transmission oil NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 15 of 3066

PREPARATION

AT-9

D

E

F

G

H

I

J

K

L

MA

B

AT

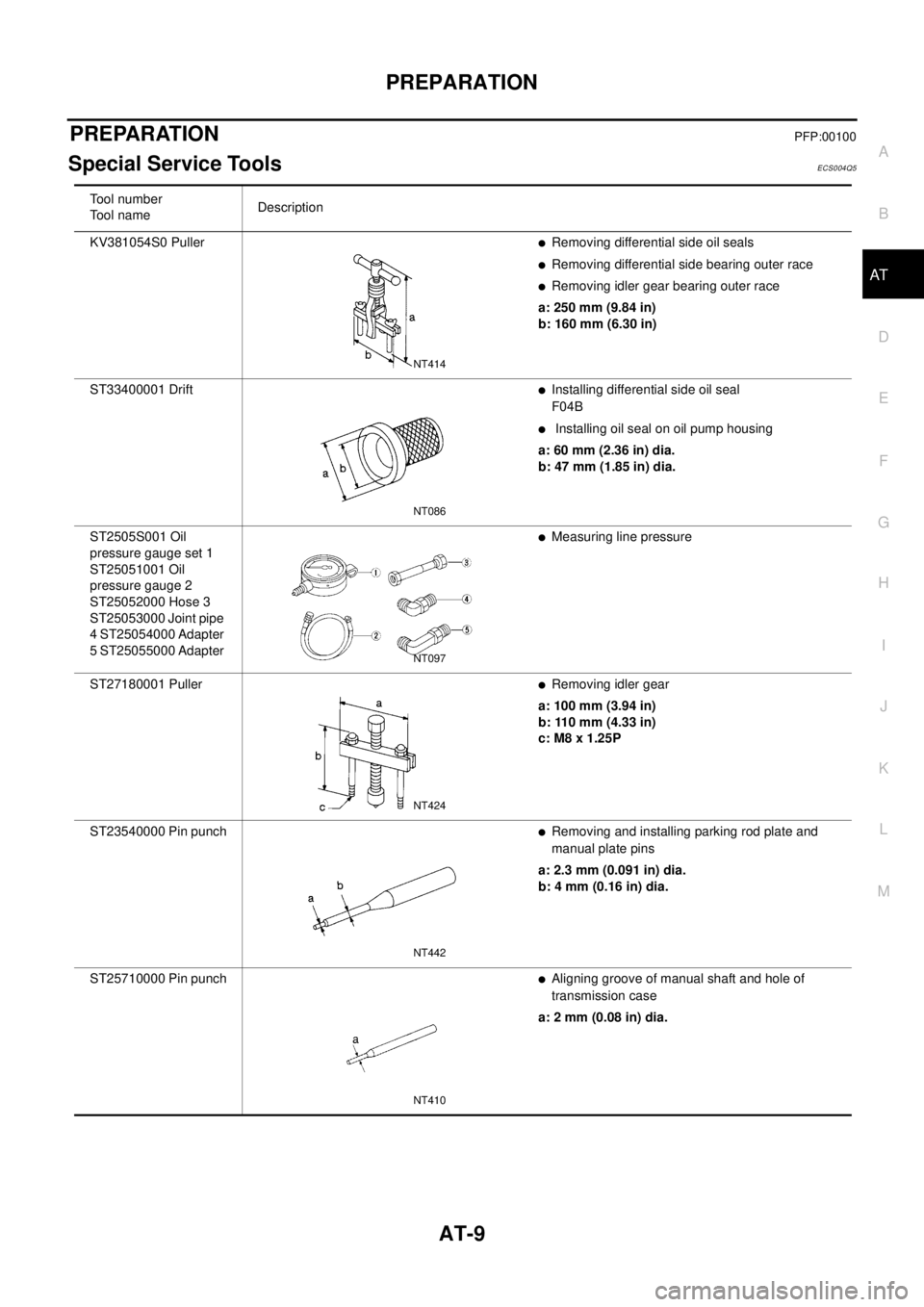

PREPARATIONPFP:00100

Special Service ToolsECS004Q5

Tool number

To o l n a m eDescription

KV381054S0 Puller

lRemoving differential side oil seals

lRemoving differential side bearing outer race

lRemoving idler gear bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33400001 Drift

lInstalling differential side oil seal

F04B

lInstalling oil seal on oil pump housing

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST2505S001 Oil

pressure gauge set 1

ST25051001 Oil

pressure gauge 2

ST25052000 Hose 3

ST25053000 Joint pipe

4 ST25054000 Adapter

5 ST25055000 Adapter

lMeasuring line pressure

ST27180001 Puller

lRemoving idler gear

a: 100 mm (3.94 in)

b: 110 mm (4.33 in)

c: M8 x 1.25P

ST23540000 Pin punch

lRemoving and installing parking rod plate and

manual plate pins

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

ST25710000 Pin punch

lAligning groove of manual shaft and hole of

transmission case

a: 2 mm (0.08 in) dia.

