secure NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 751 of 3066

HOOD

BL-7

C

D

E

F

G

H

J

K

L

MA

B

BL

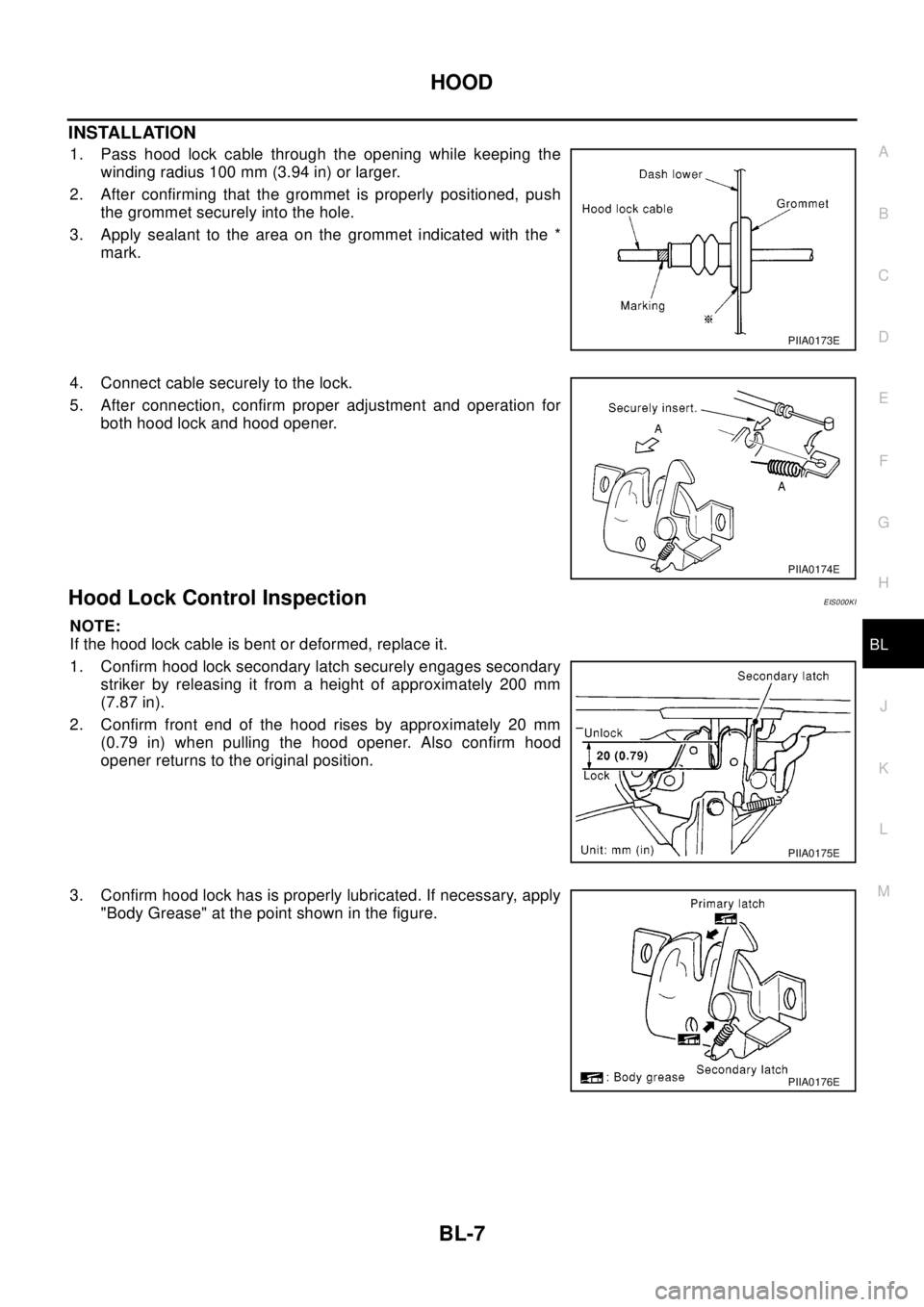

INSTALLATION

1. Pass hood lock cable through the opening while keeping the

winding radius 100 mm (3.94 in) or larger.

2. After confirming that the grommet is properly positioned, push

the grommet securely into the hole.

3. Apply sealant to the area on the grommet indicated with the *

mark.

4. Connect cable securely to the lock.

5. After connection, confirm proper adjustment and operation for

both hood lock and hood opener.

Hood Lock Control InspectionEIS000KI

NOTE:

If the hood lock cable is bent or deformed, replace it.

1. Confirm hood lock secondary latch securely engages secondary

striker by releasing it from a height of approximately 200 mm

(7.87 in).

2. Confirm front end of the hood rises by approximately 20 mm

(0.79 in) when pulling the hood opener. Also confirm hood

opener returns to the original position.

3. Confirm hood lock has is properly lubricated. If necessary, apply

"Body Grease" at the point shown in the figure.

