heater OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4726 of 6000

6E–69 ENGINE DRIVEABILITY AND EMISSIONS

HO2S BANK2, SEN. 1—Tech 2 Range 0-1132 mV—

Represents the fuel control exhaust oxygen sensor

output voltage. Should fluctuate constantly within a range

between 10mV (lean exhaust) and 1000 mV (rich

exhaust) while operating in closed loop.

HO2S BANK 1, SEN. 1—Tech 2 Displays NOT

READY or READY—

Indicates the status of the exhaust oxygen sensor. The

Tech 2 will indicate that the exhaust oxygen sensor is

ready when the PCM detects a fluctuating HO2S voltage

sufficient to allow closed loop operation. This will not

occur unless the exhaust oxygen sensor is warmed up.

HO2S BANK 2, SEN. 1 — Tech 2 Displays NOT

READY or READY —

Indicates the status of the exhaust oxygen sensor. The

Tech 2 will indicate that the exhaust oxygen sensor is

ready when the PCM detects a fluctuating HO2S voltage

sufficient to allow closed loop operation. This will not

occur unless the exhaust oxygen sensor is warmed up.

HO2S WARM UP TIME BANK 1, SEN. 1/BANK 2

SEN. 1 — Tech 2 Range 00:00:00-99:99:99

HRS:MIN:SEC —

Indicates warm-up time for each HO2S. The HO2S

warm-up time is used for the HO2S heater test. The PCM

will run the heater test only after a cold start (determined

by engine coolant and intake air temperature at the time

of start-up) and only once during an ignition cycle. When

the engine is started the PCM will monitor the HO2S

voltage. When the HO2S voltage indicates a sufficiently

active sensor, the PCM looks at how much time has

elapsed since start-up. If the PCM determines that too

much time was required for the HO2S to become active,

a DTC will set. If the engine was warm when started,

HO2S warm-up will the display “00:00:00”.

IAC POSITION — Tech 2 Range 0-255 Counts —

Displays the commanded position of the idle air control

pintle in counts. A larger number of counts means that

more air is being commanded through the idle air

passage. Idle air control should respond fairly quickly to

changes in engine load to maintain desired idle RPM.

IAT (INTAKE AIR TEMPERATURE) — Tech 2 Range

–40

C to 151C (–40F to 304F) —

The PCM converts the resistance of the intake air

temperature sensor to degrees. Intake air temperature

(IAT) is used by the PCM to adjust fuel delivery and spark

timing according to incoming air density.

IGNITION 1 — Tech 2 Range 0-25.5 Volts —

This represents the system voltage measured by the

PCM at its ignition feed.

INJ. PULSE BANK 1/INJ. PULSE BANK 2 — Tech 2

Range 0-1000 msec. —

Indicates the amount of time the PCM is commanding

each injector “ON” during each engine cycle. A longer

injector pulse width will cause more fuel to be delivered.

Injector pulse width should increase with increased

engine load.KS NOISE CHANNEL (Knock Sensor) —

Indicates the output from the KS noise channel. There is

always some electrical noise in an engine compartment

and to avoid mistaking this as engine knock, the output

from the knock sensor is compared to the output from the

noise channel. A knock condition is not set unless the

knock sensor output is greater than the noise channel

output.

LONG TERM FUEL TRIM BANK 1/BANK 2 —

The long term fuel trim is derived from the short term fuel

trim values and represents a long term correction of fuel

delivery for the bank in question. A value of 0% indicates

that fuel delivery requires no compensation to maintain

the PCM commanded air/fuel ratio. A negative value

significantly below 0% indicates that the fuel system is

rich and fuel delivery is being reduced (decreased injector

pulse width). A positive value significantly greater than

0% indicates that a lean condition exists and the PCM is

compensating by adding fuel (increased injector pulse

width). Because long term fuel trim tends to follow short

term fuel trim, a value in the negative range due to

canister purge at idle should not be considered unusual.

Fuel trim values at maximum authority may indicate an

excessively rich or lean system.

LOOP STATUS — Tech 2 Displays OPEN or

CLOSED —

“CLOSED” indicates that the PCM is controlling fuel

delivery according to oxygen sensor voltage. In “OPEN”

the PCM ignores the oxygen sensor voltage and bases

the amount of fuel to be delivered on TP sensor, engine

coolant, and MAF sensor inputs only.