NT414

NT086

NT097

NT424

NT442

NT410

Page 26 of 3066

AT-20

OVERALL SYSTEM

l*1: Operates when overdrive control switch is set in “OFF” position.

l*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not con-

tract because oil pressure area on the “release” side is greater than that on the “apply” side.

l*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

l*4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position.

l*5: Operates when overdrive control switch is “OFF”.

l:Operates.

lA: Operates when throttle opening is less than 3/16, activating engine brake.

lB: Operates during “progressive” acceleration.

lC: Operates but does not affect power transmission.

lD: Operates when throttle opening is less than 3/16, but does not affect engine brake.

POWER TRANSMISSION

“N” and “P” Positions

l“N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

l“P” position

NNEUTRAL

POSITION

D*41st *1D B B

Automatic

shift

1Û2Û3Û

4 2nd *1A B

3rd *1A *2C C B

*5

4th C *3C C

21st D B BAutomatic

shift

1Û2 2nd A B

11stBLocks (held

stationary) in

1st speed

1Ü2 2ndB Shift positionRever

se

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e

brake

19Lock-

upRemarks

2nd

apply3rd

releas

e4th

apply

Page 37 of 3066

OVERALL SYSTEM

AT-31

D

E

F

G

H

I

J

K

L

MA

B

AT

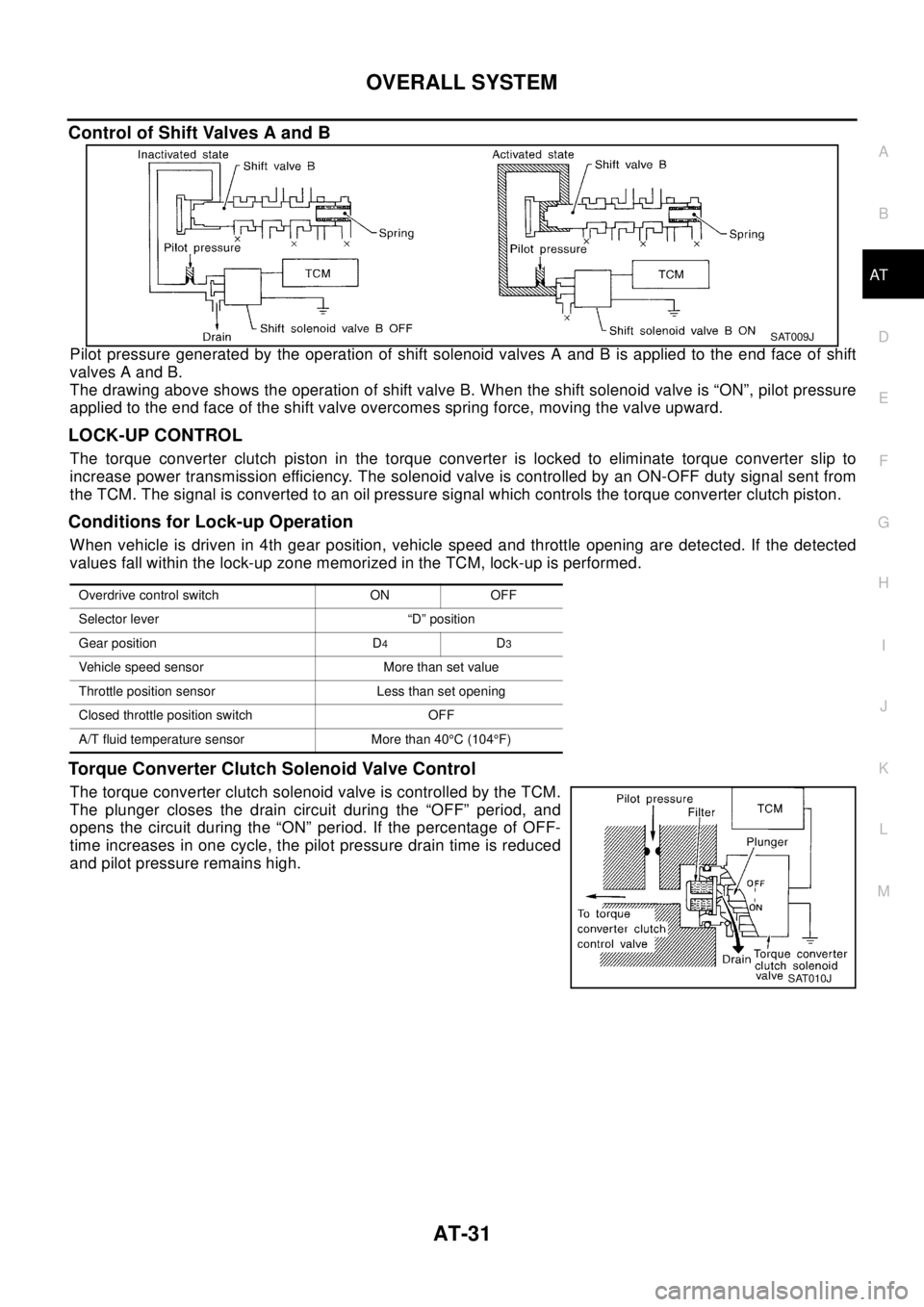

Control of Shift Valves A and B

Pilot pressure generated by the operation of shift solenoid valves A and B is applied to the end face of shift

valves A and B.

The drawing above shows the operation of shift valve B. When the shift solenoid valve is “ON”, pilot pressure

applied to the end face of the shift valve overcomes spring force, moving the valve upward.

LOCK-UP CONTROL

The torque converter clutch piston in the torque converter is locked to eliminate torque converter slip to

increase power transmission efficiency. The solenoid valve is controlled by an ON-OFF duty signal sent from

the TCM. The signal is converted to an oil pressure signal which controls the torque converter clutch piston.

Conditions for Lock-up Operation

When vehicle is driven in 4th gear position, vehicle speed and throttle opening are detected. If the detected

values fall within the lock-up zone memorized in the TCM, lock-up is performed.

Torque Converter Clutch Solenoid Valve Control

The torque converter clutch solenoid valve is controlled by the TCM.

The plunger closes the drain circuit during the “OFF” period, and

opens the circuit during the “ON” period. If the percentage of OFF-

time increases in one cycle, the pilot pressure drain time is reduced

and pilot pressure remains high.

SAT009J

Overdrive control switch ON OFF

Selector lever “D” position

Gear position D

4D3

Vehicle speed sensor More than set value

Throttle position sensor Less than set opening

Closed throttle position switch OFF

A/T fluid temperature sensor More than 40°C(104°F)

SAT010J

Page 119 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-113