PIIA0173E

PIIA0174E

PIIA0175E

PIIA0176E

Page 800 of 3066

BL-56

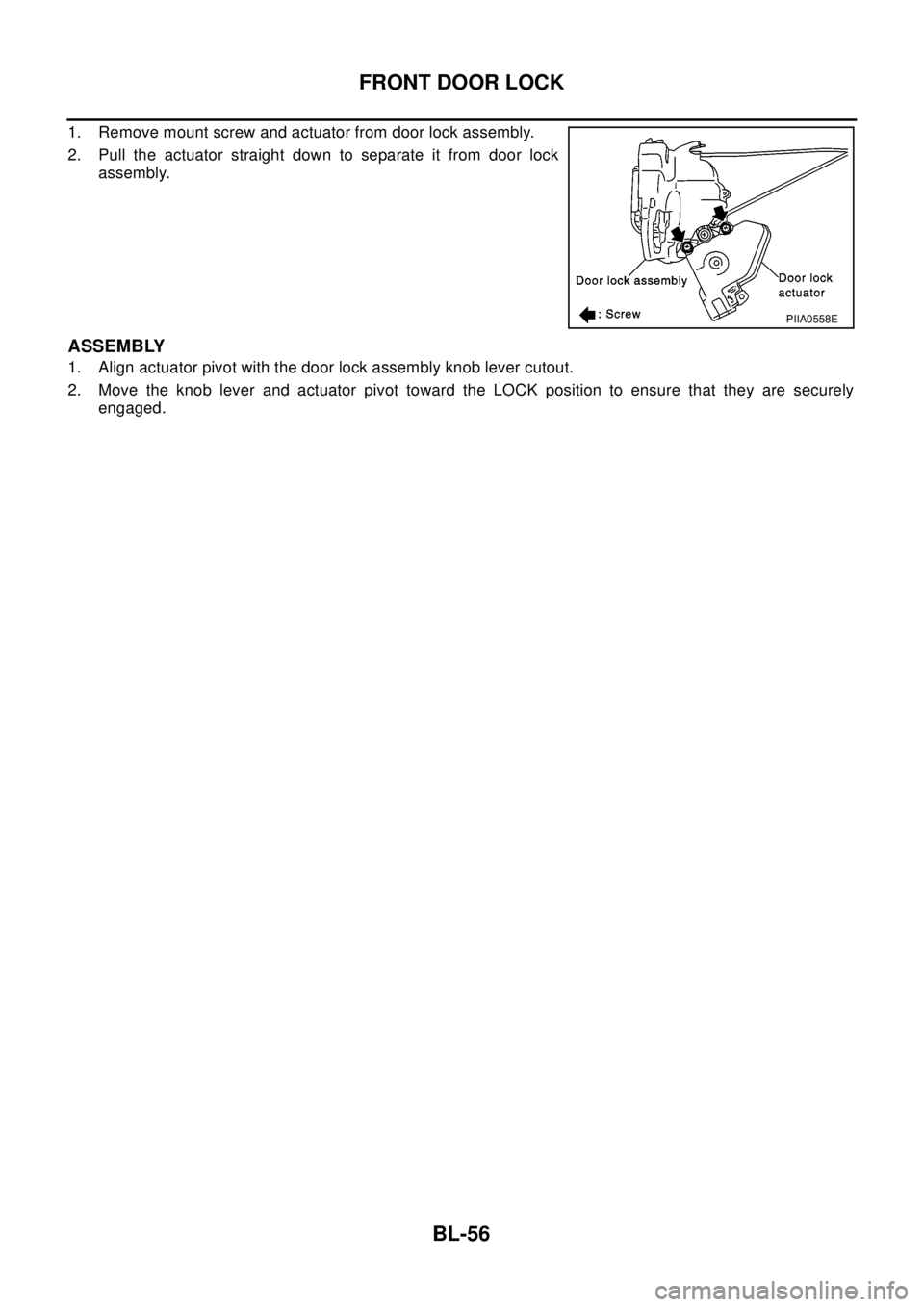

FRONT DOOR LOCK

1. Remove mount screw and actuator from door lock assembly.

2. Pull the actuator straight down to separate it from door lock

assembly.

ASSEMBLY

1. Align actuator pivot with the door lock assembly knob lever cutout.

2. Move the knob lever and actuator pivot toward the LOCK position to ensure that they are securely

engaged.

PIIA0558E

Page 803 of 3066

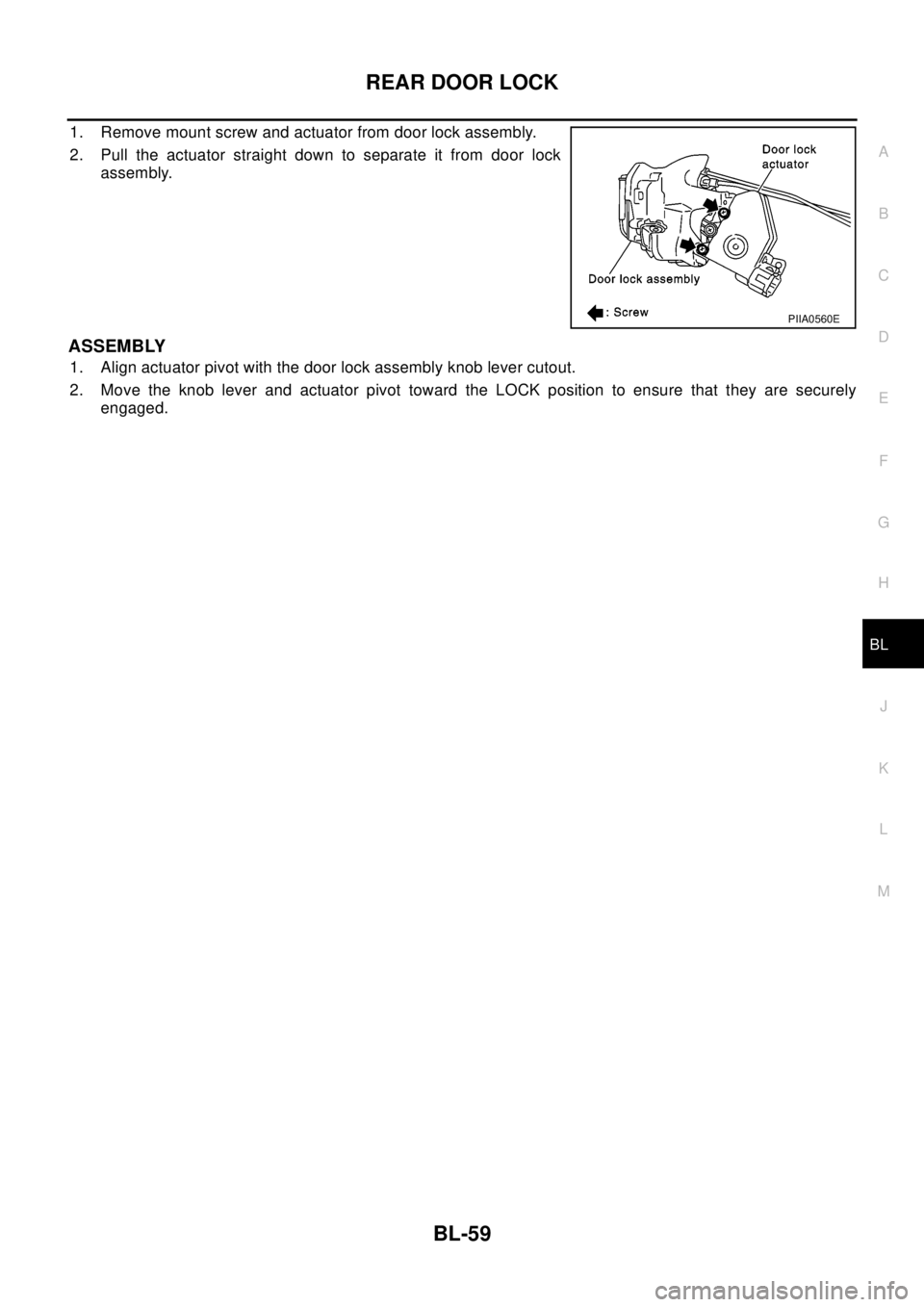

REAR DOOR LOCK

BL-59

C

D

E

F

G

H

J

K

L

MA

B

BL

1. Remove mount screw and actuator from door lock assembly.

2. Pull the actuator straight down to separate it from door lock

assembly.

