battery OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1004 of 6000

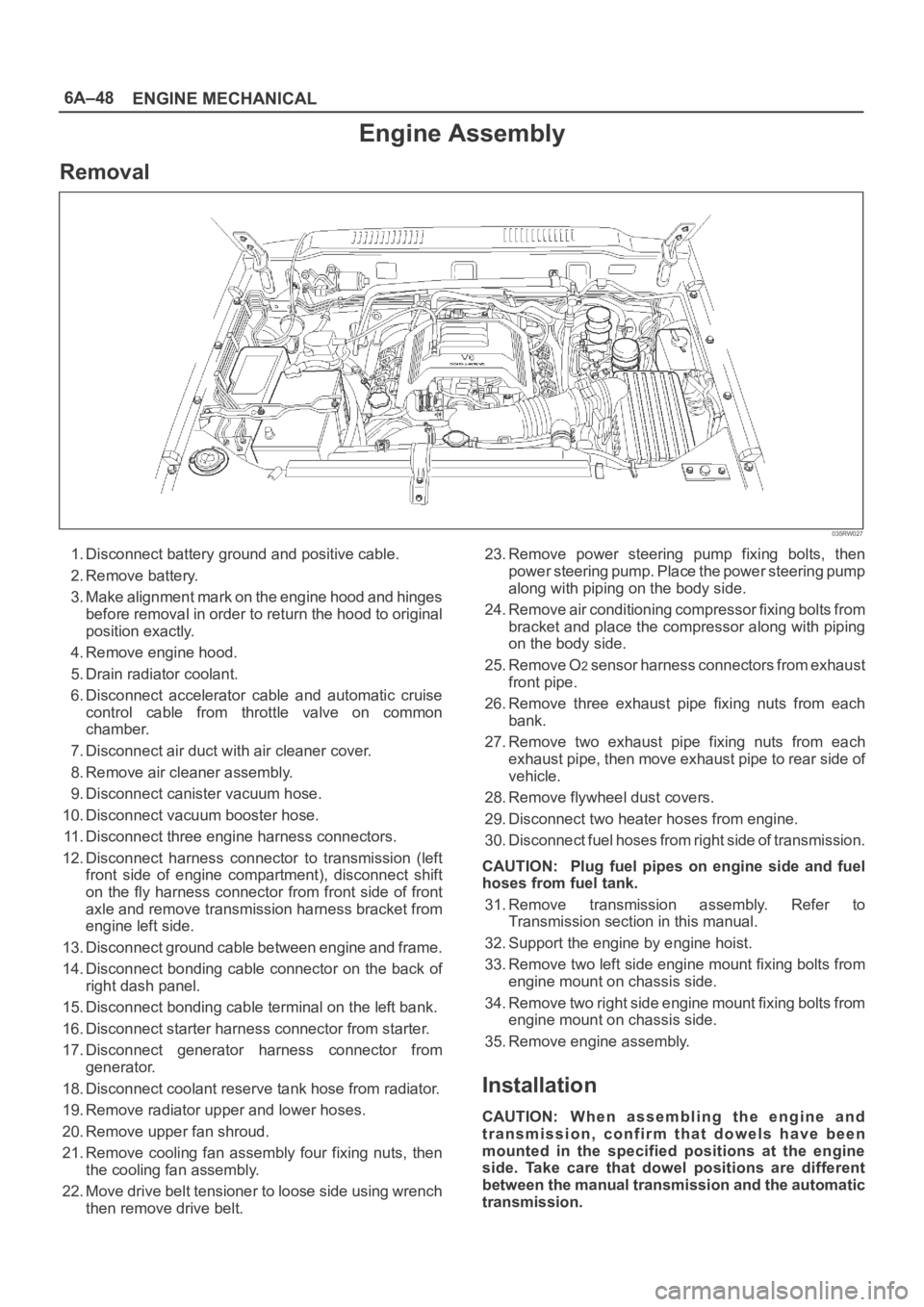

6A–48

ENGINE MECHANICAL

Engine Assembly

Removal

035RW027

1. Disconnect battery ground and positive cable.

2. Remove battery.

3. Make alignment mark on the engine hood and hinges

before removal in order to return the hood to original

position exactly.

