warning OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3499 of 6000

RESTRAINT CONTROL SYSTEM 9J1–12

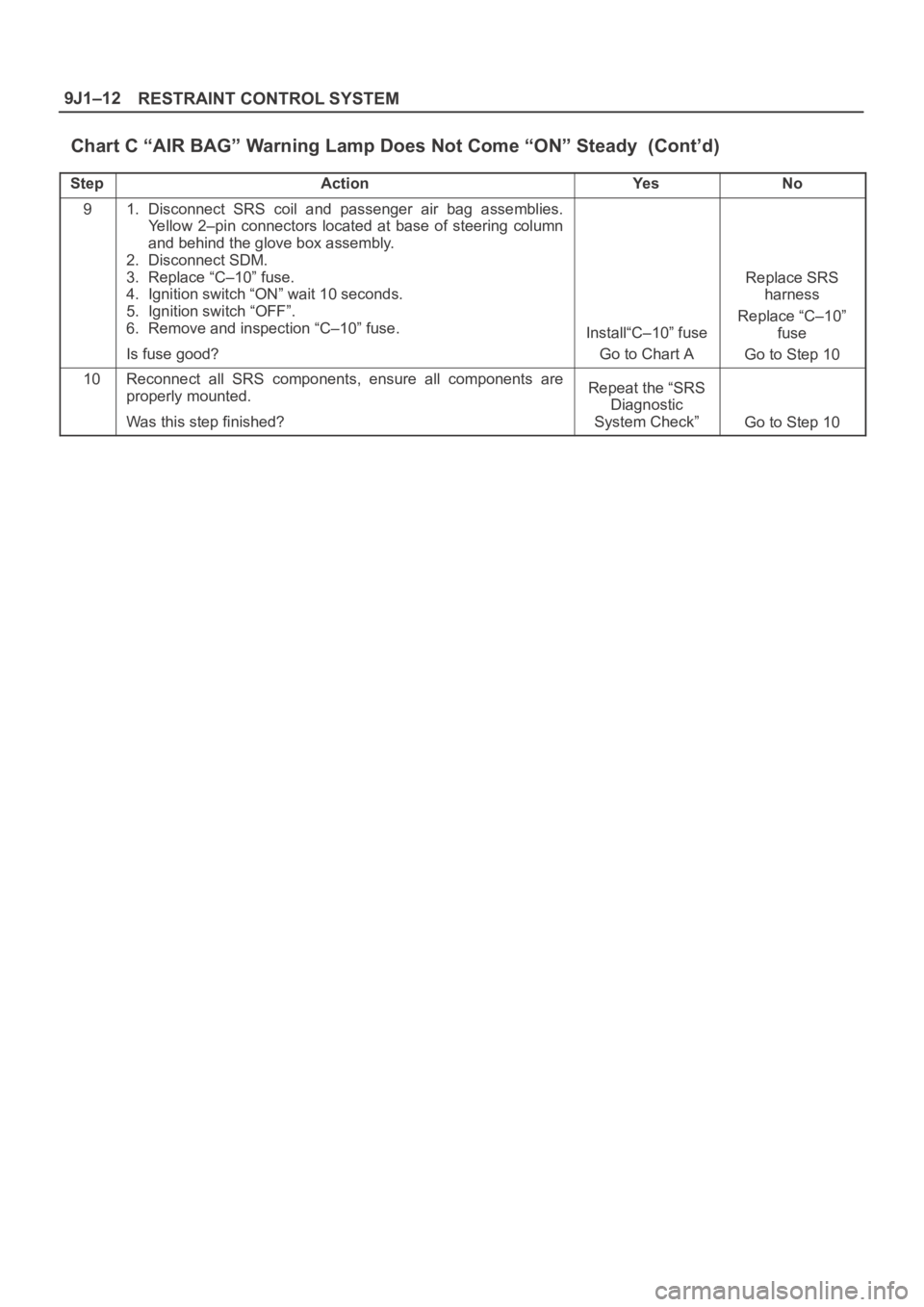

Chart C “AIR BAG” Warning Lamp Does Not Come “ON” Steady (Cont’d)

StepNo Ye s Action

91. Disconnect SRS coil and passenger air bag assemblies.

Yellow 2–pin connectors located at base of steering column

and behind the glove box assembly.

