engine oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1179 of 6000

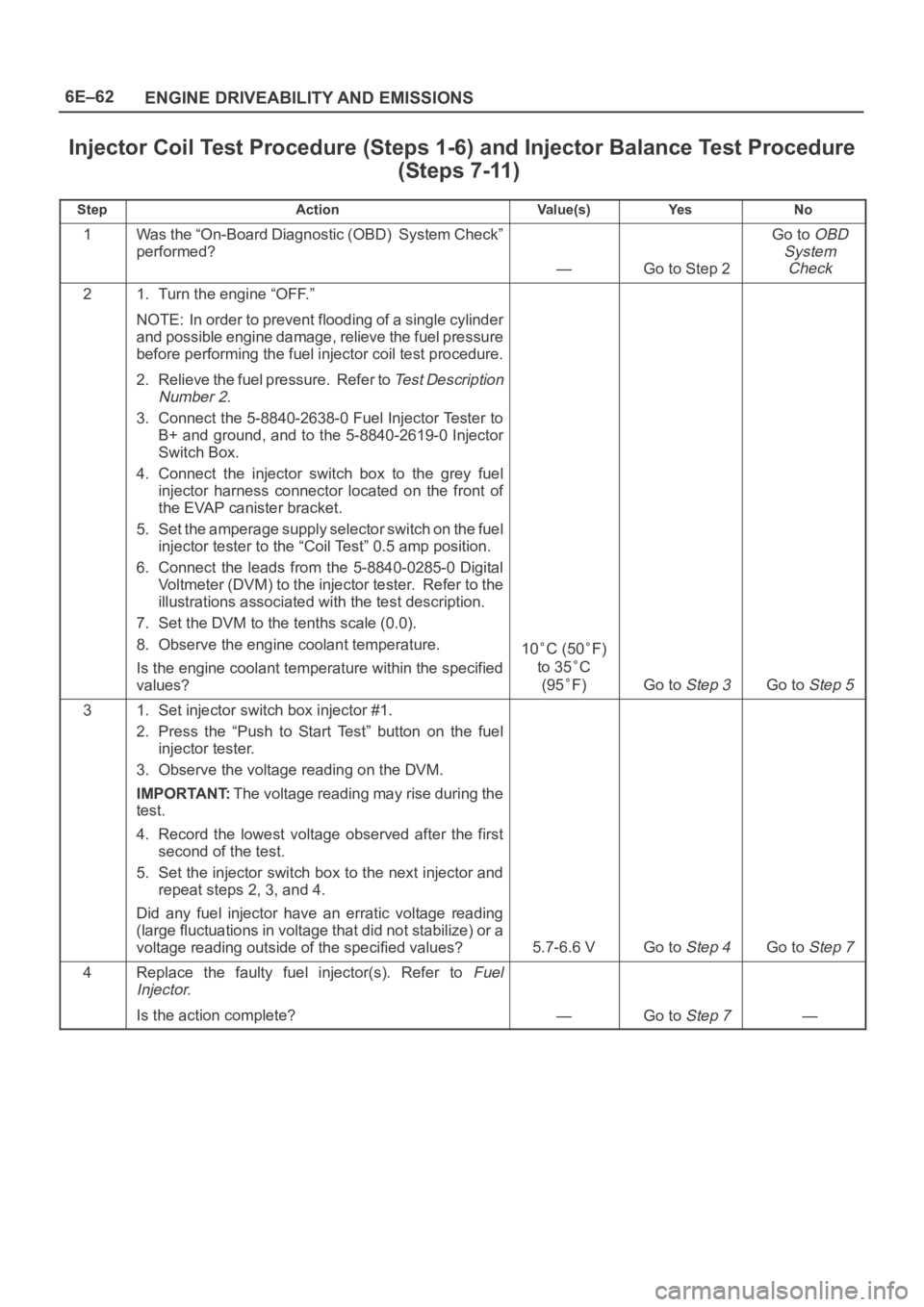

6E–62

ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Turn the engine “OFF.”

NOTE: In order to prevent flooding of a single cylinder

and possible engine damage, relieve the fuel pressure

before performing the fuel injector coil test procedure.

2. Relieve the fuel pressure. Refer to

Test Description

Number 2.

3. Connect the 5-8840-2638-0 Fuel Injector Tester to

B+ and ground, and to the 5-8840-2619-0 Injector

Switch Box.

4. Connect the injector switch box to the grey fuel

injector harness connector located on the front of

the EVAP canister bracket.

5. Set the amperage supply selector switch on the fuel

injector tester to the “Coil Test” 0.5 amp position.

6. Connect the leads from the 5-8840-0285-0 Digital

Voltmeter (DVM) to the injector tester. Refer to the

illustrations associated with the test description.

7. Set the DVM to the tenths scale (0.0).

8. Observe the engine coolant temperature.

Is the engine coolant temperature within the specified

values?

10C (50F)

to 35

C

(95

F)Go to Step 3Go to Step 5

31. Set injector switch box injector #1.

2. Press the “Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT:The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading outside of the specified values?

