battery OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 643 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–72

StepActionYe sNo

1Turn on the starter switch.

When the transfer lever is shifted to the high position, is 5V

observed between terminals 9 and 19 (4L switch)?

Go to Step 2Go to Step 4

2When the transfer lever is shifted to the neutral position, is 0V

observed between terminals 9 and 19 (4L switch)?

Go to Step 3Go to Step 4

3When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 9 and 19 (4L switch)?The ECU has

failed. Replace

the ECU.

Go to Step 4

Go to Step 4

41. Turn off the starter switch.

2. Disconnect the ECU connector.

3. Turn on the starter switch.

When the transfer lever is shifted to the high position, is 12V

observed between terminals (B–68)4 and (B–67)11?

Go to Step 5Go to Step 7

5When the transfer lever is shifted to the neutral position, is 0V

observed between terminals (B–68)4 and (B–67)11?

Go to Step 6Go to Step 7

6When the transfer lever is shifted to the 4L position, is 0V

observed between terminals (B–68)4 and (B–67)11?The 4L switch

circuit battery is

short-circuited

between ECU

and transfer.

Repair the circuit

Go to Step 13

Go to Step 7

7Turn off the starter switch.

When the transfer lever is shifted to the high position, is the

continuity established between terminals (B–68)3 and (B–67)11?

Go to Step 10Go to Step 8

8When the transfer lever is shifted to the neutral position between

high and 4L, is the continuity established between terminals

(B–68)4 and (B–67)11?

Go to Step 9Go to Step 10

9When the transfer lever is shifted to the 4L position, is the

continuity established between terminals (B–68)4 and (B–67)11?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 13

Go to Step 10

101. Disconnect the A–3 connector.

When the transfer lever is shifted to the neutral position between

high and 4L, is the continuity established between transfer

connector terminals (A–3)12 and GND?Wires are broken

between transfer

connector (A–3)

and floor

connector (H-49).

Repair the circuit.

Go to Step 11

Repair the

transfer

assembly.

Go to Step 13

11When the transfer lever is shifted to the 4L position, is the

continuity established between transfer connector terminals

(A–3)12 and GND?

Go to Step 12

Repair the

transfer

assembly.

Go to Step 13

12When the transfer lever is shifted to the high position, is the

continuity established between transfer connector terminals

(A–3)12 and GND?Repair the

transfer

assembly.