4. Remove engine hood.

5. Drain radiator coolant.

6. Disconnect accelerator cable and automatic cruise

control cable from throttle valve on common

chamber.

7. Disconnect air duct with air cleaner cover.

8. Remove air cleaner assembly.

9. Disconnect canister vacuum hose.

10. Disconnect vacuum booster hose.

11. Disconnect three engine harness connectors.

12. Disconnect harness connector to transmission (left

front side of engine compartment), disconnect shift

on the fly harness connector from front side of front

axle and remove transmission harness bracket from

engine left side.

13. Disconnect ground cable between engine and frame.

14. Disconnect bonding cable connector on the back of

right dash panel.

15. Disconnect bonding cable terminal on the left bank.

16. Disconnect starter harness connector from starter.

17. Disconnect generator harness connector from

generator.

18. Disconnect coolant reserve tank hose from radiator.

19. Remove radiator upper and lower hoses.

20. Remove upper fan shroud.

21. Remove cooling fan assembly four fixing nuts, then

the cooling fan assembly.

22. Move drive belt tensioner to loose side using wrench

then remove drive belt.23. Remove power steering pump fixing bolts, then

power steering pump. Place the power steering pump

along with piping on the body side.

24. Remove air conditioning compressor fixing bolts from

bracket and place the compressor along with piping

on the body side.

25. Remove O

2 sensor harness connectors from exhaust

front pipe.

26. Remove three exhaust pipe fixing nuts from each

bank.

27. Remove two exhaust pipe fixing nuts from each

exhaust pipe, then move exhaust pipe to rear side of

vehicle.

28. Remove flywheel dust covers.

29. Disconnect two heater hoses from engine.

30. Disconnect fuel hoses from right side of transmission.

CAUTION: Plug fuel pipes on engine side and fuel

hoses from fuel tank.

31. Remove transmission assembly. Refer to

Transmission section in this manual.

32. Support the engine by engine hoist.

33. Remove two left side engine mount fixing bolts from

engine mount on chassis side.

34. Remove two right side engine mount fixing bolts from

engine mount on chassis side.

35. Remove engine assembly.

Installation

CAUTION: W h e n a s s e m b l i n g t h e e n g i n e a n d

transmission, confirm that dowels have been

mounted in the specified positions at the engine

side. Take care that dowel positions are different

between the manual transmission and the automatic

transmission.