MAF — Tech 2 Range 0.0-512 gm/s —

MAF (mass air flow) is the MAF input frequency

converted to grams of air per second. This indicates the

amount of air entering the engine.

MAP — Tech 2 Range 10-105 kPa (0.00-4.97 Volts)

—

The manifold absolute pressure (MAP) sensor measures

the change in the intake manifold pressure from engine

load, EGR flow, and speed changes. As intake manifold

pressure increases, intake vacuum decreases, resulting

in a higher MAP sensor voltage and kPa reading. The

MAP sensor signal is used to monitor intake manifold

pressure changes during the EGR flow test, to update the

BARO reading, and as an enabling factor for several of

the diagnostics.

MIL — Tech 2 Displays ON or OFF —

Indicates the PCM commanded state of the malfunction

indicator lamp.

POWER ENRICHMENT — Tech 2 Displays ACTIVE

or INACTIVE —

“ACTIVE” displayed indicates that the PCM has detected

conditions appropriate to operate in power enrichment

mode. The PCM will command power enrichment mode

when a large increase in throttle position and load is

detected. While in power enrichment mode, the PCM will

increase the amount of fuel delivered by entering open

loop and increasing the injector pulse width. This is done

to prevent a possible sag or hesitation from occurring

during acceleration.

Page 4797 of 6000

6E–140

ENGINE DRIVEABILITY AND EMISSIONS

HO2S, causing the system to appear lean. Check for

exhaust leaks that may cause a false lean condition to

be indicated.

MAF sensor – The system can go lean if the MAF

sensor signal indicates an engine airfiow

measurement that is not correct. Disconnect the MAF

sensor to see if the lean condition is corrected. If so,

replace the MAF sensor.

Fuel contamination – Water, even in small amounts,

can be delivered to the fuel injectors. The water can

cause a lean exhaust to be indicated. Excessive

alcohol in the fuel can also cause this condition. Refer

to

Fuel System Diagnosis for the procedure to check

for fuel contamination.

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to step numbers on the diagnostic

chart.

3. DTC P0131 failing during operation may indicate a

condition described in the “Diagnostic Aids” above.

If the DTC P0131 test passes while the Failure

Records conditions are being duplicated, an

intermittent condition is indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0131 –HO2S Circuit Low Voltage Bank 1 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install the Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within the parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

4. Using a Tech 2, monitor Bank 1 HO2S 1 voltage.

Does the Bank 1 HO2S 1 voltage remain below the

specified value?

22 mVGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P0131 until the DTC P0131 test runs.

Note test result.

Does Tech 2 indicate DTC P0131 failed this ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Turn the ignition “OFF.”

2. Disconnect the PCM.

3. Check the Bank 1 HO2S 1 high and low circuits for a

short to ground or a short to the heater ground

circuit.

Are the Bank 1 HO2S 1 signal circuits shorted to

ground?

—Go to Step 5Go to Step 6

5Repair the Bank 1 HO2S 1 signal circuit.

Is the action complete?

—Verify repair—

61. Turn the ignition “OFF,” HO2S 1 and PCM

disconnected.

2. Check for continuity between the high and low

signal circuits.

Was there continuity between the high and low circuits?

—Go to Step 7Go to Step 8

7Repair the short between the high and low circuits.

Is the action complete?

—Verify repair—

Page 4802 of 6000

6E–145 ENGINE DRIVEABILITY AND EMISSIONS

D i a g n o s t i c Tr o u b l e C o d e ( D T C ) P 0 1 3 4 H O 2 S C i r c u i t I n s u f f i c i e n t Activity Bank 1

Sensor 1

060RW237

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

s e n s o r ( H O 2 S ) h i g h a n d l o w c i r c u i t s . W h e n m e a s u r e d

with a 10 megaohm digital voltmeter, this may display

as low as 320 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when

exhaust is lean. The PCM constantly monitors the

HO2S signal during “closed loop” operation and

compensates for a rich or lean condition by decreasing

or increasing injector pulse width as necessary. If the

Bank 1 HO2S 1 voltage remains at or near the 450 mV

bias for an extended period of time, DTC P0134 will be

set, indicating an open sensor signal or sensor low

circuit.