2. Disconnect SDM.

3. Replace “C–10” fuse.

4. Ignition switch “ON” wait 10 seconds.

5. Ignition switch “OFF”.

6. Remove and inspection “C–10” fuse.

Is fuse good?

Install“C–10” fuse

Go to Chart A

Replace SRS

harness

Replace “C–10”

fuse

Go to Step 10

10Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the “SRS

Diagnostic

System Check”

Go to Step 10

Page 3500 of 6000

9J1–13

RESTRAINT CONTROL SYSTEM

DTC 15 Passenger Deployment Loop Resistance High

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges. The

SDM then proceeds with the “Resistance Measurement

Test”. “Passenger Bag Low” terminal “16” is grounded

through a resister and the passenger current source

connected to “Passenger Bag High” terminal “15” allows a

known amount of current to flow. By monitoring the

voltage difference between “Passenger Bag High” and

“Passenger Bag Low” the SDM calculates the combined

resistance of the passenger air bag assembly, harness

wiring IB07–YEL/GRN and IB08–YEL/RED connector

terminal contact.

DTC Will Set When:

The combined resistance of the passenger air bag

assembly, harness wiring IB07–YEL/GRN and

IB08–YEL/RED, and connector terminal contact is above

a specified value. This test is run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”,

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The ignition switch is turned “OFF.”

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector.

4. This test checks for proper contact and/or corrosion

of the yellow 2–pin connector terminals.

5. The test checks for a malfunctioning passenger air

bag assembly.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at the passenger air bag assembly harness

connector terminals “1” and “2”, SDM terminal “15” and

“16”, or a poor wire to terminal connection in

IB07–YEL/GRN and IB08–YEL/RED. This test for this

diagnostic trouble code is only run while the “AIR BAG”

Page 3501 of 6000

RESTRAINT CONTROL SYSTEM 9J1–14

warning lamp is performing the bulb check, unless DTC

17 or DTC 26 is detected. When a scan tool “Clear

Codes” command is issued and the malfunction is stillpresent, the DTC will not reappear until the next ignition

cycle.