Page 1060 of 6000

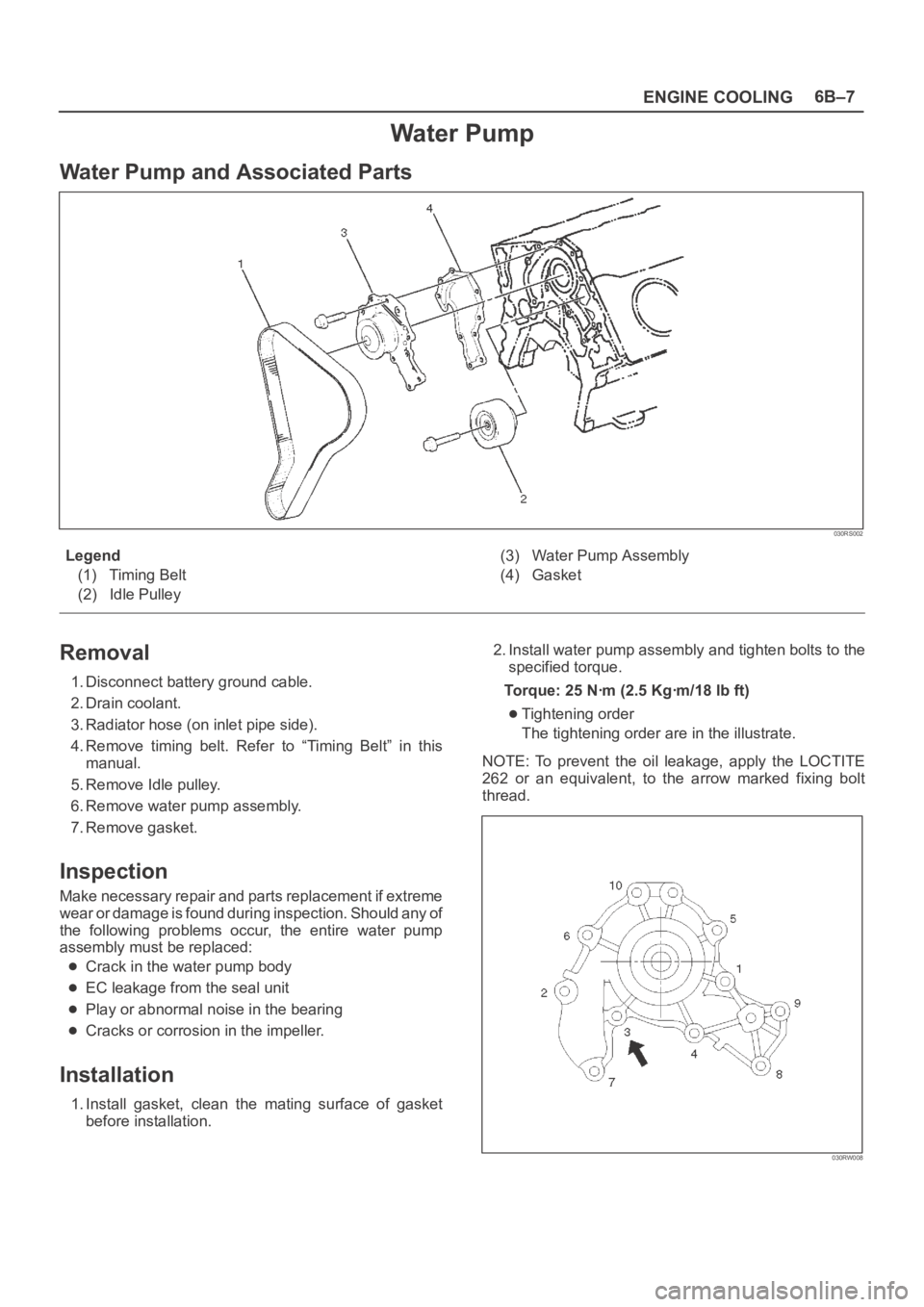

ENGINE COOLING6B–7

Water Pump

Water Pump and Associated Parts

030RS002

Legend

(1) Timing Belt

(2) Idle Pulley(3) Water Pump Assembly

(4) Gasket

Removal

1. Disconnect battery ground cable.

2. Drain coolant.

3. Radiator hose (on inlet pipe side).

4. Remove timing belt. Refer to “Timing Belt” in this

manual.

5. Remove Idle pulley.

6. Remove water pump assembly.

7. Remove gasket.

Inspection

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection. Should any of

the following problems occur, the entire water pump

assembly must be replaced:

Crack in the water pump body

EC leakage from the seal unit

Play or abnormal noise in the bearing

Cracks or corrosion in the impeller.

Installation

1. Install gasket, clean the mating surface of gasket

before installation.2. Install water pump assembly and tighten bolts to the

specified torque.

Torque: 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

Tightening order

The tightening order are in the illustrate.

NOTE: To prevent the oil leakage, apply the LOCTITE

262 or an equivalent, to the arrow marked fixing bolt

thread.

030RW008

Page 1061 of 6000

6B–8

ENGINE COOLING

3. Idle pulley

Install idle pulley and tighten bolt to the specified

torque.

Torque: 52 Nꞏm (5.3 Kgꞏm/38 lb ft)4. Timing beltInstall timing belt. Refer to timing belt installation

step in “Timing Belt” in this manual.

5. Connect radiator inlet hose and replenish EC.

6. Connect battery ground cable.

Thermostat

Thermostat and Associated Parts

031RW001

Legend

(1) Thermostat Housing

(2) Thermostat

(3) Outlet Pipe

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from the radiator and engine.

3. Disconnect radiator hose from the inlet pipe.

4. Remove thermostat housing.

5. Remove thermostat(2).

Inspection

Suspend the thermostat in a water–filled container using

thin wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water

so that the entire water is same temperature.

031RS003Confirm the temperature when the valve first begins to

open.