5.7-6.6 VGo to Step 4Go to Step 7

4Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?—Go to Step 7—

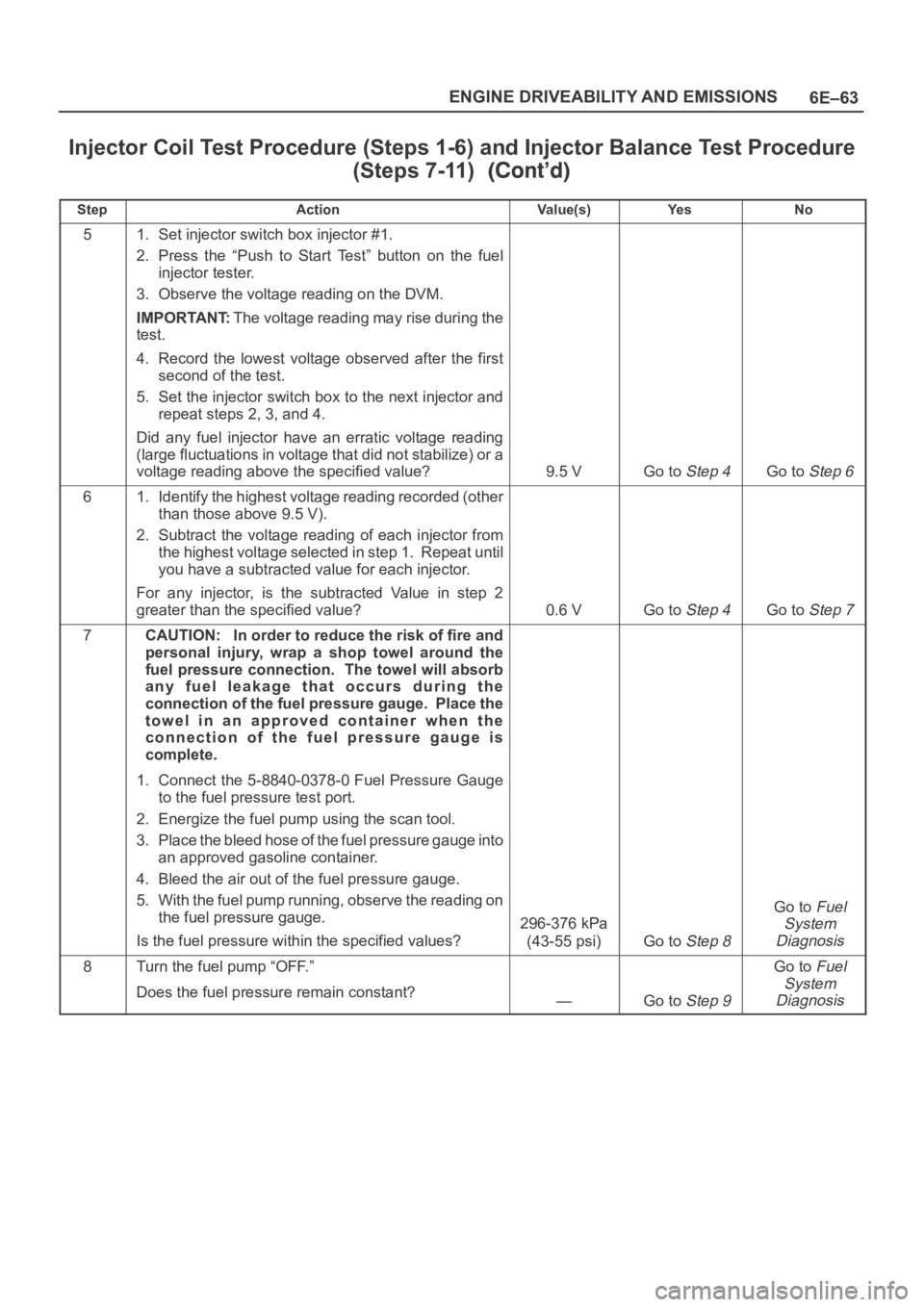

Page 1180 of 6000

6E–63 ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepNo Ye s Va l u e ( s ) Action

51. Set injector switch box injector #1.

2. Press the “Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT:The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading above the specified value?

9.5 VGo to Step 4Go to Step 6

61. Identify the highest voltage reading recorded (other

than those above 9.5 V).

2. Subtract the voltage reading of each injector from

the highest voltage selected in step 1. Repeat until

you have a subtracted value for each injector.

For any injector, is the subtracted Value in step 2

greater than the specified value?

0.6 VGo to Step 4Go to Step 7

7CAUTION: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the

fuel pressure connection. The towel will absorb

any fuel leakage that occurs during the

connection of the fuel pressure gauge. Place the

towel in an approved container when the

connection of the fuel pressure gauge is

complete.

1. Connect the 5-8840-0378-0 Fuel Pressure Gauge

to the fuel pressure test port.

2. Energize the fuel pump using the scan tool.

3. Place the bleed hose of the fuel pressure gauge into

an approved gasoline container.

4. Bleed the air out of the fuel pressure gauge.

5. With the fuel pump running, observe the reading on

the fuel pressure gauge.

Is the fuel pressure within the specified values?

296-376 kPa

(43-55 psi)

Go to Step 8

Go to Fuel

System

Diagnosis

8Turn the fuel pump “OFF.”

Does the fuel pressure remain constant?

—Go to Step 9

Go to Fuel

System

Diagnosis

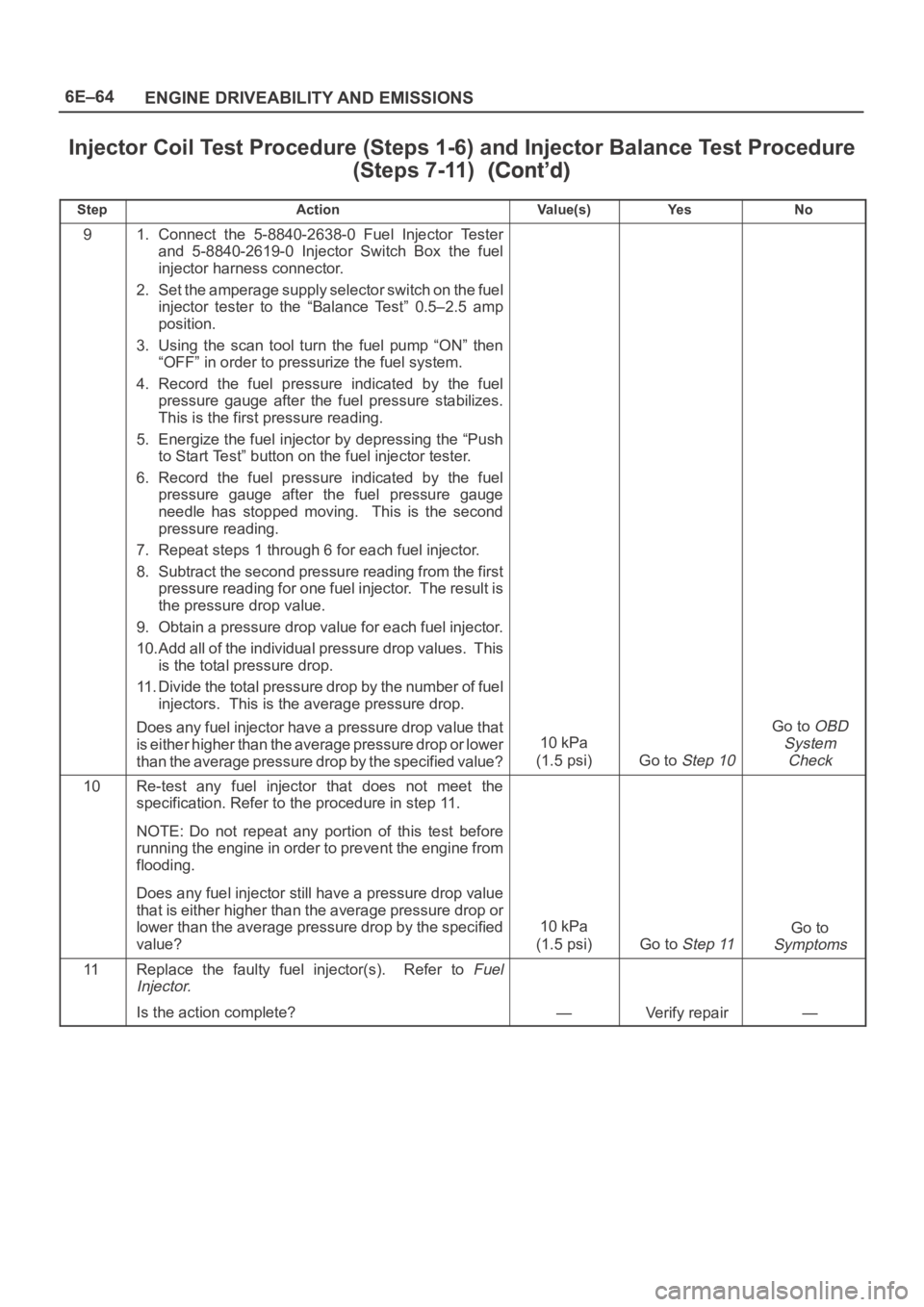

Page 1181 of 6000

6E–64

ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepNo Ye s Va l u e ( s ) Action

91. Connect the 5-8840-2638-0 Fuel Injector Tester

and 5-8840-2619-0 Injector Switch Box the fuel

injector harness connector.