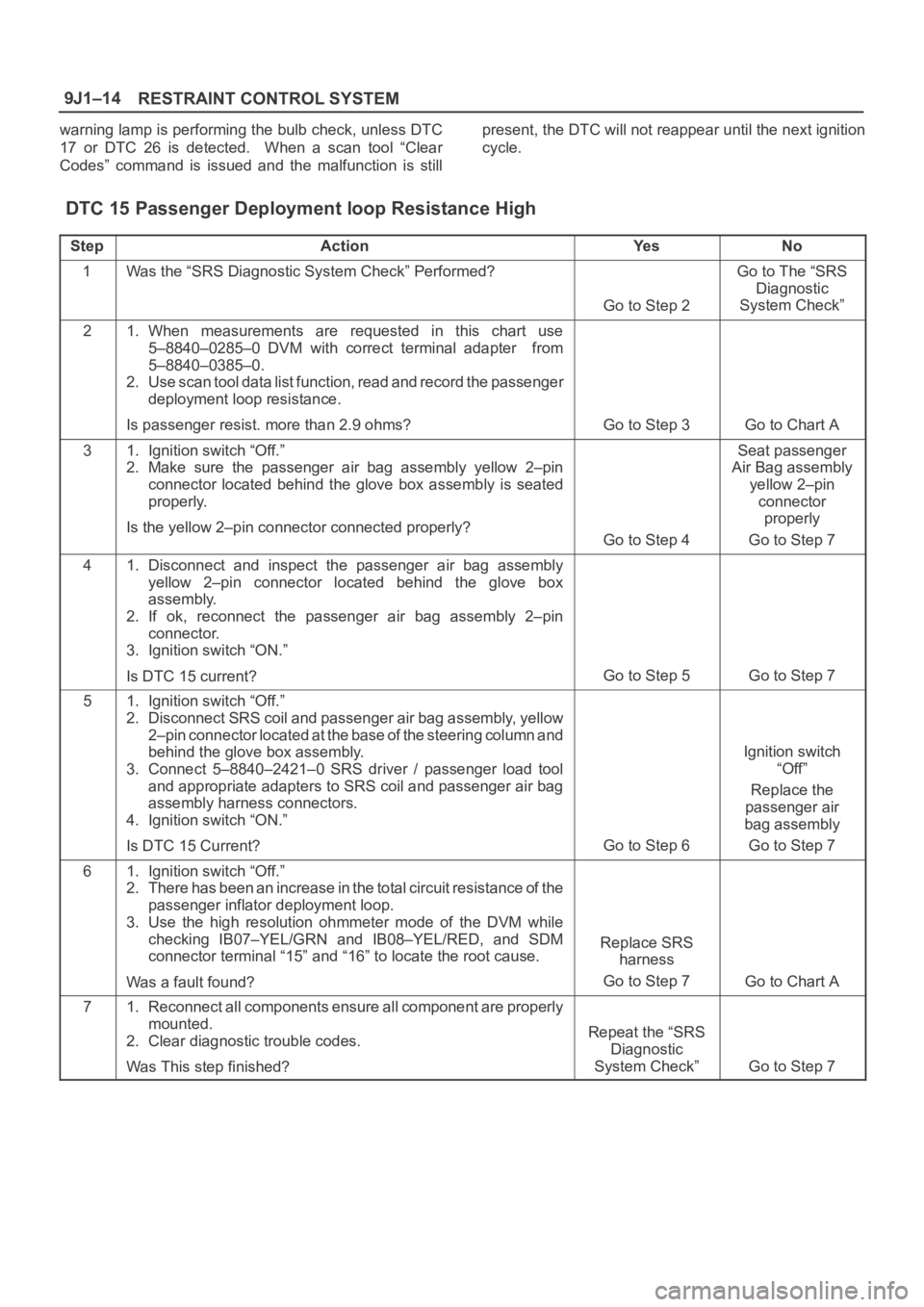

DTC 15 Passenger Deployment loop Resistance High

StepActionYe sNo

1Was the “SRS Diagnostic System Check” Performed?

Go to Step 2

Go to The “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Use scan tool data list function, read and record the passenger

deployment loop resistance.

Is passenger resist. more than 2.9 ohms?

Go to Step 3Go to Chart A

31. Ignition switch “Off.”

2. Make sure the passenger air bag assembly yellow 2–pin

connector located behind the glove box assembly is seated

properly.

Is the yellow 2–pin connector connected properly?

Go to Step 4

Seat passenger

Air Bag assembly

yellow 2–pin

connector

properly

Go to Step 7

41. Disconnect and inspect the passenger air bag assembly

yellow 2–pin connector located behind the glove box

assembly.

2. If ok, reconnect the passenger air bag assembly 2–pin

connector.

3. Ignition switch “ON.”

Is DTC 15 current?

Go to Step 5Go to Step 7

51. Ignition switch “Off.”

2. Disconnect SRS coil and passenger air bag assembly, yellow

2–pin connector located at the base of the steering column and

behind the glove box assembly.

3. Connect 5–8840–2421–0 SRS driver / passenger load tool

and appropriate adapters to SRS coil and passenger air bag

assembly harness connectors.

4. Ignition switch “ON.”

Is DTC 15 Current?

Go to Step 6

Ignition switch

“Off”

Replace the

passenger air

bag assembly

Go to Step 7

61. Ignition switch “Off.”

2. There has been an increase in the total circuit resistance of t h e

passenger inflator deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking IB07–YEL/GRN and IB08–YEL/RED, and SDM

connector terminal “15” and “16” to locate the root cause.

Was a fault found?

Replace SRS

harness

Go to Step 7

Go to Chart A

71. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was This step finished?

Repeat the “SRS

Diagnostic

System Check”

Go to Step 7

Page 3502 of 6000

9J1–15

RESTRAINT CONTROL SYSTEM

DTC 16 Passenger Deployment loop Resistance Low

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges. The

SDM then proceeds with the “Resistance Measurement

Test”. “Passenger Bag Low” terminal “16” is grounded

through a resistor and the passenger current source

connected to “Passenger Bag High” terminal “15” allows a

known amount of current to flow. By monitoring the

voltage difference between “Passenger Bag High” and

“Passenger Bag Low”, the SDM calculates the combined

resistance of the passenger air bag assembly, harness

wiring IB07–YEL/GRN and IB08–YEL/RED connector

terminal contact.

DTC Will Set When:

The combined resistance of the passenger air bag

assembly, harness wiring IB07–YEL/GRN and

IB08–YEL/RED, and connector terminal contact is above

a specified value. This test is run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”,

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The ignition switch is turned “OFF.”

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies connection of the yellow 2–pin

connector.