Go to Step 13

Go to Step 13

13Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 13

Page 648 of 6000

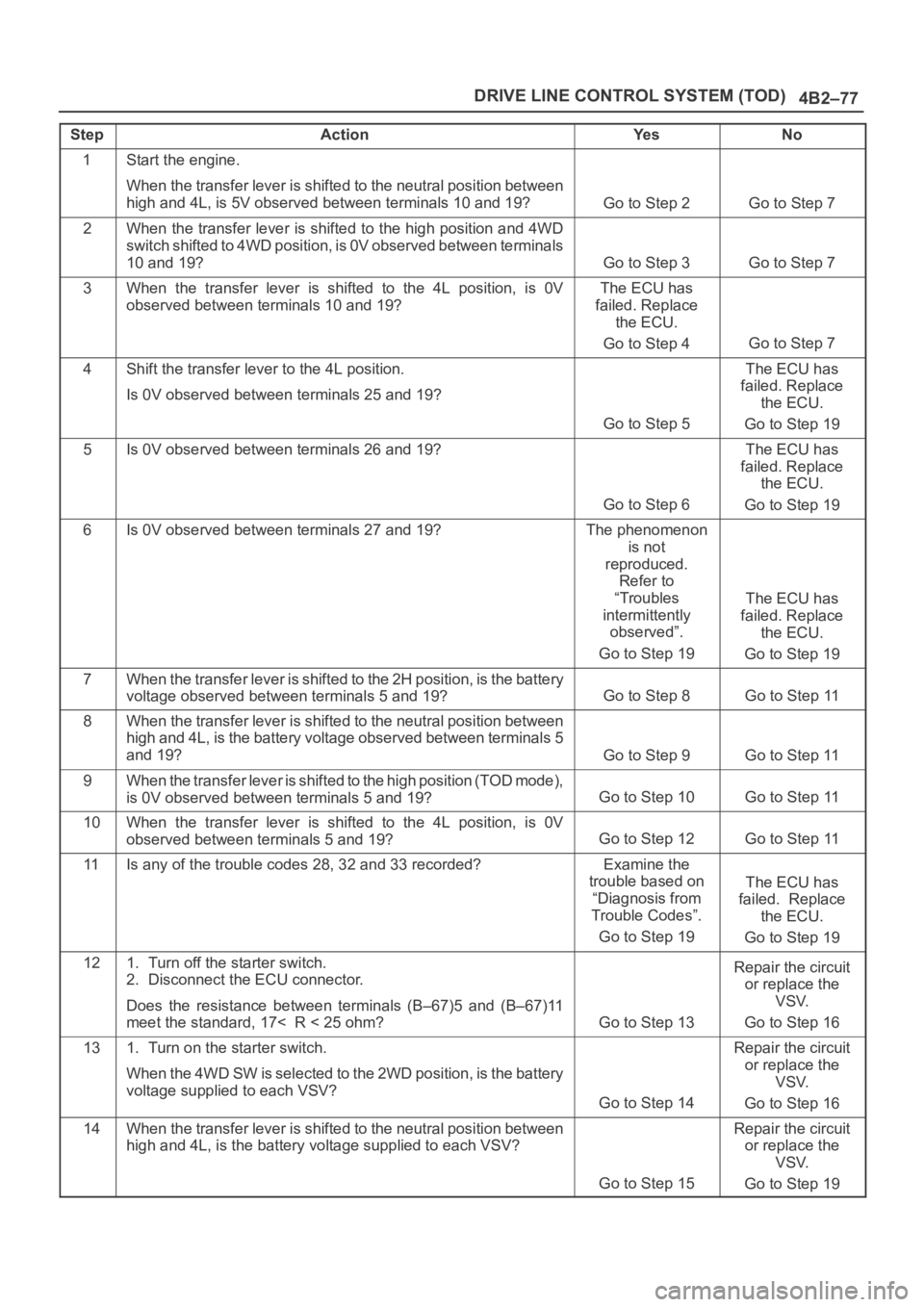

4B2–77 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

1Start the engine.

When the transfer lever is shifted to the neutral position between

high and 4L, is 5V observed between terminals 10 and 19?

Go to Step 2Go to Step 7

2When the transfer lever is shifted to the high position and 4WD

switch shifted to 4WD position, is 0V observed between terminals

10 and 19?

Go to Step 3Go to Step 7

3When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 10 and 19?The ECU has

failed. Replace

the ECU.

Go to Step 4

Go to Step 7

4Shift the transfer lever to the 4L position.

Is 0V observed between terminals 25 and 19?

Go to Step 5

The ECU has

failed. Replace

the ECU.

Go to Step 19

5Is 0V observed between terminals 26 and 19?

Go to Step 6

The ECU has

failed. Replace

the ECU.

Go to Step 19

6Is 0V observed between terminals 27 and 19?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 19

The ECU has

failed. Replace

the ECU.

Go to Step 19

7When the transfer lever is shifted to the 2H position, is the battery

voltage observed between terminals 5 and 19?

Go to Step 8Go to Step 11

8When the transfer lever is shifted to the neutral position between

high and 4L, is the battery voltage observed between terminals 5

and 19?

Go to Step 9Go to Step 11

9When the transfer lever is shifted to the high position (TOD mode),

is 0V observed between terminals 5 and 19?

Go to Step 10Go to Step 11

10When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 5 and 19?

Go to Step 12Go to Step 11

11Is any of the trouble codes 28, 32 and 33 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 19

The ECU has

failed. Replace

the ECU.

Go to Step 19

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Does the resistance between terminals (B–67)5 and (B–67)11

meet the standard, 17< R < 25 ohm?

