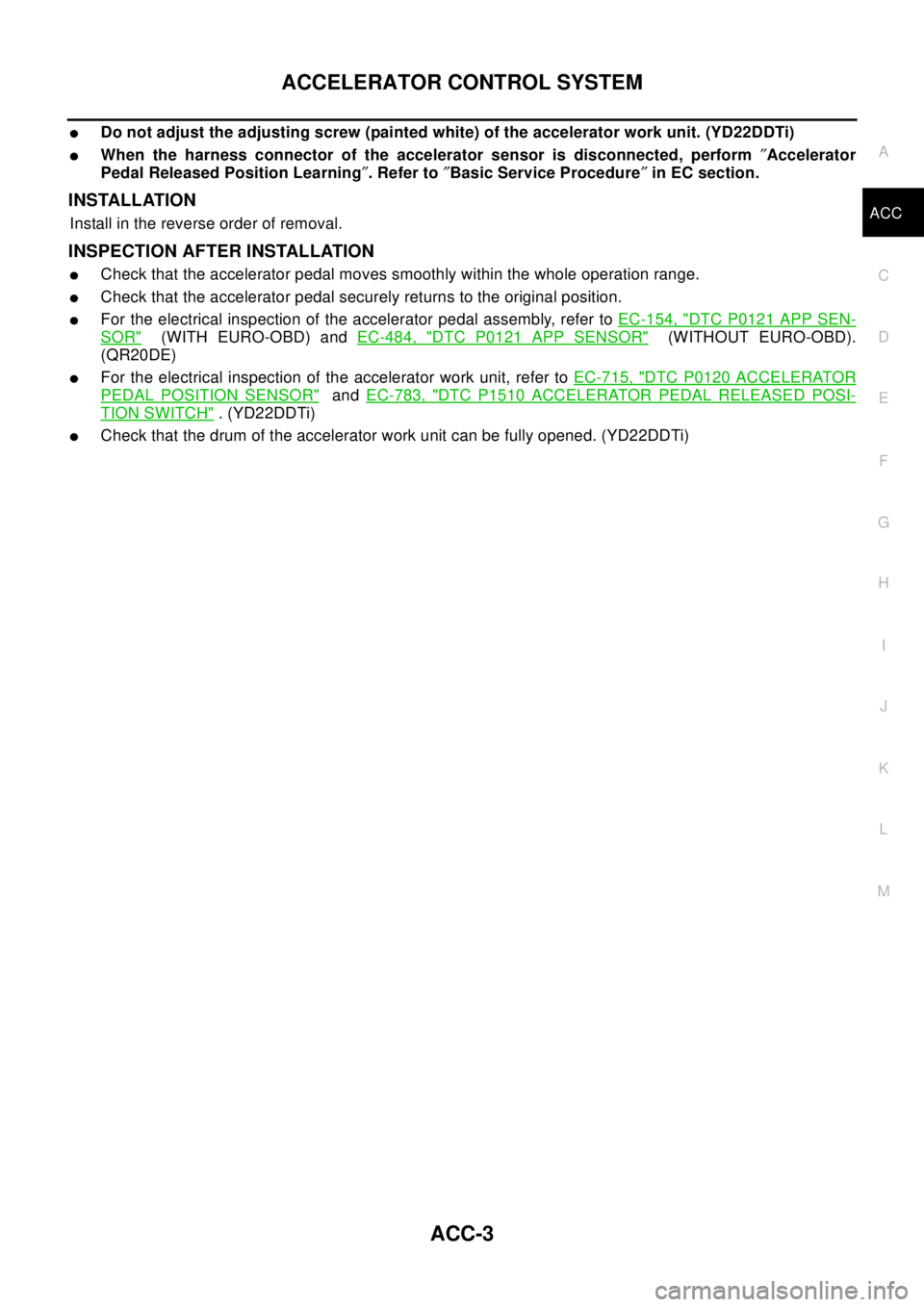

1. Remove the glove box assembly.

2. Remove the glove box cover, the instrument lower assist panel

and instrument reinforcement.

3. Remove the ECM with ECM bracket.

4. Remove the instrument panel fixing screw.

5. Remove the blower unit fixing bolt and screw.

6. Disconnect the blower motor connector and fan control amp.

connector.

7. Remove the blower unit.

8. Disconnect the intake door motor connector and harness clip.

CAUTION:

Slide the blower unit toward the right, remove location pins (2

pieces), then move it downwards.

INSTALLATION

CAUTION:

lMake sure the location pins (2 pieces) are securely installed.