2. Set the amperage supply selector switch on the fuel

injector tester to the “Balance Test” 0.5–2.5 amp

position.

3. Using the scan tool turn the fuel pump “ON” then

“OFF” in order to pressurize the fuel system.

4. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure stabilizes.

This is the first pressure reading.

5. Energize the fuel injector by depressing the “Push

to Start Test” button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure gauge

needle has stopped moving. This is the second

pressure reading.

7. Repeat steps 1 through 6 for each fuel injector.

8. Subtract the second pressure reading from the first

pressure reading for one fuel injector. The result is

the pressure drop value.

9. Obtain a pressure drop value for each fuel injector.

10.Add all of the individual pressure drop values. This

is the total pressure drop.

11. Divide the total pressure drop by the number of fuel

injectors. This is the average pressure drop.

Does any fuel injector have a pressure drop value that

is either higher than the average pressure drop or lower

than the average pressure drop by the specified value?

10 kPa

(1.5 psi)

Go to Step 10

Go to OBD

System

Check

10Re-test any fuel injector that does not meet the

specification. Refer to the procedure in step 11.

NOTE: Do not repeat any portion of this test before

running the engine in order to prevent the engine from

flooding.

Does any fuel injector still have a pressure drop value

that is either higher than the average pressure drop or

lower than the average pressure drop by the specified

value?

10 kPa

(1.5 psi)

Go to Step 11

Go to

Symptoms

11Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?—Verify repair—

Page 1182 of 6000

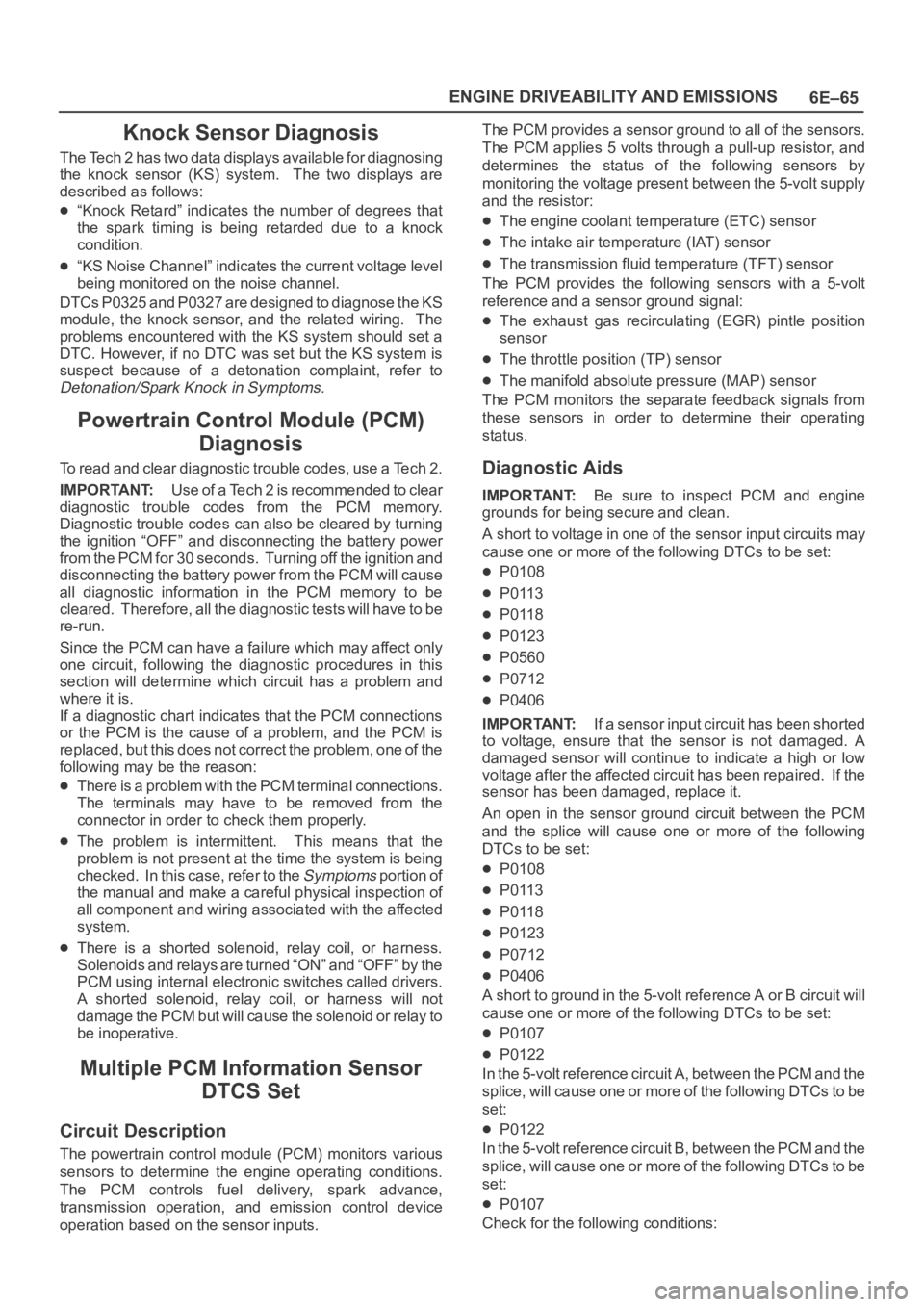

6E–65 ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor Diagnosis

The Tech 2 has two data displays available for diagnosing

the knock sensor (KS) system. The two displays are

described as follows:

“Knock Retard” indicates the number of degrees that

the spark timing is being retarded due to a knock

condition.

“KS Noise Channel” indicates the current voltage level

being monitored on the noise channel.

DTCs P0325 and P0327 are designed to diagnose the KS

module, the knock sensor, and the related wiring. The

problems encountered with the KS system should set a

DTC. However, if no DTC was set but the KS system is

suspect because of a detonation complaint, refer to

Detonation/Spark Knock in Symptoms.

Powertrain Control Module (PCM)

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the PCM terminal connections.

The terminals may have to be removed from the

connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms p o r t i o n o f

the manual and make a careful physical inspection of

all component and wiring associated with the affected

system.

There is a shorted solenoid, relay coil, or harness.

S o l e n o i d s a n d r e l a y s a r e t u r n e d “ O N ” a n d “ O F F ” b y t h e

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay to

be inoperative.