ASSEMBLY

1. Align actuator pivot with the door lock assembly knob lever cutout.

2. Move the knob lever and actuator pivot toward the LOCK position to ensure that they are securely

engaged.

PIIA0560E

Page 837 of 3066

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

PRECAUTIONSPFP:00001

Precautions for Models with SRS Air Bag and Pre-Tensioner Seat BeltEFS000BY

WA RN ING:

lBefore removing and installing components and harnesses of SRS air bag and seat belt pre-ten-

sioner system, turn ignition switch OFF, disconnect battery ground cable, and wait at least 3 min-

utes. (This discharges electricity held in the air bag sensor unit's additional power circuit.)

lDo not use pneumatic or electric tools to remove and install the components.

lDo not solder SRS air bag and seat belt pre-tensioner system harnesses when making repairs.

Make sure harness is not pinched and there is no contact with other components.

lWhen checking the SRS air bag and the seat belt pre-tensioner circuit or the components of each

system, do not use an electric tester such as a circuit tester. (This is to prevent accidental trigger-

ing caused by the weak electric current of a tester.)

lNever insert foreign material (such as a screwdriver) in the air bag module and pre-tensioner seat

belt connectors. (The units may be actuated by mistake by static electricity.)

lSeat belt pre-tensioner and SRS air bag harnesses can be distinguished from other harnesses by

their yellow connectors.

lWhen servicing, refer to “SB Seat Belt” and “SRS Air Bag” for safety.

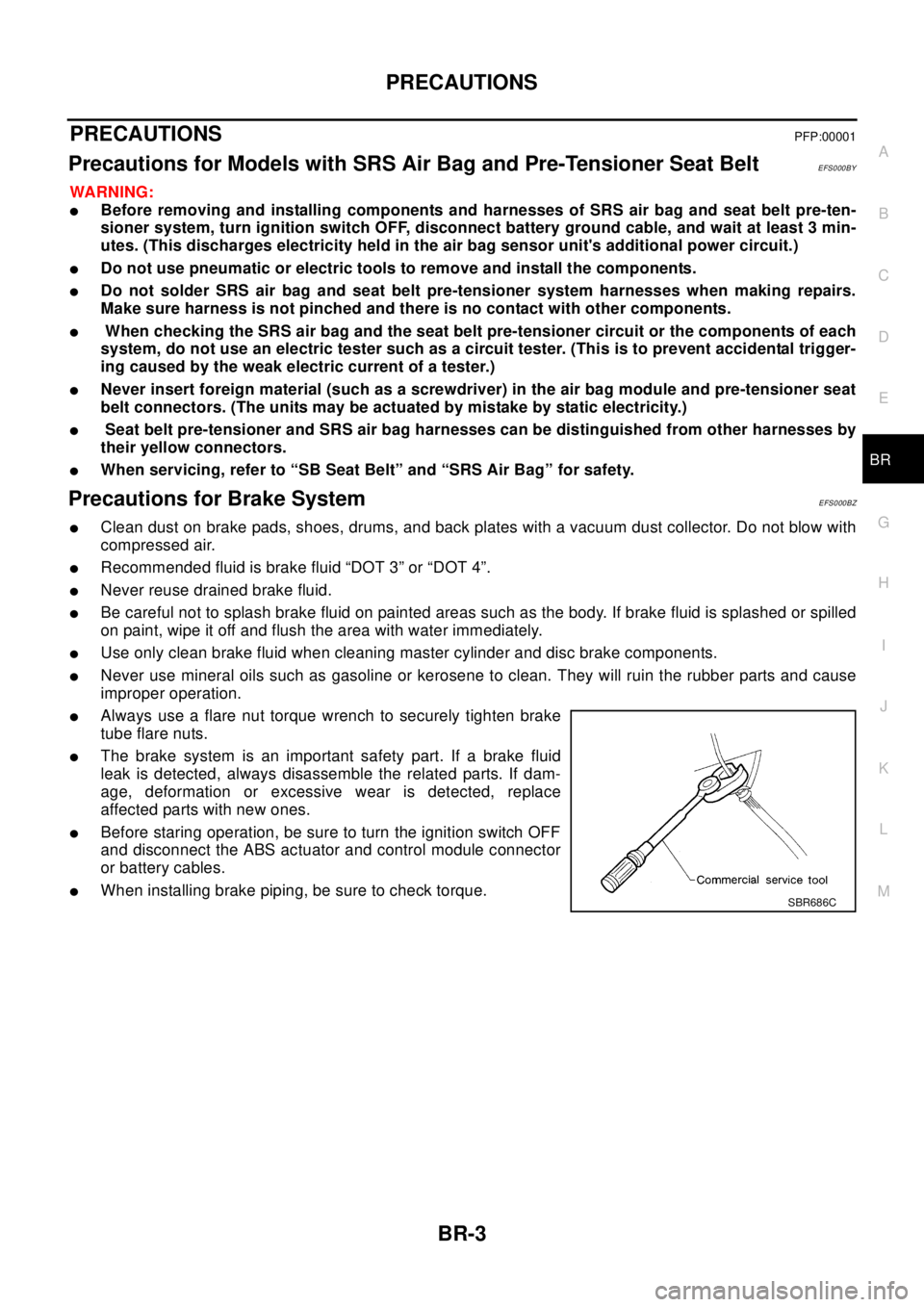

Precautions for Brake SystemEFS000BZ

lClean dust on brake pads, shoes, drums, and back plates with a vacuum dust collector. Do not blow with

compressed air.

