Back OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2586 of 6000

ENTERTAINMENT8C–3

Digital Clock

Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover

assembly(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

5. Remove the instrument panel cluster assembly(4).

Refer to the Instrument Panel Assembly in Body

Structure section.

6. Disconnect the connector and push the lock from the

back side of the instrument panel cluster assembly to

remove the digital clock(5).

821RW034

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Push in the switch with your fingers until it locks

securely.

Page 2601 of 6000

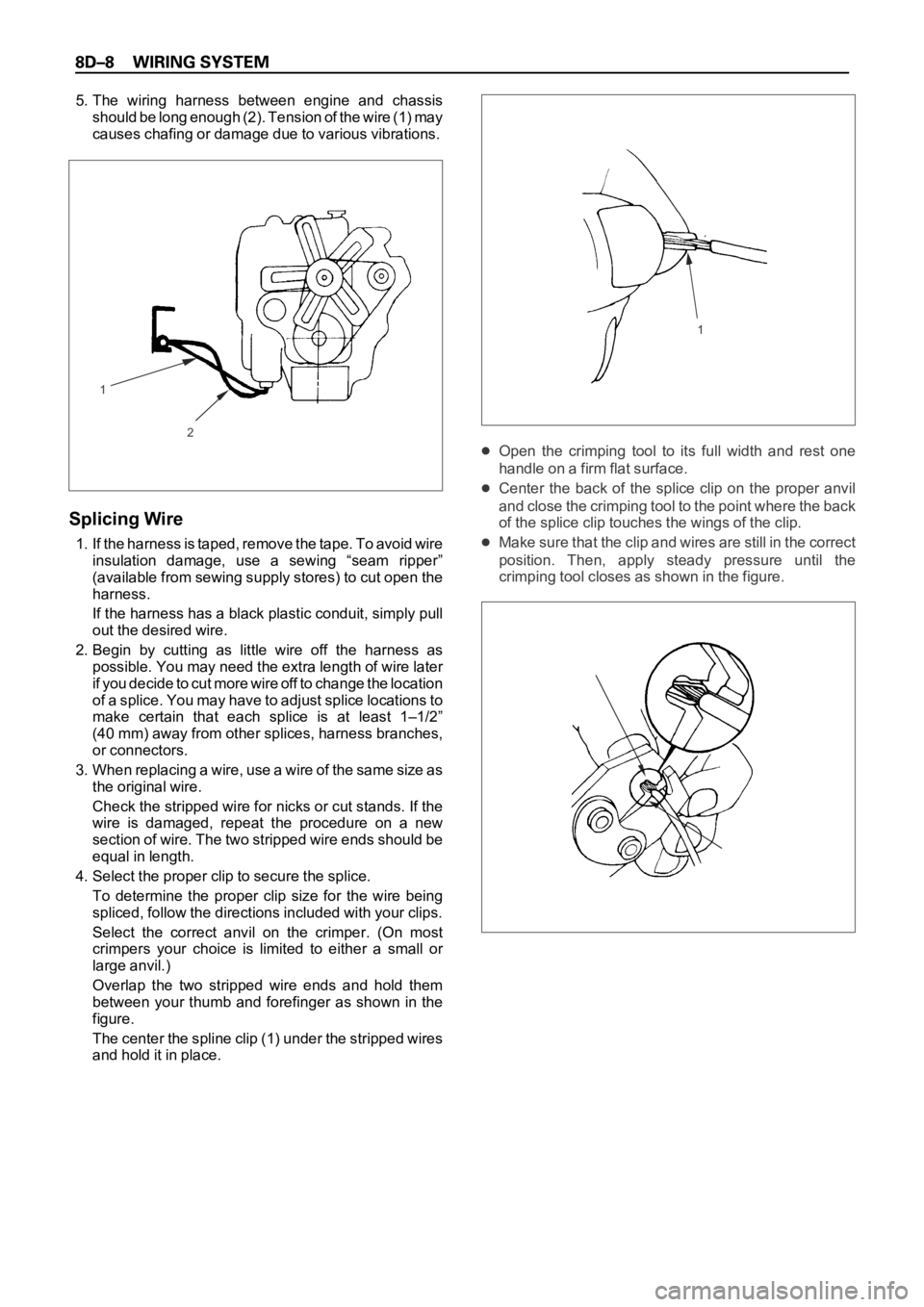

5. The wiring harness between engine and chassis

should be long enough (2). Tension of the wire (1) may

causes chafing or damage due to various vibrations.

Splicing Wire

1. If the harness is taped, remove the tape. To avoid wire

insulation damage, use a sewing “seam ripper”

(available from sewing supply stores) to cut open the

harness.

If the harness has a black plastic conduit, simply pull

out the desired wire.