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

2. Control cable adjust NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-113

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

2. Control cable adjust](/img/5/57402/w960_57402-118.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-113

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

2. Control cable adjustmentAT-456,

"Control

Cable

Adjustment"

¬

3. Line pressure testAT-68, "

Line

Pressure

Te s t"

¬

4. Line pressure solenoid valveAT-436,

"LINE

PRES-

SURE

SOLENOID

VA LV E"

AT-186,

"DTC P0745

LINE PRES-

SURE

SOLENOID

VA LV E"

OFF vehicle5. Oil pumpAT-485, "

Oil

Pump"¬

6. High clutchAT-507,

"High

Clutch"

¬

7. Brake bandAT-530,

"Band

Servo Pis-

ton Assem-

bly"

¬

8. Low & reverse brakeAT-518,

"Low&

Reverse

Brake"

¬

9. Torque converterAT-465,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬

10. Parking componentsAT-461,

"Compo-

nents"

¬

Transmission noise in “D”, “2”, “1”

and “R” positions.ON vehicle 1. Fluid levelAT-64,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle 2. Torque converterAT-465,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 124 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-118

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Transmission overheats. OFF vehicle7. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

8. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

9. High clutchAT- 5 NISSAN X-TRAIL 2003 Electronic Repair Manual AT-118

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Transmission overheats. OFF vehicle7. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

8. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

9. High clutchAT- 5](/img/5/57402/w960_57402-123.png)

AT-118

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Transmission overheats. OFF vehicle7. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

8. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

9. High clutchAT- 5 0 7 ,

"High

Clutch"

¬

10. Brake bandAT- 5 3 0 ,

"Band

Servo Pis-

ton Assem-

bly"

¬

11. Forward clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

12. Overrun clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

13. Low & reverse brakeAT- 5 1 8 ,

"Low&

Reverse

Brake"

¬

14. Torque converterAT- 4 6 5 ,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 341 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-335

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-286,

"FLUID

LEVEL

CHECK"

¬

2. Control cable NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-335

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-286,

"FLUID

LEVEL

CHECK"

¬

2. Control cable](/img/5/57402/w960_57402-340.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-335

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-286,

"FLUID

LEVEL

CHECK"

¬

2. Control cable adjustmentAT-456,

"Control

Cable

Adjustment"