Disassembly and AssemblyEJS000UM

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA0052E

RJIA0098E

Page 718 of 3066

ATC-140

REFRIGERANT LINES

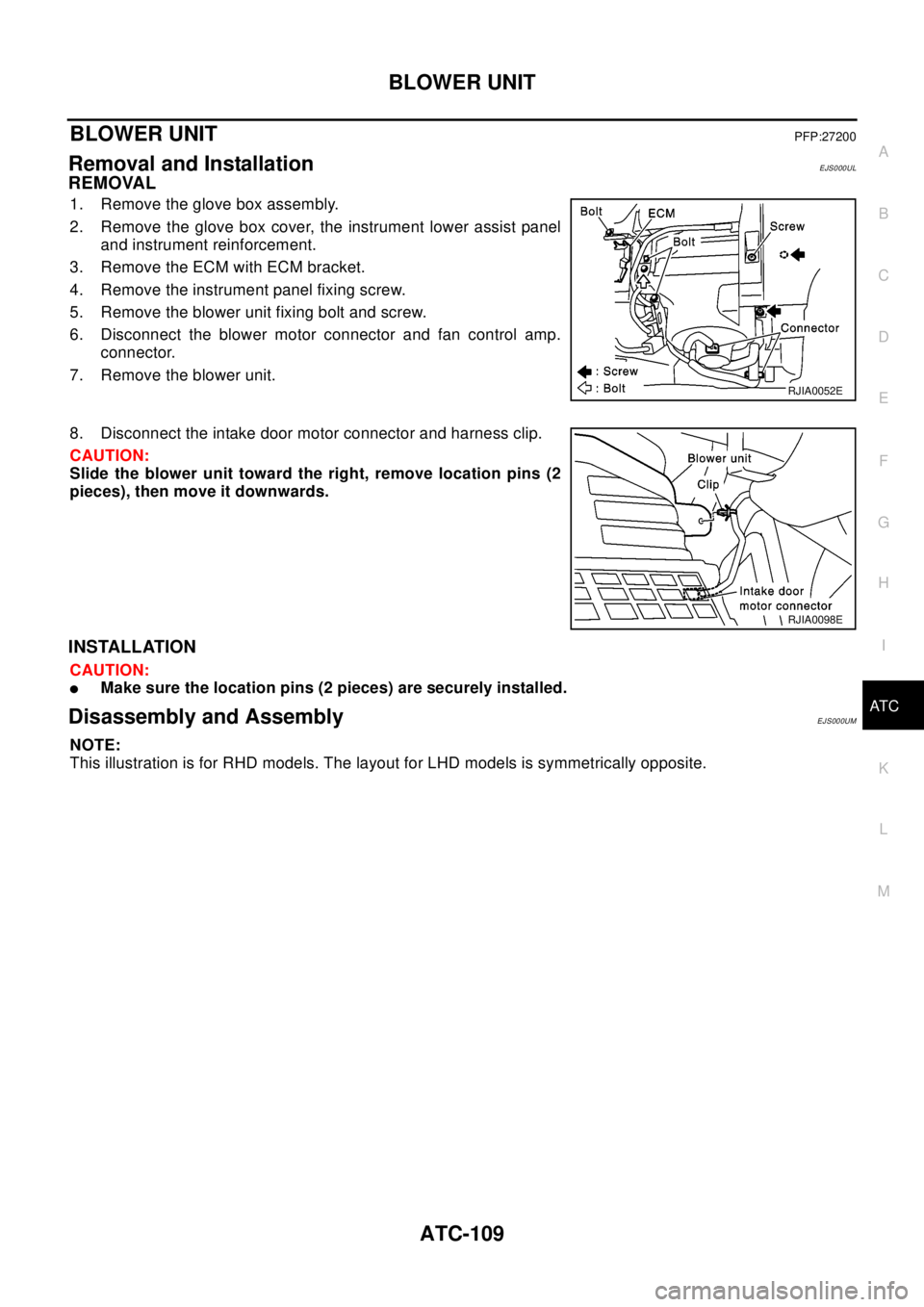

Removal and Installation for Expansion Valve

EJS000VH

1. Using the recycling and recovery equipment (for HFC-134a),

discharge the refrigerant.

2. Disconnect the low-pressure flexible hose and high-pressure

pipe from the evaporator.

CAUTION:

Cap or wrap the joint of the low-pressure flexible hose and

the high-pressure pipe with a suitable tool such as a vinyl

tape to avoid the entry of air.