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas such as the body. If brake fluid is splashed or spilled

on paint, wipe it off and flush the area with water immediately.

lUse only clean brake fluid when cleaning master cylinder and disc brake components.

lNever use mineral oils such as gasoline or kerosene to clean. They will ruin the rubber parts and cause

improper operation.

lAlways use a flare nut torque wrench to securely tighten brake

tube flare nuts.

lThe brake system is an important safety part. If a brake fluid

leak is detected, always disassemble the related parts. If dam-

age, deformation or excessive wear is detected, replace

affected parts with new ones.

lBefore staring operation, be sure to turn the ignition switch OFF

and disconnect the ABS actuator and control module connector

or battery cables.

lWhen installing brake piping, be sure to check torque.SBR686C

Page 841 of 3066

BRAKE PEDAL

BR-7

C

D

E

G

H

I

J

K

L

MA

B

BR

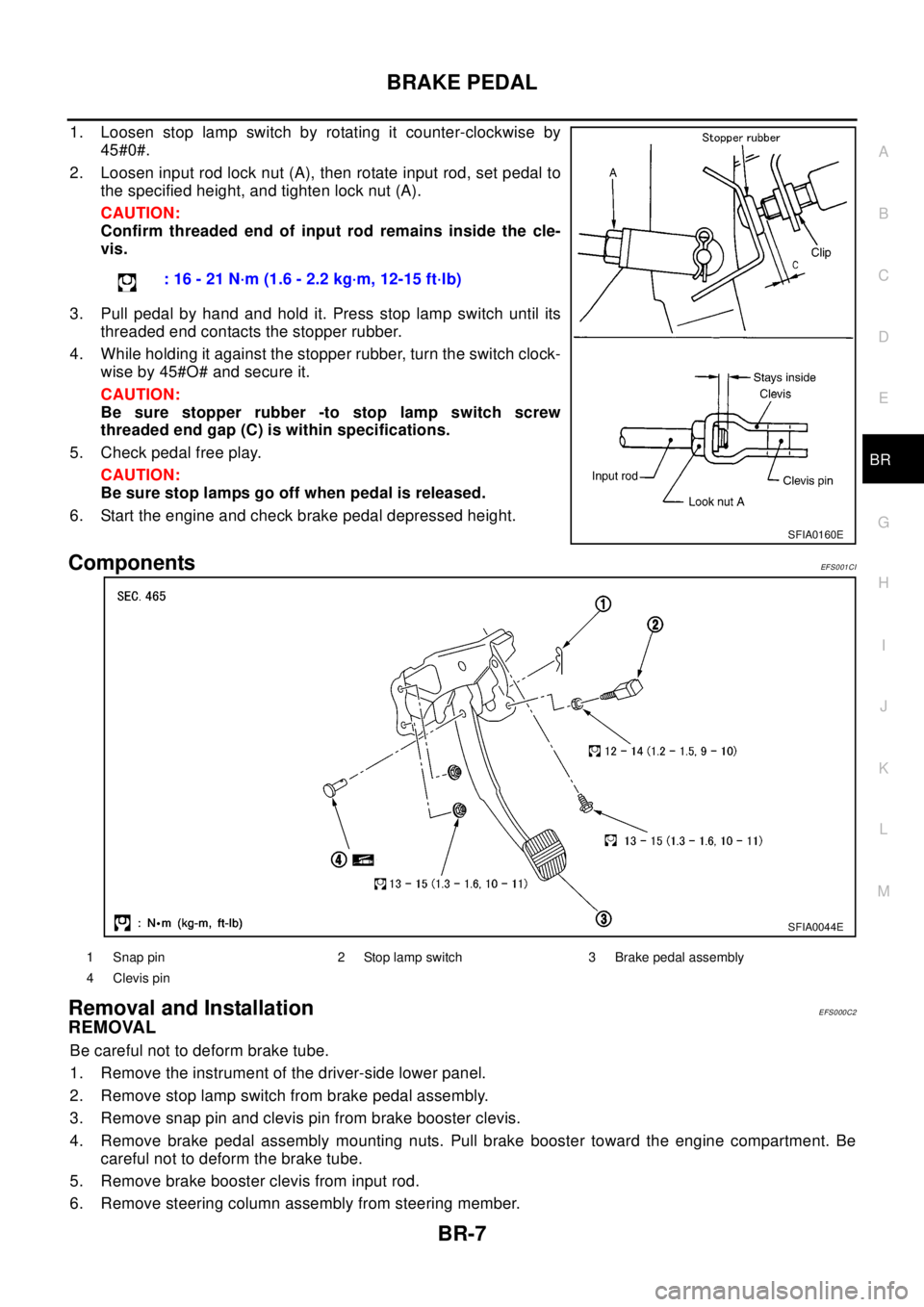

1. Loosen stop lamp switch by rotating it counter-clockwise by

45#0#.

2. Loosen input rod lock nut (A), then rotate input rod, set pedal to

the specified height, and tighten lock nut (A).

CAUTION:

Confirm threaded end of input rod remains inside the cle-

vis.

3. Pull pedal by hand and hold it. Press stop lamp switch until its

threaded end contacts the stopper rubber.

4. While holding it against the stopper rubber, turn the switch clock-

wise by 45#O# and secure it.

CAUTION:

Be sure stopper rubber -to stop lamp switch screw

threaded end gap (C) is within specifications.

5. Check pedal free play.

CAUTION:

Be sure stop lamps go off when pedal is released.

6. Start the engine and check brake pedal depressed height.

ComponentsEF S0 01 CI

Removal and InstallationEFS000C2

REMOVAL

Be careful not to deform brake tube.

1. Remove the instrument of the driver-side lower panel.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from brake booster clevis.

4. Remove brake pedal assembly mounting nuts. Pull brake booster toward the engine compartment. Be

careful not to deform the brake tube.

