belt OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3542 of 6000

9J1–55

RESTRAINT CONTROL SYSTEM

DTC 42 Driver Pretensioner Loop Resistance Low

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM then proceeds with the “Resistance

Measurement Test” “Driver Belt Low” terminal “22” is

grounded through a current sink and the driver current

source connected to “Driver Belt High” terminal “21”

allows a known amount of current to flow. By monitoring

the voltage difference between “Driver Belt High” and

“Driver Belt Low” the SDM calculates the combined

resistance of the driver pretensioner assembly, harness

wiring IB13–BLU/RED and IB14–BLU/YEL and

connector terminal contact.

DTC Will Set When:

The combined resistance of the driver pretensioner

assembly, harness wiring IB13–BLU/RED and

IB14–BLU/YEL and connector terminal contact is above

a specified value. This test is run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 42.

DTC Will Clear When:

The ignition switch is turned “OFF.”

DTC Chart Test Description:

Number(s) below refer to circled number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the driver seat.

4. This test checks for proper operation of the shorting

clip in the yellow 2–pin connector.

5. This test isolate the malfunction to one side of the

pretensioner assembly yellow 2–pin connector

located at the base of driver seat.

6. This test determines whether the malfunction is due

to shortening in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

between IB13–BLU/RED or IB14–BLU/YEL or a

malfunctioning shorting clip on the driver pretensioner

assembly which would require replacement of the

component. The test for this diagnostic trouble code is

Page 3544 of 6000

9J1–57

RESTRAINT CONTROL SYSTEM

DTC 44 Driver Pretensioner Loop Open

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

During “Continuous Monitoring” diagnostics, a fixed

amount of current is following in the pretensioner loop.

This produces proportional voltage drops in the loop. By

monitoring the voltage difference between “Driver Belt

High” and “Driver Belt Low”, the SDM calculates the

combined resistance of the driver pretensioner assembly,

harness wiring IB13–BLU/RED and IB14–BLU/YEL, and

connector terminal contact.

DTC Will Set When:

The voltage difference between “Driver Belt High”

terminal “21” and “Driver Belt Low” terminal “22” is above

or equal to a specified value for 500 milliseconds during

“Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The voltage difference between “Driver Belt High”

terminal “21” and “Driver Belt Low” terminal “22” is belowa specified value for 500 milliseconds during “Continuous

Monitoring”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the driver seat.

4. This test checks for proper contact and/or corrosion

of the yellow 2–pin connector at the base of the

driver seat.

5. This test isolates the malfunction to one side of the

driver pretensioner assembly yellow 2–pin

connector located at the base of driver seat.

6. This test determines whether the open is in the

wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at the driver pretensioner assembly harness

2–pin connector terminals “3” and “4” at the top of the

steering column, SDM terminals “21” and “22”, or an open

in IB13–BLU/RED and IB14–BLU/YEL.

Page 3546 of 6000

9J1–59

RESTRAINT CONTROL SYSTEM

DTC 45 Driver Pretensioner Loop Short To Ground

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltage at “Driver Belt Low”

terminal “22” and “passenger Belt Low” terminal “10” to

detect shorts to ground in the air bag assembly circuits.

DTC Will Set When:

Neither of the air bag and the pretensioner belt are open.

“Ignition 1” is within the normal operating voltage range.

This test is run once each ignition cycle and “Continuous

Monitoring”. Once these conditions are met and the

voltage at “Driver Belt Low” is below a specified value,

DTC 45 will set.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The malfunction is no longer occurring and the ignition is

turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the SDM is

malfunctioning

3. This test isolates the malfunction to one side of the

driver pretensioner assembly yellow 2–pin

connector at the base of the driver seat.

4. This test determines whether the malfunction is in

IB13–BLU/RED.

5. This test determines whether the malfunction is in

IB14–BLU/YEL.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

to ground in the driver pretensioner assembly circuit.

Inspect IB13–BLU/RED and IB14–BLU/YEL carefully for

cutting or chafing.

Page 3547 of 6000

RESTRAINT CONTROL SYSTEM 9J1–60

DTC 45 Driver Pretensioner Loop Short To Ground

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Ignition switch “OFF.”