Heated oxygen sensors are used to minimize the

amount of time required for “closed loop” fuel control

operation and to allow accurate catalyst monitoring.

The oxygen sensor heater greatly decreases the

amount of time required for fuel control sensors Bank

1 HO2S 1 and Bank 2 HO2S 1 to become active.

Oxygen sensor heaters are required by post-catalyst

monitor sensors to maintain a sufficiently high

temperature for accurate exhaust oxygen content

readings further from the engine.

Conditions for Setting the DTC

No related DTCs.

Battery voltage is above 10 volts.

Engine run time is longer than 40 seconds.

Oxygen sensor heater has been determined to be

functioning properly.

Bank 1 HO2S 1 signal voltage remains between

400 mV and 500 mV for a total of 77 seconds over a

90-second period of time.

Action Take When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0134 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

Faulty HO2S heater or heater circuit – With the ignition

“ON,” engine “OFF,” after a cool down period, the

HO2S 1 voltage displayed on Tech 2 is normally

455-460 mV. A reading over 1000 mV indicates a

signal line shorted to voltage. A reading under 5 mV

Page 4803 of 6000

6E–146

ENGINE DRIVEABILITY AND EMISSIONS

indicates a signal line shorted to ground or signal lines

shorted together. Disconnect the HO2S and connect

a test light between the HO2S ignition feed and heater

ground circuits. If the test light does not light for 2

seconds when the ignition is turned on, repair the open

ignition feed or sensor ground circuit as necessary. If

the test light lights and the HO2S signal and low circuits

are OK, replace the HO2S.

Intermittent test – With the Ignition “ON,” monitor the

HO2S signal voltage while moving the wiring harness

and related connectors. If the fault is induced, the

HO2S signal voltage will change. This may help isolate

the location of the malfunction.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. If the DTC P0134 test passes while the Failure

Records conditions are being duplicated, an

intermittent conditions is indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0134 –HO2S Circuit Insufficient Activity Bank 1 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install Tech 2.

2. Run the engine at operating temperature.

3. Operate the engine above 1200 RPM for two

minutes.

Does Tech 2 indicate Bank 1 HO2S 1 voltage varying

outside the specified values?

400-500 mVGo to Step 3Go to Step 4

31. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “Specific DTC” info for DTC

P0134 until the DTC P0134 test runs.

4. Note the test result.

Does Tech 2 indicate DTC P0134 failed this ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

4Check for a damaged harness.

Was a problem found?

—Verify repairGo to Step 5

5Check for poor Bank 1 HO2S 1 high and low circuit

terminal connections at the Bank 1 HO2S 1 harness

connector and replace terminal(s) if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 6

6Check for poor Bank 1 HO2S 1 high and low circuit

terminal connections at the PCM and replace terminals

if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 7

71. Ignition “OFF.”

2. With the PCM disconnected, check continuity of the

Bank 1 HO2S 1 high circuit.

3. If the Bank 1 HO2S 1 high circuit measures over 5.0

ohms, repair open or poor connection as necessary.

Was a Bank 1 HO2S 1 high circuit problem found and

corrected?

—Verify repairGo to Step 8

Page 4806 of 6000

6E–149 ENGINE DRIVEABILITY AND EMISSIONS

exhaust leaks that may cause a false lean condition to

be indicated.

MAF sensor –The system can go lean if the MAF

sensor signal indicates an engine airflow

measurement that is not correct. Disconnect the MAF

sensor to see if the lean condition is corrected. If so,

replace the MAF sensor.

Fuel contamination – Water, even in small amounts,

can be delivered to the fuel injectors. The water can

cause a lean exhaust to be indicated. Excessive

alcohol in the fuel can also cause this condition. Refer

to

Fuel System Diagnosis for the procedure to check

for fuel contamination.

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. DTC P0151 failing during operation may indicate a

condition described in the “Diagnostic Aids” above.

If the DTC P0151 test passes while the Failure

Records conditions are being duplicated, an

intermittent condition is indicate.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0151 – HO2S Circuit Low Voltage Bank 2 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Install Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within the parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

4. Using Tech 2, monitor Bank 2 HO2S 1 voltage.

Does the Bank 2 HO2S 1 voltage remain below the

specified value?

22 mVGo to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “Specific DTC” info for DTC

P0151 until the DTC P0151 test runs.