3. Remove the expansion valve cover.

4. Remove the expansion valve.

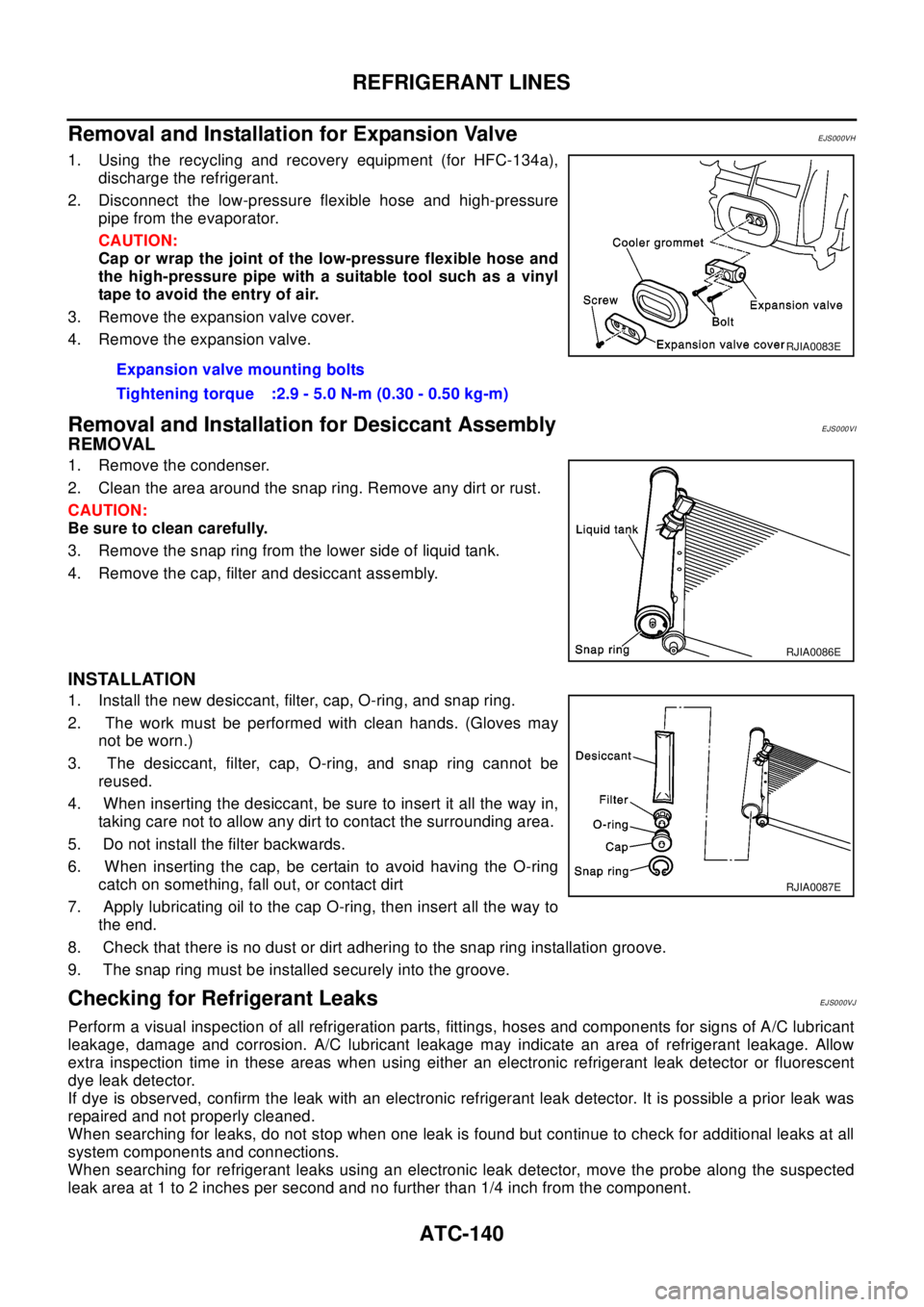

Removal and Installation for Desiccant AssemblyEJS000VI

REMOVAL

1. Remove the condenser.

2. Clean the area around the snap ring. Remove any dirt or rust.

CAUTION:

Be sure to clean carefully.

3. Remove the snap ring from the lower side of liquid tank.

4. Remove the cap, filter and desiccant assembly.

INSTALLATION

1. Install the new desiccant, filter, cap, O-ring, and snap ring.

2. The work must be performed with clean hands. (Gloves may

not be worn.)

3. The desiccant, filter, cap, O-ring, and snap ring cannot be

reused.

4. When inserting the desiccant, be sure to insert it all the way in,

taking care not to allow any dirt to contact the surrounding area.