Valve opening temperature 74.5C

78.5C

(166.1

F 173.3F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature and lift More than

8.5mm (0.33 in) at 90

C (194F)

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection.

Installation

1. Install thermostat into the outlet pipe(4) making sure

that the air hole is in the up position.

2. Install thermostat housing and tighten bolts to the

specified torque.

Torque: 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

3. Installation rubber hose.

4. Replenish engine coolant (EC).

5. Start engine and check for EC leakage.

Page 1062 of 6000

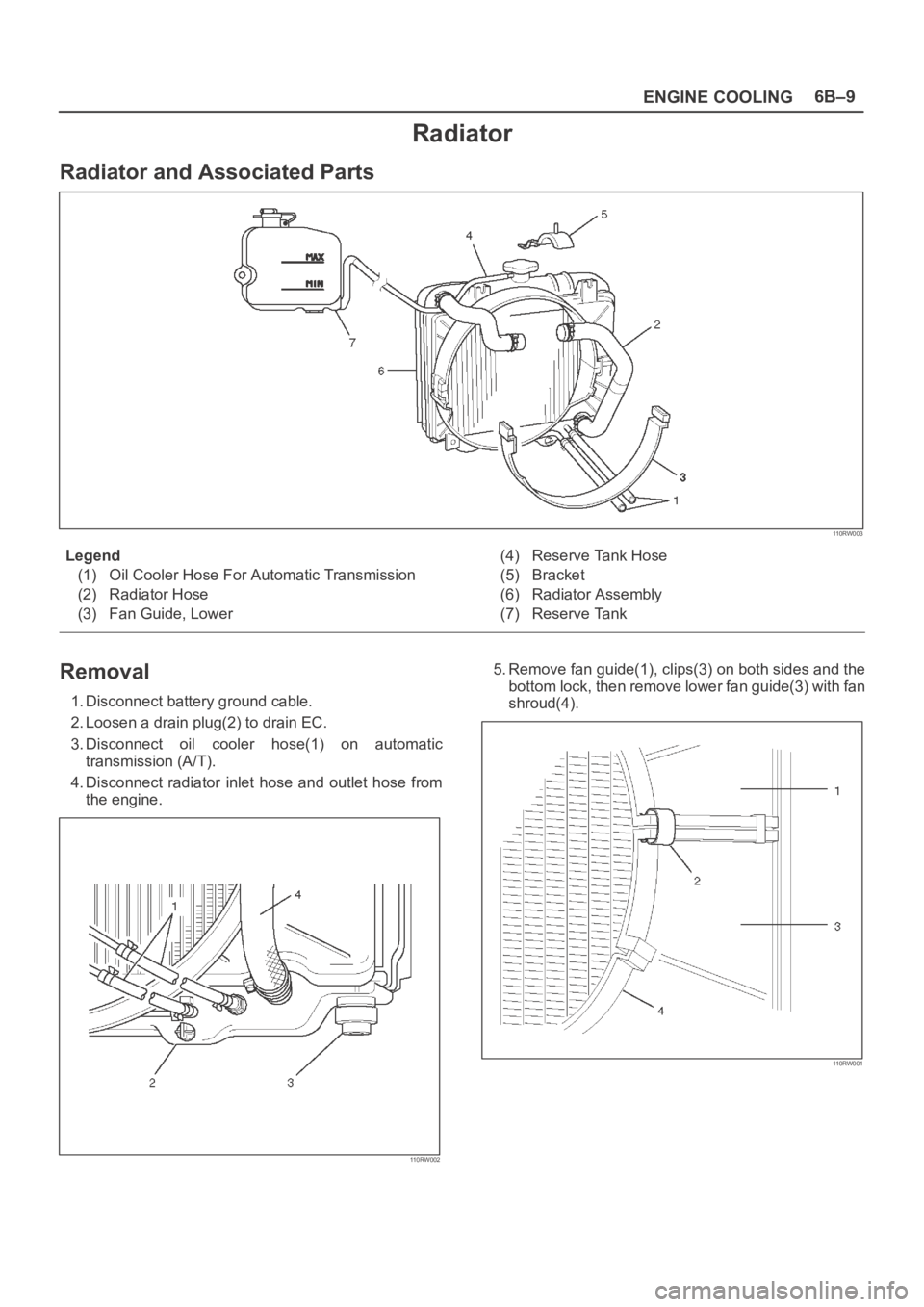

ENGINE COOLING6B–9

Radiator

Radiator and Associated Parts

110RW003

Legend

(1) Oil Cooler Hose For Automatic Transmission

(2) Radiator Hose

(3) Fan Guide, Lower(4) Reserve Tank Hose

(5) Bracket

(6) Radiator Assembly

(7) Reserve Tank

Removal

1. Disconnect battery ground cable.

2. Loosen a drain plug(2) to drain EC.

3. Disconnect oil cooler hose(1) on automatic

transmission (A/T).

4. Disconnect radiator inlet hose and outlet hose from

the engine.

110RW002

5. Remove fan guide(1), clips(3) on both sides and the

bottom lock, then remove lower fan guide(3) with fan

shroud(4).

