ECU OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4617 of 6000

6C–10

ENGINE FUEL

Reuse of Quick–Connector

(Delivery Pipe)

Replace the pipe and connector if scratch, dent or

crack is found.

Remove mud and dust from the pipe and make sure

that the end including spool is free of defects, such as

scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

If the retainer removed according to the removal step

above is attached to the pipe, clean and insert it

straight into the quick-connector till it clicks. After it

clicks, try pulling it out to make sure that it is not drawn

and is securely locked.

NOTE: The retainer, once removed from the pipe, cannot

be reused. Just replace with a new retainer. Insert the

new retainer into the connector side until it clicks, and

connect the pipe as inserting it into the retainer until it

clicks.

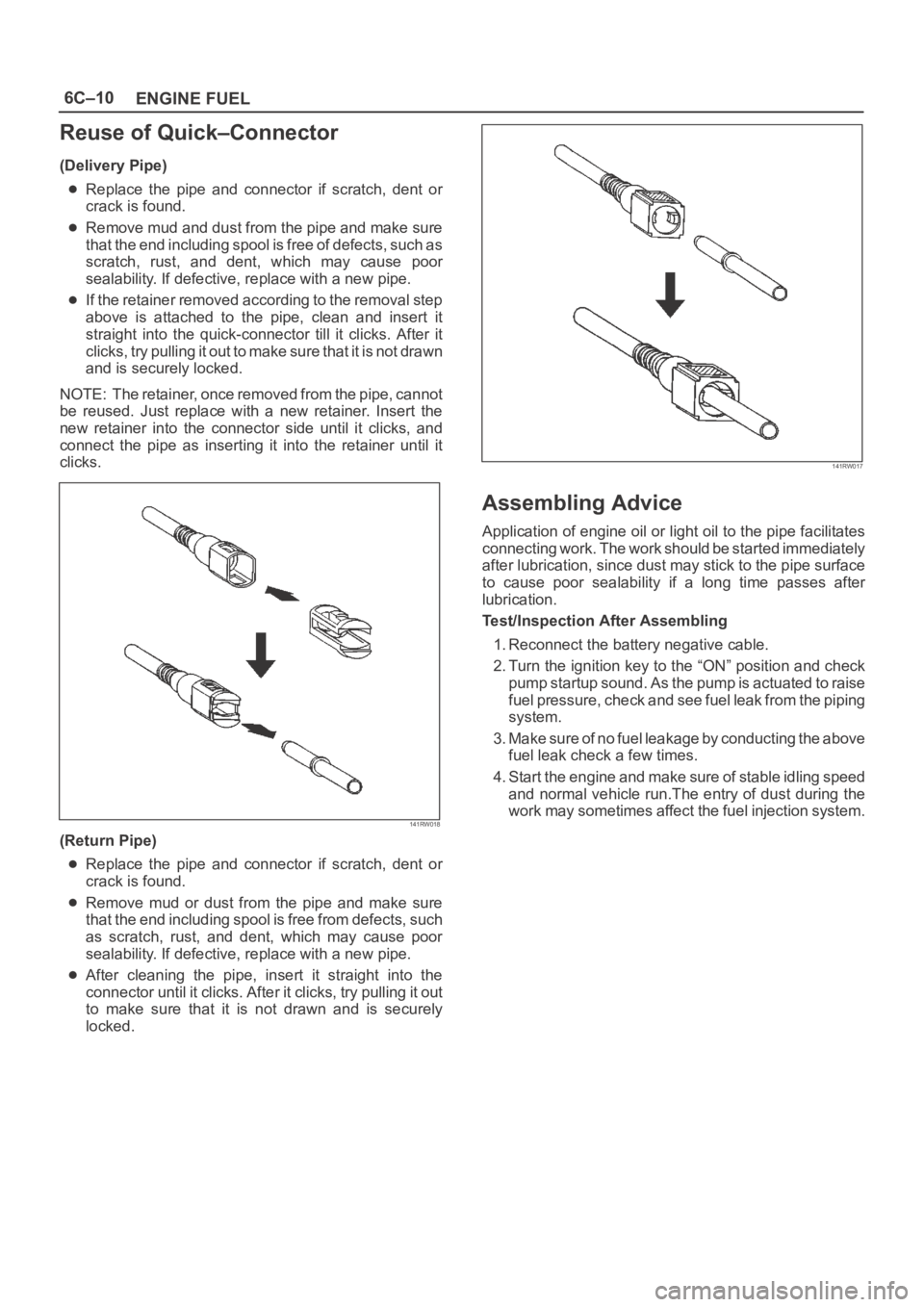

141RW018

(Return Pipe)

Replace the pipe and connector if scratch, dent or

crack is found.