Multiple PCM Information Sensor

DTCS Set

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The engine coolant temperature (ETC) sensor

The intake air temperature (IAT) sensor

The transmission fluid temperature (TFT) sensor

The PCM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The exhaust gas recirculating (EGR) pintle position

sensor

The throttle position (TP) sensor

The manifold absolute pressure (MAP) sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

IMPORTANT:Be sure to inspect PCM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0108

P0113

P0118

P0123

P0560

P0712

P0406

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

P0108

P0113

P0118

P0123

P0712

P0406

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0107

P0122

In the 5-volt reference circuit A, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0122

In the 5-volt reference circuit B, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0107

Check for the following conditions:

Page 1197 of 6000

6E–80

ENGINE DRIVEABILITY AND EMISSIONS

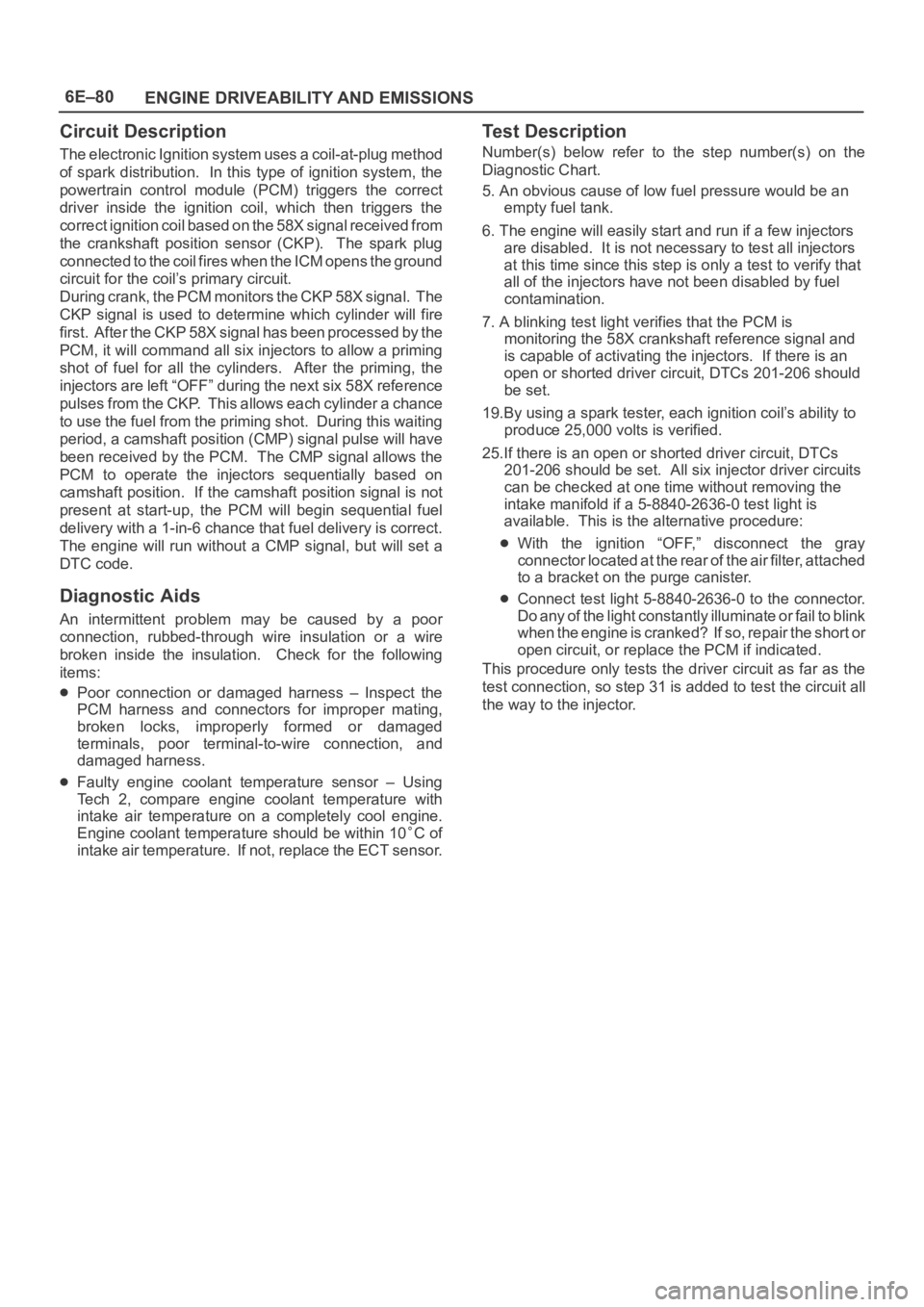

Circuit Description

The electronic Ignition system uses a coil-at-plug method

of spark distribution. In this type of ignition system, the

powertrain control module (PCM) triggers the correct

driver inside the ignition coil, which then triggers the

correct ignition coil based on the 58X signal received from

the crankshaft position sensor (CKP). The spark plug

connected to the coil fires when the ICM opens the ground

circuit for the coil’s primary circuit.

During crank, the PCM monitors the CKP 58X signal. The

CKP signal is used to determine which cylinder will fire

first. After the CKP 58X signal has been processed by the

PCM, it will command all six injectors to allow a priming

shot of fuel for all the cylinders. After the priming, the

injectors are left “OFF” during the next six 58X reference

pulses from the CKP. This allows each cylinder a chance

to use the fuel from the priming shot. During this waiting

period, a camshaft position (CMP) signal pulse will have

been received by the PCM. The CMP signal allows the

PCM to operate the injectors sequentially based on

camshaft position. If the camshaft position signal is not

present at start-up, the PCM will begin sequential fuel

delivery with a 1-in-6 chance that fuel delivery is correct.

The engine will run without a CMP signal, but will set a

DTC code.

Diagnostic Aids

An intermittent problem may be caused by a poor

connection, rubbed-through wire insulation or a wire

broken inside the insulation. Check for the following

items:

Poor connection or damaged harness – Inspect the

PCM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Faulty engine coolant temperature sensor – Using

Tech 2, compare engine coolant temperature with

intake air temperature on a completely cool engine.

Engine coolant temperature should be within 10

C of

intake air temperature. If not, replace the ECT sensor.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

5. An obvious cause of low fuel pressure would be an

empty fuel tank.

6. The engine will easily start and run if a few injectors

are disabled. It is not necessary to test all injectors

at this time since this step is only a test to verify that

all of the injectors have not been disabled by fuel

contamination.

7. A blinking test light verifies that the PCM is

monitoring the 58X crankshaft reference signal and

is capable of activating the injectors. If there is an

open or shorted driver circuit, DTCs 201-206 should

be set.

19.By using a spark tester, each ignition coil’s ability to

produce 25,000 volts is verified.

25.If there is an open or shorted driver circuit, DTCs

201-206 should be set. All six injector driver circuits

can be checked at one time without removing the

intake manifold if a 5-8840-2636-0 test light is

available. This is the alternative procedure:

With the ignition “OFF,” disconnect the gray

connector located at the rear of the air filter, attached

to a bracket on the purge canister.

Connect test light 5-8840-2636-0 to the connector.

Do any of the light constantly illuminate or fail to blink

when the engine is cranked? If so, repair the short or

open circuit, or replace the PCM if indicated.

This procedure only tests the driver circuit as far as the

test connection, so step 31 is added to test the circuit all

the way to the injector.

