OPEL COMBO 2010 Owners Manual

Manufacturer: OPEL, Model Year: 2010, Model line: COMBO, Model: OPEL COMBO 2010Pages: 212, PDF Size: 2.49 MB

Page 141 of 212

135

Self-help, vehicle care

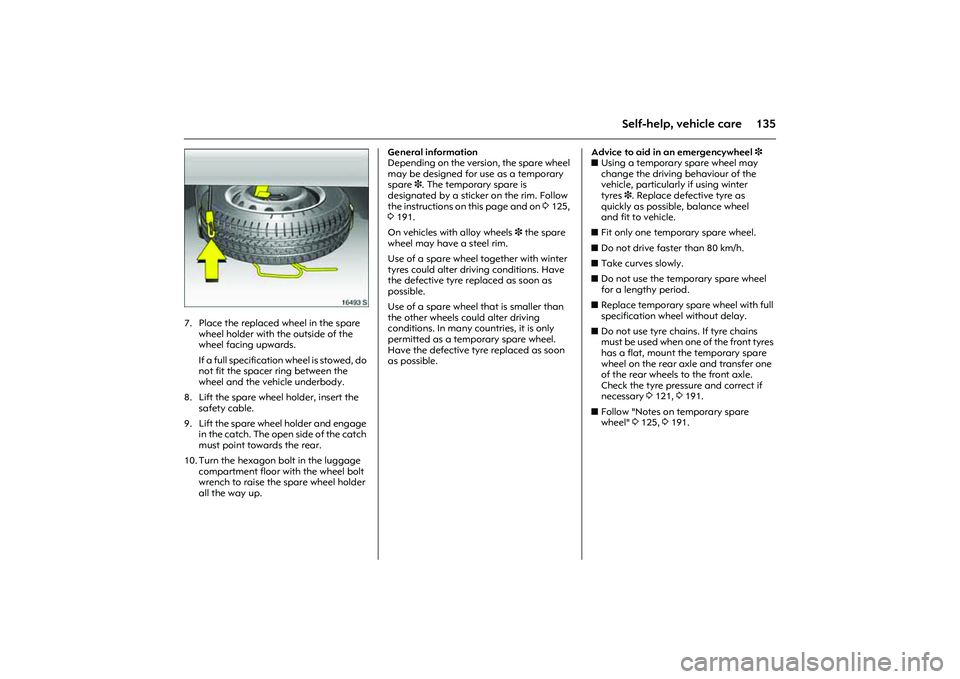

Picture no: 16493s.tif

7. Place the replaced wheel in the spare

wheel holder with the outside of the

wheel facing upwards.

If a full specification wheel is stowed, do

not fit the spacer ring between the

wheel and the vehicle underbody.

8. Lift the spare wheel holder, insert the

safety cable.

9. Lift the spare wheel holder and engage

in the catch. The open side of the catch

must point towards the rear.

10. Turn the hexagon bolt in the luggage

compartment floor with the wheel bolt

wrench to raise the spare wheel holder

all the way up. General information

Depending on the version, the spare wheel

may be designed for use as a temporary

spare 3. The temporary spare is

designated by a sticker on the rim. Follow

the instructions on this page and on 3125,

3191.

On vehicles with alloy wheels 3 the spare

wheel may have a steel rim.

Use of a spare wheel together with winter

tyres could alter driving conditions. Have

the defective tyre replaced as soon as

possible.

Use of a spare wheel that is smaller than

the other wheels could alter driving

conditions. In many countries, it is only

permitted as a temporary spare wheel.

Have the defective tyre replaced as soon

as possible. Advice to aid in an emergencywheel 3

zUsing a temporary spare wheel may

change the driving behaviour of the

vehicle, particularly if using winter

tyres3. Replace defective tyre as

quickly as possible, balance wheel

and fit to vehicle.

zFit only one temporary spare wheel.

zDo not drive faster than 80 km/h.

zTake curves slowly.

zDo not use the temporary spare wheel

for a lengthy period.

zReplace temporary spare wheel with full

specification wheel without delay.

zDo not use tyre chains. If tyre chains

must be used when one of the front tyres

has a flat, mount the temporary spare

wheel on the rear axle and transfer one

of the rear wheels to the front axle.