5. Do not install the filter backwards.

6. When inserting the cap, be certain to avoid having the O-ring

catch on something, fall out, or contact dirt

7. Apply lubricating oil to the cap O-ring, then insert all the way to

the end.

8. Check that there is no dust or dirt adhering to the snap ring installation groove.

9. The snap ring must be installed securely into the groove.

Checking for Refrigerant LeaksEJS000VJ

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.Expansion valve mounting bolts

Tightening torque :2.9 - 5.0 N-m (0.30 - 0.50 kg-m)

RJIA0083E

RJIA0086E

RJIA0087E

Page 721 of 3066

REFRIGERANT LINES

ATC-143

C

D

E

F

G

H

I

K

L

MA

B

AT C

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on "High" for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer's recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Face mode

c. Intake position: Recirculation

d. Max cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

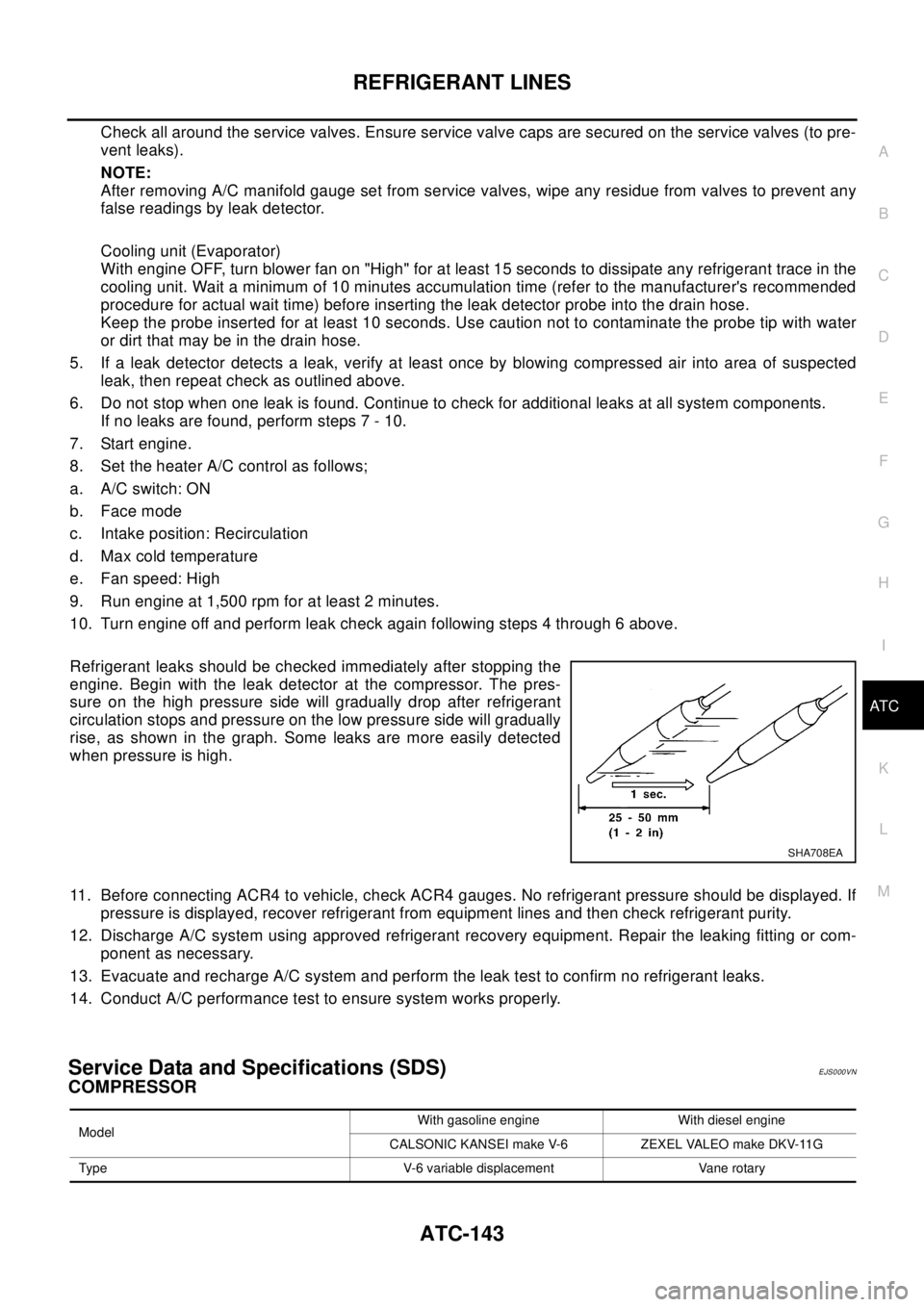

Refrigerant leaks should be checked immediately after stopping the

engine. Begin with the leak detector at the compressor. The pres-

sure on the high pressure side will gradually drop after refrigerant

circulation stops and pressure on the low pressure side will gradually

rise, as shown in the graph. Some leaks are more easily detected

when pressure is high.