Go to Step 13

Repair the circuit

or replace the

VSV.

Go to Step 16

131. Turn on the starter switch.

When the 4WD SW is selected to the 2WD position, is the battery

voltage supplied to each VSV?

Go to Step 14

Repair the circuit

or replace the

VSV.

Go to Step 16

14When the transfer lever is shifted to the neutral position between

high and 4L, is the battery voltage supplied to each VSV?

Go to Step 15

Repair the circuit

or replace the

VSV.

Go to Step 19

Page 651 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–80

StepActionYe sNo

1Start the engine.

When the transfer lever is shifted to the neutral position between

high and 4L, is 5V observed between terminals 10 and 19?

Go to Step 2Go to Step 7

2When the transfer lever is shifted to the high position and 4WD

switch shifted to 4WD position, is 0V observed between terminals

10 and 19?

Go to Step 3Go to Step 7

3When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 10 and 19?

Go to Step 4Go to Step 7

4Select the 4WD SW to the 2WD position.

Is 12V observed between terminals 25 and 19?

Go to Step 5Go to Step 19

5Is 12V observed between terminals 26 and 19?Go to Step 6Go to Step 19

6Is 12V observed between terminals 27 and 19?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 19

The ECU has

failed. Replace

the ECU.

Go to Step 19

7When the 4WD SW is select to the 2WD position, is the battery

voltage observed between terminals 5 and 19?

Go to Step 8Go to Step 11

8When the transfer lever is shifted to the neutral position between

high and 4L, is the battery voltage observed between terminals 5

and 19?

Go to Step 9Go to Step 11

9When the transfer lever is shifted to the high position and 4WD

switch shifted to 4WD position, is 0V observed between terminals

5 and 19?

Go to Step 10Go to Step 11

10When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 5 and 19?

Go to Step 12Go to Step 11

11Is any of the trouble codes 28, 32 and 33 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 19

The ECU has

failed. Replace

the ECU.

Go to Step 19

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Does the resistance between terminals (B–67)5 and (B–67)11

meet the standard, 17< R < 25 ohm?

Go to Step 13

Repair the circuit

or replace the

VSV.

Go to Step 19

131. Connect the ECU connector.

2. Turn on the starter switch.

When the 4WD SW is select to the 2WD position, is the battery

voltage supplied to each VSV?

Go to Step 14

Repair the circuit

or replace the

VSV.

Go to Step 19

14When the transfer lever is shifted to the neutral position between

high and 4L, is the battery voltage supplied to each VSV?

Go to Step 15

Repair the circuit

or replace the

VSV.

Go to Step 19

15When the transfer lever is shifted to the high position and 4WD

switch shifted to 4WD position, is 0V observed on each VSV?

Go to Step 16

Repair the circuit

or replace the

VSV.

Go to Step 19

Page 656 of 6000

4B2–85 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

11. Disconnect ECU terminal.

2. Turn on the starter switch.

Is battery voltage observed between ECU terminals (B–68)1 and

(B–67)11?

Go to Step 2

Wirers are broken

lighting SW

circuit. Repair

the circuit.

Go to Step 4

2Turn lighting SW “ON”.

Is 0 V observed between ECU terminal (B–68)1 and (B–67)11?

Go to Step 3

Lighting SW

circuit battery

short. Repair the

circuit.

Go to Step 4

3Connect ECU terminal.

While the lighting switch is pressed on and off, does the

brightness of the indicator change?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”

Go to Step 4

The ECU has

failed. Replace

the ECU.