110RW001

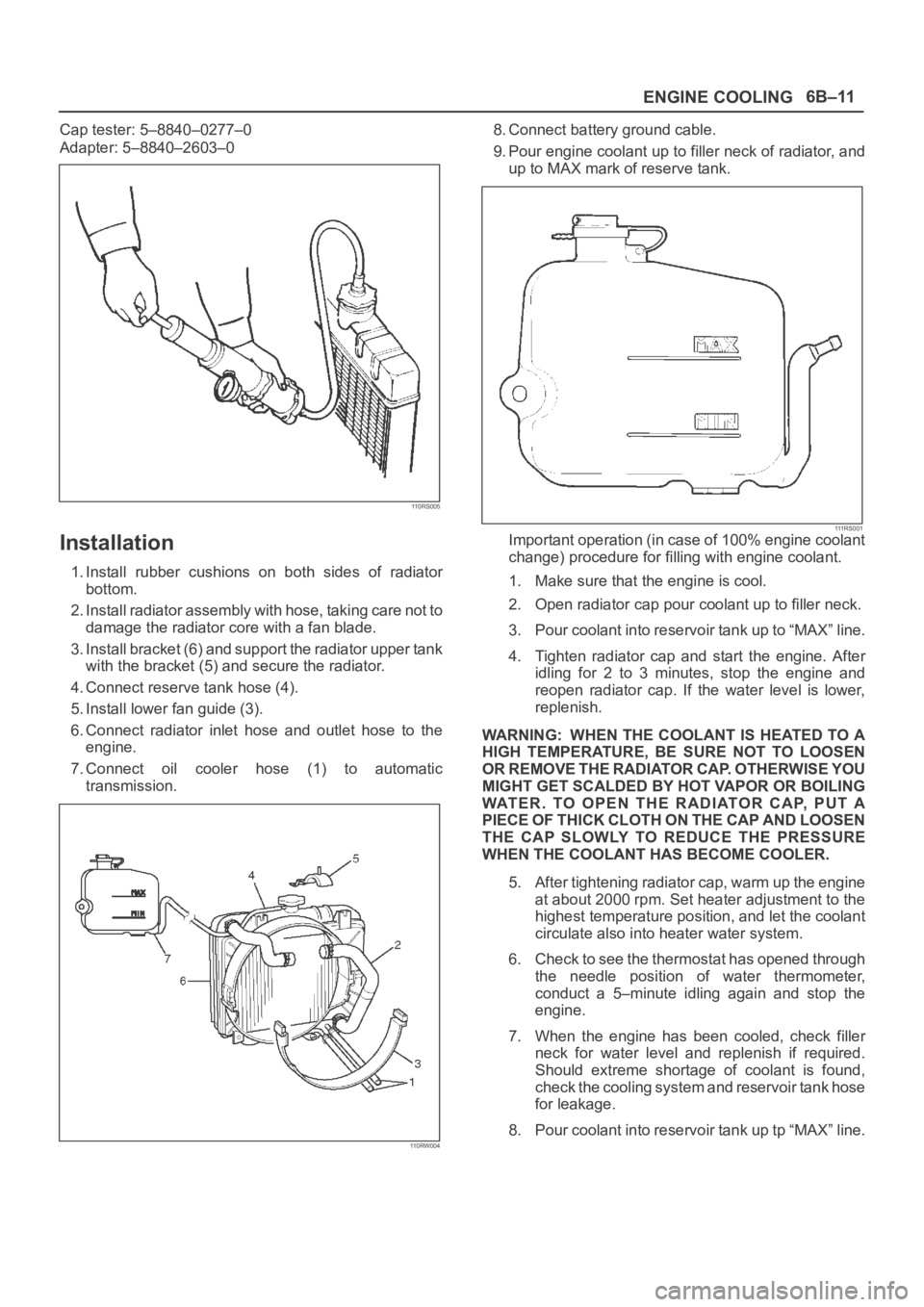

Page 1064 of 6000

ENGINE COOLING6B–11

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

Installation

1. Install rubber cushions on both sides of radiator

bottom.

2. Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3. Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4. Connect reserve tank hose (4).

5. Install lower fan guide (3).

6. Connect radiator inlet hose and outlet hose to the

engine.

7. Connect oil cooler hose (1) to automatic

transmission.

110RW004

8. Connect battery ground cable.

9. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111 R S 0 0 1Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

1. Make sure that the engine is cool.

2. Open radiator cap pour coolant up to filler neck.

3. Pour coolant into reservoir tank up to “MAX” line.

4. Tighten radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING: WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

5. After tightening radiator cap, warm up the engine

at about 2000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

6. Check to see the thermostat has opened through

the needle position of water thermometer,

conduct a 5–minute idling again and stop the

engine.

7. When the engine has been cooled, check filler

neck for water level and replenish if required.

Should extreme shortage of coolant is found,

check the cooling system and reservoir tank hose

for leakage.

8. Pour coolant into reservoir tank up tp “MAX” line.

Page 1069 of 6000

6C–2

ENGINE FUEL

General Description