Page 1198 of 6000

6E–81 ENGINE DRIVEABILITY AND EMISSIONS

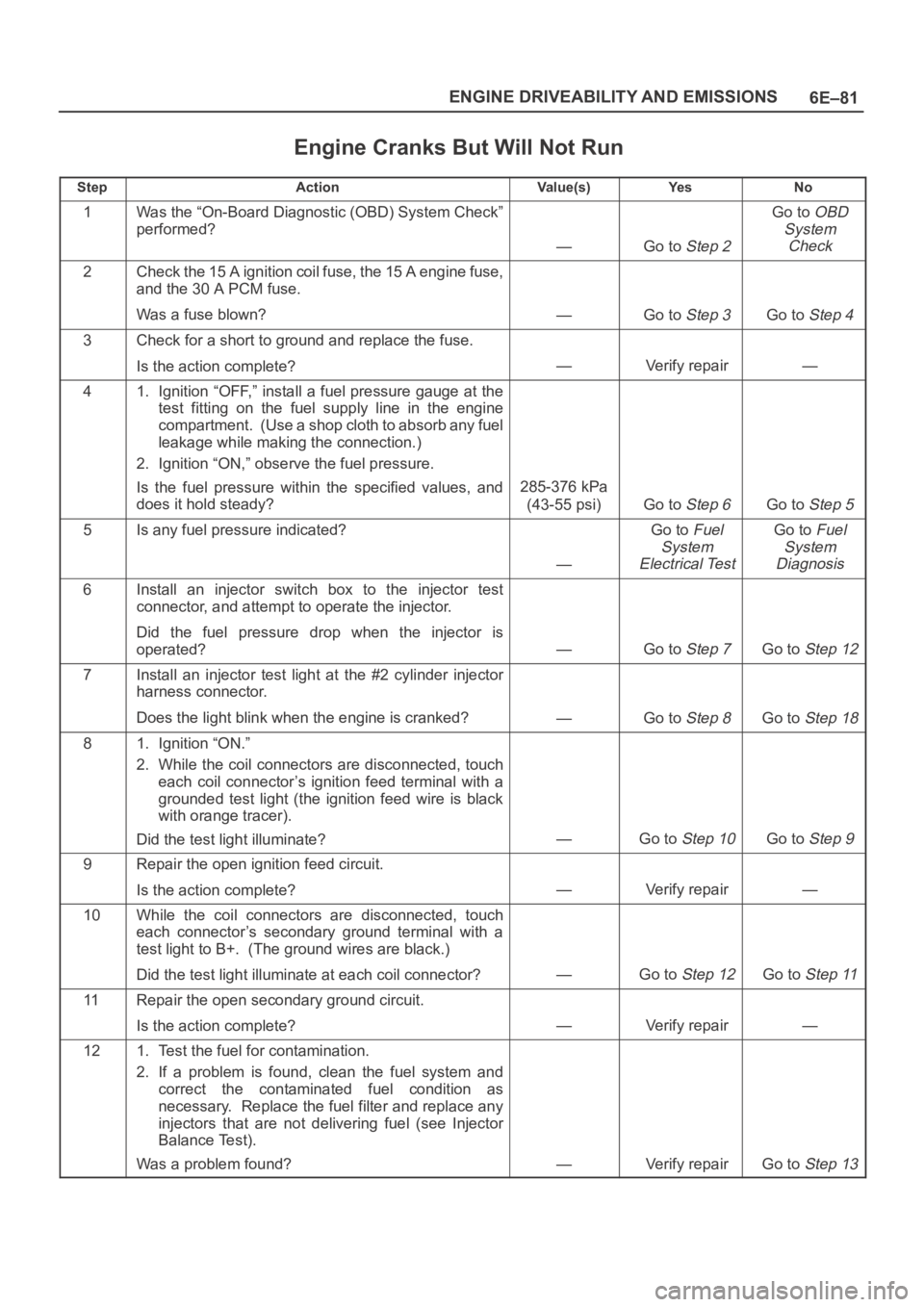

Engine Cranks But Will Not Run

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the 15 A ignition coil fuse, the 15 A engine fuse,

and the 30 A PCM fuse.

Was a fuse blown?

—Go to Step 3Go to Step 4

3Check for a short to ground and replace the fuse.

Is the action complete?

—Verify repair—

41. Ignition “OFF,” install a fuel pressure gauge at the

test fitting on the fuel supply line in the engine

compartment. (Use a shop cloth to absorb any fuel

leakage while making the connection.)

2. Ignition “ON,” observe the fuel pressure.

Is the fuel pressure within the specified values, and

does it hold steady?

285-376 kPa

(43-55 psi)

Go to Step 6Go to Step 5

5Is any fuel pressure indicated?

—

Go to Fuel

System

Electrical TestGo to Fuel

System

Diagnosis

6Install an injector switch box to the injector test

connector, and attempt to operate the injector.

Did the fuel pressure drop when the injector is

operated?

—Go to Step 7Go to Step 12

7Install an injector test light at the #2 cylinder injector

harness connector.

Does the light blink when the engine is cranked?

—Go to Step 8Go to Step 18

81. Ignition “ON.”

2. While the coil connectors are disconnected, touch

each coil connector’s ignition feed terminal with a

grounded test light (the ignition feed wire is black

with orange tracer).

Did the test light illuminate?

—Go to Step 10Go to Step 9

9Repair the open ignition feed circuit.

Is the action complete?

—Verify repair—

10While the coil connectors are disconnected, touch

each connector’s secondary ground terminal with a

test light to B+. (The ground wires are black.)

Did the test light illuminate at each coil connector?

—Go to Step 12Go to Step 11

11Repair the open secondary ground circuit.

Is the action complete?

—Verify repair—

121. Test the fuel for contamination.

2. If a problem is found, clean the fuel system and

correct the contaminated fuel condition as

necessary. Replace the fuel filter and replace any

injectors that are not delivering fuel (see Injector

Balance Test).

Was a problem found?