Check the tyre pressure and correct if

necessary 3121, 3191.

zFollow "Notes on temporary spare

wheel" 3125, 3191.

Page 142 of 212

136 Self-help, vehicle careInformation on directional tyres 3

Fit directional tyres such that they roll in the

direction of travel. The rolling direction is

indicated by a symbol (e.g. an arrow) on

the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

zDriving conditions may be altered. Have

the defective tyre replaced as soon as

possible.

zDo not drive faster than 80 km/h.

zDrive especially carefully in wet and

snowy weather.

Further information on directional tyres

3121.

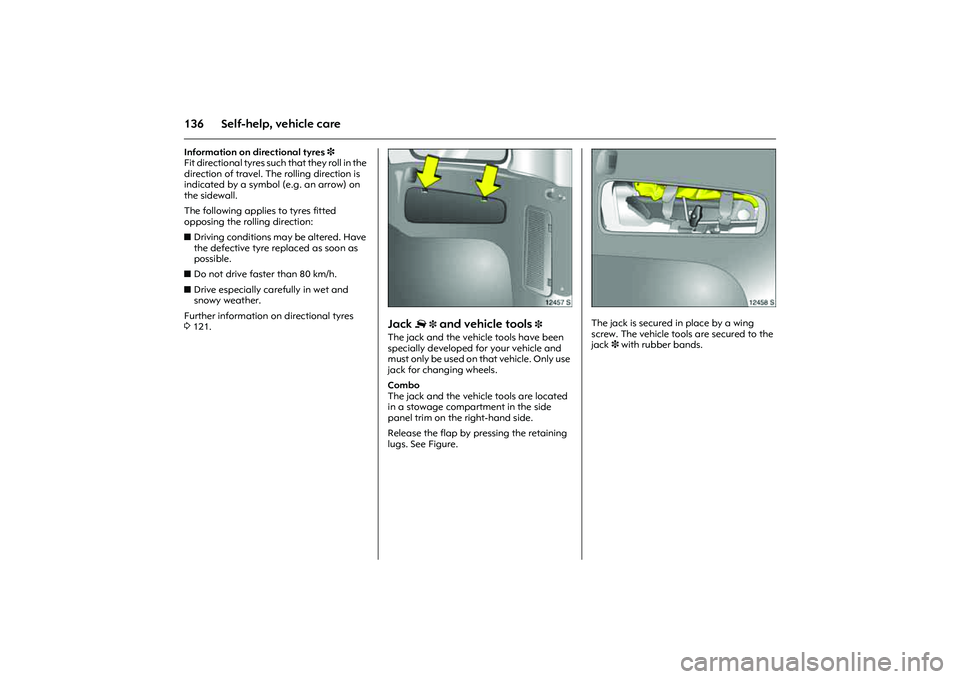

Picture no: 2457s.tif

Jack

£

3 and vehicle tools

3

The jack and the vehicle tools have been

specially developed for your vehicle and

must only be used on that vehicle. Only use

jack for changing wheels.

Combo

The jack and the vehicle tools are located

in a stowage compartment in the side

panel trim on the right-hand side.

Release the flap by pressing the retaining

lugs. See Figure.

Picture no: 12458s.tif

The jack is secured in place by a wing

screw. The vehicle tools are secured to the

jack 3 with rubber bands.