11. Before connecting ACR4 to vehicle, check ACR4 gauges. No refrigerant pressure should be displayed. If

pressure is displayed, recover refrigerant from equipment lines and then check refrigerant purity.

12. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent as necessary.

13. Evacuate and recharge A/C system and perform the leak test to confirm no refrigerant leaks.

14. Conduct A/C performance test to ensure system works properly.

Service Data and Specifications (SDS)EJS000VN

COMPRESSOR

SHA708EA

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Type V-6 variable displacement Vane rotary

Page 725 of 3066

AUDIO

AV-3

C

D

E

F

G

H

I

J

L

MA

B

AV

AUDIOP F P : 2 8 111

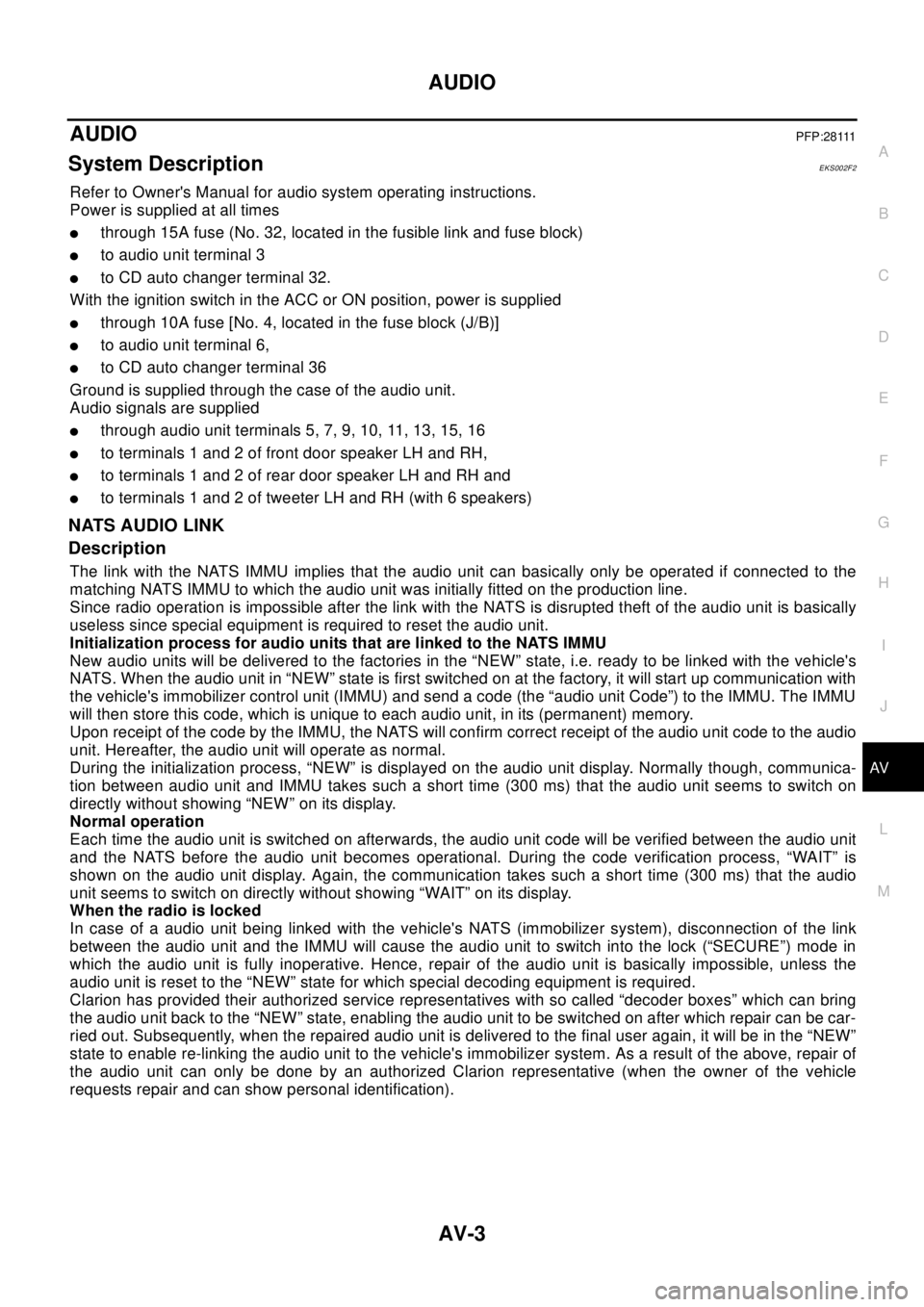

System DescriptionEKS002F2

Refer to Owner's Manual for audio system operating instructions.