Remove mud or dust from the pipe and make sure

that the end including spool is free from defects, such

as scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

After cleaning the pipe, insert it straight into the

connector until it clicks. After it clicks, try pulling it out

to make sure that it is not drawn and is securely

locked.

141RW017

Assembling Advice

Application of engine oil or light oil to the pipe facilitates

connecting work. The work should be started immediately

after lubrication, since dust may stick to the pipe surface

to cause poor sealability if a long time passes after

lubrication.

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Turn the ignition key to the “ON” position and check

pump startup sound. As the pump is actuated to raise

fuel pressure, check and see fuel leak from the piping

system.

3. Make sure of no fuel leakage by conducting the above

fuel leak check a few times.

4. Start the engine and make sure of stable idling speed

and normal vehicle run.The entry of dust during the

work may sometimes affect the fuel injection system.

Page 4653 of 6000

6D3–22STARTING AND CHARGING SYSTEM

6. Secure the pulley directly in the vise between two

copper plates, and remove the nut and pulley.

066RS010

7. Remove four nuts(8) that secure the front cover

assembly and rear end cover, and an insulator(9).

066RW005

8. Use the puller to remove the rear end cover.

9. Rotor assembly

066RS012

10. Pull the rotor assembly(10) off the front cover

assembly(12) using a bench press(11).

066RW006

Page 4656 of 6000

6D3–25 STARTING AND CHARGING SYSTEM

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in the

front cover.

066RS022

2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified torque.

Torque: 111 Nꞏm (11.3 Kgꞏm/82 lb ft)

066RS010

Bench Test

Conduct a bench test of the generator.

066RS023

Preparation

Remove generator from the vehicle (see “Generator

removal”).

1. Secure generator to the bench test equipment and

connect wires.

Terminal “IG” for energization

Terminal “L” for neutral (warning lamp)

Terminal “B” for output

2. Conduct the generator characteristic test.

Characteristics of generator are shown in illustration.

Repair or replace the generator if its outputs are

abnormal.

B06RW001

Page 4658 of 6000

6E–1 ENGINE DRIVEABILITY AND EMISSIONS

ENGINE

ENGINE DRIVEABILITY AND EMISSIONS

CONTENTS

Specifications 6E–5. . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–5. . . . . . . . . . . . . . .

Vehicle Type Specifications 6E–5. . . . . . . . . . . . .

Diagrams and Schematics 6E–6. . . . . . . . . . . . . . . .

PCM Wiring Diagram (1 of 11) 6E–6. . . . . . . . . . .

PCM Wiring Diagram (2 of 11) For EC,

THAILAND, SOUTH EAST ASIA, LATIN

AMERICA, GULF, SAUDI, CHINA. 6E–7. . . . . .

PCM Wiring Diagram (3 of 11) For SOUTH

AFRICA and EXP. 6E–8. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (4 of 11) 6E–9. . . . . . . . . . .

PCM Wiring Diagram (5 of 11) 6E–10. . . . . . . . . . .

PCM Wiring Diagram (6 of 11) For

AUSTRALIA, THAILAND, SOUTH EAST

ASIA, LATIN AMERICA, GULF, SAUDI,

LATIN AMERICA. 6E–11. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (7 of 11) For EC. 6E–12. . .

PCM Wiring Diagram (8 of 11) For EXPORT

and SOUTH AFRICA. 6E–13. . . . . . . . . . . . . . . . .

PCM Wiring Diagram (9 of 11) Except EXP

and SOUTH AFRICA 6E–14. . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (10 of 11) For

EXPORT and SOUTH AFRICA 6E–15. . . . . . . . .

PCM Wiring Diagram (11 of 11) 6E–16. . . . . . . . . .

PCM Pinouts 6E–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “A” 6E–17. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “B” 6E–19. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For EC) 6E–20. . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For except EC) 6E–21. . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For except EXPORT and SOUTH

AFRICA) 6E–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For EXPORT and SOUTH AFRICA) 6E–23. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For except EXPORT and SOUTH

AFRICA) 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For EXPORT and SOUTH AFRICA) 6E–26. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “F” 6E–27. . . . . . . . . . . . . . . . . .

Component Locators 6E–28. . . . . . . . . . . . . . . . . . . .

Engine Component Locator (This illustration

is based on RHD model.) 6E–28. . . . . . . . . . . . . . Engine Component Locator Table 6E–29. . . . . . . .

Engine Component Locator Table 6E–31. . . . . . . .

Undercarriage Component Locator 6E–32. . . . . .

Undercarriage Component Locator Table

(Automatic Transmission) 6E–32. . . . . . . . . . . . . .

Undercarriage Component Locator Table

(Manual Transmission) 6E–33. . . . . . . . . . . . . . . .

Fuse and Relay Panel (Underhood

Electrical Center) 6E–33. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

DTC Stored 6E–37

. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–37. . . . . . . . . . . . . . . . .