Page 143 of 212

137

Self-help, vehicle care

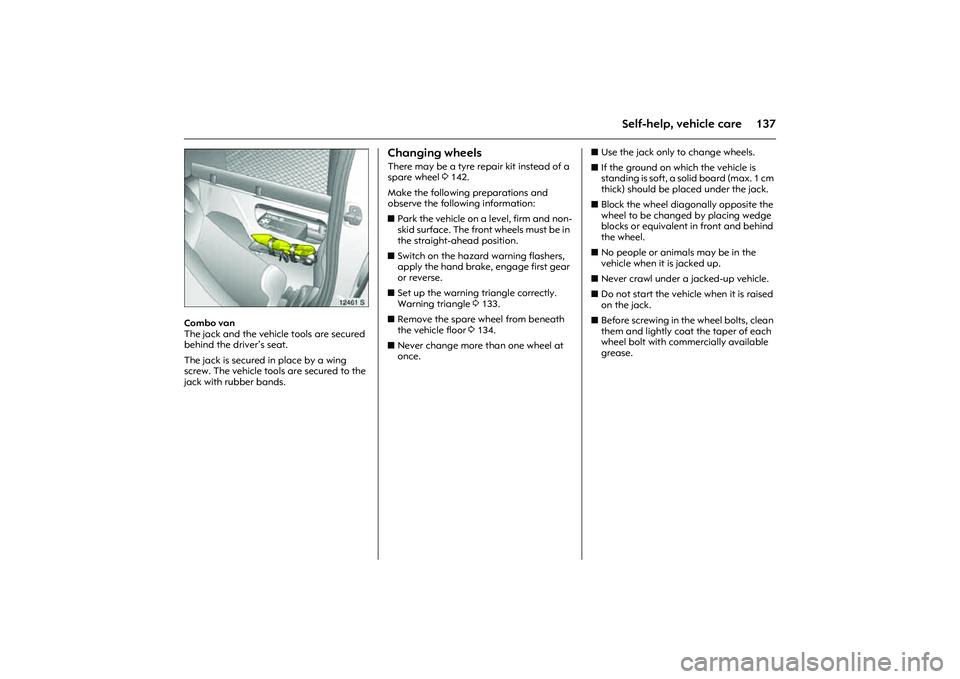

Picture no: 12461s.tif

Combo van

The jack and the vehicle tools are secured

behind the driver’s seat.

The jack is secured in place by a wing

screw. The vehicle tools are secured to the

jack with rubber bands.

Changing wheels There may be a tyre repair kit instead of a

spare wheel 3142.

Make the following preparations and

observe the following information:

zPark the vehicle on a level, firm and non-

skid surface. The front wheels must be in

the straight-ahead position.

zSwitch on the hazard warning flashers,

apply the hand brake, engage first gear

or reverse.

zSet up the warning triangle correctly.

Warning triangle 3133.

zRemove the spare wheel from beneath

the vehicle floor 3134.

zNever change more than one wheel at

once. zUse the jack only to change wheels.

zIf the ground on which the vehicle is

standing is soft, a solid board (max. 1 cm

thick) should be placed under the jack.

zBlock the wheel diagonally opposite the

wheel to be changed by placing wedge

blocks or equivalent in front and behind

the wheel.

zNo people or animals may be in the

vehicle when it is jacked up.

zNever crawl under a jacked-up vehicle.

zDo not start the vehicle when it is raised

on the jack.

zBefore screwing in the wheel bolts, clean

them and lightly coat the taper of each

wheel bolt with commercially available

grease.