3. Connect scan tool data link connector. follow directions as

given in the scan tool operator’s manual.

4. Ignition switch “ON.”

5. Read driver belt sense LO.

Is driver belt sense LO less than 1.5 volts?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly yellow 2–pin

connector located at base of the driver seat, leave passenger

pretensioner assembly connected.

3. Connect SRS driver / passenger load tool 5–8840–2421–0

and appropriate adapter to driver pretensioner assembly

harness connector.

4. Ignition switch “ON.”

Is DTC 45 current?

Go to Step 4Go to Step 6

41. Ignition switch “OFF.”

2. Disconnect SDM.

3. Disconnect SRS driver / passenger load tool.

4. Measure resistance on SDM harness connector “21” to

terminal “6” (ground).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Step 5

Replace SRS

harness or repair

chassis harness

Go to Step 6

5Measure resistance on SDM harness connector from terminal

“22” to terminal “6” (ground).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Chart A

Replace SRS

harness or repair

chassis harness

Go to Step 6

61. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 6

Page 3548 of 6000

9J1–61

RESTRAINT CONTROL SYSTEM

DTC 46 Driver Pretensioner Loop Short To Voltage

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

pretensioner loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltage at “Driver Belt Low”

terminal “22” and “Passenger Belt Low” terminal “10” to

detect shorts to B+ in the pretensioner assembly circuits.

DTC Will Set When:

“Ignition 1” is in the normal operating voltage range. This

test is run once each ignition cycle and “Continuous

monitoring”. Once these conditions are met and the

voltage at “Driver Belt Low” is above a specified value,

DTC 46 will set.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 46.

DTC Will Clear When:

The malfunction is no longer occurring and the ignition is

turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the SDM is

malfunctioning.

3. This test isolates the malfunction to one side of the

driver pretensioner assembly yellow 2–pin

connector at the base of the driver seat.

4. This test determines whether the malfunction is in

IB13–BLU/RED.

5. This test determines whether the malfunction is in

IB14–BLU/YEL.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

to B+ in the driver pretensioner assembly circuit. Inspect

IB13–BLU/RED and IB14–BLU/YEL carefully for cutting

or chafing. If the wiring pigtail of the driver pretensioner

assembly is damaged, the components must be

replaced. A careful inspection of IB13–BLU/RED and

IB14–BLU/YEL, including the driver pretensioner

assembly is essential to ensure that the replacement

SDM will not be damaged.

Page 3549 of 6000

RESTRAINT CONTROL SYSTEM 9J1–62

DTC 46 Driver Pretensioner Loop Short To Ignition

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

Ignition switch “OFF.”

Connect scan tool data link connector. follow directions as

given in the scan tool operator’s manual.

2. Ignition switch “ON.”

3. Read driver belt sense LO .

Is driver belt sense LO more than 3.5 volts?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly yellow 2–pin

connector at the base of the driver seat, leave passenger

pretensioner assembly connected.

3. Connect SRS driver /passenger load tool 5–8840–2421–0 and

appropriate adapter to driver pretensioner assembly harness

connector.

4. Ignition switch “ON.”

Is DTC 46 current?

Go to Step 4

Ignition switch

“OFF”

Replace driver

pretensioner

assembly

Go to Step 6

41. Ignition switch “OFF.”

2. Disconnect SDM.

3. Disconnect SRS driver /passenger load tool.

4. Measure resistance on SDM harness connector “21” to

terminal “12” (ignition).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Step 5

Replace SRS

harness or repair

chassis harness

Go to Step 6

5Measure resistance on SDM harness connector from terminal

“22” to terminal “12” (ignition).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Chart A

Replace SRS

harness or repair

chassis harness

Go to Step 6

61. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 6

Page 3550 of 6000

9J1–63

RESTRAINT CONTROL SYSTEM

DTC 52 Pretensioner Deployment Event Commanded

D09RW014

Circuit Description:

The SDM contains a sensing device which converts

vehicle velocity changes to an electrical signal. The

electrical signal generated is processed by the SDM and

then compared to a value stored in memory. When the

generated signal exceeds the stored value, the SDM will

cause current to flow through the pretensioner assembly

deploying the pretensioners and causing DTC 52 to set.