5. Remove brake booster clevis from input rod.

6. Remove steering column assembly from steering member.: 16 - 21 N·m (1.6 - 2.2 kg·m, 12-15 ft·lb)

SFIA0160E

SFIA0044E

1 Snap pin 2 Stop lamp switch 3 Brake pedal assembly

4 Clevis pin

Page 845 of 3066

BRAKE PIPING AND HOSE

BR-11

C

D

E

G

H

I

J

K

L

MA

B

BR

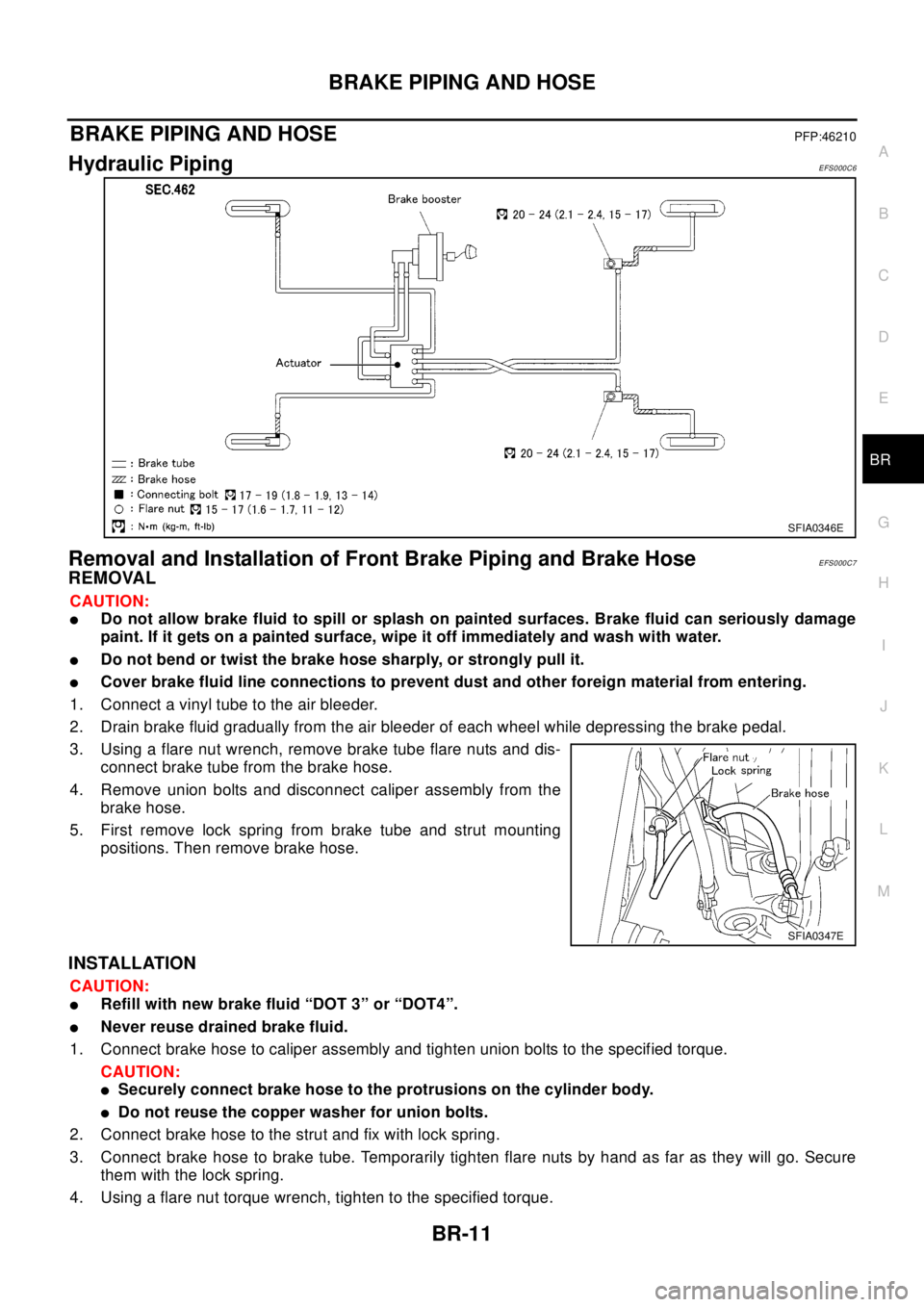

BRAKE PIPING AND HOSEPFP:46210

Hydraulic PipingEFS000C6

Removal and Installation of Front Brake Piping and Brake HoseEFS000C7

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove union bolts and disconnect caliper assembly from the

brake hose.

5. First remove lock spring from brake tube and strut mounting

positions. Then remove brake hose.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT4”.

lNever reuse drained brake fluid.

1. Connect brake hose to caliper assembly and tighten union bolts to the specified torque.

CAUTION:

lSecurely connect brake hose to the protrusions on the cylinder body.

lDo not reuse the copper washer for union bolts.

2. Connect brake hose to the strut and fix with lock spring.

3. Connect brake hose to brake tube. Temporarily tighten flare nuts by hand as far as they will go. Secure

them with the lock spring.