Intermittents 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–37. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–37. . . . . . . . . . . . . . . .

General Service Information 6E–38. . . . . . . . . . . . . .

OBD Serviceablity Issues 6E–38. . . . . . . . . . . . . . .

Maintenance Schedule 6E–38. . . . . . . . . . . . . . . . .

Visual / Physical Engine Compartment

Inspection 6E–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–38. . . . . .

Serial Data Communications 6E–38. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–38. . . . .

On-Board Diagnostic (OBD) 6E–39. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–39. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–39. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–40. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–40. . . . . . . . . . . . . . .

DTC Types 6E–41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–42. . . . . . . . . . . . . . . .

Reading Diagnostic Trouble Codes Using

A Tech 2 6E–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Tech 2 6E–43. . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Features 6E–43. . . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure (For Example) 6E–44. . . . .

DTC Modes 6E–45. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–46. . . . . . . . . . . . . . . . .

Injector Balance Test 6E–46. . . . . . . . . . . . . . . . . . .

EGR Control Test 6E–47. . . . . . . . . . . . . . . . . . . . . .

Idle Air Control System Test 6E–48. . . . . . . . . . . . .

Page 4676 of 6000

6E–19 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way Red Connector – Row “B”

TS23344

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

B15 Volt Reference “B”RED/YEL5.0 V5.0 VAppropriate Sensor

B2lgnition coilRED/WHT0.0 V0.1 VGeneral Description and

Operation

B3lgnition coilRED/BLK0.0 V0.1 VGeneral Description and

Operation

B4lgnition coilRED/GRN0.0 V0.1 VGeneral Description and

Operation

B5Not Used————

B6Not Used————

B7Exhaust Gas Recirculation

(EGR)YEL/RED0.6 V0.6 VGeneral Description and

Operation, Linear EGR

Control

B8Intake Air Temperature

(IAT) SensorYEL/GRN0.5-4.9 V

(depends on

temperature)0.5-4.9 V

(depends on

temperature)General Description and

Operation, IAT

B9Not Used————

B10Not Used————

B11Power Steering Pressure

(PSP) SwitchGRN/YELB+B+General Description and

Operation, PSP

B12Illuminated SwitchGRNB+B+Chassis Electrical

B13Class 2 DataORN/GRN0.0 V0.0 VDiagnosis, Class 2 Serial

Data

B14A/C ClutchGRN/BLKB+

(A/C OFF)B+

(A/C OFF)General Description and

Operation, A/C Clutch Circuit

Operation

B15ECM to ECU

CommunicationViolet0.0 V0.1 V—

B16Not Used————

Page 4696 of 6000

6E–39 ENGINE DRIVEABILITY AND EMISSIONS

The data displayed on the other Tech 2 will appear the

same, with some exceptions. Some Tech 2s will only be

able to display certain vehicle parameters as values that

are a coded representation of the true or actual value. For

more information on this system of coding, refer to

Decimal/Binary/Hexadecimal Conversions. On this

vehicle Tech 2 displays the actual values for vehicle

parameters. It will not be necessary to perform any

conversions from coded values to actual values.