—Verify repairGo to Step 13

Page 1199 of 6000

6E–82

ENGINE DRIVEABILITY AND EMISSIONS

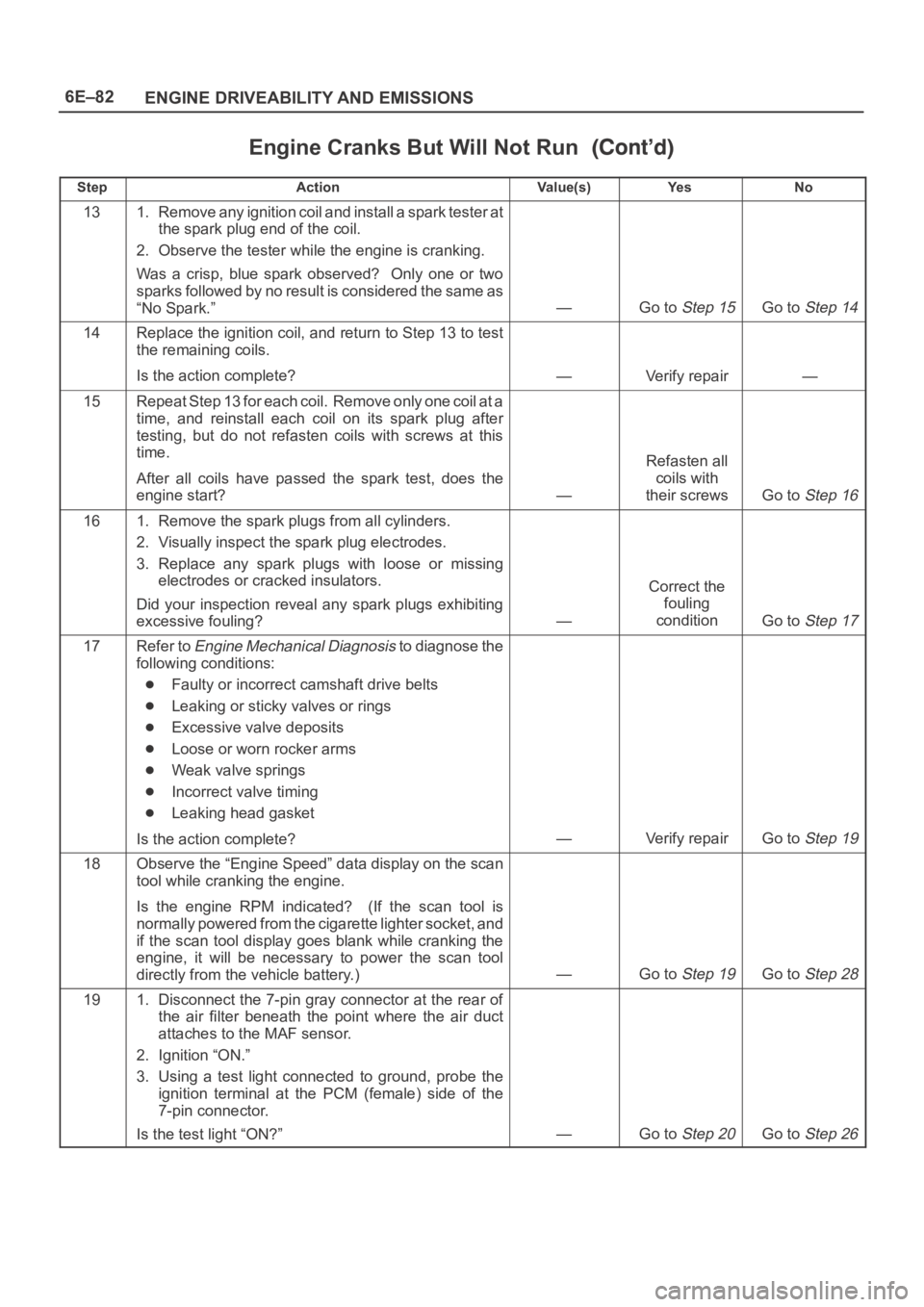

Engine Cranks But Will Not Run

StepNo Ye s Va l u e ( s ) Action

131. Remove any ignition coil and install a spark tester at

the spark plug end of the coil.

2. Observe the tester while the engine is cranking.

Was a crisp, blue spark observed? Only one or two

sparks followed by no result is considered the same as

“No Spark.”

—Go to Step 15Go to Step 14

14Replace the ignition coil, and return to Step 13 to test

the remaining coils.

Is the action complete?

—Verify repair—

15Repeat Step 13 for each coil. Remove only one coil at a

time, and reinstall each coil on its spark plug after

testing, but do not refasten coils with screws at this

time.

After all coils have passed the spark test, does the

engine start?

—

Refasten all

coils with

their screws

Go to Step 16

161. Remove the spark plugs from all cylinders.

2. Visually inspect the spark plug electrodes.

3. Replace any spark plugs with loose or missing

electrodes or cracked insulators.

Did your inspection reveal any spark plugs exhibiting

excessive fouling?

—

Correct the

fouling

condition

Go to Step 17

17Refer to Engine Mechanical Diagnosis to diagnose the

following conditions:

Faulty or incorrect camshaft drive belts

Leaking or sticky valves or rings

Excessive valve deposits

Loose or worn rocker arms

Weak valve springs

Incorrect valve timing

Leaking head gasket

Is the action complete?

—Verify repairGo to Step 19

18Observe the “Engine Speed” data display on the scan

tool while cranking the engine.

Is the engine RPM indicated? (If the scan tool is

normally powered from the cigarette lighter socket, and

if the scan tool display goes blank while cranking the

engine, it will be necessary to power the scan tool

directly from the vehicle battery.)

—Go to Step 19Go to Step 28

191. Disconnect the 7-pin gray connector at the rear of

the air filter beneath the point where the air duct

attaches to the MAF sensor.

2. Ignition “ON.”

3. Using a test light connected to ground, probe the

ignition terminal at the PCM (female) side of the

7-pin connector.

Is the test light “ON?”