Power is supplied at all times

lthrough 15A fuse (No. 32, located in the fusible link and fuse block)

lto audio unit terminal 3

lto CD auto changer terminal 32.

With the ignition switch in the ACC or ON position, power is supplied

lthrough 10A fuse [No. 4, located in the fuse block (J/B)]

lto audio unit terminal 6,

lto CD auto changer terminal 36

Ground is supplied through the case of the audio unit.

Audio signals are supplied

lthrough audio unit terminals 5, 7, 9, 10, 11, 13, 15, 16

lto terminals 1 and 2 of front door speaker LH and RH,

lto terminals 1 and 2 of rear door speaker LH and RH and

lto terminals 1 and 2 of tweeter LH and RH (with 6 speakers)

NATS AUDIO LINK

Description

The link with the NATS IMMU implies that the audio unit can basically only be operated if connected to the

matching NATS IMMU to which the audio unit was initially fitted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the audio unit is basically

useless since special equipment is required to reset the audio unit.

Initialization process for audio units that are linked to the NATS IMMU

New audio units will be delivered to the factories in the “NEW” state, i.e. ready to be linked with the vehicle's

NATS. When the audio unit in “NEW” state is first switched on at the factory, it will start up communication with

the vehicle's immobilizer control unit (IMMU) and send a code (the “audio unit Code”) to the IMMU. The IMMU

will then store this code, which is unique to each audio unit, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will confirm correct receipt of the audio unit code to the audio

unit. Hereafter, the audio unit will operate as normal.

During the initialization process, “NEW” is displayed on the audio unit display. Normally though, communica-

tion between audio unit and IMMU takes such a short time (300 ms) that the audio unit seems to switch on

directly without showing “NEW” on its display.

Normal operation

Each time the audio unit is switched on afterwards, the audio unit code will be verified between the audio unit

and the NATS before the audio unit becomes operational. During the code verification process, “WAIT” is

shown on the audio unit display. Again, the communication takes such a short time (300 ms) that the audio

unit seems to switch on directly without showing “WAIT” on its display.

When the radio is locked

In case of a audio unit being linked with the vehicle's NATS (immobilizer system), disconnection of the link

between the audio unit and the IMMU will cause the audio unit to switch into the lock (“SECURE”) mode in

which the audio unit is fully inoperative. Hence, repair of the audio unit is basically impossible, unless the

audio unit is reset to the “NEW” state for which special decoding equipment is required.

Clarion has provided their authorized service representatives with so called “decoder boxes” which can bring

the audio unit back to the “NEW” state, enabling the audio unit to be switched on after which repair can be car-

ried out. Subsequently, when the repaired audio unit is delivered to the final user again, it will be in the “NEW”

state to enable re-linking the audio unit to the vehicle's immobilizer system. As a result of the above, repair of

the audio unit can only be done by an authorized Clarion representative (when the owner of the vehicle

requests repair and can show personal identification).