140RW030

Legend

(1) Fuel Filler Cap

(2) Fuel Tank

(3) Rollover Valve

(4) Fuel Pump

(5) Fuel Filter

(6) Fuel Rail Right

(7) Right Bank(8) Fuel Rail Left

(9) Left Bank

(10) Fuel Pressure Control Valve

(11) Common Chamber

(12) Duty Solenoid Valve

(13) Throttle Valve

(14) Canister

When working on the fuel system, there are several

things to keep in mind:

Any time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

Always keep a dry chemical (Class B) fire

extinguisher near the work area.

Replace all pipes with the same pipe and fittings that

were removed.

Clean and inspect “O” rings. Replace if required.

Always relieve the line pressure before servicing any

fuel system components.

Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

Page 1071 of 6000

6C–4

ENGINE FUEL

Fuel Filter

Fuel Filter and Associated Parts

041RW014

Legend

(1) Fuel Filler Cap

(2) Fuel Hose(3) Fuel Filter Fixing Bolt

(4) Fuel Filter

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

1. Disconnect battery ground cable.

2. Remove Fuel filler cap(1).

3. Disconnect fuel hoses(2) from fuel filter on both

engine side and fuel tank side.

4. Fuel filter fixing bolt(3).

Remove the fuel filter fixing bolt(3) on fuel filter

holder.

5. Remove fuel filter(4).

Inspection

1. Replace the fuel filter if the fuel leaks from fuel filter

body or if the fuel filter body itself is damaged.

2. Replace the filter if it is clogged with dirt or sediment.

3. Check the drain of receive rubber and if it is clogged

with dust, clean it up with air.