DTC Will Set When:

The SDM detects a frontal crash, up to 30 degrees off the

centerline of the vehicle, of sufficient force to warrant

deployment of the air bags and pretensioner seat belt.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp records

“Crash Data”, and sets a diagnostic trouble code.

DTC Will Clear When:

The SDM is replaced.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If pretensioner assembly (s) has not deployed, DTC

52 may have falsely set.

3. If DTC 52 has set with no signs of frontal impact, the

diagnostic trouble code has falsely set.

Page 3570 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

9A SEAT BELT SYSTEM

9J SUPPLEMENTAL RESTRAINT SYSTEM

9J1 RESTRAINT CONTROL SYSTEM

HOME

9A

9J

9J1

Page 3783 of 6000

6. Remove any excess oil resulting from installing the

new seal parts from the shaft and inside the

compressor neck.

7. Install the clutch plate and hub assembly as

described previously.8. Reinstall compressor belt and tighten bracket.

9. Evacuate and charge the refrigerant system.

COMPRESSOR PRESSURE RELIEF VALVE

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Remove old pressure relief valve.

Installation

1. Clean valve seat area on rear head.2. Lubricate O-ring of new pressure relief valve and

O-ring assembly with new 525 viscosity refrigerant

oil. Install new valve and torque in place, 9.0 Nꞏm

(6.1 ft lbs)

3. Evacuate and recharge the system.

4. Leak test system.

COMPRESSOR OIL

Compressor Oil Check

The oil used to lubricate the compressor is circulating

with the refrigerant.

Whenever replacing any component of the system or a

large amount of gas leakage occurs, add oil to maintain

the original amount of oil.

Checking and Adjusting Oil Quantity for

Used Compressor

1. Perform oil return operation. Refer to Oil Return

Operation in this section.

2. Discharge and recover refrigerant and remove the

compressor.

3. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

4. If the amount of oil drained is much less than 90 cc

(3.0 fl. oz.), some refrigerant may have leaked out.

Conduct a leak tests on the connections of each

system, and if necessary, repair or replace faulty

parts.

5. Check the compressor oil contamination. (Refer to

Contamination of Compressor Oil in this section.)

6. Adjust the oil level following the next procedure

below.7. Install the compressor, then evacuate, charge and

perform the oil return operation.

8. Check system operation.

When it is impossible to preform oil return

operation, the compressor oil should be checked in

the following order:

1. Discharge and recover refrigerant and remove the

compressor.

2. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

3. Check the oil for contamination.

4. If more than 90 cc (3.0 fl. oz.) of oil is extracted from

the compressor, supply the same amount of oil to

the compressor to be installed. If the amount of oil

extracted is less than 90 cc (3.0 fl. oz.), recheck the

compressor oil in the following order:

5. Supply 90 cc (3.0 fl. oz.) of oil to the compressor

and install it onto the vehicle.

6. Evacuate and recharge with the proper amount of

refrigerant.

7. Perform the oil return operation.

8. Remove the compressor and recheck the amount of

oil.

9. Adjust the compressor oil, if necessary.

Checking and Adjusting for Compressor

Replacement

The oil is not charged in compressor (service parts). So

it is necessary to charge the proper amount of oil to the

new compressor. (Oil Capacity)

Capacity total in system 150 cc (5.0 fl.oz)

Compressor (Service 150 cc (5.0 fl.oz)

parts) charging amount

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 4309 of 6000

4D2–2

TRANSFER CASE (TOD)