Page 144 of 212

138 Self-help, vehicle care

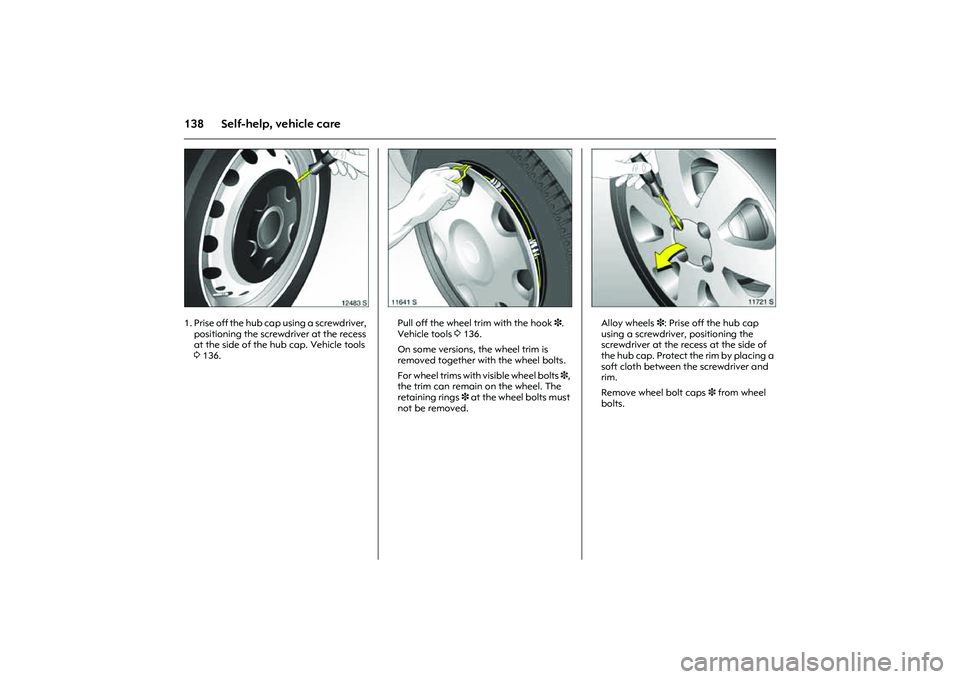

Picture no: 12483s.tif

1. Prise off the hub cap using a screwdriver,

positioning the screwdriver at the recess

at the side of the hub cap. Vehicle tools

3136.

Picture no: 11641s.tif

Pull off the wheel trim with the hook 3.

Vehicle tools 3136.

On some versions, the wheel trim is

removed together with the wheel bolts.

For wheel trims with visible wheel bolts 3,

the trim can remain on the wheel. The

retaining rings 3 at the wheel bolts must

not be removed.

Picture no: 11721s.tif

Alloy wheels 3: Prise off the hub cap

using a screwdriver, positioning the

screwdriver at the recess at the side of

the hub cap. Protect the rim by placing a

soft cloth between the screwdriver and

rim.

Remove wheel bolt caps 3 from wheel

bolts.

Page 145 of 212

139

Self-help, vehicle care

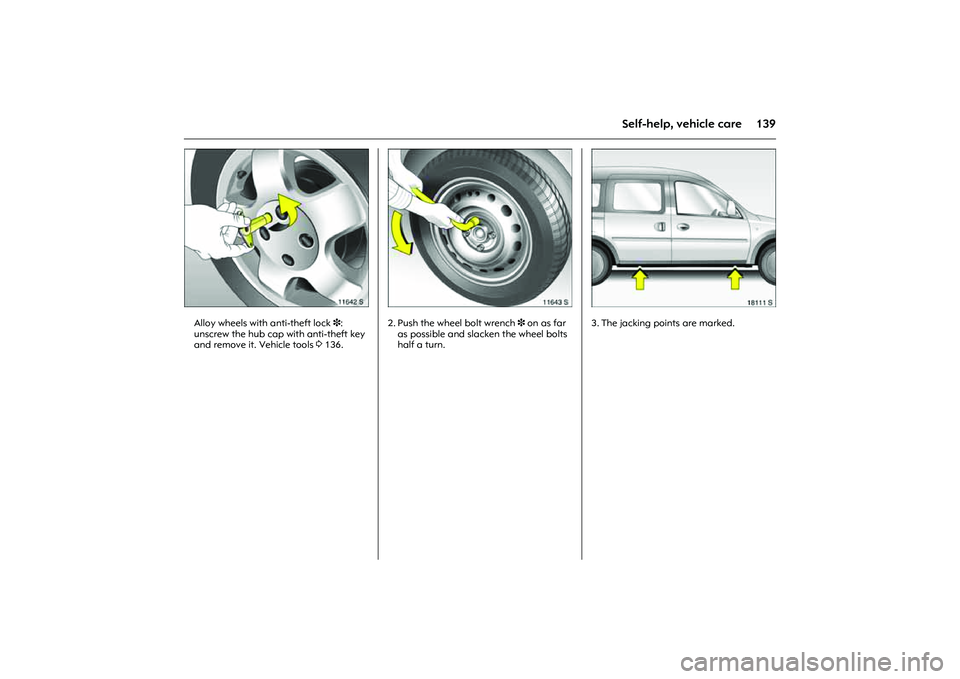

Picture no: 11642s.tif

Alloy wheels with anti-theft lock3:

unscrew the hub cap with anti-theft key

and remove it. Vehicle tools 3136.

Picture no: 11643s.tif

2. Push the wheel bolt wrench 3 on as far

as possible and slacken the wheel bolts

half a turn.