4. Note test result.

Does Tech 2 indicate DTC P0151 failed this ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Turn ignition “OFF.”

2. Disconnect the PCM.

3. Check the Bank 2 HO2S 1 high and low signal

circuits for a short to ground or a short to the heater

ground circuit.

Were Bank 2 HO2S 1 signal circuits shorted?

—Go to Step 5Go to Step 6

5Repair the Bank 2 HO2S 1 signal circuit.

Is the action complete?

—Verify repair—

61. Ignition “OFF.”

2. Leave the PCM and HO2S 1 disconnected.

3. Check for continuity between the high and low

signal circuits.

Was there continuity between the high and low circuits?

—Go to Step 7Go to Step 8

7Repair the short between the high and low circuits.

Is the action complete?

—Verify repair—

Page 4898 of 6000

6E–241 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1154 HO2S Circuit Transition Time Ratio

Bank 2 Sensor 1

060RW190

Circuit Description

The powertrain control module (PCM) monitors the

heated oxygen sensor (HO2S) activity for 90 seconds

after “closed loop” and stoichiometric operation have

been enabled. During the monitor period the PCM counts

the number of times that the HO2S responds from

rich-to-lean and from lean-to-rich and adds the amount of

time it took to complete all transitions. With this

information, an average time for all transitions can be

determined. The PCM then divides the rich-to-lean

average by the lean-to-rich average to obtain a ratio. If

the HO2S transition time ratio is not within this range,

DTC P1154 will be set, indicating that the oxygen sensor

is not responding as expected to changes in exhaust

oxygen content.

Conditions for Setting the DTC

No related DTCs.

Engine coolant temperature (ETC) is above 50C

(122F) for automatic transmission; 75C (167F) for

manual transmission.

The engine is operating in “closed loop.”

The engine has been running at least one minute.

Canister purge duty cycle is greater than 2%.

Engine speed is between 1500 RPM and 3000 RPM.

Mass air flow is between 9 g/second and 42 g/second.

Above conditions are present for a 3-second

monitoring period.

90 seconds after “closed loop” and stoichiometric

operation have been enabled, Bank 2 HO2S 1

transition ratio between lean to rich and rich to lean is

less than 0.44 or greater than 3.8.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

”Open loop” fuel control will be in effect.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1154 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

A multifunction in the HO2S heater ignition feed or ground

circuit may cause a DTC P1154 to set. Check HO2S

heater circuitry for intermittent faults or poor connections.

If connections and wiring are OK and DTC P1154

continues to set, replace the Bank 2 HO2S 1.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

Page 4956 of 6000

6E–299 ENGINE DRIVEABILITY AND EMISSIONS

damage, therefore, it is important to use care when

handling and testing electronic components.

NOTE: To prevent possible Electrostatic Discharge

damage, follow these guidelines:

Do not touch the control module connector pins or

soldered components on the control module circuit

board.

Do not open the replacement part package until the

part is ready to be installed.

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

If the part has been handled while sliding across the

seat, or while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

NOTE: To prevent internal PCM damage, the ignition

must be in the “OFF” position in order to disconnect or

reconnect power to the PCM (for example: battery cable,

PCM pigtail, PCM fuse, jumper cables, etc.).

IMPORTANT:When replacing the production PCM

with a service PCM, it is important to transfer the

broadcast code and production PCM number to the

service PCM label. This will allow positive identification of

PCM parts throughout the service life of the vehicle. Do

not record this information on the metal PCM cover.

IMPORTANT:The ignition should always be in the

“OFF” position in order to install or remove the PCM

connectors.

Service of the PCM should normally consist of either re-

placement of the PCM or EEPROM programming. If the

diagnostic procedures call for the PCM to be replaced,

the PCM should be checked first to ensure it is the correct

part. If it is, remove the faulty PCM and install the new

service PCM.

The service PCM EEPROM will not be programmed.

DTC P0601 indicates the check sum error.