Page 726 of 3066

AV-4

AUDIO

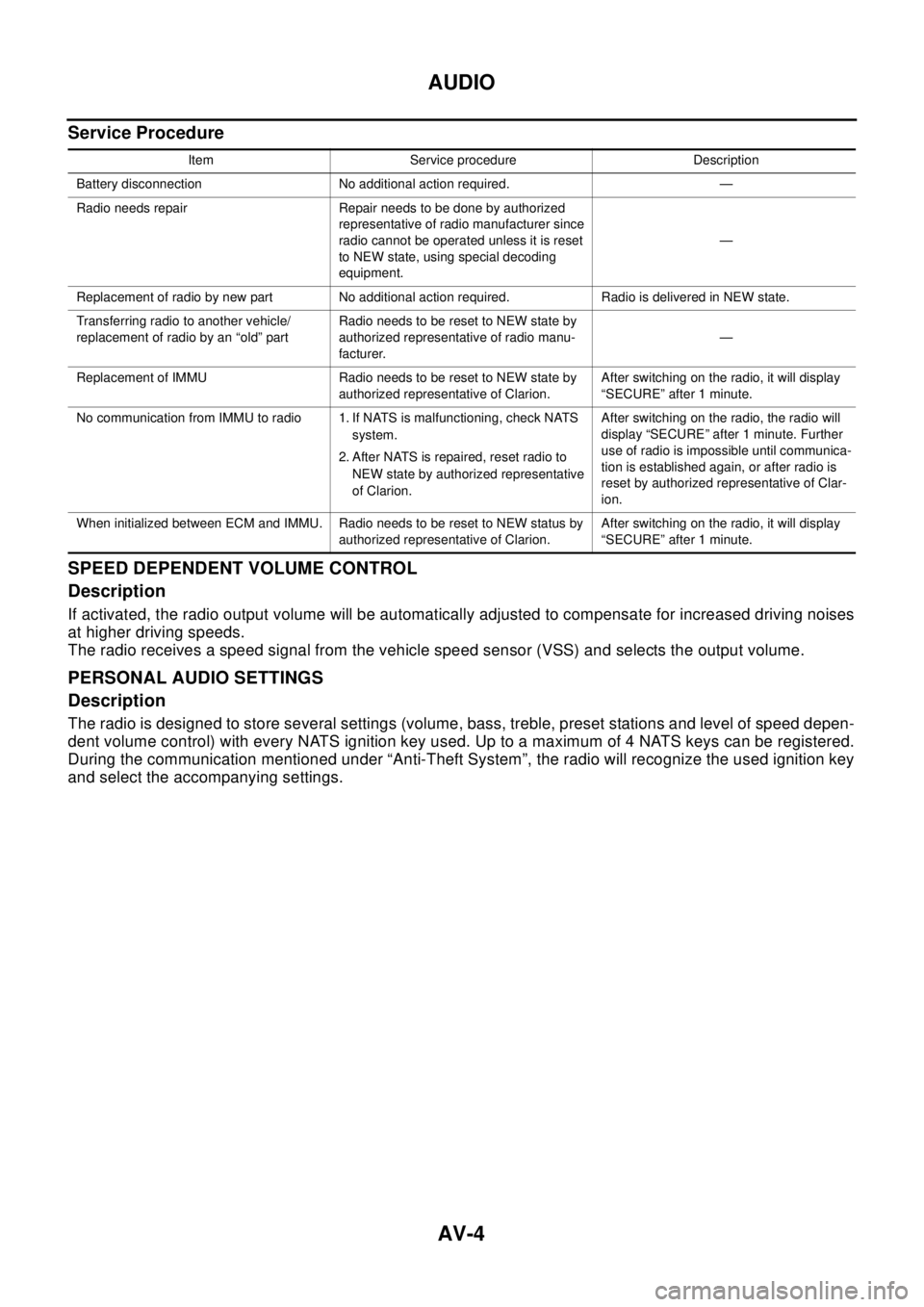

Service Procedure

SPEED DEPENDENT VOLUME CONTROL

Description

If activated, the radio output volume will be automatically adjusted to compensate for increased driving noises

at higher driving speeds.

The radio receives a speed signal from the vehicle speed sensor (VSS) and selects the output volume.

PERSONAL AUDIO SETTINGS

Description

The radio is designed to store several settings (volume, bass, treble, preset stations and level of speed depen-

dent volume control) with every NATS ignition key used. Up to a maximum of 4 NATS keys can be registered.

During the communication mentioned under “Anti-Theft System”, the radio will recognize the used ignition key

and select the accompanying settings.

Item Service procedure Description

Battery disconnection No additional action required. —

Radio needs repair Repair needs to be done by authorized

representative of radio manufacturer since

radio cannot be operated unless it is reset

to NEW state, using special decoding

equipment.—

Replacement of radio by new part No additional action required. Radio is delivered in NEW state.

Transferring radio to another vehicle/

replacement of radio by an “old” partRadio needs to be reset to NEW state by

authorized representative of radio manu-

facturer.—

Replacement of IMMU Radio needs to be reset to NEW state by

authorized representative of Clarion.After switching on the radio, it will display

“SECURE” after 1 minute.

No communication from IMMU to radio 1. If NATS is malfunctioning, check NATS

system.

2. After NATS is repaired, reset radio to

NEW state by authorized representative

of Clarion.After switching on the radio, the radio will

display “SECURE” after 1 minute. Further

use of radio is impossible until communica-

tion is established again, or after radio is

reset by authorized representative of Clar-

ion.

When initialized between ECM and IMMU. Radio needs to be reset to NEW status by

authorized representative of Clarion.After switching on the radio, it will display

“SECURE” after 1 minute.