2. Begin by cutting as little wire off the harness as

possible. You may need the extra length of wire later

if you decide to cut more wire off to change the location

of a splice. You may have to adjust splice locations to

make certain that each splice is at least 1–1/2”

(40 mm) away from other splices, harness branches,

or connectors.

3 . W h e n r e p l a c i n g a w i r e , u s e a w i r e o f t h e s a m e s i z e a s

the original wire.

Check the stripped wire for nicks or cut stands. If the

wire is damaged, repeat the procedure on a new

section of wire. The two stripped wire ends should be

equal in length.

4. Select the proper clip to secure the splice.

To determine the proper clip size for the wire being

spliced, follow the directions included with your clips.

Select the correct anvil on the crimper. (On most

crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them

between your thumb and forefinger as shown in the

figure.

The center the spline clip (1) under the stripped wires

and hold it in place.

Open the crimping tool to its full width and rest one

handle on a firm flat surface.

Center the back of the splice clip on the proper anvil

and close the crimping tool to the point where the back

of the splice clip touches the wings of the clip.

Make sure that the clip and wires are still in the correct

position. Then, apply steady pressure until the

crimping tool closes as shown in the figure.

2

11

Page 2602 of 6000

Before crimping the ends of the clip (1), be sure that:

The wires extend beyond the clip in each direction.

No strands of wire are cut loose, and

No insulation is caught under the clip.

Crimp the splice again, once on each end.

Does not let the crimping tool (2) extend beyond the edge

of the clip or you may damage or nick the wires as shown

in the figure.

5. Apply 60/40 resin core solder to the opening in the

back of the clip as shown in the figure.

Follow the manufacturer’s instructions for the solder

equipment you are using.6. Center and roll the splicing tape.

The tape should cover the entire splice.

Roll on enough tape (1) to duplicate the thickness of

the insulation on the existing wires.

Does not flag the tape (2). Flagged tape may not

provide enough insulation, and the flagged ends will

tangle with the other wires in the harness as shown in

the figure.

If the wire does not belong in a conduit or other

harness covering, tape the wire again. use a winding

motion to cover the first piece of tape as shown in the

figure.