4. Using a flare nut torque wrench, tighten to the specified torque.

SFIA0346E

SFIA0347E

Page 846 of 3066

BR-12

BRAKE PIPING AND HOSE

5. Refill brake fluid until new brake fluid comes out of each air bleeder.

6. Afterwards, bleed air.

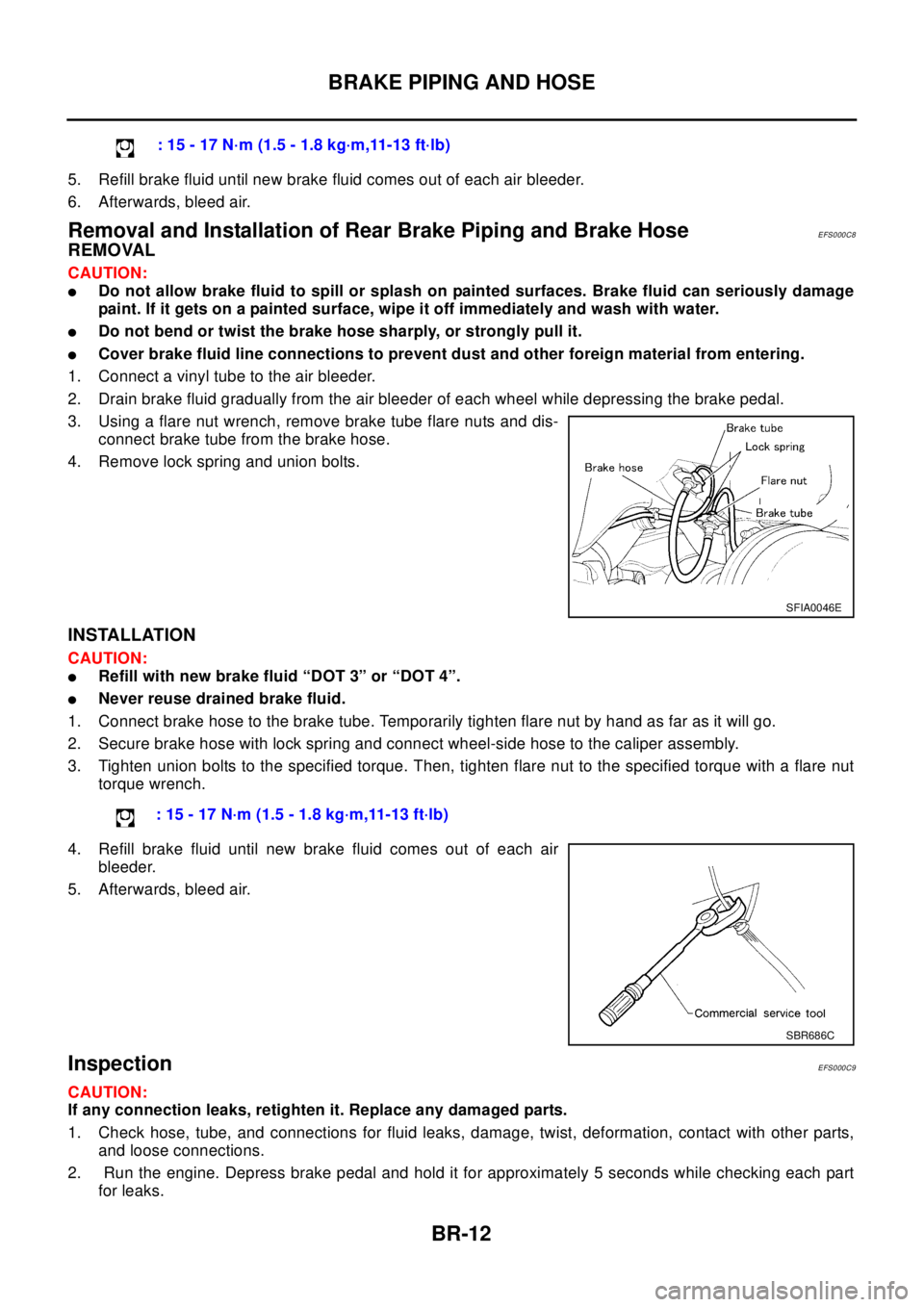

Removal and Installation of Rear Brake Piping and Brake HoseEFS000C8

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove lock spring and union bolts.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Connect brake hose to the brake tube. Temporarily tighten flare nut by hand as far as it will go.

2. Secure brake hose with lock spring and connect wheel-side hose to the caliper assembly.

3. Tighten union bolts to the specified torque. Then, tighten flare nut to the specified torque with a flare nut

torque wrench.

4. Refill brake fluid until new brake fluid comes out of each air

bleeder.

5. Afterwards, bleed air.

InspectionEFS000C9

CAUTION:

If any connection leaks, retighten it. Replace any damaged parts.

1. Check hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other parts,

and loose connections.

2. Run the engine. Depress brake pedal and hold it for approximately 5 seconds while checking each part

for leaks.:15-17N·m(1.5-1.8kg·m,11-13ft·lb)

SFIA0046E

: 15 - 17 N·m (1.5 - 1.8 kg·m,11-13 ft·lb)

SBR686C

Page 848 of 3066

BR-14

BRAKE MASTER CYLINDER

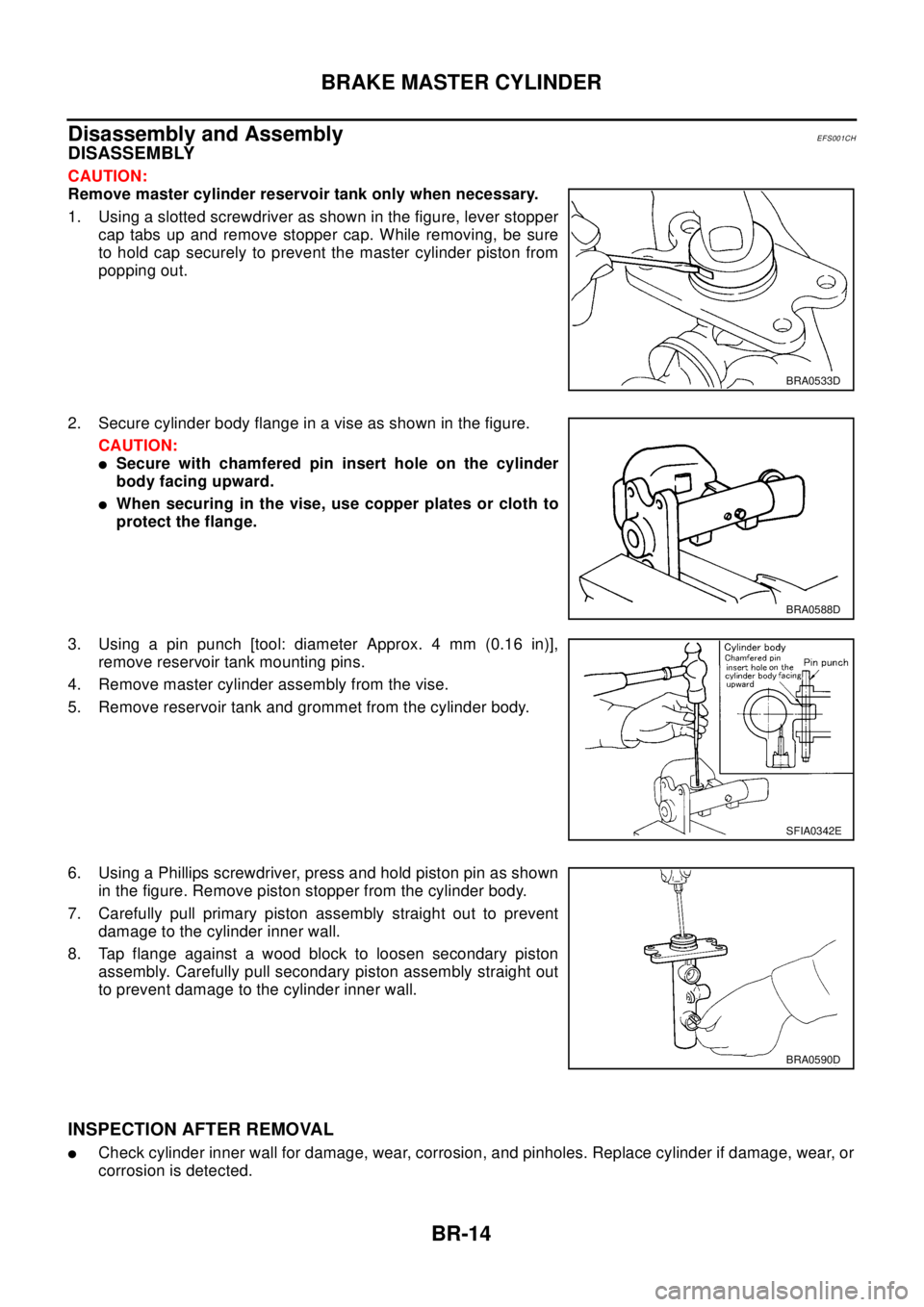

Disassembly and Assembly

EFS001CH

DISASSEMBLY

CAUTION:

Remove master cylinder reservoir tank only when necessary.