Picture no: 18111s.tif

3. The jacking points are marked.

Page 146 of 212

140 Self-help, vehicle care

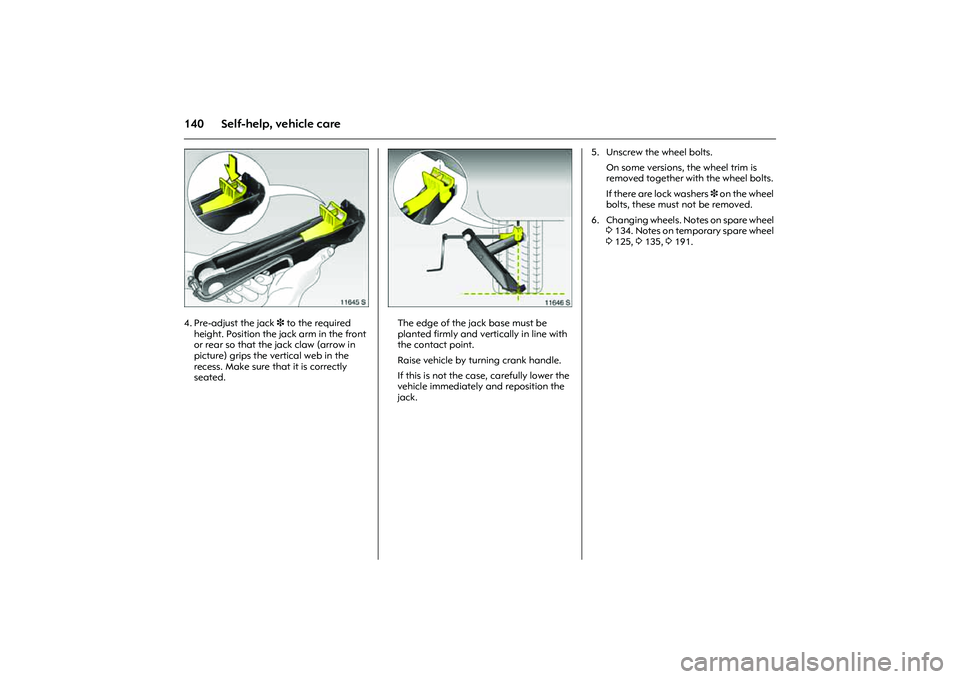

Picture no: 11645s.tif

4. Pre-adjust the jack 3 to the required

height. Position the jack arm in the front

or rear so that the jack claw (arrow in

picture) grips the vertical web in the

recess. Make sure that it is correctly

seated.

Picture no: 11646s.tif

The edge of the jack base must be

planted firmly and vertically in line with

the contact point.

Raise vehicle by turning crank handle.

If this is not the case, carefully lower the

vehicle immediately and reposition the

jack.5. Unscrew the wheel bolts.

On some versions, the wheel trim is

removed together with the wheel bolts.

If there are lock washers 3 on the wheel

bolts, these must not be removed.

6. Changing wheels. Notes on spare wheel

3134. Notes on temporary spare wheel

3125, 3135, 3191.

Page 147 of 212

141

Self-help, vehicle care

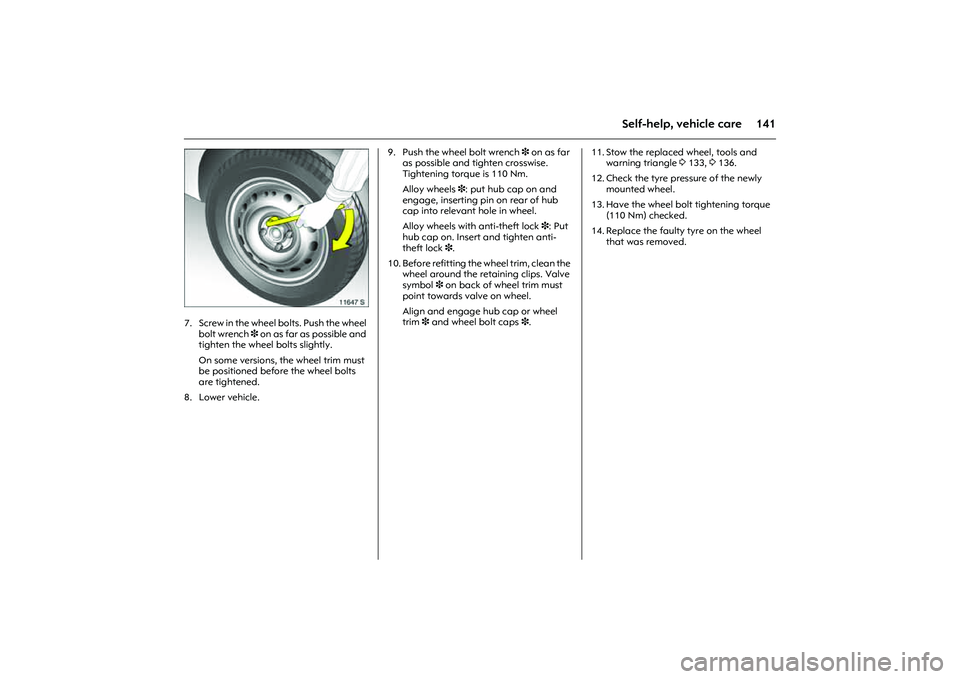

Picture no: 11647s.tif

7. Screw in the wheel bolts. Push the wheel

bolt wrench 3 on as far as possible and

tighten the wheel bolts slightly.

On some versions, the wheel trim must

be positioned before the wheel bolts

are tightened.

8. Lower vehicle. 9. Push the wheel bolt wrench 3 on as far

as possible and tighten crosswise.

Tightening torque is 110 Nm.

Alloy wheels 3: put hub cap on and

engage, inserting pin on rear of hub

cap into relevant hole in wheel.

Alloy wheels with anti-theft lock3: Put

hub cap on. Insert and tighten anti-

theft lock3.

10. Before refitting the wheel trim, clean the

wheel around the retaining clips. Valve

symbol 3 on back of wheel trim must

point towards valve on wheel.

Align and engage hub cap or wheel

trim 3 and wheel bolt caps 3.11. Stow the replaced wheel, tools and

warning triangle 3133, 3136.

12. Check the tyre pressure of the newly

mounted wheel.

13. Have the wheel bolt tightening torque

(110 Nm) checked.

14. Replace the faulty tyre on the wheel

that was removed.

Page 148 of 212

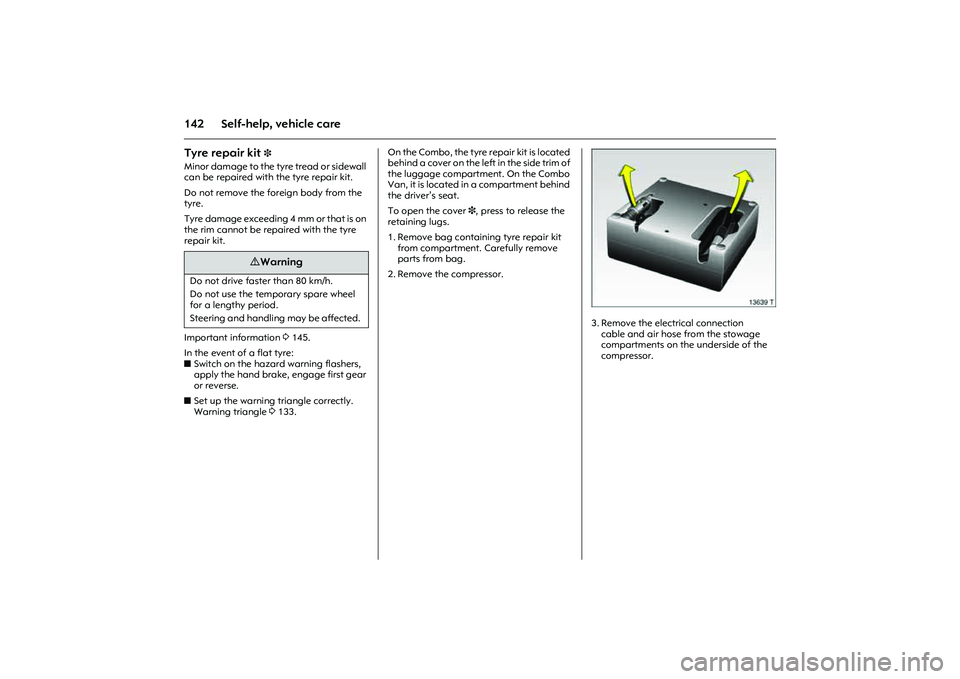

142 Self-help, vehicle careTyre repair kit

3

Minor damage to the tyre tread or sidewall

can be repaired with the tyre repair kit.

Do not remove the foreign body from the

tyre.

T y r e d a m a g e e x c e e d i n g 4 m m o r t ha t i s o n

the rim cannot be repaired with the tyre

repair kit.

Important information 3145.

In the event of a flat tyre:

zSwitch on the hazard warning flashers,

apply the hand brake, engage first gear

or reverse.

zSet up the warning triangle correctly.

Warning triangle 3133.On the Combo, the tyre repair kit is located

behind a cover on the left in the side trim of

the luggage compartment. On the Combo

Van, it is located in a compartment behind

the driver’s seat.

To open the cover 3, press to release the

retaining lugs.

1. Remove bag containing tyre repair kit

from compartment. Carefully remove

parts from bag.

2. Remove the compressor.

Picture no: 13639T.tif

3. Remove the electrical connection

cable and air hose from the stowage

compartments on the underside of the

compressor.

9 Warning

Do not drive faster than 80 km/h.

Do not use the temporary spare wheel

for a lengthy period.

Steering and handling may be affected.

Page 149 of 212

143

Self-help, vehicle care

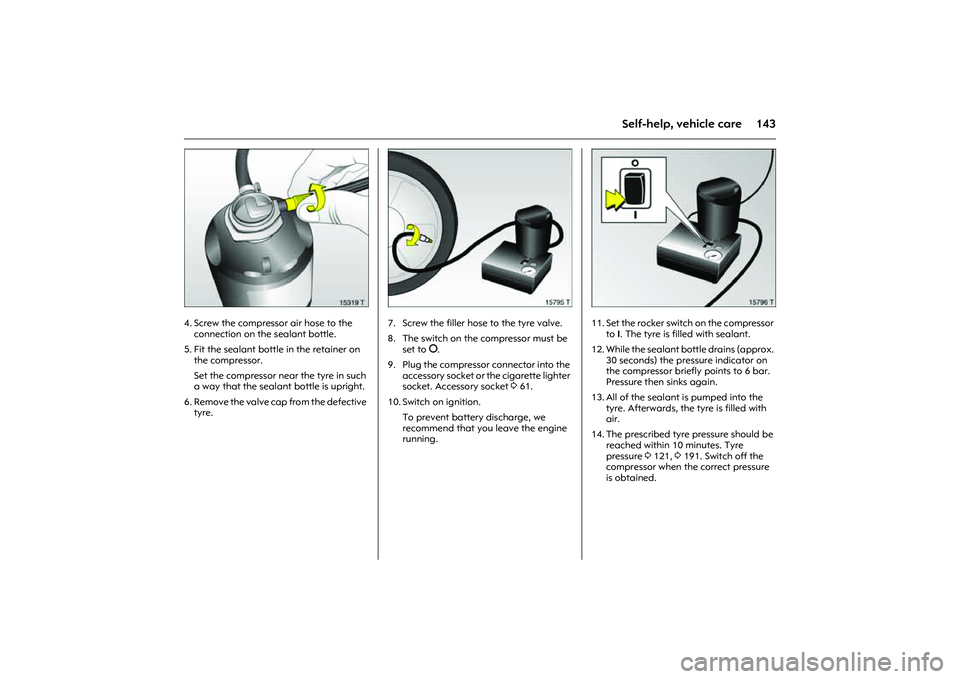

Picture no: 15319t.tif

4. Screw the compressor air hose to the

connection on the sealant bottle.

5. Fit the sealant bottle in the retainer on

the compressor.

Set the compressor near the tyre in such

a way that the sealant bottle is upright.

6. Remove the valve cap from the defective

tyre.

Picture no: 15795t.tif

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be

set to §.

9. Plug the compressor connector into the

accessory socket or the cigarette lighter

socket. Accessory socket 361.

10. Switch on ignition.

To prevent battery discharge, we

recommend that you leave the engine

running.

Picture no: 15796t.tif

11. Set the rocker switch on the compressor

to I. The tyre is filled with sealant.