Page 749 of 3066

HOOD

BL-5

C

D

E

F

G

H

J

K

L

MA

B

BL

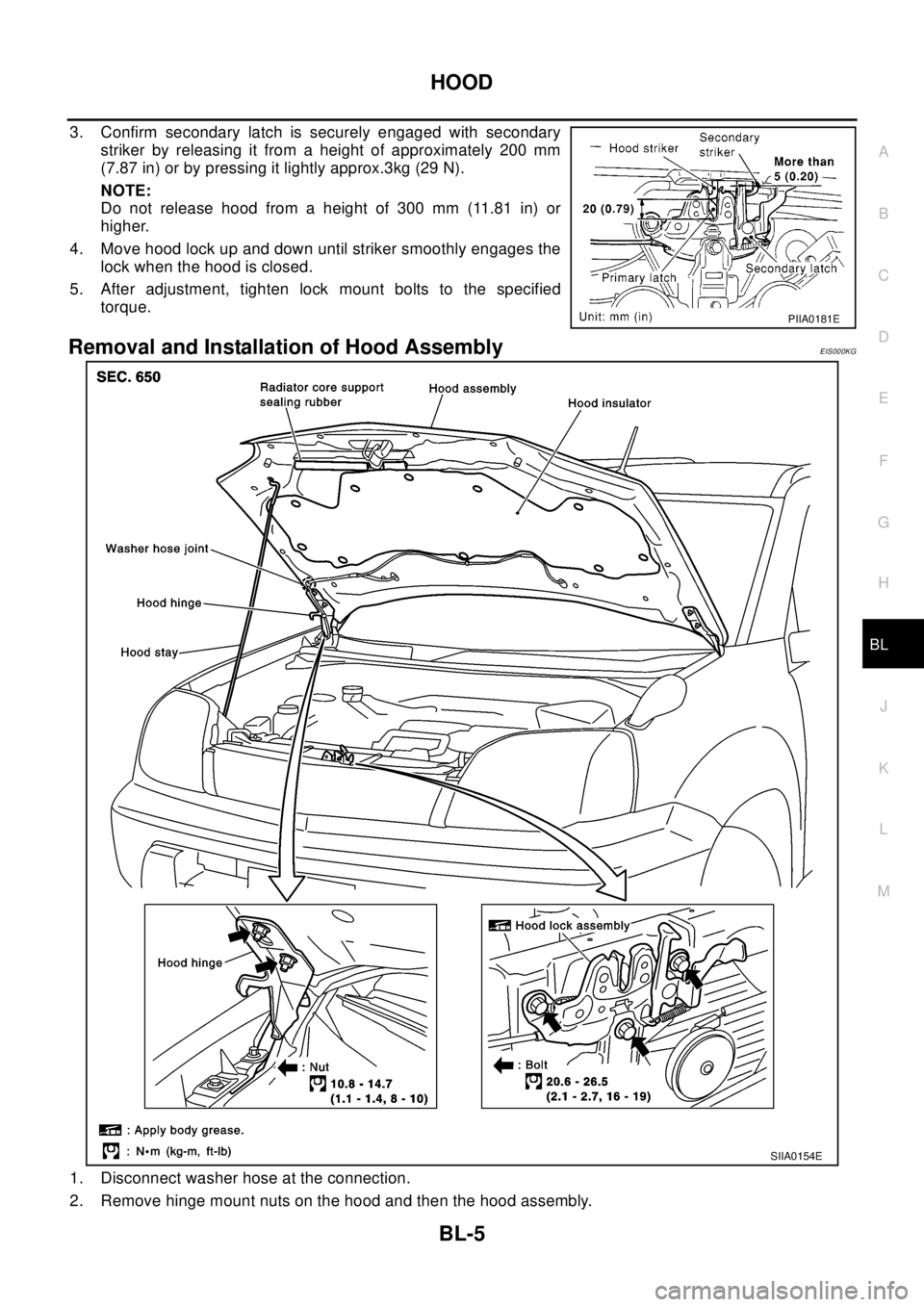

3. Confirm secondary latch is securely engaged with secondary

striker by releasing it from a height of approximately 200 mm

(7.87 in) or by pressing it lightly approx.3kg (29 N).

NOTE:

Do not release hood from a height of 300 mm (11.81 in) or

higher.

4. Move hood lock up and down until striker smoothly engages the

lock when the hood is closed.

5. After adjustment, tighten lock mount bolts to the specified

torque.

Removal and Installation of Hood AssemblyEIS000KG

1. Disconnect washer hose at the connection.

2. Remove hinge mount nuts on the hood and then the hood assembly.

PIIA0181E

SIIA0154E