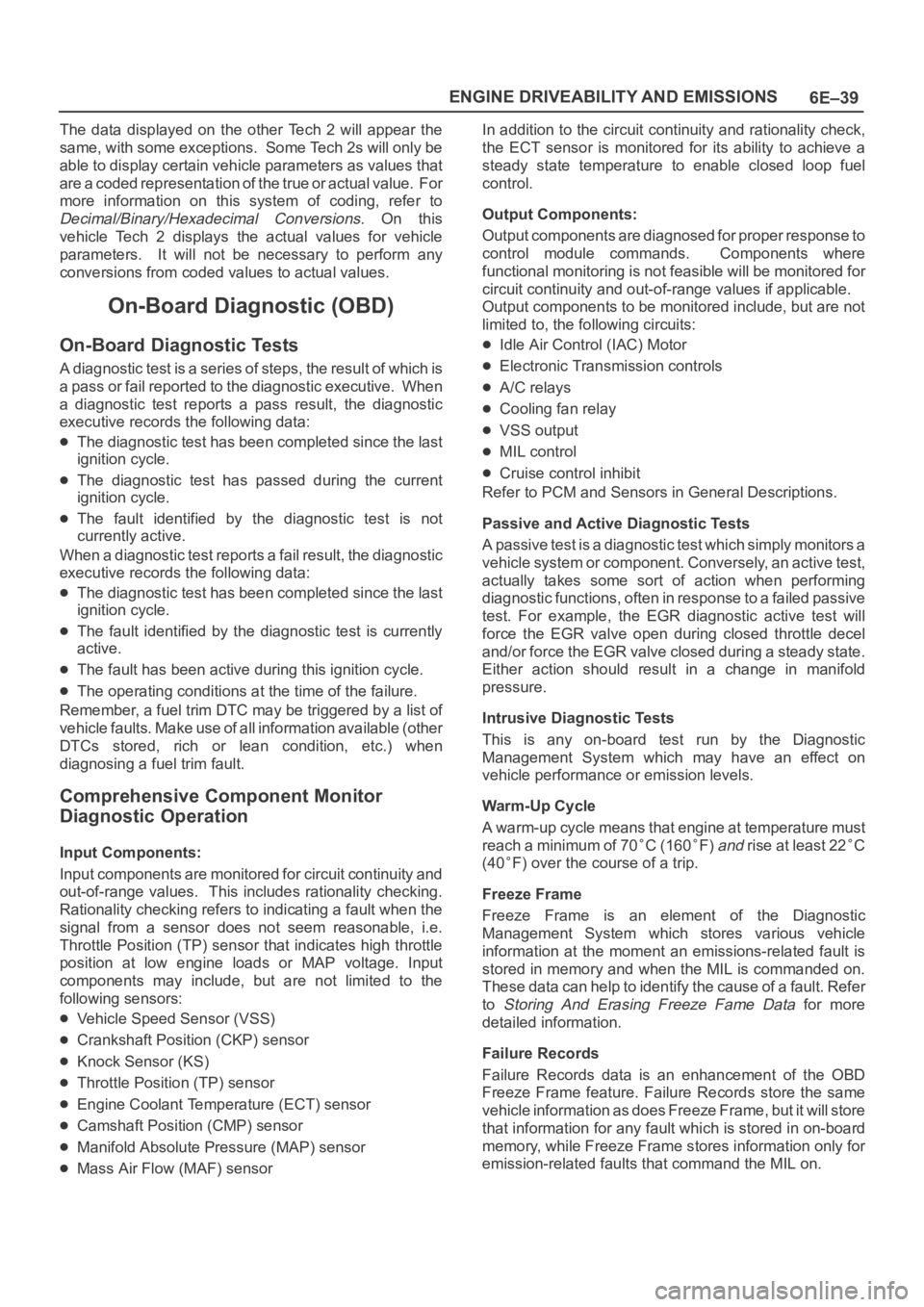

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

W h e n a d i a g n o s t i c t e s t r e p o r t s a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Remember, a fuel trim DTC may be triggered by a list of

vehicle faults. Make use of all information available (other

DTCs stored, rich or lean condition, etc.) when

diagnosing a fuel trim fault.

Comprehensive Component Monitor

Diagnostic Operation

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable, i.e.

Throttle Position (TP) sensor that indicates high throttle

position at low engine loads or MAP voltage. Input

components may include, but are not limited to the

following sensors:

Vehicle Speed Sensor (VSS)

Crankshaft Position (CKP) sensor

Knock Sensor (KS)

Throttle Position (TP) sensor

Engine Coolant Temperature (ECT) sensor

Camshaft Position (CMP) sensor

Manifold Absolute Pressure (MAP) sensor

Mass Air Flow (MAF) sensorIn addition to the circuit continuity and rationality check,

the ECT sensor is monitored for its ability to achieve a

steady state temperature to enable closed loop fuel

control.

Output Components:

Output components are diagnosed for proper response to

control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuits:

Idle Air Control (IAC) Motor

Electronic Transmission controls

A/C relays

Cooling fan relay

VSS output

MIL control

Cruise control inhibit

Refer to PCM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors a

vehicle system or component. Conversely, an active test,

actually takes some sort of action when performing

diagnostic functions, often in response to a failed passive

test. For example, the EGR diagnostic active test will

force the EGR valve open during closed throttle decel

and/or force the EGR valve closed during a steady state.

Either action should result in a change in manifold

pressure.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature must

reach a minimum of 70

C (160F) and rise at least 22C

(40

F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in memory and when the MIL is commanded on.

These data can help to identify the cause of a fault. Refer

to

Storing And Erasing Freeze Fame Data for more

detailed information.

Failure Records

Failure Records data is an enhancement of the OBD

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will store

that information for any fault which is stored in on-board

memory, while Freeze Frame stores information only for

emission-related faults that command the MIL on.