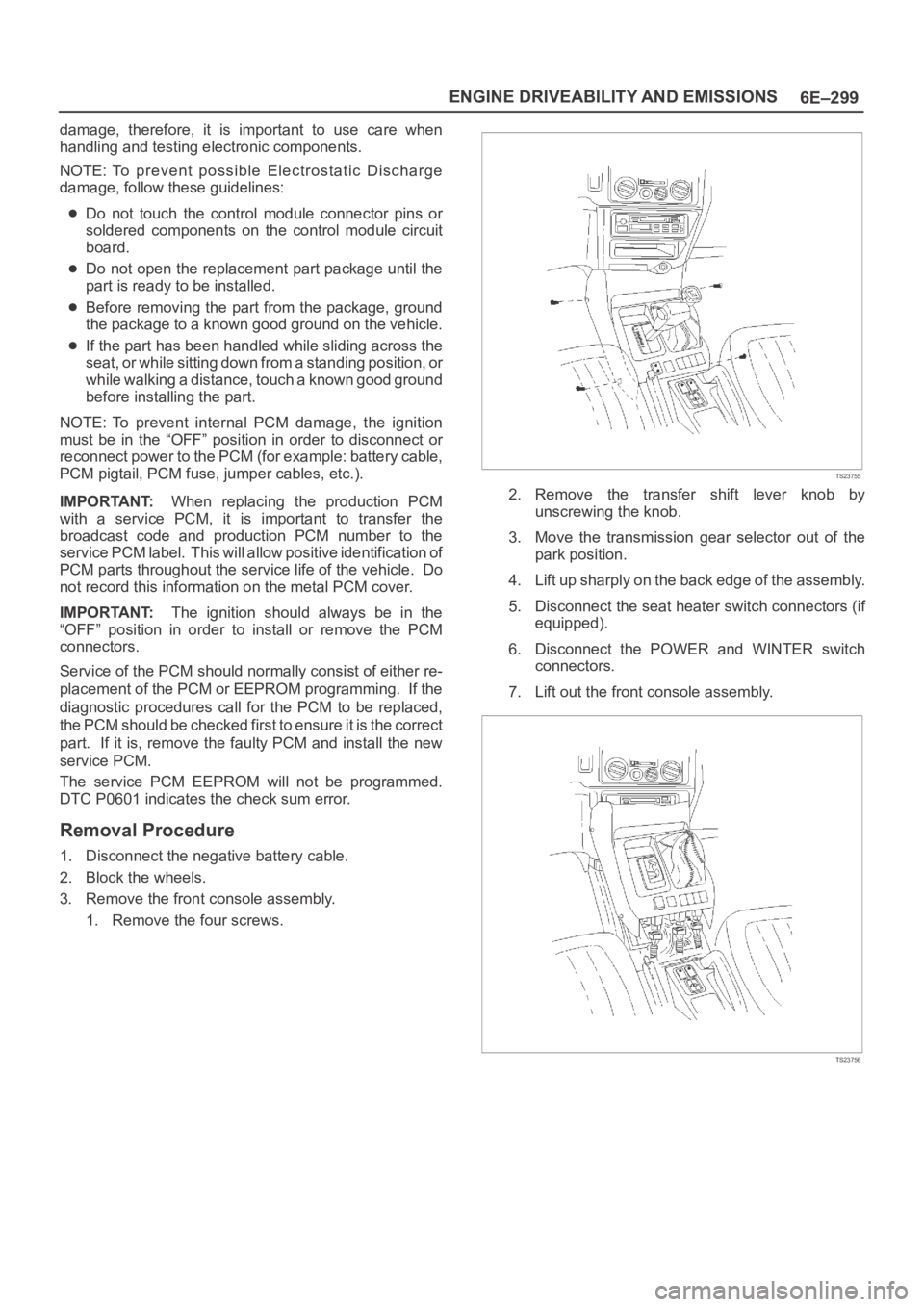

Removal Procedure

1. Disconnect the negative battery cable.

2. Block the wheels.

3. Remove the front console assembly.

1. Remove the four screws.

TS23755

2. Remove the transfer shift lever knob by

unscrewing the knob.

3. Move the transmission gear selector out of the

park position.

4. Lift up sharply on the back edge of the assembly.

5. Disconnect the seat heater switch connectors (if

equipped).

6. Disconnect the POWER and WINTER switch

connectors.

7. Lift out the front console assembly.

TS23756

Page 5300 of 6000

ENGINE MECHANICAL 6A – 27

2) Remove transmission rear mount.

3) Remove transmission fixing bolt from rear of

engine assembly except two bolts.

4) Carefully hang up engine assembly with a hoist.