4. This test cheeks for proper operation of the shorting

clip in the yellow 2–pin connector.

5. The test checks for a malfunction passenger air bag

assembly.

6. This test determines whether the malfunctioning is

due to shortening in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

between IB07–YEL/GRN and IB08–YEL/RED, or a

malfunctioning shorting clip on the passenger air bag

assembly which would require replacement of the air bag

assembly. The test for this diagnostic trouble code is only

run while “AIR BAG” warning lamp is performing the bulb

Page 3504 of 6000

9J1–17

RESTRAINT CONTROL SYSTEM

DTC 17 Passenger Deployment Loop Open

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges. During

“Continuous Monitoring” diagnostics, a fixed amount of

current is flowing in the deployment loop. This produces

proportional voltage drops in the loop. By monitoring the

voltage difference between “Passenger Bag High” and

“Passenger Bag Low”, the SDM calculates the combined

resistance of the passenger air bag assembly, harness

wiring IB07–YEL/GRN AND IB08–YEL/RED, and

connector terminal contact.

DTC Will Set When:

The voltage difference between “Passenger Bag High”

terminal “15” and “Passenger Bag Low” terminal “16” is

above or equal to a specified value for 500 milliseconds

during “Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The voltage difference between “Passenger Bag High”

terminal “15” and “Passenger Bag Low” terminal “16” is

below a specified value for 500 milliseconds during

“Continuous Monitoring”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector.

4. This test cheeks for proper contact and/or corrosion

of the shorting clip in the yellow 2–pin connector

terminals.

5. The test checks for a malfunctioning passenger air

bag assembly.

6. This test determines whether the open in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at the passenger air bag assembly harness

connector terminals“2” and “3”, SDM terminals “15” and

“16”, or an open in IB07–YEL/GRN and IB08–YEL/RED.

Page 3506 of 6000

9J1–19

RESTRAINT CONTROL SYSTEM

DTC 18 Passenger Deployment Loop Short To Ground

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltages at “Driver Bag Low”

terminal “4” and “Passenger Bag Low” terminal “16” to

detect short to ground in the air bag assembly circuits.

DTC Will Set When:

Neither of the two air bag assemblies is open.

“Ignition 1” is within the normal operating voltage range.

Once these conditions are met and the voltage at

“Passenger Bag Low” is below a specified value, DTC 18

will set. This test is run once each ignition cycle and

“Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

This malfunction is no longer occurring and the ignition

switch is turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to circled number(s) on the

diagnostic chart.

2. This test determines whether the SDM is

malfunctioning.

3. This test isolates the malfunction to one side of the

passenger air bag assembly yellow 2–pin connector

behind glove box assembly.

4. This test determines whether the malfunction is in

IB07–YEL/GRN.

5. This test determines whether the malfunction is in

IB08–YEL/RED.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

to ground in the passenger air bag assembly circuit.

Inspect IB07–YEL/GRN and IB08–YEL/RED carefully for

cutting or chafing. If the wiring pigtail of the passenger air

bag assembly is damaged, the component must be

replaced.

Page 3508 of 6000

9J1–21

RESTRAINT CONTROL SYSTEM

DTC 19 Passenger Deployment Loop Short To B+

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltages at “Driver Bag Low”

terminal “4” and “Passenger Bag Low” terminal “16” to

detect short to B+ in the air bag assembly circuits.

DTC Will Set When:

“Ignition 1” is within the normal operating voltage range.

Once these conditions are met and the voltage at

“Passenger Bag Low” is above a specified value, DTC 19

will set. This test is run once each ignition cycle and

“Continuous Monitoring”.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 19 and also DTC 71.

DTC Will Clear When:

The SDM is replaced.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test isolates the malfunction to one side of the

passenger air bag assembly yellow 2–pin connector

behind glove box assembly.

4. This test determines whether the malfunction is in

IB07–YEL/GRN.

5. This test determines whether the malfunction is in

IB08–YEL/RED.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

to B+ in the passenger air bag assembly circuit. Inspect

IB07–YEL/GRN and IB08–YEL/RED carefully for cutting

or chafing. If the wiring pigtail of the passenger air bag

assembly is damaged, the component must be replaced.

A careful inspection of IB07–YEL/GRN and

IB08–YEL/RED, including the passenger air bag

assembly pigtail is essential to ensure that the

replacement SDM will not be damaged.