—Go to Step 20Go to Step 26

Page 1203 of 6000

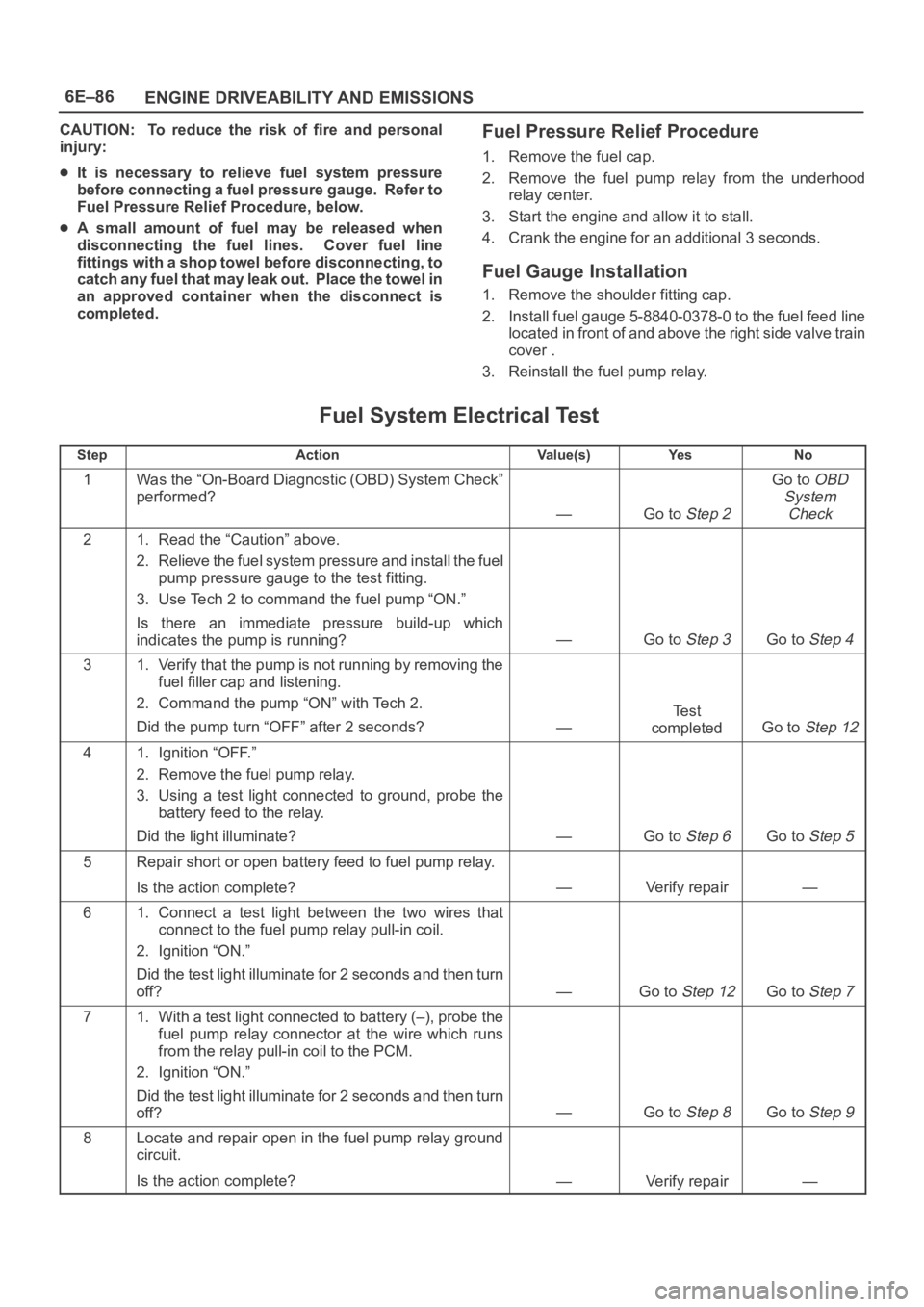

6E–86

ENGINE DRIVEABILITY AND EMISSIONS

CAUTION: To reduce the risk of fire and personal

injury:

It is necessary to relieve fuel system pressure

before connecting a fuel pressure gauge. Refer to

Fuel Pressure Relief Procedure, below.

A small amount of fuel may be released when

disconnecting the fuel lines. Cover fuel line

fittings with a shop towel before disconnecting, to

catch any fuel that may leak out. Place the towel in

an approved container when the disconnect is

completed.

Fuel Pressure Relief Procedure

1. Remove the fuel cap.

2. Remove the fuel pump relay from the underhood

relay center.

3. Start the engine and allow it to stall.

4. Crank the engine for an additional 3 seconds.

Fuel Gauge Installation

1. Remove the shoulder fitting cap.

2. Install fuel gauge 5-8840-0378-0 to the fuel feed line

located in front of and above the right side valve train

cover .

3. Reinstall the fuel pump relay.

Fuel System Electrical Test

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Read the “Caution” above.

2. Relieve the fuel system pressure and install the fuel

pump pressure gauge to the test fitting.

3. Use Tech 2 to command the fuel pump “ON.”

Is there an immediate pressure build-up which

indicates the pump is running?

—Go to Step 3Go to Step 4

31. Verify that the pump is not running by removing the

fuel filler cap and listening.

2. Command the pump “ON” with Tech 2.

Did the pump turn “OFF” after 2 seconds?

—

Te s t

completed

Go to Step 12

41. Ignition “OFF.”

2. Remove the fuel pump relay.

3. Using a test light connected to ground, probe the

battery feed to the relay.

Did the light illuminate?

—Go to Step 6Go to Step 5

5Repair short or open battery feed to fuel pump relay.

Is the action complete?

—Verify repair—

61. Connect a test light between the two wires that

connect to the fuel pump relay pull-in coil.

2. Ignition “ON.”

Did the test light illuminate for 2 seconds and then turn

off?

—Go to Step 12Go to Step 7

71. With a test light connected to battery (–), probe the

fuel pump relay connector at the wire which runs

from the relay pull-in coil to the PCM.

2. Ignition “ON.”

Did the test light illuminate for 2 seconds and then turn

off?

—Go to Step 8Go to Step 9

8Locate and repair open in the fuel pump relay ground

circuit.

Is the action complete?

—Verify repair—

Page 1222 of 6000

6E–105 ENGINE DRIVEABILITY AND EMISSIONS

The engine oil dip stick not fully seated.

The engine oil fill cap loose or missing.

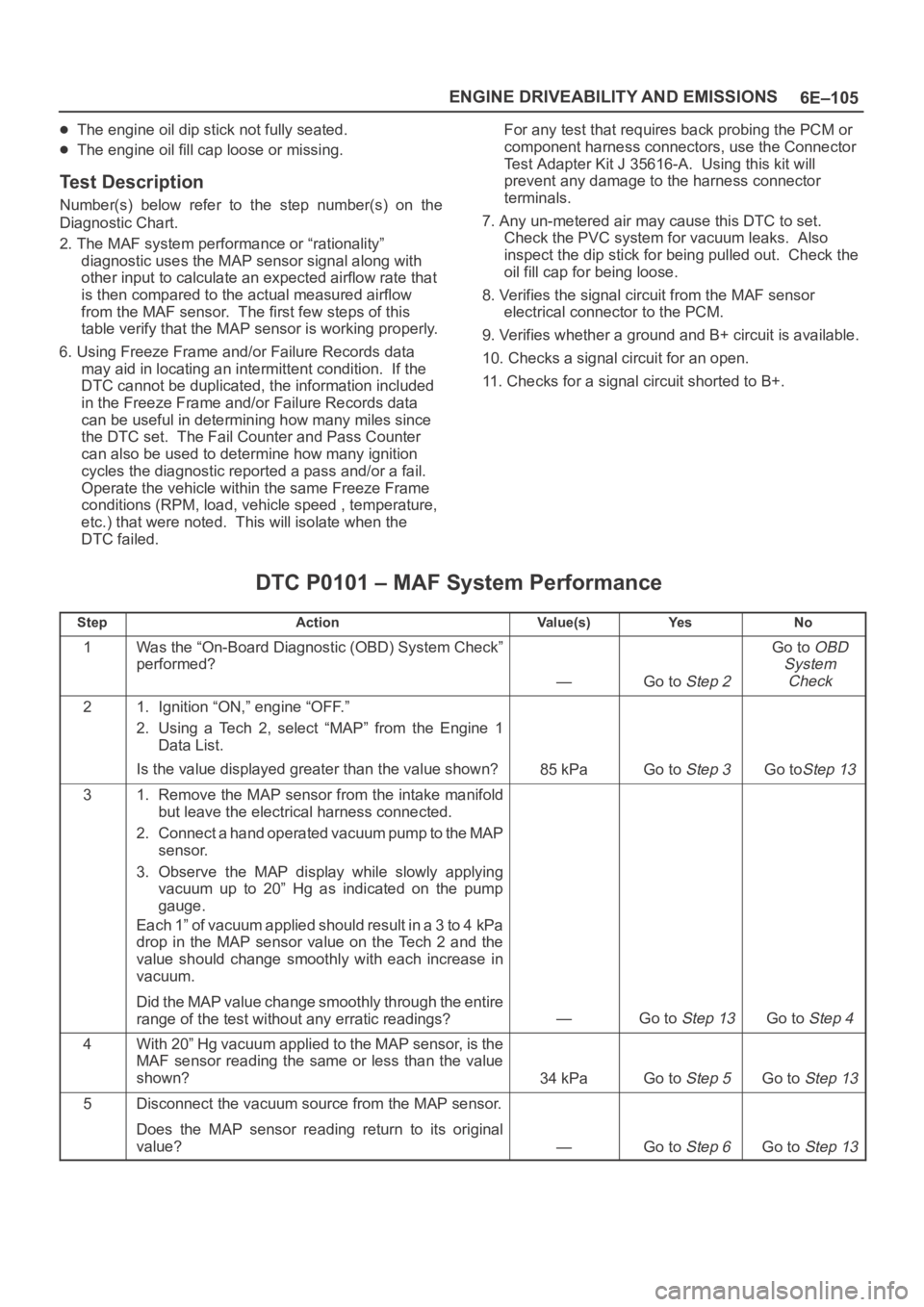

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. The MAF system performance or “rationality”

diagnostic uses the MAP sensor signal along with

other input to calculate an expected airflow rate that

is then compared to the actual measured airflow

from the MAF sensor. The first few steps of this

table verify that the MAP sensor is working properly.