Page 4697 of 6000

6E–40

ENGINE DRIVEABILITY AND EMISSIONS

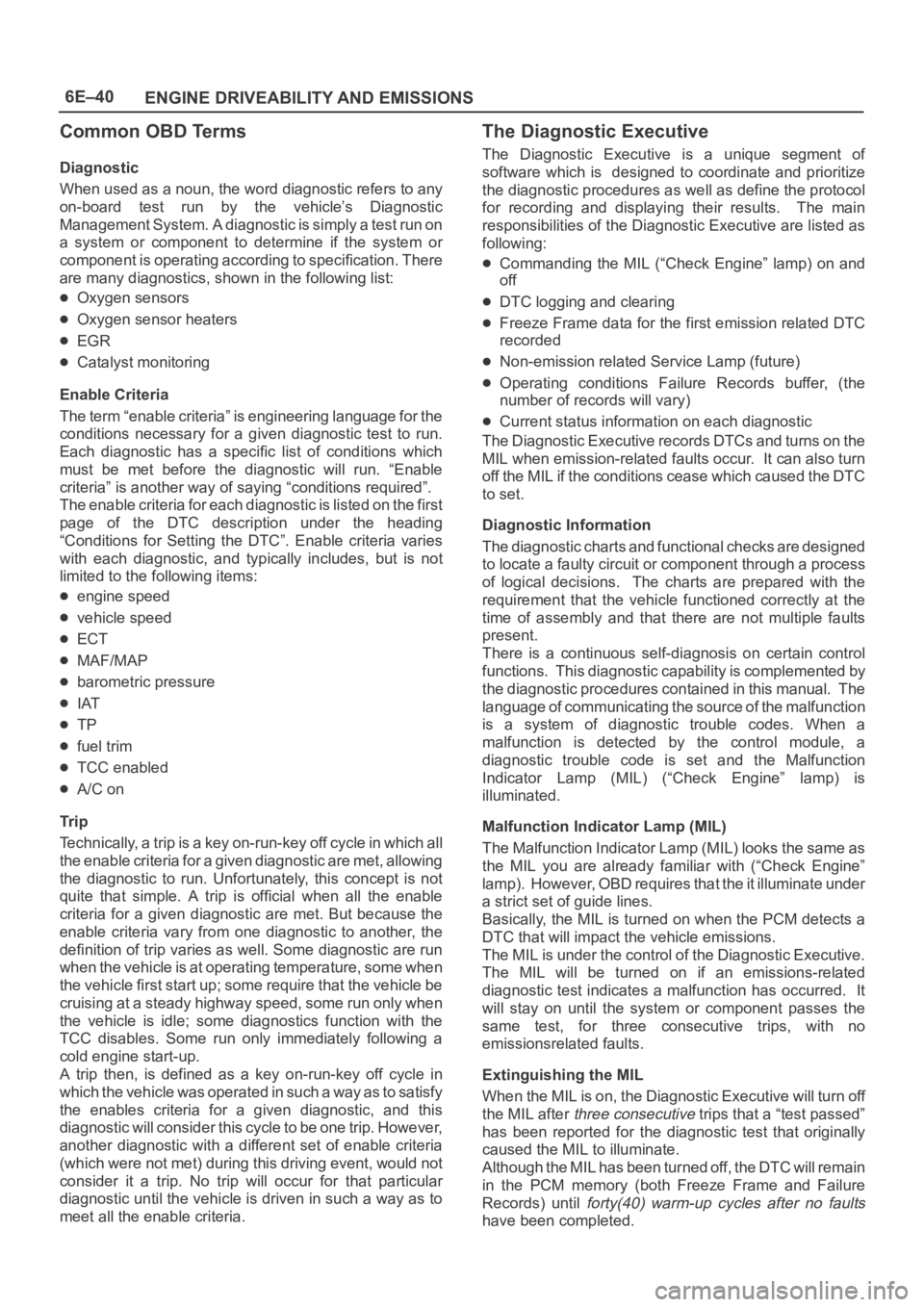

Common OBD Terms

Diagnostic

When used as a noun, the word diagnostic refers to any

on-board test run by the vehicle’s Diagnostic

Management System. A diagnostic is simply a test run on

a system or component to determine if the system or

component is operating according to specification. There

are many diagnostics, shown in the following list:

Oxygen sensors

Oxygen sensor heaters

EGR

Catalyst monitoring

Enable Criteria

The term “enable criteria” is engineering language for the

conditions necessary for a given diagnostic test to run.

Each diagnostic has a specific list of conditions which

must be met before the diagnostic will run. “Enable

criteria” is another way of saying “conditions required”.

The enable criteria for each diagnostic is listed on the first

page of the DTC description under the heading

“Conditions for Setting the DTC”. Enable criteria varies

with each diagnostic, and typically includes, but is not

limited to the following items:

engine speed

vehicle speed

ECT

MAF/MAP

barometric pressure

IAT

TP

fuel trim

TCC enabled

A/C on

Tr i p

Technically, a trip is a key on-run-key off cycle in which all

the enable criteria for a given diagnostic are met, allowing

the diagnostic to run. Unfortunately, this concept is not

quite that simple. A trip is official when all the enable

criteria for a given diagnostic are met. But because the

enable criteria vary from one diagnostic to another, the

definition of trip varies as well. Some diagnostic are run

when the vehicle is at operating temperature, some when

the vehicle first start up; some require that the vehicle be

cruising at a steady highway speed, some run only when

the vehicle is idle; some diagnostics function with the

TCC disables. Some run only immediately following a

cold engine start-up.