1

2

12

Page 2650 of 6000

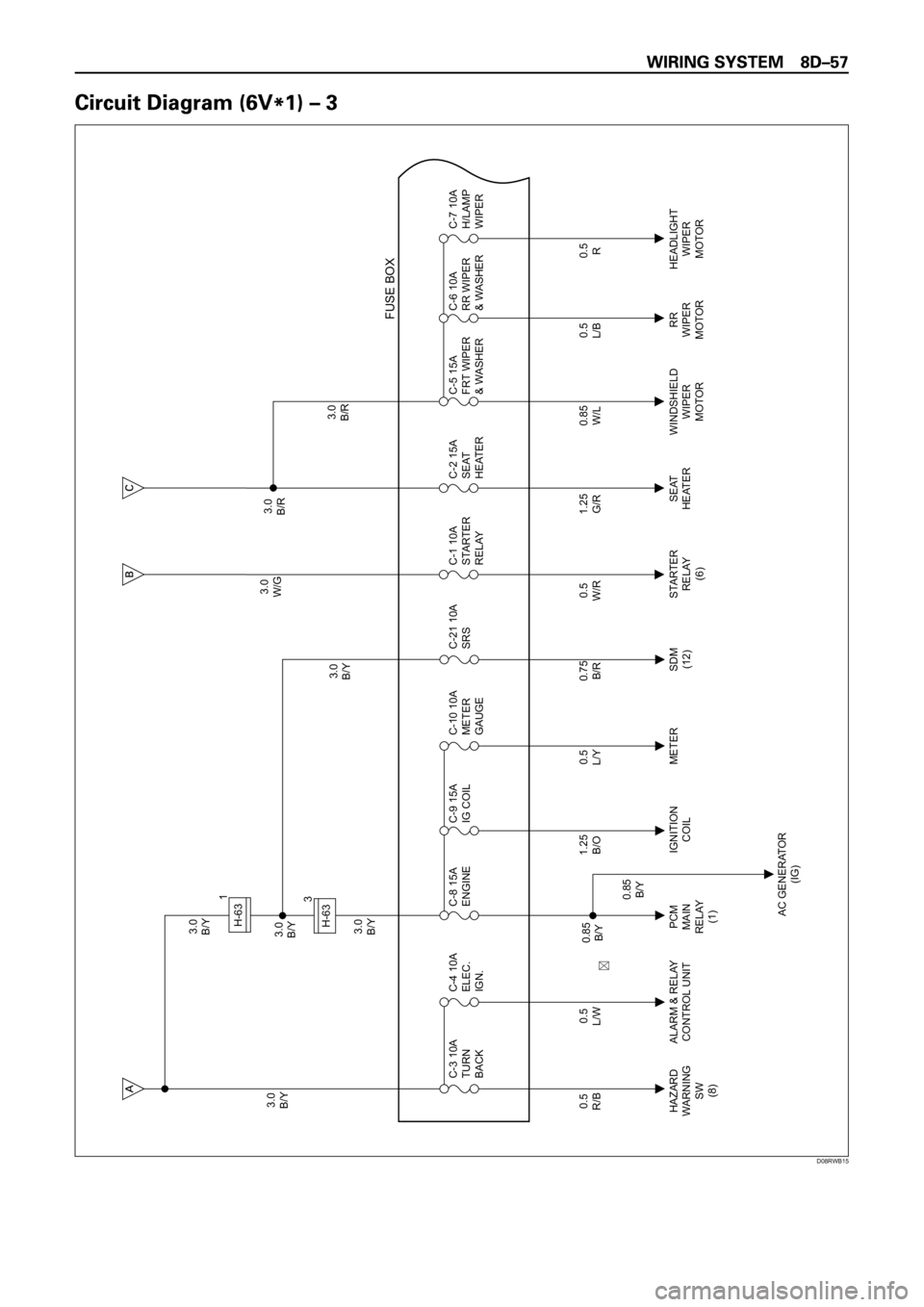

3.0

B/Y3.0

B/Y

3.0

B/Y3.0

B/Y3.0

W/G3.0

B/R

3.0

B/R 3.0

B/Y

0.5

R/B

HAZARD

WARNING

SW

(8)PCM

MAIN

RELAY

(1)IGNITION

COILMETER STARTER

RELAY

(6)SEAT

HEATERWINDSHIELD

WIPER

MOTORRR

WIPER

MOTORHEADLIGHT

WIPER

MOTOR

AC GENERATOR

(IG) ALARM & RELAY

CONTROL UNIT C-3 10A

TURN

BACK

0.5

L/WC-4 10A

ELEC.

IGN.

0.5

L/YC-10 10A

METER

GAUGE

0.5

W/RC-1 10A

STARTER

RELAY

0.85

W/LC-5 15A

FRT WIPER

& WASHERC-6 10A

RR WIPER

& WASHERC-7 10A

H/LAMP

WIPER

FUSE BOX

1.25

B/OC-9 15A

IG COIL C-8 15A

ENGINE

0.5

L/B

0.85

B/Y

0.85

B/Y

0.5

R

0.75

B/R

SDM

(12)C-21 10A

SRS

1.25

G/RC-2 15A

SEAT

HEATER

H-631

3

H-63

��

D08RWB15

Page 2658 of 6000

3.0

B/Y3.0

B/Y

3.0

B/Y3.0

B/Y3.0

W/G3.0

B/R

3.0

B/R 3.0

B/Y

0.5

R/B

HAZARD

WARNING

SW

(8)C-3 10A

TURN

BACK

0.5

L/WC-4 10A

ELEC.

IGN.

0.5

L/Y

METER ECM

(J2-9) ALARM & RELAY��

C O NTR O L UNITC-10 10A

METER

GAUGE

0.5

W/R

STARTER

RELAY

(6)C-1 10A

STARTER

RELAY

0.85

W/L

WINDSHIELD

WIPER

MOTORC-5 15A

FRT WIPER

& WASHERC-6 10A

RR WIPER

& WASHERC-7 10A

H/LAMP

WIPER

FUSE BOX

C-8 15A

ENGINE

0.5

L/B

RR

WIPER

MOTORHEADLIGHT

WIPER

MOTOR

0.85

B/Y

0.5

R

0.75

B/R

SDM

(12)C-21 10A

SRS

1.25

G/R

SEAT

HEATERC-2 15A

SEAT

HEATER

H-631

3

H-63

��

D08RWB20

Page 2682 of 6000

3.0

B/Y

C-3 10A

TURN, BACKC-1 10A

STARTER RELAYSTARTER SW

(IG1)EHCU : ELECTRONIC HYDRAULIC CONTROL UNIT

PCM : POWERTRAIN CONTROL MODULE

P C M

H-11H-7

6M-25

3 0.85

R/B

0.75

R/B

0.75

R/L

BACKUP

LIGHT 0.5

R/B

17M-258H-117

3.0

W/GSTARTER SW

(ST)

H-10H-12

0.5

W/L

1.25

W/L

STARTER

RELAY (6)0.5

W/RM-25

M-25

5C-3

E12 0.5

L/W

0.5

L/WH-531

M-25

6C-3

E7 0.5

L/Y

0.5

L/YH-532

M-25

7C-3

F2 0.5

L/B

0.5

L/BH-533

M-25

2C-3

F3 0.5

Y/G

0.5

Y/GH-534

8

H-87

MODE SW

1 152

C-1EHCU (6)