5) Remove remaining two transmission fixing bolts.

6) Remove transmission assembly.

7) Remove heater hose.

8) Disconnect wire harness connector for shift on

the fly.

9) Remove vacuum hose.

21. Prepare Engine Stand

22. Engine Assembly

1) Remove engine mount fixing bolts.

2) Carefully hang up the engine assembly.

3) Take out the engine assembly making sure not

to damage the brake oil pipe and other pipe etc.

INSTALLATION

1. Engine assembly

1) Install engine in mounting position by using

hoist.

2. Transmission Assembly

1) Refer to transmission installation steps in

section 7.

3. Engine Mounting

1) After all fixing bolts (left: two bolts, rights: two

bolts) were inserted in every hole, tighten fixing

bolts to the specified torque.

Torque: 40 Nꞏm (4 kgꞏm/29 lbꞏft)

4. Glow Plug Harness

5. Vacuum Hose

1) Connect Vacuum Hose to Vacuum Pump

6. Engine Ground Cable

7. Fuel Pipe

1) Install fuel pipe to fuel pump.

8. Engine Harness

9. Starter Harness

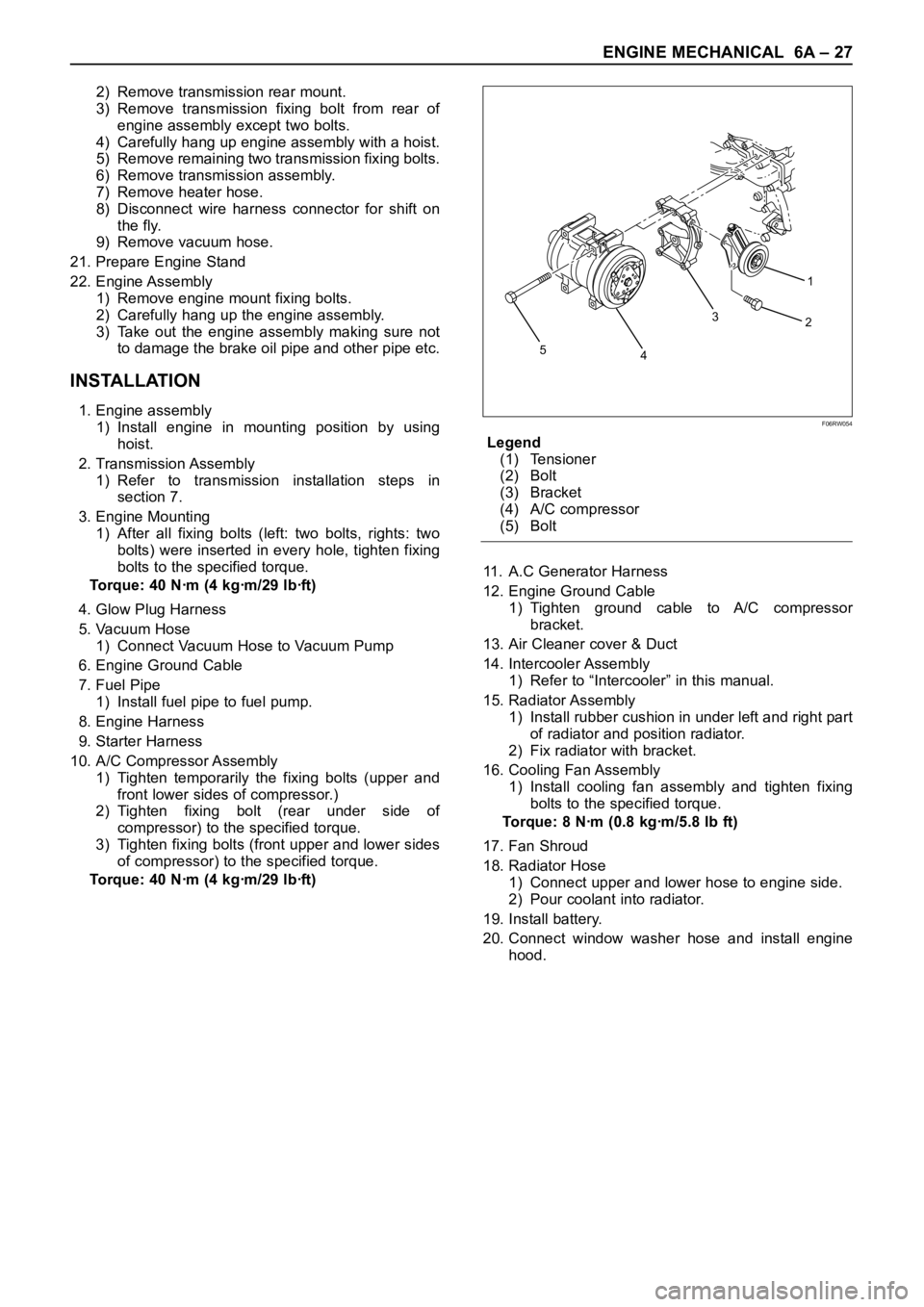

10. A/C Compressor Assembly

1) Tighten temporarily the fixing bolts (upper and

front lower sides of compressor.)

2) Tighten fixing bolt (rear under side of

compressor) to the specified torque.

3) Tighten fixing bolts (front upper and lower sides

of compressor) to the specified torque.

Torque: 40 Nꞏm (4 kgꞏm/29 lbꞏft)Legend

(1) Tensioner

(2) Bolt

(3) Bracket

(4) A/C compressor

(5) Bolt

11. A.C Generator Harness

12. Engine Ground Cable

1) Tighten ground cable to A/C compressor

bracket.

13. Air Cleaner cover & Duct

14. Intercooler Assembly

1) Refer to “Intercooler” in this manual.

15. Radiator Assembly

1) Install rubber cushion in under left and right part

of radiator and position radiator.

2) Fix radiator with bracket.

16. Cooling Fan Assembly

1) Install cooling fan assembly and tighten fixing

bolts to the specified torque.

Torque: 8 Nꞏm (0.8 kgꞏm/5.8 lb ft)

17. Fan Shroud

18. Radiator Hose

1) Connect upper and lower hose to engine side.

2) Pour coolant into radiator.

19. Install battery.

20. Connect window washer hose and install engine

hood.

1

2

3

4

5

F06RW054

Page 5306 of 6000

ENGINE MECHANICAL 6A – 33

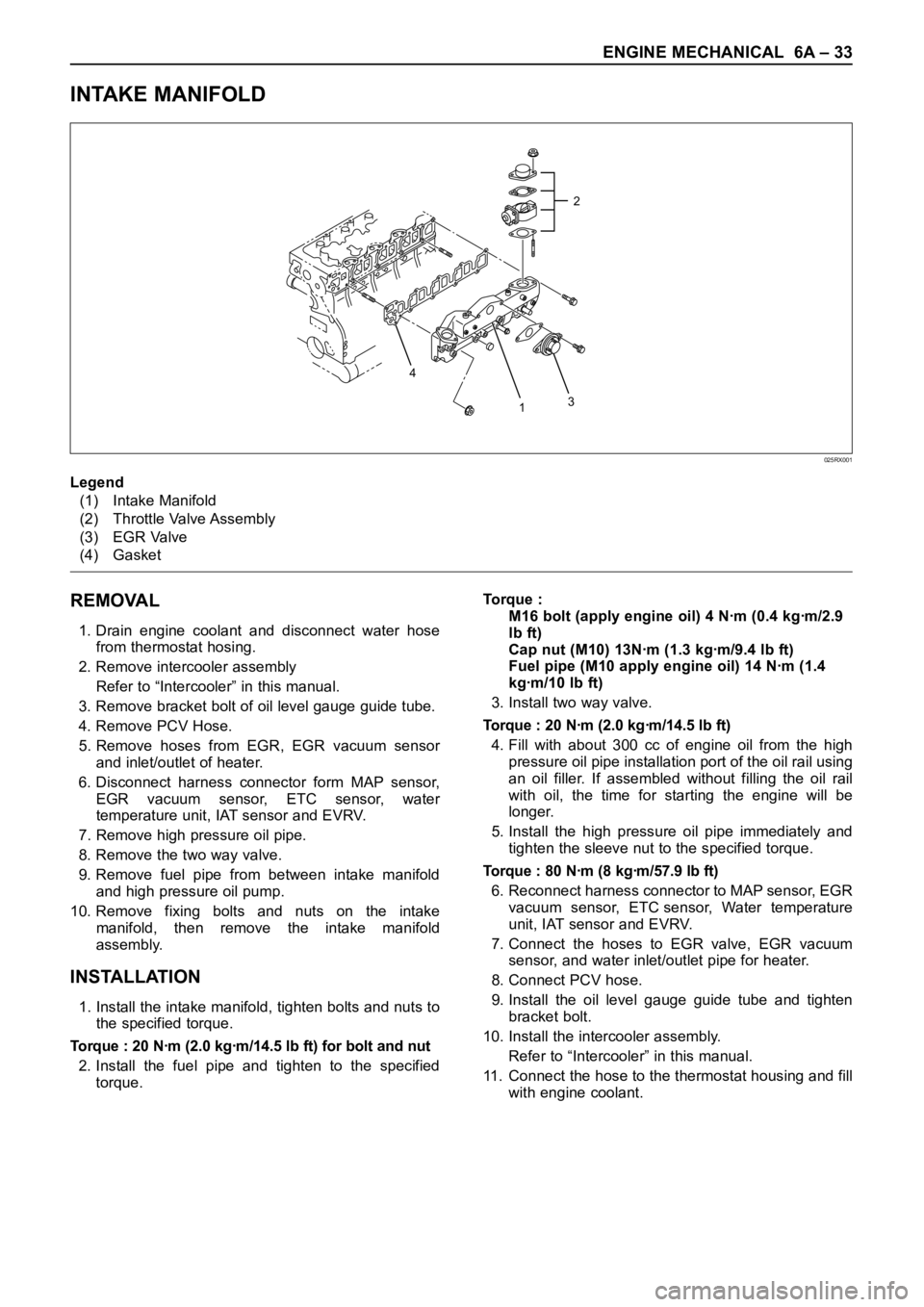

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and disconnect water hose

from thermostat hosing.

2. Remove intercooler assembly

Refer to “Intercooler” in this manual.

3. Remove bracket bolt of oil level gauge guide tube.

4. Remove PCV Hose.

5. Remove hoses from EGR, EGR vacuum sensor

and inlet/outlet of heater.

6. Disconnect harness connector form MAP sensor,

EGR vacuum sensor, ETC sensor, water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove the two way valve.

9. Remove fuel pipe from between intake manifold

and high pressure oil pump.

10. Remove fixing bolts and nuts on the intake

manifold, then remove the intake manifold

assembly.

INSTALLATION

1. Install the intake manifold, tighten bolts and nuts to

the specified torque.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for bolt and nut

2. Install the fuel pipe and tighten to the specified

torque.To r q u e :

M16 bolt (apply engine oil) 4 Nꞏm (0.4 kgꞏm/2.9

lb ft)

Cap nut (M10) 13Nꞏm (1.3 kgꞏm/9.4 lb ft)

Fuel pipe (M10 apply engine oil) 14 Nꞏm (1.4

kgꞏm/10 lb ft)

3. Install two way valve.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler. If assembled without filling the oil rail