A trip then, is defined as a key on-run-key off cycle in

which the vehicle was operated in such a way as to satisfy

the enables criteria for a given diagnostic, and this

diagnostic will consider this cycle to be one trip. However,

another diagnostic with a different set of enable criteria

(which were not met) during this driving event, would not

consider it a trip. No trip will occur for that particular

diagnostic until the vehicle is driven in such a way as to

meet all the enable criteria.

The Diagnostic Executive

The Diagnostic Executive is a unique segment of

software which is designed to coordinate and prioritize

the diagnostic procedures as well as define the protocol

for recording and displaying their results. The main

responsibilities of the Diagnostic Executive are listed as

following:

Commanding the MIL (“Check Engine” lamp) on and

off

DTC logging and clearing

Freeze Frame data for the first emission related DTC

recorded

Non-emission related Service Lamp (future)

Operating conditions Failure Records buffer, (the

number of records will vary)

Current status information on each diagnostic

The Diagnostic Executive records DTCs and turns on the

MIL when emission-related faults occur. It can also turn

off the MIL if the conditions cease which caused the DTC

to set.

Diagnostic Information

The diagnostic charts and functional checks are designed

to locate a faulty circuit or component through a process

of logical decisions. The charts are prepared with the

requirement that the vehicle functioned correctly at the

time of assembly and that there are not multiple faults

present.

There is a continuous self-diagnosis on certain control

functions. This diagnostic capability is complemented by

the diagnostic procedures contained in this manual. The

language of communicating the source of the malfunction

is a system of diagnostic trouble codes. When a

malfunction is detected by the control module, a

diagnostic trouble code is set and the Malfunction

Indicator Lamp (MIL) (“Check Engine” lamp) is

illuminated.

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) looks the same as

the MIL you are already familiar with (“Check Engine”

lamp). However, OBD requires that the it illuminate under

a strict set of guide lines.

Basically, the MIL is turned on when the PCM detects a

DTC that will impact the vehicle emissions.

The MIL is under the control of the Diagnostic Executive.

The MIL will be turned on if an emissions-related

diagnostic test indicates a malfunction has occurred. It

will stay on until the system or component passes the

same test, for three consecutive trips, with no

emissionsrelated faults.

Extinguishing the MIL

When the MIL is on, the Diagnostic Executive will turn off

the MIL after

three consecutive trips that a “test passed”

has been reported for the diagnostic test that originally

caused the MIL to illuminate.

Although the MIL has been turned off, the DTC will remain

in the PCM memory (both Freeze Frame and Failure

Records) until

forty(40) warm-up cycles after no faults

have been completed.

Page 4698 of 6000

6E–41 ENGINE DRIVEABILITY AND EMISSIONS

If the MIL was set by either a fuel trim or misfire-related

DTC, additional requirements must be met. In addition to

the requirements stated in the previous paragraph, these

requirements are as follows:

The diagnostic tests that are passed must occur with

375 RPM of the RPM data stored at the time the last

test failed.

Plus or minus ten (10) percent of the engine load that

was stored at the time the last failed.

Similar engine temperature conditions (warmed up or

warming up ) as those stored at the time the last test

failed.

Meeting these requirements ensures that the fault which

turned on the MIL has been corrected.

The MIL (“Check Engine” lamp) is on the instrument

panel and has the following function:

It informs the driver that a fault affects vehicle emission

levels has occurred and that the vehicle should be

taken for service as soon as possible.

As a bulb and system check, the MIL will come “ON”

with the key “ON” and the engine not running. When

the engine is started, the MIL will turn “OFF.”

When the MIL remains “ON” while the engine is

running, or when a malfunction is suspected due to a

driveability or emissions problem, a Powertrain

On-Board Diagnostic (OBD ll) System Check must be

performed. The procedures for these checks are given

in On-Board Diagnostic (OBD) System Check. These

checks will expose faults which may not be detected if

other diagnostics are performed first.