¬

3. Line pressure testAT-290,

"Line Pres-

sure Test"

¬

4. Line pressure solenoid valveAT-436,

"LINE

PRES-

SURE

SOLENOID

VA LV E"

AT-186,

"DTC P0745

LINE PRES-

SURE

SOLENOID

VA LV E"

OFF vehicle5. Oil pumpAT-485, "

Oil

Pump"¬

6. High clutchAT-507,

"High

Clutch"

¬

7. Brake bandAT-530,

"Band

Servo Pis-

ton Assem-

bly"

¬

8. Low & reverse brakeAT-518,

"Low&

Reverse

Brake"

¬

9. Torque converterAT-465,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬

10. Parking componentsAT-461,

"Compo-

nents"

¬

Transmission noise in “D”, “2”, “1”

and “R” positions.ON vehicle 1. Fluid levelAT-286,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle 2. Torque converterAT-465,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 346 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-340

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Transmission overheats. OFF vehicle7. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

8. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

9. High clutc NISSAN X-TRAIL 2003 Electronic Repair Manual AT-340

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Transmission overheats. OFF vehicle7. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

8. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

9. High clutc](/img/5/57402/w960_57402-345.png)

AT-340

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Transmission overheats. OFF vehicle7. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

8. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

9. High clutchAT- 5 0 7 ,

"High

Clutch"

¬

10. Brake bandAT- 5 3 0 ,

"Band

Servo Pis-

ton Assem-

bly"

¬

11. Forward clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

12. Overrun clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

13. Low & reverse brakeAT- 5 1 8 ,

"Low&

Reverse

Brake"

¬

14. Torque converterAT- 4 6 5 ,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 460 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-454

[ALL]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Control Valve Assembly and AccumulatorsECS0040C

REMOVAL

1. Drain ATF from transaxle.

2. Remove oil pan and gasket.

3. Disconnect A/T soleno NISSAN X-TRAIL 2003 Electronic Repair Manual AT-454

[ALL]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Control Valve Assembly and AccumulatorsECS0040C

REMOVAL

1. Drain ATF from transaxle.

2. Remove oil pan and gasket.

3. Disconnect A/T soleno](/img/5/57402/w960_57402-459.png)

AT-454

[ALL]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Control Valve Assembly and AccumulatorsECS0040C

REMOVAL

1. Drain ATF from transaxle.

2. Remove oil pan and gasket.

3. Disconnect A/T solenoid valve harness connector.

4. Remove snap ring from A/T solenoid harness terminal body.

5. Remove A/T solenoid harness by pushing terminal body into

transmission case.

SAT992C

SAT064K

SCIA0789E

Page 475 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DISASSEMBLY

AT-469

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

14. Remove N-D accumulator piston and return spring with com-

pressed air.

15. Remove O-rings from N-D accumulator piston.

16. Check accumulator pist NISSAN X-TRAIL 2003 Electronic Repair Manual DISASSEMBLY

AT-469

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

14. Remove N-D accumulator piston and return spring with com-

pressed air.

15. Remove O-rings from N-D accumulator piston.

16. Check accumulator pist](/img/5/57402/w960_57402-474.png)

DISASSEMBLY

AT-469

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

14. Remove N-D accumulator piston and return spring with com-

pressed air.

15. Remove O-rings from N-D accumulator piston.

16. Check accumulator pistons and contact surface of transmission

case for damage.

17. Check accumulator return springs for damage and free length.

18. Remove lip seals.

19. Remove L & R oil tube and oil sleeve.

20. Remove converter housing according to the following proce-

dures.

a. Remove converter housing mounting bolts.

b. Remove converter housing by tapping it lightly.

SAT020D

SAT023DA

SAT006F

SAT862HA

SAT008F

Page 476 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-470

[ALL]

DISASSEMBLY

c. Remove O-ring from differential oil port.

21. Remove final drive assembly from transmission case.

22. Remove differential side bearing outer race and side bearing

adjusting NISSAN X-TRAIL 2003 Electronic Repair Manual AT-470

[ALL]

DISASSEMBLY

c. Remove O-ring from differential oil port.

21. Remove final drive assembly from transmission case.

22. Remove differential side bearing outer race and side bearing

adjusting](/img/5/57402/w960_57402-475.png)

AT-470

[ALL]

DISASSEMBLY

c. Remove O-ring from differential oil port.

21. Remove final drive assembly from transmission case.

22. Remove differential side bearing outer race and side bearing

adjusting shim from transmission case.

23. Remove differential side bearing adjusting shim from transmis-

sion case.

SAT235F

SAT228F

SAT010FC

SAT031D