0.5

GR

A12

C-3

CRUISE CONTROL

UNIT (5)

0.5

GR/L

F10

M-25

1.25

W/RH-104

16H-42

D08RW595

Page 2697 of 6000

3.0

B/Y

C-3 10A

TURN, BACKC-1 10A

STARTER RELAYSTARTER SW

(IG1)EHCU : ELECTRONIC HYDRAULIC CONTROL UNIT

PCM : POWERTRAIN CONTROL MODULE

P C M

H-11H-8

6M-25

3 0.85

R/B

0.75

R/B

0.75

R/L

BACKUP

LIGHT 0.5

R/B

4M-258H-117

3.0

W/GSTARTER SW

(ST)

H-10H-8

0.5

W/L

1.25

W/L

STARTER

RELAY (6)0.5

W/RM-25

M-25

5C-3

E12 0.5

L/W

0.5

L/WH-531

M-25

6C-3

E7 0.5

L/Y

0.5

L/YH-532

M-25

7C-3

F2 0.5

L/B

0.5

L/BH-533

M-25

2C-3

F3 0.5

Y/G

0.5

Y/GH-534

8

H-72

MODE SW

1 151

C-1EHCU (6)

0.5

GR

A12

C-3

CRUISE CONTROL

UNIT (5)

0.5

GR/L

F10

M-25

1.25

W/RH-104

16H-42

D08RW909

Page 2787 of 6000

I-115

B-53

B1

H-2716

H-257

B-53

2 L

H-25100.85

R/B0.85

G/O

H-1612

HAZARD

WARNING

SW

TURN SIGNAL

LIGHT SWFLASHER

UNIT

0.85

G/B0.85

G/B

0.85

G/B0.85

P/B

0.85

P/B2.0

G/O0.3

R/G 0.85

G/R

ILLUMINATION

CONTROLLER

(3) 0.85

P/B 2.0

LG/B 0.5

B

1.25

B2.0

LG/B

2.0

LG/B

2.0

LG/B2.0

B/R2.0

B/R

0.85

R/B 0.85

R/B2.0

G/O

5.0

W BATT.(+)

F-3 15A

HORN,HAZARD3.0

B/Y STARTER SW

(IG1)

C-3 10A

TURN

BACK

B-12

B-12

4

B-12

5 3

LR

A

I-11I-11I-11I-11

64 2 1

I-117I-118I-11 TAIL RELAY

(4) BACK UP

LIGHT

3

B

B-53

3 E

HORN RELAY

(2)

H-276H-2710

B-19

BODY-RH

D08RW683

Page 2791 of 6000

I-115

B-53

B1

H-204

H-202

B-53

2 L

H-25170.85

R/B0.85

G/O

H-1614

HAZARD

WARNING

SW

TURN SIGNAL

LIGHT SWFLASHER

UNIT

0.85

G/B0.85

G/B

0.85

G/B0.85

P/B

0.85

P/B2.0

G/O0.3

R/G 0.85

G/R

ILLUMINATION

CONTROLLER

(3) 0.85

P/B 2.0

LG/B 0.5

B

1.25

B2.0

LG/B

2.0

LG/B

2.0

LG/B2.0

B/R2.0

B/R

0.85

R/B 0.85

R/B2.0

G/O

5.0

W BATT.(+)

F-3 15A

HORN,HAZARD3.0

B/Y STARTER SW

(IG1)

C-3 10A

TURN

BACK

B-12

B-12

4

B-12

5 3

LR

A

I-11I-11I-11I-11

64 2 1

I-117I-118I-11 TAIL RELAY

(4) BACK UP

LIGHT

3

B

B-53

3 E

HORN RELAY

(2)

H-2519H-2520

B-19

BODY-LH

D08RW872

Page 2814 of 6000

3.0

B/Y STARTER SW

(IG1)

MODE

SW

(A/T)

HAZARD

WARN ING

SWITCH (8)0.5

R/B

0.5

R/B 0.5

R/B

0.85

R/B

0.5

R/L0.75

R/L 0.75

R/LC-3 10A

TURN,BACK

H-2517H-717

M-25

M-258

H-117

R-4 3

A

BACKUP

LIGHT SW

(6VD1 M/T)

BACKUP

LIGHT

-LHBACKUP

LIGHT

-RH

0.85

R/B

0.75

R/B

0.5

R/L

H-11

1 6

M-8

M-91

0.85

R/L

H-55

BACKUP

LIGHT SW

(4JG2)

0.5

R/B

0.85

R/B

0.5

R/L

H-5

E-43

1 6

E-421

0.5

R/L

0.85

R/L

0.5

R/L

1.25

B1.25

B 0.5

R/L

H-328

H-716

A

BODY-RR

R-133

R-13

1

R-123

1

R-12 0.75

R/B

H-116

H-117

D08RWC64