DTC Types

Each DTC is directly related to a diagnostic test. The

Diagnostic Management System sets DTC based on the

failure of the tests during a trip or trips. Certain tests must

fail two (2) consecutive trips before the DTC is set. The

following are the four (4) types of DTCs and the

characteristics of those codes:

Ty p e A

Emissions related

Requests illumination of the MIL of the first trip with a

fail

Stores a History DTC on the first trip with a fail

Stores a Freeze Frame (if empty)

Stores a Fail Record

Updates the Fail Record each time the diagnostic

test fails

Ty p e B

Emissions related

“Armed” after one (1) trip with a fail

“Disarmed” after one (1) trip with a pass

Requests illumination of the MIL on the second

consecutive trip

with a fail

Stores a History DTC on the second consecutive trip

with a fail (The DTC will be armed after the first fail)

Stores a Freeze Frame on the second consecutive

trip with a fail (if empty)

Stores a Fail Record when the first test fails (not

dependent on

consecutive trip fails)

Updates the Fail Record each time the diagnostic

test fails

Type C (if the vehicle is so equipped)

Non-Emissions related

Requests illumination of the Service Lamp or the

service message on the Drive Information Center

(DIC) on the

first trip with a fail

Stores a History DTC on the first trip with a fail

Does not store a Freeze Frame

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic

test fails

Type D (Ty p e D non-emissions related are not utilized

on certain vehicle applications).

Non-Emissions related

Dose not request illumination of any lamp

Stores a History DTC on the first trip with a fail

Does not store a Freeze Frame

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic

test fails

IMPORTANT:Only four Fail Records can be stored.

Each Fail Record is for a different DTC. It is possible that

there will not be Fail Records for every DTC if multiple

DTCs are set.

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

Air Fuel Ratio

Air Flow Rate

Fuel Trim

Engine Speed

Engine Load

Engine Coolant Temperature

Vehicle Speed

TP Angle

MAP/BARO

Injector Base Pulse Width

Loop Status

Page 4699 of 6000

6E–42

ENGINE DRIVEABILITY AND EMISSIONS

Intermittent Malfunction Indicator Lamp

In the case of an “intermittent” fault, the MIL (“Check

Engine” lamp) may illuminate and then (after three trips)

go “OFF”. However, the corresponding diagnostic trouble

code will be stored in the memory. When unexpected

diagnostic trouble codes appear, check for an intermittent

malfunction.

A diagnostic trouble code may reset. Consult the

“Diagnostic Aids” associated with the diagnostic trouble

code. A physical inspection of the applicable sub-system

most often will resolve the problem.