Page 3510 of 6000

9J1–23

RESTRAINT CONTROL SYSTEM

DTC 21 Driver Deployment Loop Resistance High

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM then proceeds with the “Resistance

Measurement Test” “Driver Bag Low” terminal “4” is

grounded through a current sink and the driver current

source connected to “Driver Bag High” terminal “3” allows

a known amount of current to flow. By monitoring the

voltage difference between “Driver Bag High” and “Driver

Bag Low”, the SDM calculates the combined resistance

of the driver air bag assembly, SRS coil assembly,

harness wiring IB05–YEL and IB06–YEL/BLK, and

connector terminal contact.

DTC Will Set When:

The combined resistance of the driver air bag assembly,

SRS Coil assembly, harness wiring IB05–YEL and

IB06–YEL/BLK, and connector terminal contact is above

a specified value. This test run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 21.

DTC Will Clear When:

The ignition switch is turned “OFF”.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the steering column.

4. This test checks for proper contact and/or corrosion

of the 2–pin connector terminals at the base of

steering column.

5. This test isolate the malfunction to one side of the

SRS coil assembly yellow 2–pin connector located

at the base of the steering column.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

7. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Page 3511 of 6000

RESTRAINT CONTROL SYSTEM 9J1–24

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at terminals “1” and “2” of the SRS coil 2–pin

connector at the base of the steering column, terminal “1”

and “2” of the driver air bag assembly 2–pin connector at

the top of the steering column, SDM terminals “3” and “4”

or a poor wire to terminal connection in IB05–YEL orIB06–YEL/BLK. The test for this diagnostic trouble code

is only run while the “AIR BAG” warning lamp is

performing the bulb check, unless DTC 17 or DTC 26 is

detected. When a scan tool “Clear Codes” command is

issued and the malfunction is still present, the DTC will not

reappear until the next ignition cycle.