Go to Step 4

4Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 4

Page 659 of 6000

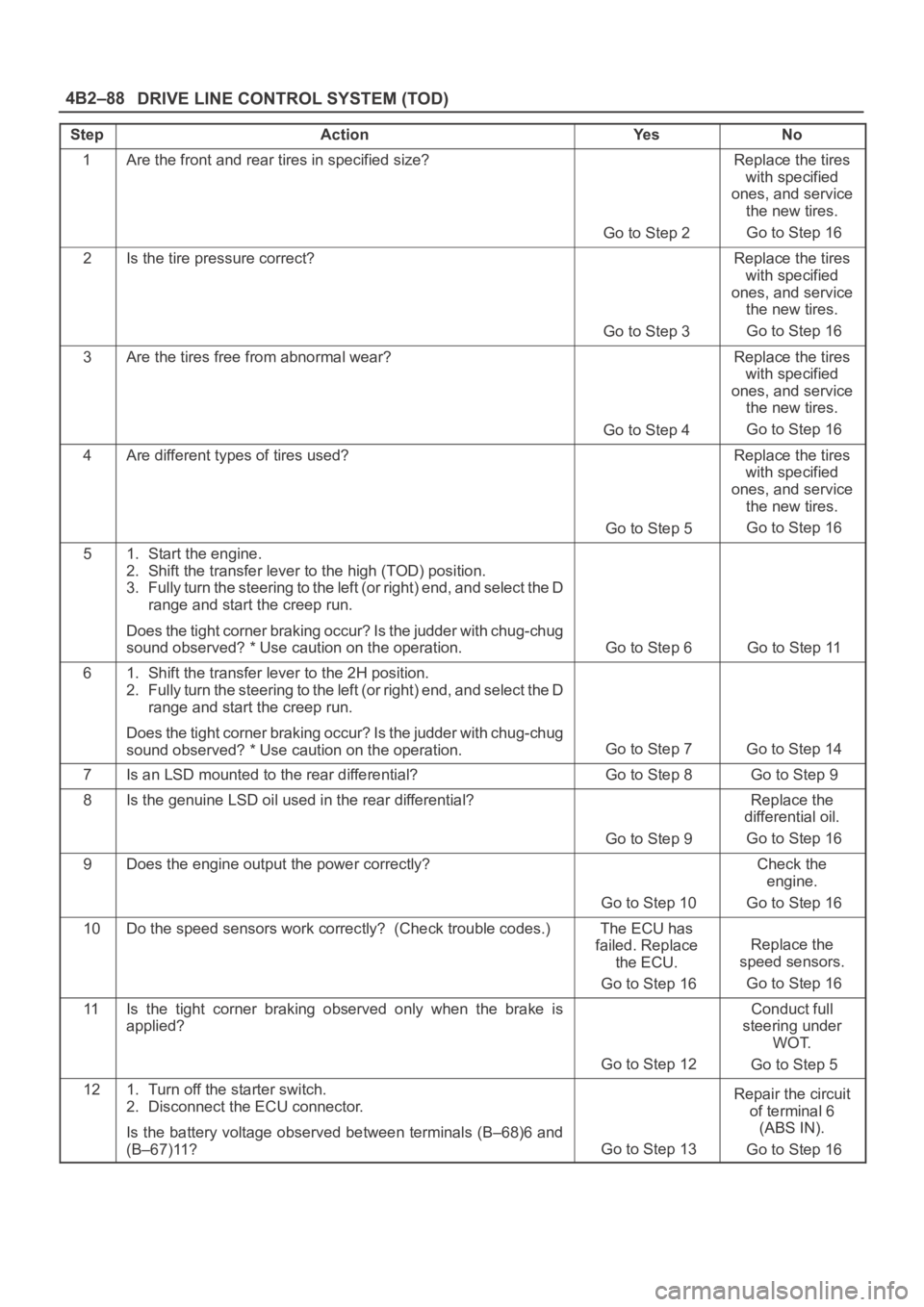

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 664 of 6000

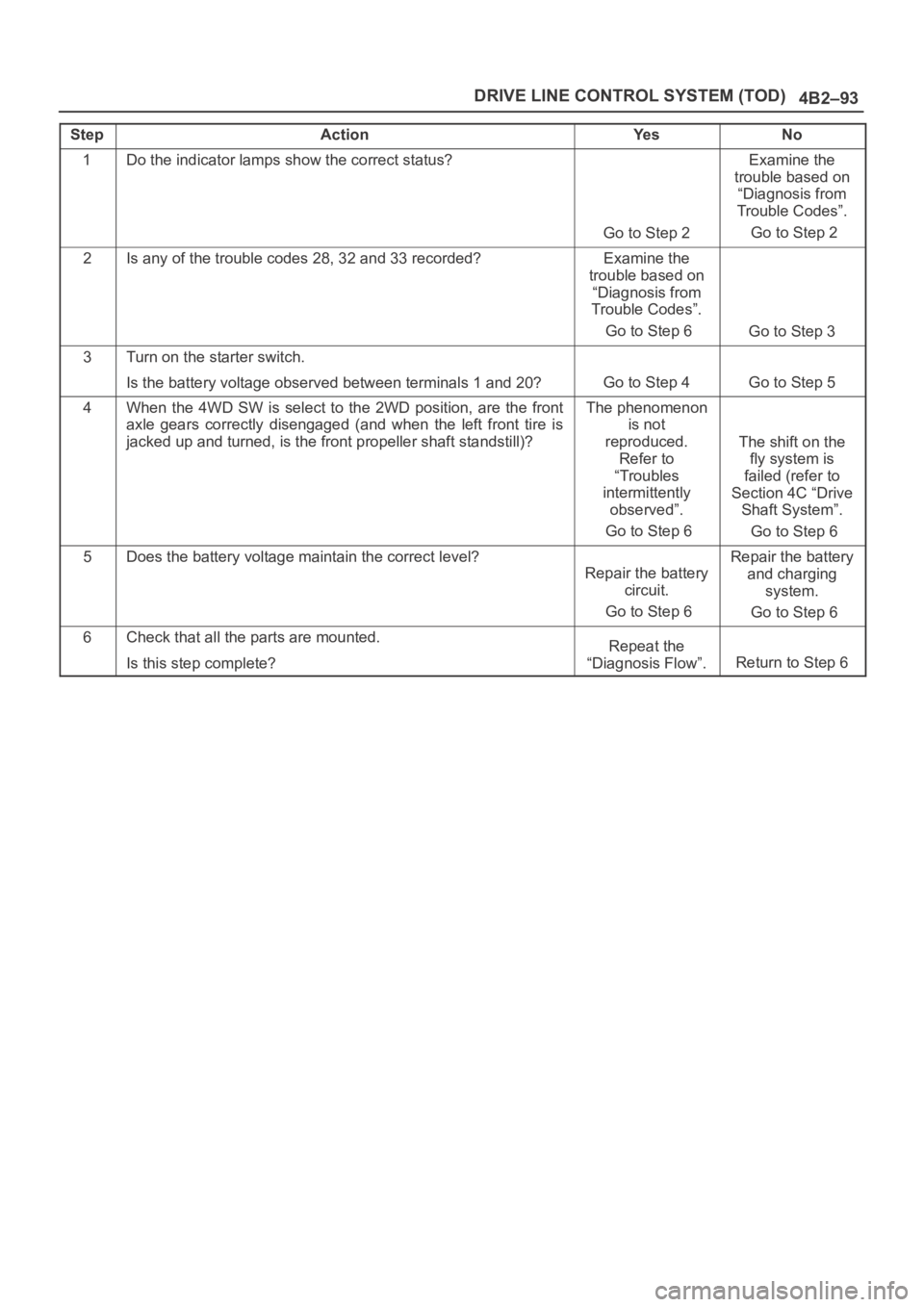

4B2–93 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

1Do the indicator lamps show the correct status?

Go to Step 2

Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 2

2Is any of the trouble codes 28, 32 and 33 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 6

Go to Step 3

3Turn on the starter switch.

Is the battery voltage observed between terminals 1 and 20?

Go to Step 4Go to Step 5

4When the 4WD SW is select to the 2WD position, are the front

axle gears correctly disengaged (and when the left front tire is

jacked up and turned, is the front propeller shaft standstill)?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 6

The shift on the

fly system is

failed (refer to

Section 4C “Drive

Shaft System”.

Go to Step 6

5Does the battery voltage maintain the correct level?

Repair the battery

circuit.