with oil, the time for starting the engine will be

longer.

5. Install the high pressure oil pipe immediately and

tighten the sleeve nut to the specified torque.

Torque : 80 Nꞏm (8 kgꞏm/57.9 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water temperature

unit, IAT sensor and EVRV.

7. Connect the hoses to EGR valve, EGR vacuum

sensor, and water inlet/outlet pipe for heater.

8. Connect PCV hose.

9. Install the oil level gauge guide tube and tighten

bracket bolt.

10. Install the intercooler assembly.

Refer to “Intercooler” in this manual.

11. Connect the hose to the thermostat housing and fill

with engine coolant.

2

3

4

1

025RX001

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

Page 5371 of 6000

6B – 2 ENGINE COOLING

Legend

(1) Turbocharger

(2) Thermostat

(3) Reservoir Tank

(4) Radiator

(5) Bypass(6) Oil Cooler

(7) Cooling fan

(8) Water Pump

(9) Thermo Valve

(10) Car Heater

GENERAL DESCRIPTION

COOLANT FLOW

1

6

9

10

8

4

325

7

032RW001

The cooling system is a pressurized coolant forced

circulation type which consists of water pump,

thermostat, cooling fan, radiator and other components. The circulating coolant cools the lubricating oil in the oil

cooler and turbocharger.