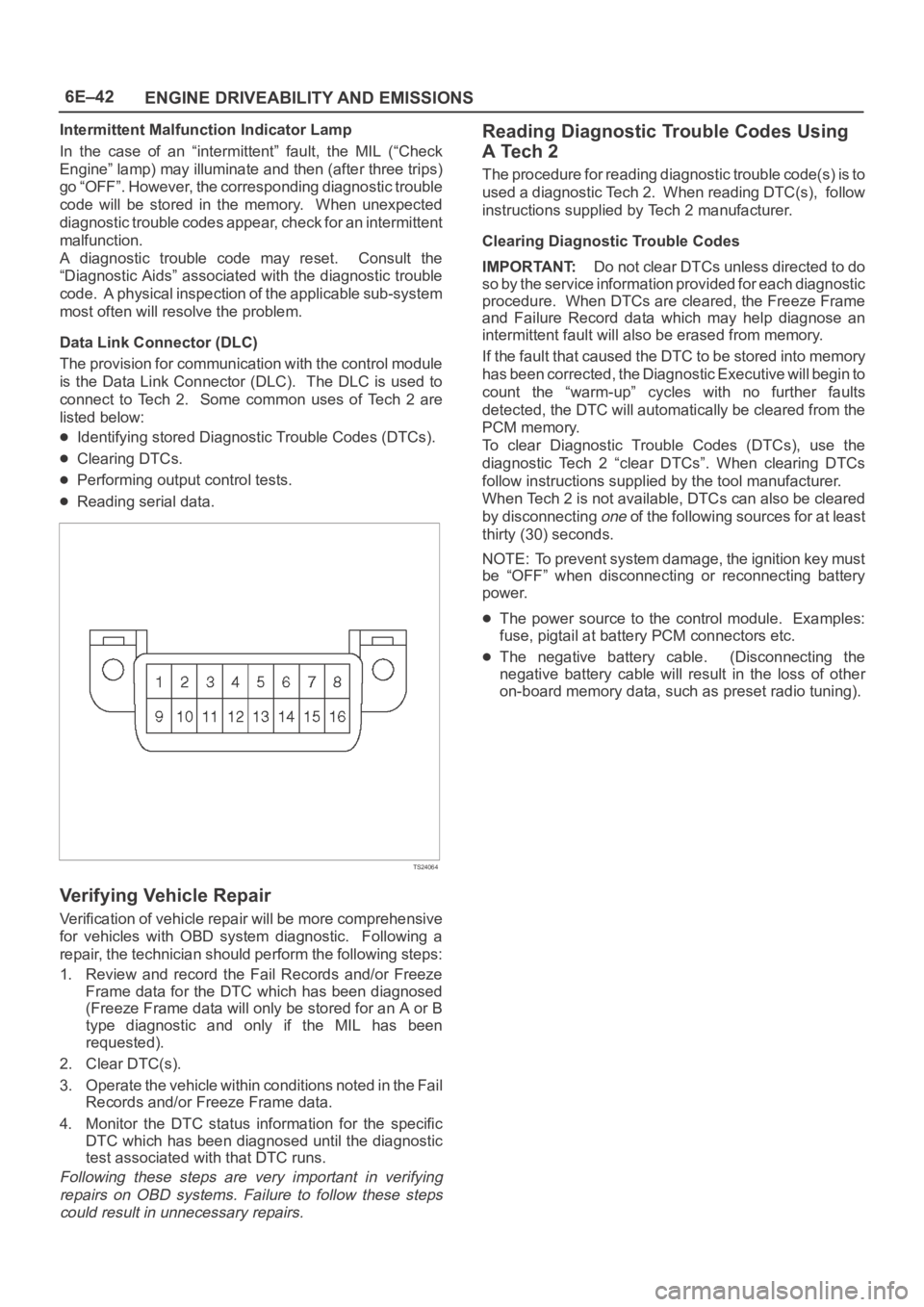

Data Link Connector (DLC)

The provision for communication with the control module

is the Data Link Connector (DLC). The DLC is used to

connect to Tech 2. Some common uses of Tech 2 are

listed below:

Identifying stored Diagnostic Trouble Codes (DTCs).

Clearing DTCs.

Performing output control tests.

Reading serial data.

TS24064

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensive

for vehicles with OBD system diagnostic. Following a

repair, the technician should perform the following steps:

1. Review and record the Fail Records and/or Freeze

Frame data for the DTC which has been diagnosed

(Freeze Frame data will only be stored for an A or B

type diagnostic and only if the MIL has been

requested).

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the Fail

Records and/or Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Reading Diagnostic Trouble Codes Using

A Tech 2

The procedure for reading diagnostic trouble code(s) is to

used a diagnostic Tech 2. When reading DTC(s), follow

instructions supplied by Tech 2 manufacturer.

Clearing Diagnostic Trouble Codes

IMPORTANT:Do not clear DTCs unless directed to do

so by the service information provided for each diagnostic

procedure. When DTCs are cleared, the Freeze Frame

and Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

If the fault that caused the DTC to be stored into memory

has been corrected, the Diagnostic Executive will begin to

count the “warm-up” cycles with no further faults

detected, the DTC will automatically be cleared from the

PCM memory.

To clear Diagnostic Trouble Codes (DTCs), use the

diagnostic Tech 2 “clear DTCs”. When clearing DTCs

follow instructions supplied by the tool manufacturer.

When Tech 2 is not available, DTCs can also be cleared

by disconnecting

one of the following sources for at least

thirty (30) seconds.

NOTE: To prevent system damage, the ignition key must

be “OFF” when disconnecting or reconnecting battery

power.

The power source to the control module. Examples:

fuse, pigtail at battery PCM connectors etc.

The negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board memory data, such as preset radio tuning).

Page 4722 of 6000

6E–65 ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor Diagnosis

The Tech 2 has two data displays available for diagnosing

the knock sensor (KS) system. The two displays are

described as follows:

“Knock Retard” indicates the number of degrees that

the spark timing is being retarded due to a knock

condition.

“KS Noise Channel” indicates the current voltage level

being monitored on the noise channel.

DTCs P0325 and P0327 are designed to diagnose the KS

module, the knock sensor, and the related wiring. The

problems encountered with the KS system should set a

DTC. However, if no DTC was set but the KS system is

suspect because of a detonation complaint, refer to

Detonation/Spark Knock in Symptoms.

Powertrain Control Module (PCM)

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the PCM terminal connections.

The terminals may have to be removed from the

connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms p o r t i o n o f

the manual and make a careful physical inspection of

all component and wiring associated with the affected

system.

There is a shorted solenoid, relay coil, or harness.

S o l e n o i d s a n d r e l a y s a r e t u r n e d “ O N ” a n d “ O F F ” b y t h e

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay to

be inoperative.

Multiple PCM Information Sensor

DTCS Set

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The engine coolant temperature (ETC) sensor

The intake air temperature (IAT) sensor

The transmission fluid temperature (TFT) sensor

The PCM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The exhaust gas recirculating (EGR) pintle position

sensor

The throttle position (TP) sensor

The manifold absolute pressure (MAP) sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

IMPORTANT:Be sure to inspect PCM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0108

P0113

P0118

P0123

P0560

P0712

P0406

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

P0108

P0113

P0118

P0123

P0712

P0406

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0107

P0122

In the 5-volt reference circuit A, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0122

In the 5-volt reference circuit B, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0107

Check for the following conditions: