Back OPEL FRONTERA 1998 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1336 of 6000

6E–219 ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0355 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0355 – Ignition 5 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0355 until the DTC P0355 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0355 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 5 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 5 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 5 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 5 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1339 of 6000

6E–222

ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0356 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0356 – Ignition 6 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0356 until the DTC P0356 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0356 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 6 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 6 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 6 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 6 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1346 of 6000

6E–229 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0405 – EGR Low Volt

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “DTC” info for DTC P0405

until the DTC P0405 test runs. Note the result.

Does Tech 2 indicates DTC P0405 failed this ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—Go to Step 4Go to Step 5

4Repair the damaged pin or terminal.

Is the action complete?

—Verify repair—

51. Disconnect the EGR harness connector.

2. Ignition “ON”.

3. At the EGR valve, use a DVM to check the voltage

at the 5 volt reference wire (RED) and ground (B).

Did the DVM indicate the specified value?

4–6 VGo to Step 6Go to Step 7

61. Disconnect the EGR harness connector.

2. Measure resistance between terminal B and D.

Was resistance in range?

5–5.5 KGo to Step 10Go to Step 17

71. Ignition “ON”.

2. At the PCM connector, backprobe with a DVM at the

5 volt reference for the EGR valve.

Did the DVM indicate the specified value?

4–6 VGo to Step 8Go to Step 9

8Repair the open 5 volt reference circuit.

Is the action complete?

—Verify repair—

9Repair the damaged sensor ground wire.

Is the action complete?

—Verify repair—

101. Disconnect the EGR harness

2. Use an ohmmeter to measure between the pintle

position pin and the sensor ground pin on the EGR

valve.

NOTE: J-35616 Connector Test Adapter Kit may be

useful for gaining access to the recessed pins on the

valve.

Was the ohmmeter reading approximately equal to the

specified value?

1 to 1.25 KGo to Step 11Go to Step 17

111. Ignition “ON”.

2. Backprobe with a DVM to measure voltage at EGR

valve pintle position pin and sensor ground pin.

Was voltage in range?

Less than

0.1 V

Go to Step 17Go to Step 12

Page 1347 of 6000

6E–230

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0405 – EGR Low Volt

StepNo Ye s Va l u e ( s ) Action

121. Ignition “ON”.

2. Backprobe with a DVM to measure voltage at PCM

sensor ground pin and pintle position pin.

Was voltage in range?

Less than

0.1 V

Go to Step 13Go to Step 18

131. Ignition “OFF”.

2. Disconnect the EGR harness.

3. Check short circuit between EGR pintle position

circuit and EGR ground circuit.

Was any short circuit?

—Go to Step 14Go to Step 18

14Locate and repair the short to ground in the pintle

position circuit

Is the action complete?

—Verify repair—

151. Ignition “OFF”.

2. Disconnect the PCM.

3. Ignition “ON”.

4. Measure the voltage between the EGR pintle

position circuit and ground.

Is the measured voltage near the specified value?

Less than

0.1 V

Go to Step 17Go to Step 16

16Check for a short circuit between other wires and the

pintle position circuit

Was any short circuit?

—

Repair short

circuit

Verify repair

Go to Step 17

17Replace the EGR valve.

Does DTC P1404 still fail “specific DTC test on Tech 2?

—Go to Step 18Verify repair

18Examine the PCM pin and terminal connection.

Was there a damaged terminal?

—Go to Step 4Go to Step 19

19Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1349 of 6000

6E–232

ENGINE DRIVEABILITY AND EMISSIONS

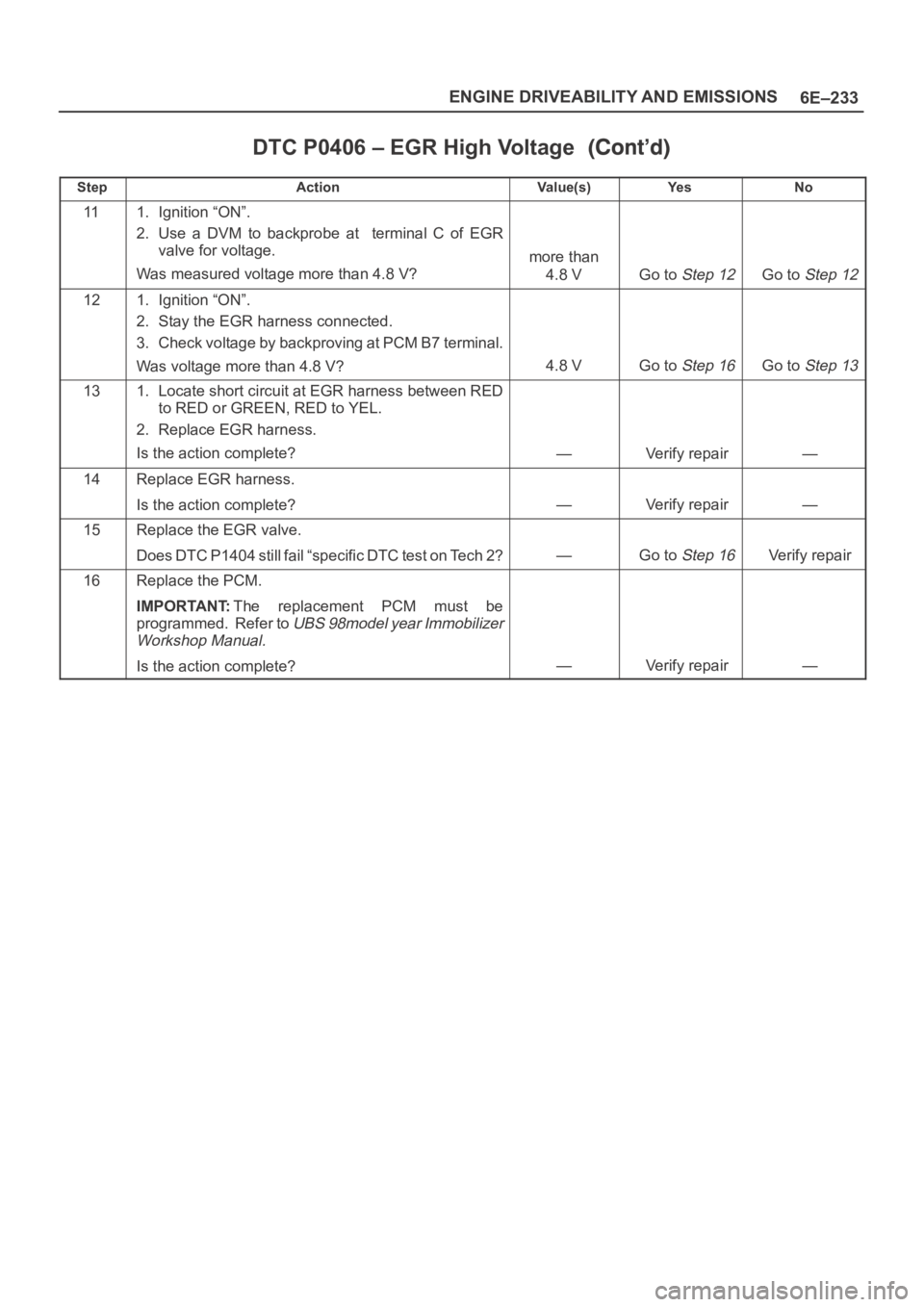

DTC P0406 – EGR High Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “DTC” info for DTC P0406

until the DTC P0406 test runs. Note the result.

Does Tech 2 indicates DTC P0406 failed this ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—Go to Step 4Go to Step 5

4Repair the damaged pin or terminal.

Is the action complete?

—Verify repair

Is the action

complete?

51. Disconnect the EGR harness connector.

2. Ignition “ON”.

3. At the EGR valve, use a DVM to check the voltage

at the 5 volt reference wire (RED).

Did the DVM indicate the specified value?

4–6 VGo to Step 8Go to Step 6

61. Ignition “ON”.

2. At the PCM connector, backprobe with a DVM at the

5 volt reference for the EGR valve.

Did the DVM indicate the specified value?

4–6 VGo to Step 7Go to Step 16

7Repair the open 5 volt reference circuit

Is the action complete?

—Verify repair—

81. Ignition “OFF”

2. Disconnect the EGR harness.

3. Use a DVM to check for an resistance between D (5

V reference) and B (Sensor Ground) at EGR sensor

terminals.

NOTE: J-35616 Connector Test Adapter Kit may be

useful for gaining access to the recessed pins on the

valve.

Was there measured resistance in range?

5 to 5 KGo to Step 9Go to Step 15

91. Ignition “OFF”.

2. Disconnect the EGR harness.

3. Use a DVM to check for an resistance between B

and C at EGR sensor terminal.

Was there open circuit?

—Go to Step 15Go to Step 10

101. Ignition “OFF”.

2. Disconnect the EGR harness at PCM connector.

3. Use a DVM to check for shorted wire between A1

and B7.

Was there shorted wire?

—Go to Step 14Go to Step 11

Page 1350 of 6000

6E–233 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0406 – EGR High Voltage

StepNo Ye s Va l u e ( s ) Action

111. Ignition “ON”.

2. Use a DVM to backprobe at terminal C of EGR

valve for voltage.

Was measured voltage more than 4.8 V?

more than

4.8 V

Go to Step 12Go to Step 12

121. Ignition “ON”.

2. Stay the EGR harness connected.

3. Check voltage by backproving at PCM B7 terminal.

Was voltage more than 4.8 V?

4.8 VGo to Step 16Go to Step 13

131. Locate short circuit at EGR harness between RED

to RED or GREEN, RED to YEL.

2. Replace EGR harness.

Is the action complete?

—Verify repair—

14Replace EGR harness.

Is the action complete?