Go to Step 6

Repair the battery

and charging

system.

Go to Step 6

6Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 6

Page 666 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–95

Step Action Yes No

1 Are the brake and ABS systems healthy?

Go to Step 2Repair the

brake and ABS.

Go to Step 4

2 Turn on the starter switch.

Is the battery voltage observed between terminals 1 and 20?

Go to Step 3Repair the

battery system.

Go to Step 4

3 1. Select the 4WD SW to the 2WD position.

2. The voltage between terminals 3 and 19 range between 7.5

and 16V (0.24 seconds make a cycle)

Does the voltage within the range specified?Examine the

trouble based

on “Diagnosis

from Trouble

Codes".

Go to Step 4The ECU has

failed. Replace

the ECU.

Go to Step 4

4 Check that all the par ts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow". Return to Step 4

Page 730 of 6000

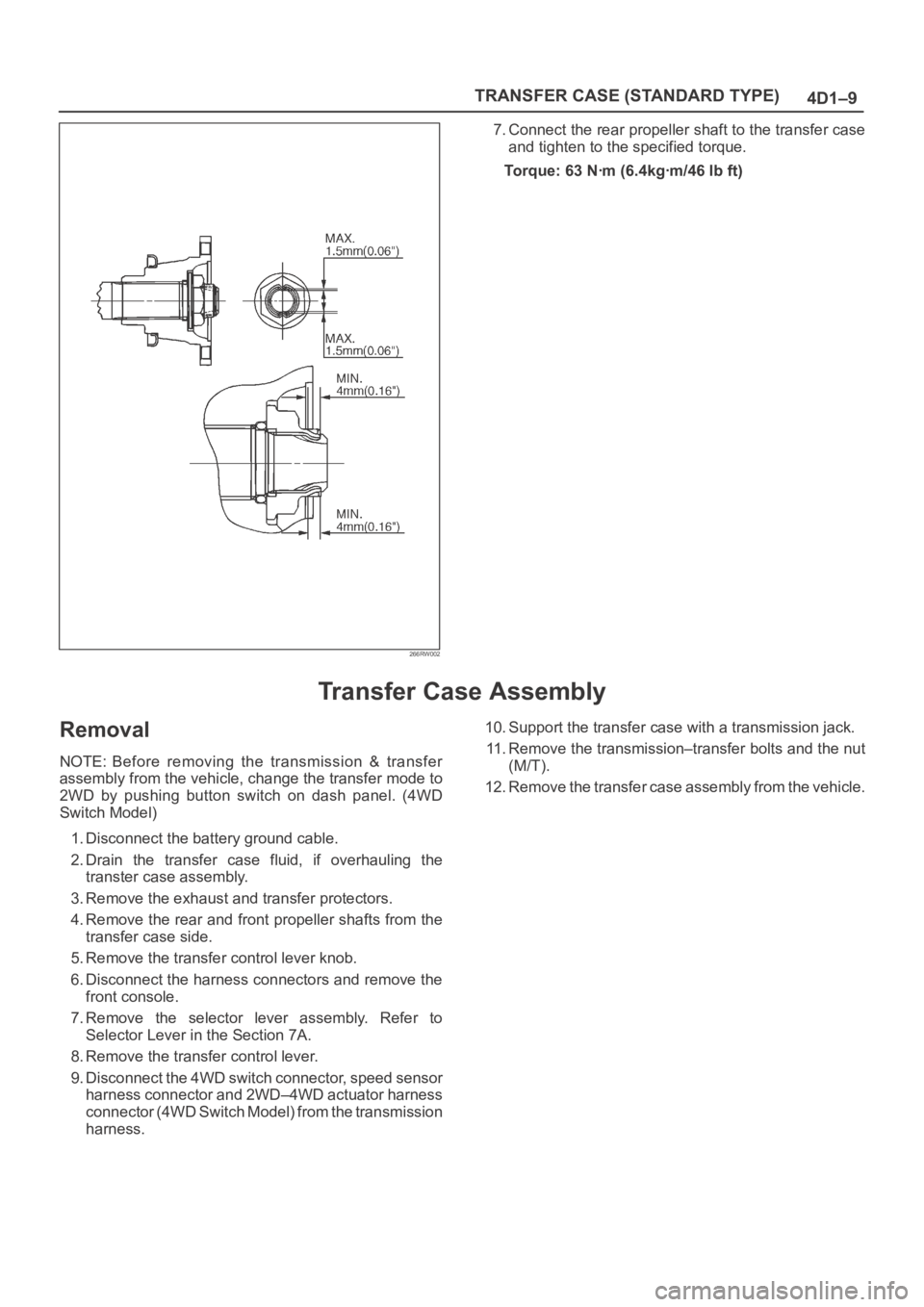

TRANSFER CASE (STANDARD TYPE)

4D1–9

266RW002

7. Connect the rear propeller shaft to the transfer case

and tighten to the specified torque.

Torque: 63 Nꞏm (6.4kgꞏm/46 lb ft)

Transfer Case Assembly

Removal

NOTE: Before removing the transmission & transfer

assembly from the vehicle, change the transfer mode to

2WD by pushing button switch on dash panel. (4WD

Switch Model)

1. Disconnect the battery ground cable.

2. Drain the transfer case fluid, if overhauling the

transter case assembly.

3. Remove the exhaust and transfer protectors.

4. Remove the rear and front propeller shafts from the

transfer case side.

5. Remove the transfer control lever knob.

6. Disconnect the harness connectors and remove the

front console.

7. Remove the selector lever assembly. Refer to

Selector Lever in the Section 7A.

8. Remove the transfer control lever.

9. Disconnect the 4WD switch connector, speed sensor

harness connector and 2WD–4WD actuator harness

connector (4WD Switch Model) from the transmission

harness.10. Support the transfer case with a transmission jack.

11. Remove the transmission–transfer bolts and the nut

(M/T).

12. Remove the transfer case assembly from the vehicle.

Page 815 of 6000

5A–5 BRAKE CONTROL SYSTEM

FR

Front Right

GEN

Generator

MV

Millivolts

RL

Rear Left

RR

Rear RightRPS

Revolution per Second

VDC

Vo l t s D C

VA C

Vo l t s A C

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS malfunction can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

Box Wrench

Brake Fluid

Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure toobserve these precautions may result in Anti-lock Brake

System damage.

If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

EHCU of the Anti-lock Brake System are not

separately serviceable and must be replaced as

assemblies. Do not disassemble any component

which is designated as non-serviceable in this

Section.

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(40A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

Improperly formed or damaged terminals.