1. Using a slotted screwdriver as shown in the figure, lever stopper

cap tabs up and remove stopper cap. While removing, be sure

to hold cap securely to prevent the master cylinder piston from

popping out.

2. Secure cylinder body flange in a vise as shown in the figure.

CAUTION:

lSecure with chamfered pin insert hole on the cylinder

body facing upward.

lWhen securing in the vise, use copper plates or cloth to

protect the flange.

3. Using a pin punch [tool: diameter Approx. 4 mm (0.16 in)],

remove reservoir tank mounting pins.

4. Remove master cylinder assembly from the vise.

5. Remove reservoir tank and grommet from the cylinder body.

6. Using a Phillips screwdriver, press and hold piston pin as shown

in the figure. Remove piston stopper from the cylinder body.

7. Carefully pull primary piston assembly straight out to prevent

damage to the cylinder inner wall.

8. Tap flange against a wood block to loosen secondary piston

assembly. Carefully pull secondary piston assembly straight out

to prevent damage to the cylinder inner wall.

INSPECTION AFTER REMOVAL

lCheck cylinder inner wall for damage, wear, corrosion, and pinholes. Replace cylinder if damage, wear, or

corrosion is detected.

BRA0533D

BRA0588D

SFIA0342E

BRA0590D

Page 849 of 3066

BRAKE MASTER CYLINDER

BR-15

C

D

E

G

H

I

J

K

L

MA

B

BR

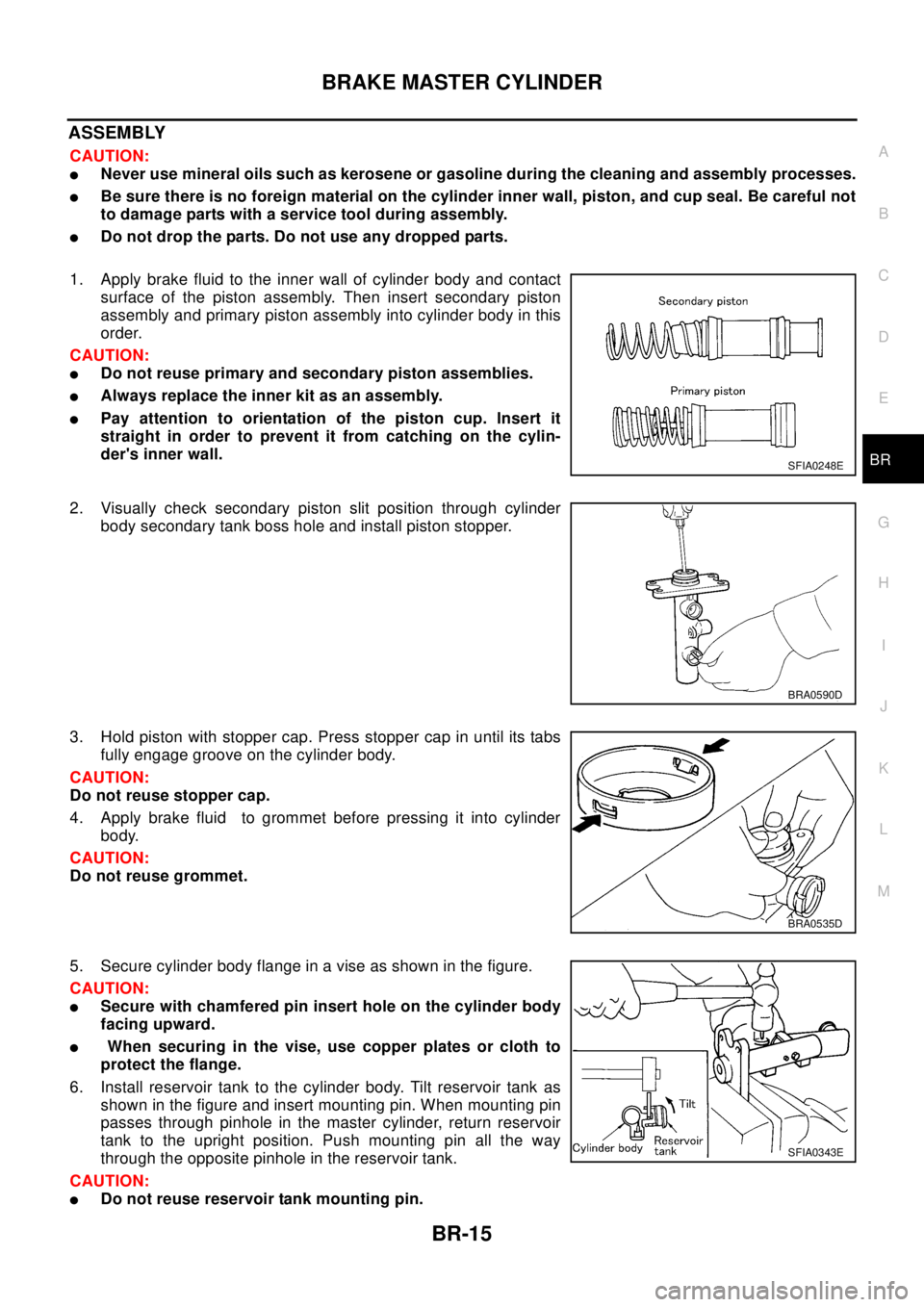

ASSEMBLY

CAUTION:

lNever use mineral oils such as kerosene or gasoline during the cleaning and assembly processes.

lBe sure there is no foreign material on the cylinder inner wall, piston, and cup seal. Be careful not

to damage parts with a service tool during assembly.

lDo not drop the parts. Do not use any dropped parts.

1. Apply brake fluid to the inner wall of cylinder body and contact

surface of the piston assembly. Then insert secondary piston

assembly and primary piston assembly into cylinder body in this

order.

CAUTION:

lDo not reuse primary and secondary piston assemblies.

lAlways replace the inner kit as an assembly.

lPay attention to orientation of the piston cup. Insert it

straight in order to prevent it from catching on the cylin-

der's inner wall.

2. Visually check secondary piston slit position through cylinder

body secondary tank boss hole and install piston stopper.

3. Hold piston with stopper cap. Press stopper cap in until its tabs

fully engage groove on the cylinder body.

CAUTION:

Do not reuse stopper cap.

4. Apply brake fluid to grommet before pressing it into cylinder

body.

CAUTION:

Do not reuse grommet.

5. Secure cylinder body flange in a vise as shown in the figure.

CAUTION:

lSecure with chamfered pin insert hole on the cylinder body

facing upward.

lWhen securing in the vise, use copper plates or cloth to

protect the flange.

6. Install reservoir tank to the cylinder body. Tilt reservoir tank as

shown in the figure and insert mounting pin. When mounting pin

passes through pinhole in the master cylinder, return reservoir

tank to the upright position. Push mounting pin all the way

through the opposite pinhole in the reservoir tank.

CAUTION:

lDo not reuse reservoir tank mounting pin.

SFIA0248E

BRA0590D

BRA0535D

SFIA0343E

Page 852 of 3066

BR-18

BRAKE BOOSTER

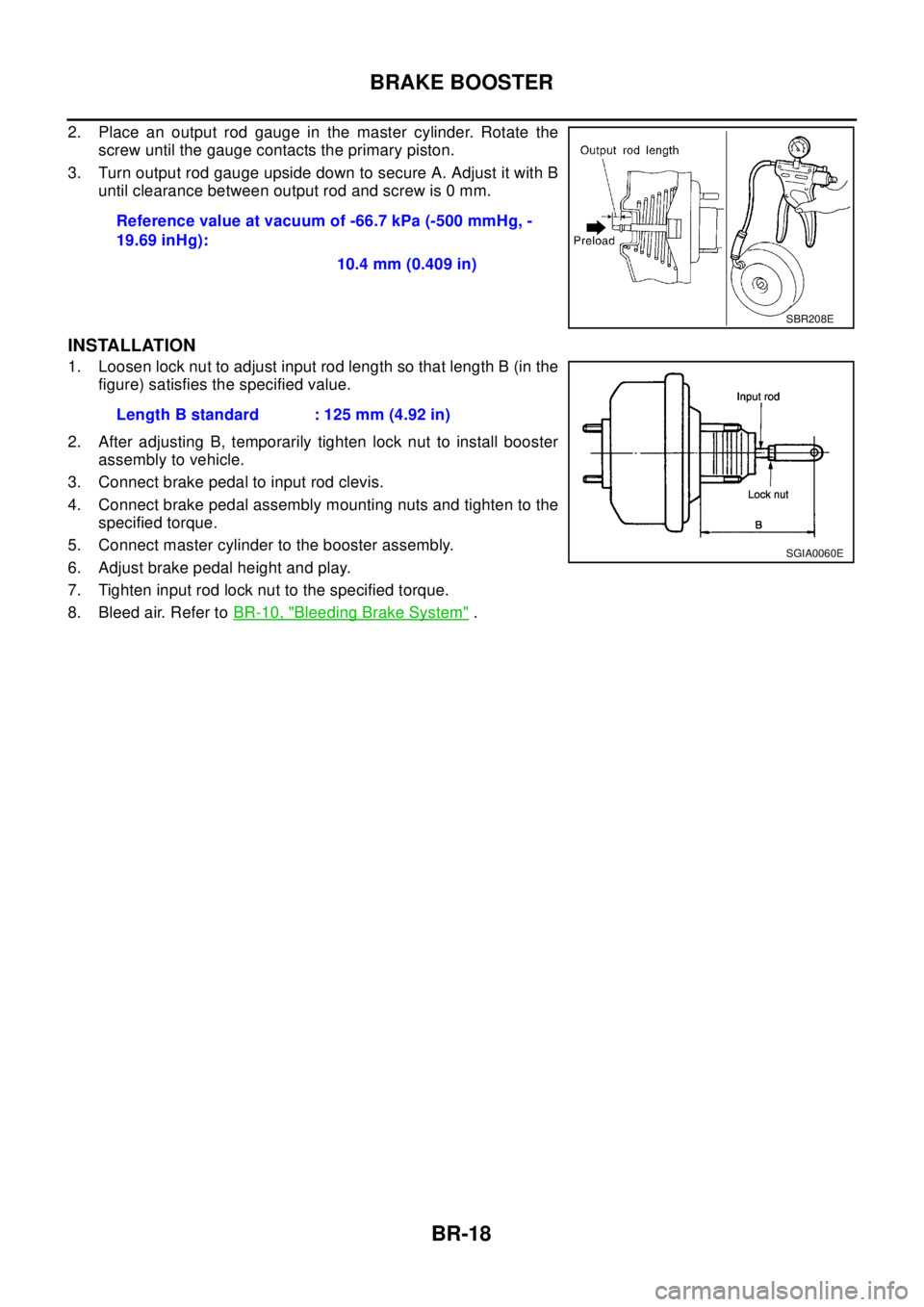

2. Place an output rod gauge in the master cylinder. Rotate the

screw until the gauge contacts the primary piston.

3. Turn output rod gauge upside down to secure A. Adjust it with B

until clearance between output rod and screw is 0 mm.

INSTALLATION

1. Loosen lock nut to adjust input rod length so that length B (in the

figure) satisfies the specified value.

2. After adjusting B, temporarily tighten lock nut to install booster

assembly to vehicle.

3. Connect brake pedal to input rod clevis.

4. Connect brake pedal assembly mounting nuts and tighten to the

specified torque.

5. Connect master cylinder to the booster assembly.

6. Adjust brake pedal height and play.

7. Tighten input rod lock nut to the specified torque.

8. Bleed air. Refer toBR-10, "

Bleeding Brake System". Reference value at vacuum of -66.7 kPa (-500 mmHg, -

19.69 inHg):

10.4 mm (0.409 in)

SBR208E

Length B standard : 125 mm (4.92 in)

SGIA0060E