—Verify repair—

15Replace the EGR valve.

Does DTC P1404 still fail “specific DTC test on Tech 2?

—Go to Step 16Verify repair

16Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1351 of 6000

6E–234

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0502 VSS Circuit Low Input

D06RW019

Circuit Description

The vehicle speed sensor has a magnet rotated by the

transmission output shaft. Attached to the sensor is a hall

effect circuit the interacts with the magnetic field treated

by the rotating magnet. A 12-volt operating supply for the

speed sensor hall circuit is supplied from the meter fuse.

The VSS pulses to ground the 9-volt signal sent from the

powertrain control module (PCM) on the reference circuit.

The PCM interprets vehicle speed by the number of

pulses to ground per second on the reference circuit.

Conditions for Setting the DTC

Engine is running.

Engine coolant temperature is above 60C (140F).

Engine speed is between 1800 RPM and 2500 RPM.

Throttle angle is between 10% and 40%.

Engine load is greater than 50 kPa.

MAP sensor indicates greater than 50 kPa manifold

pressure.

PCM detects no VSS signal for 12.5 seconds over a

period of 25 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0502 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

10. To avoid backprobing the VSS and possibly

damaging a seal or terminal, the VSS output can be

tested at the point where the transmission harness

connects to the engine harness. Power and ground

are applied by jumpers to the VSS through the

connectors which are located just in front of the air

cleaner assembly. The VSS signal is monitored

with a DVM as the rear driveshaft turns. The

wheels can be turned to rotate the driveshaft, or in

2-wheels-drive vehicles the driveshaft can be turned

directly.

12. The speedometer-to-PCM VSS signal wire is

spliced to a wire leading to the cruise control

module. If a short to ground or voltage is indicated

between the PCM and speedometer, it could be on

the cruise control circuit if the vehicle is equipped

with cruise control.

Page 1353 of 6000

6E–236

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0502 – VSS Circuit Low Input

StepNo Ye s Va l u e ( s ) Action

101. Ignition “OFF.”

2. Disconnect the MAF sensor and remove the air

cleaner assembly and filter element to gain access

to the 16-way black connector located immediately

to the rear of the left front headlamp. The connector

attaches the VSS wires from the transmission

harness to the left-side engine harness.

3. Disconnect the black 16-way connector.

4. Select a terminal adapter from kit J 35616 that can

be used with a jumper to supply B+ to the blue wire

with a yellow tracer (transmission side of the

connector).

5. Use another terminal adapter to attach a voltmeter

to the light-green wire with a w h i l e t r a c e r ( n e x t t o t h e

wire in the previous step.)

6. Disconnect the blue connector next to the black

16-way connector, and locate the black/red tracer

wire at one corner of the blue connector. The

black/red wire is the VSS ground. Use a terminal

adapter to attach a jumper to ground to the

black/red VSS ground wire at the transmission side

of the blue connector.

7. Raise the rear wheels off the ground with

transmission in neutral.

Does the DVM toggle back and forth between 0.6 V and

10 V as the wheels (and driveshaft) are rotated?

—Go to Step 11Go to Step 12

11Replace the VSS.

Is the action complete?

—Verify repair—

12Check for an open or short between the PCM and the

speedometer.

Was a problem found?

—Verify repairGo to Step 13

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1368 of 6000

6E–251 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1508 IAC System Low RPM

T321115

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detects a condition where too low of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1508 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

Barometric pressure is above 75 kPa.

Engine coolant temperature (ECT) is above 50C

(120

F).

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

The engine has been running for at least 125 seconds.

Vehicle speed is less than 1 mph.

Canister purge duty cycle is above 10%.

Ignition voltage is between 9.5 volts and 16.7 volts.

The throttle is closed.

Engine speed is lower than desired idle.

All of the above conditions are met for 10 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1508 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

Damaged harness – Inspect the wiring for damage.

Restricted air intake system – Check for a possible

collapsed air intake duct, restricted air filter element,

or foreign objects blocking the air intake system.

Throttle body – Check for objects blocking the IAC

passage or throttle bore, excessive deposits in the IAC

Page 1371 of 6000

6E–254

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1509 IAC System High RPM

T321115

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detect a condition where too high of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1509 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

Barometric pressure is above 75 kPa.

Engine coolant temperature is above 50C (120F).

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

The engine has been running for at least 125 seconds.

Vehicle speed is less than 1 mph.

Canister purge duty cycle is above 10%.

Ignition voltage is between 9.5 volts and 16.7 volts.

Engine speed is lower than desired idle.

All of the above conditions are met for 5 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1509 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

Damaged harness – Inspect the wiring for damage.

Vacuum leak – Check for a condition that causes a

vacuum leak, such as disconnected or damaged

h o s e s , l e a k s a t t h e E G R v a l v e a n d t h e E G R p i p e t o t h e

intake manifold, leaks at the throttle body, faulty or

incorrectly installed PCV valve, leaks at the intake

manifold, etc.