6. Using Freeze Frame and/or Failure Records data

may aid in locating an intermittent condition. If the

DTC cannot be duplicated, the information included

in the Freeze Frame and/or Failure Records data

can be useful in determining how many miles since

the DTC set. The Fail Counter and Pass Counter

can also be used to determine how many ignition

cycles the diagnostic reported a pass and/or a fail.

Operate the vehicle within the same Freeze Frame

conditions (RPM, load, vehicle speed , temperature,

etc.) that were noted. This will isolate when the

DTC failed.For any test that requires back probing the PCM or

component harness connectors, use the Connector

Test Adapter Kit J 35616-A. Using this kit will

prevent any damage to the harness connector

terminals.

7. Any un-metered air may cause this DTC to set.

Check the PVC system for vacuum leaks. Also

inspect the dip stick for being pulled out. Check the

oil fill cap for being loose.

8. Verifies the signal circuit from the MAF sensor

electrical connector to the PCM.

9. Verifies whether a ground and B+ circuit is available.

10. Checks a signal circuit for an open.

11. Checks for a signal circuit shorted to B+.

DTC P0101 – MAF System Performance

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Using a Tech 2, select “MAP” from the Engine 1

Data List.

Is the value displayed greater than the value shown?

85 kPaGo to Step 3Go toStep 13

31. Remove the MAP sensor from the intake manifold

but leave the electrical harness connected.

2. Connect a hand operated vacuum pump to the MAP

sensor.

3. Observe the MAP display while slowly applying

vacuum up to 20” Hg as indicated on the pump

gauge.

Each 1” of vacuum applied should result in a 3 to 4 kPa

drop in the MAP sensor value on the Tech 2 and the

value should change smoothly with each increase in

vacuum.

Did the MAP value change smoothly through the entire

range of the test without any erratic readings?

—Go to Step 13Go to Step 4

4With 20” Hg vacuum applied to the MAP sensor, is the

MAF sensor reading the same or less than the value

shown?

34 kPaGo to Step 5Go to Step 13

5Disconnect the vacuum source from the MAP sensor.

Does the MAP sensor reading return to its original

value?

—Go to Step 6Go to Step 13

Page 1287 of 6000

6E–170

ENGINE DRIVEABILITY AND EMISSIONS

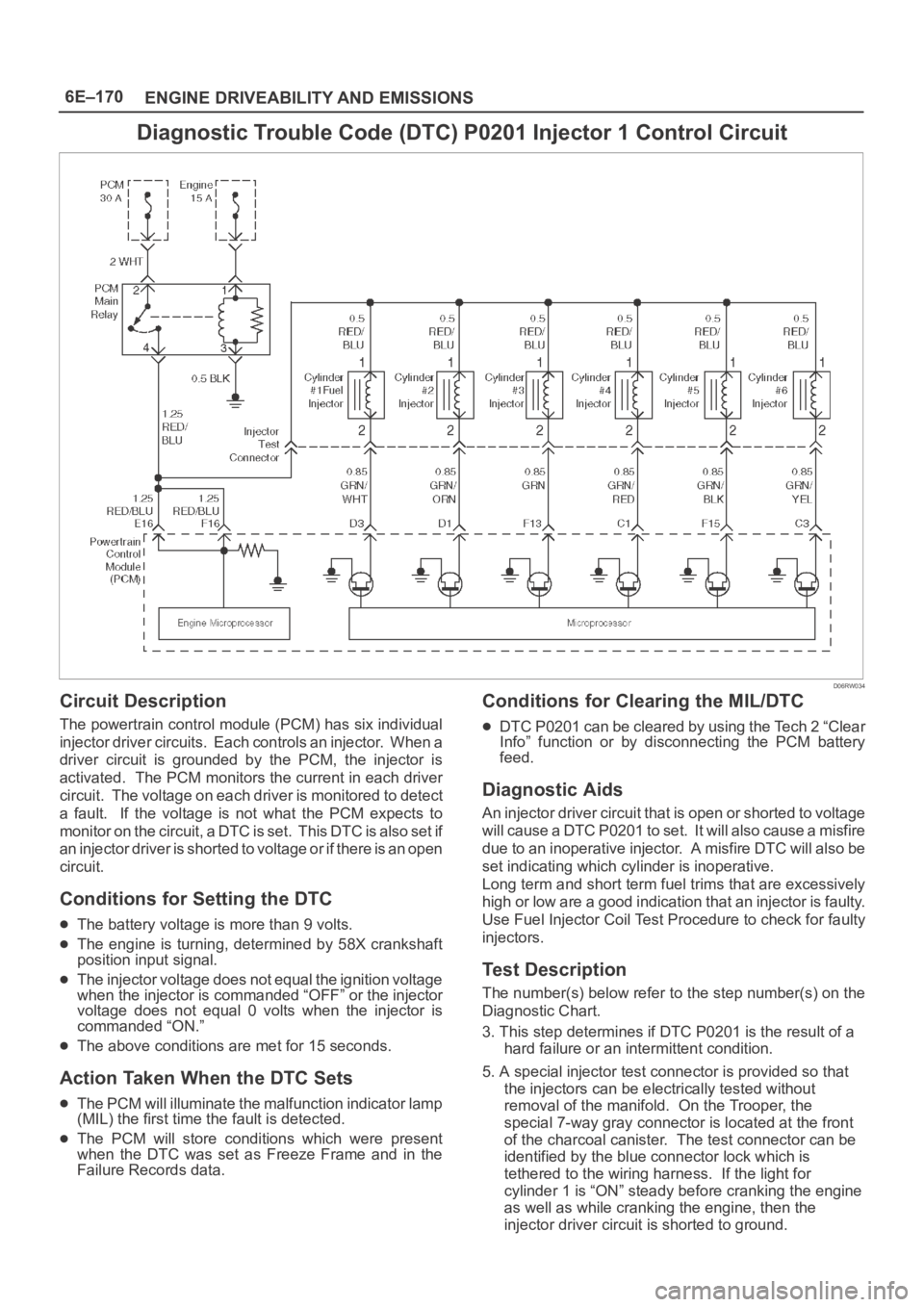

Diagnostic Trouble Code (DTC) P0201 Injector 1 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When a

driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0201 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0201 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0201 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 1 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.