Page 821 of 6000

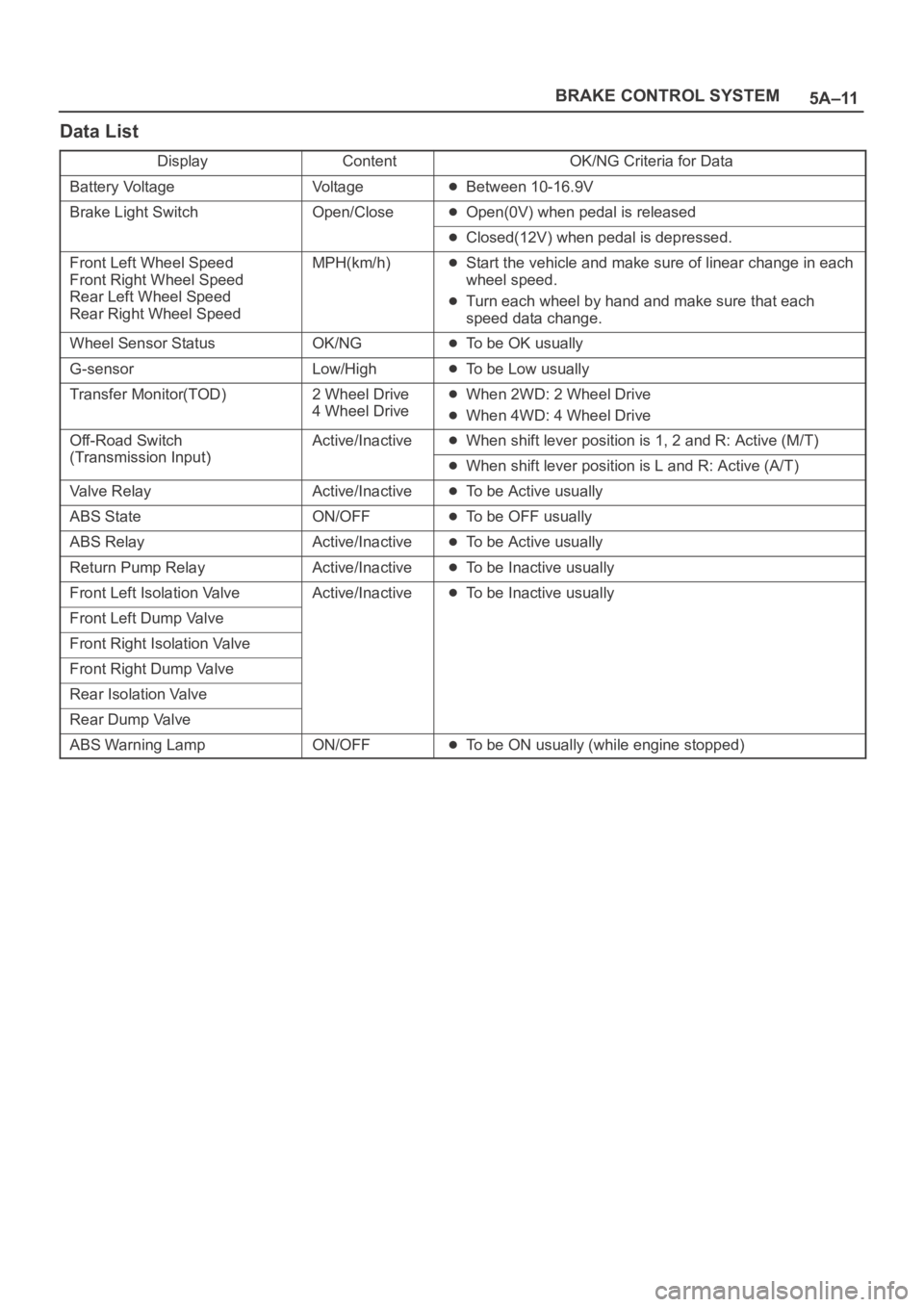

5A–11 BRAKE CONTROL SYSTEM

Data List

DisplayContentOK/NG Criteria for Data

Battery VoltageVo l t a g eBetween 10-16.9V

Brake Light SwitchOpen/CloseOpen(0V) when pedal is released

Closed(12V) when pedal is depressed.

Front Left Wheel Speed

Front Right Wheel Speed

Rear Left Wheel Speed

Rear Right Wheel SpeedMPH(km/h)Start the vehicle and make sure of linear change in each

wheel speed.

Turn each wheel by hand and make sure that each

speed data change.

Wheel Sensor StatusOK/NGTo be OK usually

G-sensorLow/HighTo be Low usually

Transfer Monitor(TOD)2 Wheel Drive

4 Wheel DriveWhen 2WD: 2 Wheel Drive

When 4WD: 4 Wheel Drive

Off-Road Switch

(Transmission Input)

Active/InactiveWhen shift lever position is 1, 2 and R: Active (M/T)

(Transmission Input)When shift lever position is L and R: Active (A/T)

Valve RelayActive/InactiveTo be Active usually

ABS StateON/OFFTo be OFF usually

ABS RelayActive/InactiveTo be Active usually

Return Pump RelayActive/InactiveTo be Inactive usually

Front Left Isolation ValveActive/InactiveTo be Inactive usually

Front Left Dump Valve

Front Right Isolation Valve

Front Right Dump Valve

Rear Isolation Valve

Rear Dump Valve

ABS Warning LampON/OFFTo be ON usually (while engine stopped)