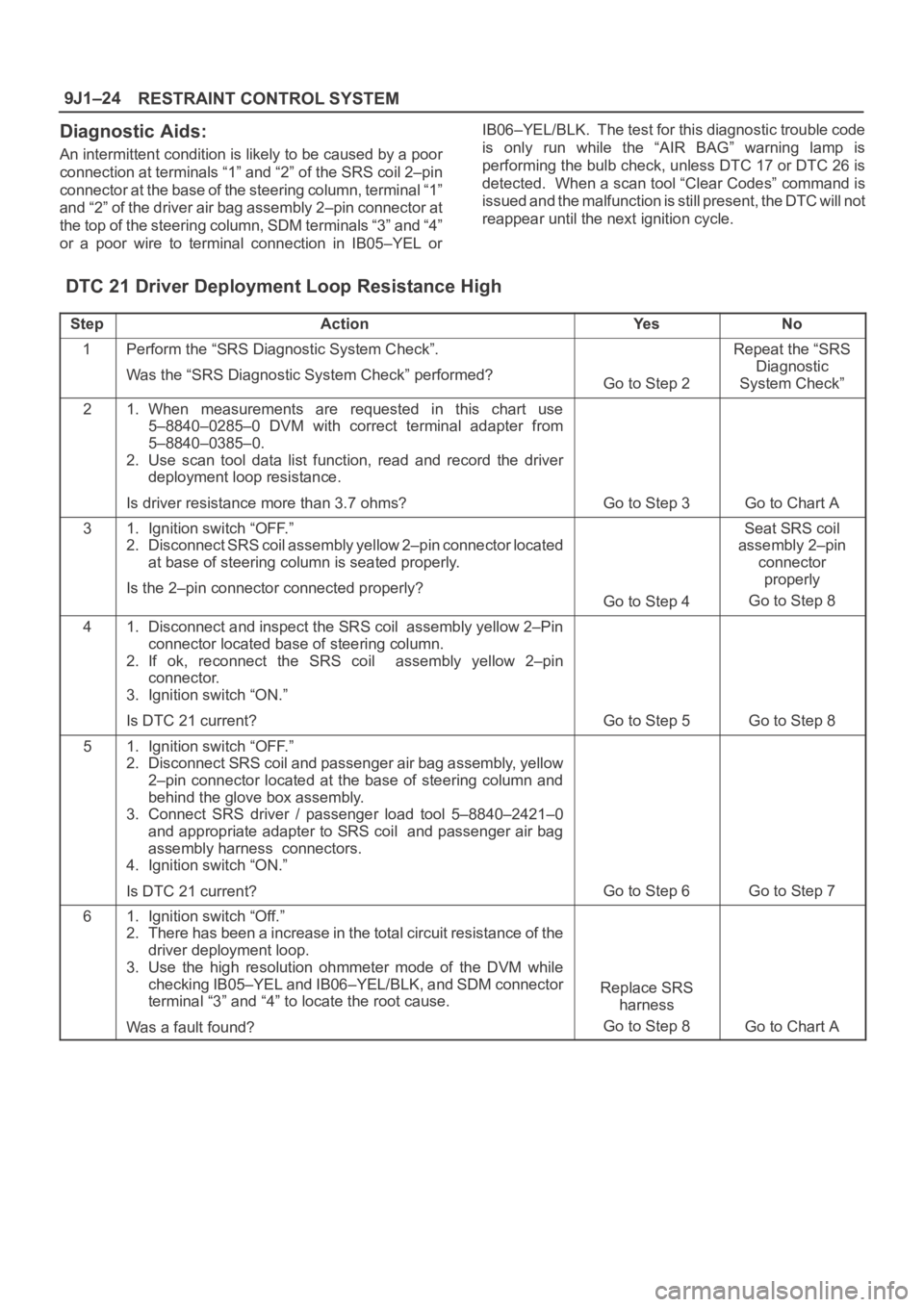

DTC 21 Driver Deployment Loop Resistance High

StepActionYe sNo

1Perform the “SRS Diagnostic System Check”.

Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Repeat the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Use scan tool data list function, read and record the driver

deployment loop resistance.

Is driver resistance more than 3.7 ohms?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect SRS coil assembly yellow 2–pin connector located

at base of steering column is seated properly.

Is the 2–pin connector connected properly?

Go to Step 4

Seat SRS coil

assembly 2–pin

connector

properly

Go to Step 8

41. Disconnect and inspect the SRS coil assembly yellow 2–Pin

connector located base of steering column.

2. If ok, reconnect the SRS coil assembly yellow 2–pin

connector.

3. Ignition switch “ON.”

Is DTC 21 current?

Go to Step 5Go to Step 8

51. Ignition switch “OFF.”

2. Disconnect SRS coil and passenger air bag assembly, yellow

2–pin connector located at the base of steering column and

behind the glove box assembly.

3. Connect SRS driver / passenger load tool 5–8840–2421–0

and appropriate adapter to SRS coil and passenger air bag

assembly harness connectors.

4. Ignition switch “ON.”

Is DTC 21 current?

Go to Step 6Go to Step 7

61. Ignition switch “Off.”

2. There has been a increase in the total circuit resistance of the

driver deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking IB05–YEL and IB06–YEL/BLK, and SDM connector

terminal “3” and “4” to locate the root cause.

Was a fault found?

Replace SRS

harness

Go to Step 8

Go to Chart A

Page 3513 of 6000

RESTRAINT CONTROL SYSTEM 9J1–26

DTC 22 Driver Deployment Loop Resistance Low

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests “Ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM then proceeds with the “Resistance

Measurement Test” “Driver Bag Low” terminal “4” is

grounded through a current sink and the driver current

source connected to “Driver Bag High” terminal “3” allows

a known amount of current to flow. By monitoring the

voltage difference between “Driver Bag High” and “Driver

Bag Low” the SDM calculates the combined resistance of

the driver air bag assembly, SRS coil assembly, harness

wiring IB05–YEL and IB06–YEL/BLK and connector

terminal contact.

DTC Will Set When:

The combined resistance of the driver air bag assembly,

SRS Coil assembly, harness wiring IB05–YEL and

IB06–YEL/BLK and connector terminal contact is above a

specified value. This test is run once each ignition cycle

during the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during

“Turn–ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 22.

DTC Will Clear When:

The ignition switch is turned “OFF.”

DTC Chart Test Description:

Number(s) below refer to circled number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2–pin connector at the base of the steering column.

4. This test checks for proper operation of the shorting

clip in the yellow 2–pin connector.

5. This test isolate the malfunction to one side of the

SRS coil assembly yellow 2–pin connector located

at the base of steering column.

6. This test determines whether the malfunction is due

to shortening in the wiring.

7. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Diagnostic Aids:

An intermittent condition is likely to be caused by a short

between IB05–YEL or IB06–YEL/BLK or a