12. While the sealant bottle drains (approx.

30 seconds) the pressure indicator on

the compressor briefly points to 6 bar.

Pressure then sinks again.

13. All of the sealant is pumped into the

tyre. Afterwards, the tyre is filled with

air.

14. The prescribed tyre pressure should be

reached within 10 minutes. Tyre

pressure 3121, 3191. Switch off the

compressor when the correct pressure

is obtained.

Page 150 of 212

144 Self-help, vehicle care

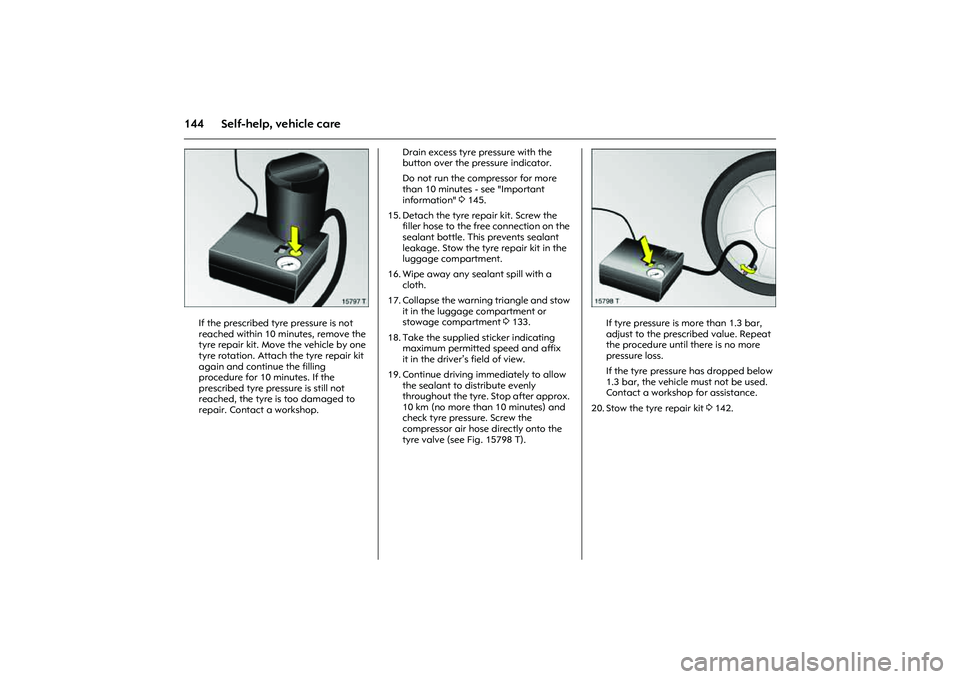

Picture no: 15797t.tif

If the prescribed tyre pressure is not

reached within 10 minutes, remove the

tyre repair kit. Move the vehicle by one

tyre rotation. Attach the tyre repair kit

again and continue the filling

procedure for 10 minutes. If the

prescribed tyre pressure is still not

reached, the tyre is too damaged to

repair. Contact a workshop. Drain excess tyre pressure with the

button over the pressure indicator.

Do not run the compressor for more

than 10 minutes - see "Important

information" 3145.

15. Detach the tyre repair kit. Screw the

filler hose to the free connection on the

sealant bottle. This prevents sealant

leakage. Stow the tyre repair kit in the

luggage compartment.

16. Wipe away any sealant spill with a

cloth.

17. Collapse the warning triangle and stow

it in the luggage compartment or

stowage compartment 3133.

18. Take the supplied sticker indicating

maximum permitted speed and affix

it in the driver’s field of view.

19. Continue driving immediately to allow

the sealant to distribute evenly

throughout the tyre. Stop after approx.

10 km (no more than 10 minutes) and

check tyre pressure. Screw the

compressor air hose directly onto the

tyre valve (see Fig. 15798 T).

Picture no: 15798t.tif

If tyre pressure is more than 1.3 bar,

adjust to the prescribed value. Repeat

the procedure until there is no more

pressure loss.

If the tyre pressure has dropped below

1.3 bar, the vehicle must not be used.

Contact a workshop for assistance.

20. Stow the tyre repair kit 3142.