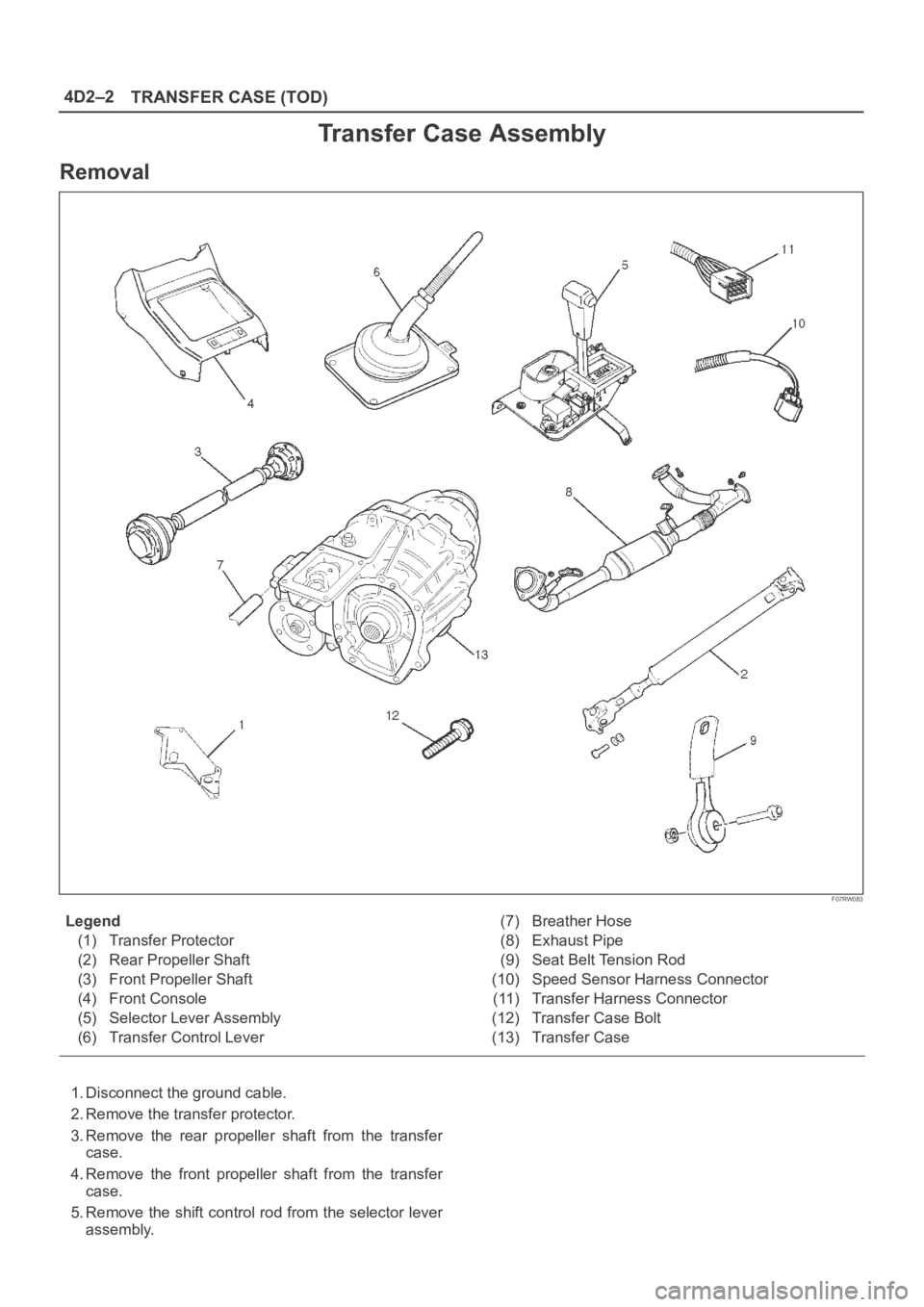

Transfer Case Assembly

Removal

F07RW083

Legend

(1) Transfer Protector

(2) Rear Propeller Shaft

(3) Front Propeller Shaft

(4) Front Console

(5) Selector Lever Assembly

(6) Transfer Control Lever(7) Breather Hose

(8) Exhaust Pipe

(9) Seat Belt Tension Rod

(10) Speed Sensor Harness Connector

(11) Transfer Harness Connector

(12) Transfer Case Bolt

(13) Transfer Case

1. Disconnect the ground cable.

2. Remove the transfer protector.

3. Remove the rear propeller shaft from the transfer

case.

4. Remove the front propeller shaft from the transfer

case.

5. Remove the shift control rod from the selector lever

assembly.