Page 1072 of 6000

6C–5

ENGINE FUEL

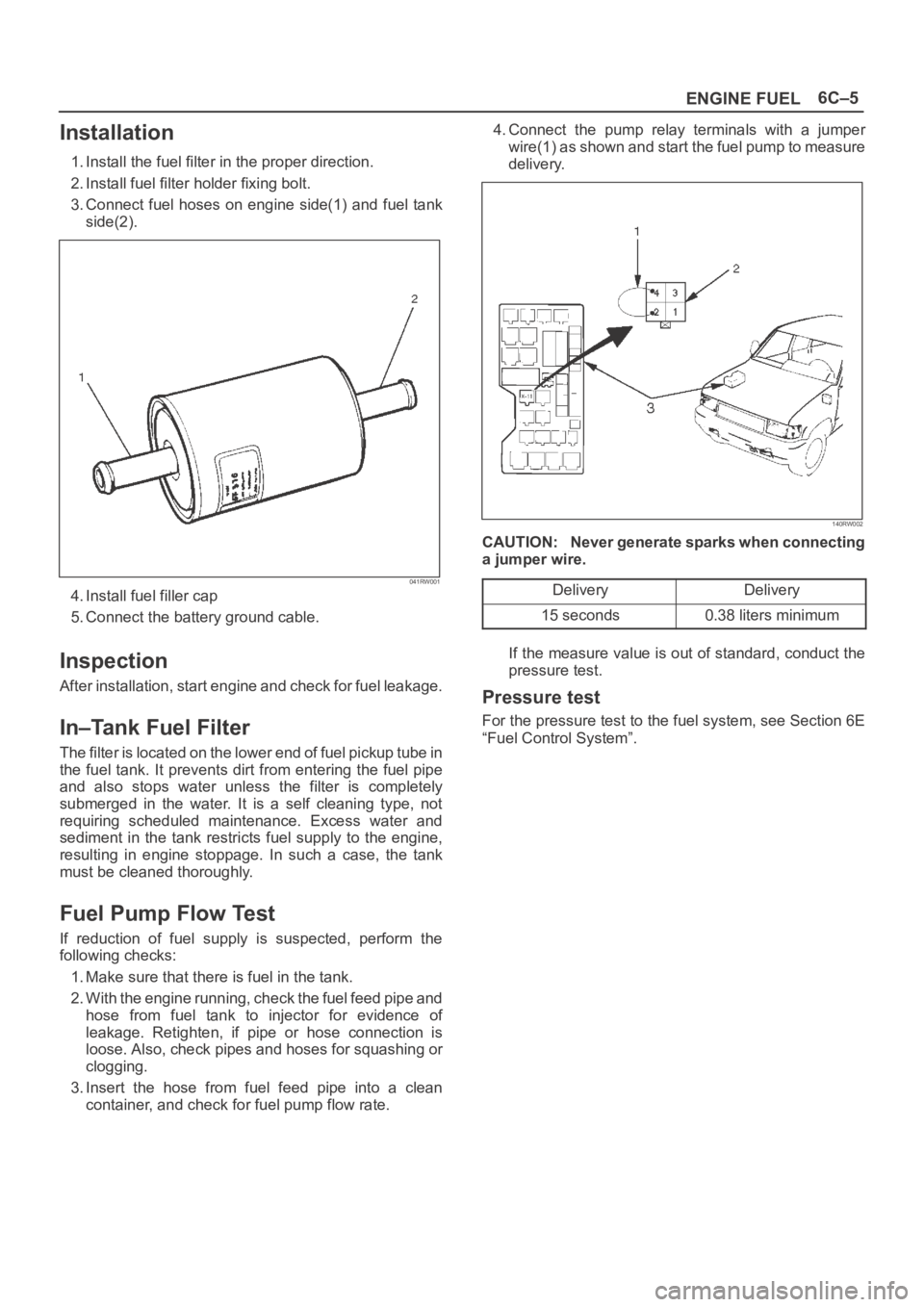

Installation

1. Install the fuel filter in the proper direction.

2. Install fuel filter holder fixing bolt.

3. Connect fuel hoses on engine side(1) and fuel tank

side(2).

041RW001

4. Install fuel filler cap

5. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube in

the fuel tank. It prevents dirt from entering the fuel pipe

and also stops water unless the filter is completely

submerged in the water. It is a self cleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks:

1. Make sure that there is fuel in the tank.

2. With the engine running, check the fuel feed pipe and

hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, check pipes and hoses for squashing or

clogging.

3. Insert the hose from fuel feed pipe into a clean

container, and check for fuel pump flow rate.4. Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to measure

delivery.

140RW002

CAUTION: Never generate sparks when connecting

a jumper wire.

Delivery

Delivery

15 seconds0.38 liters minimum

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

“Fuel Control System”.

Page 1073 of 6000

6C–6

ENGINE FUEL

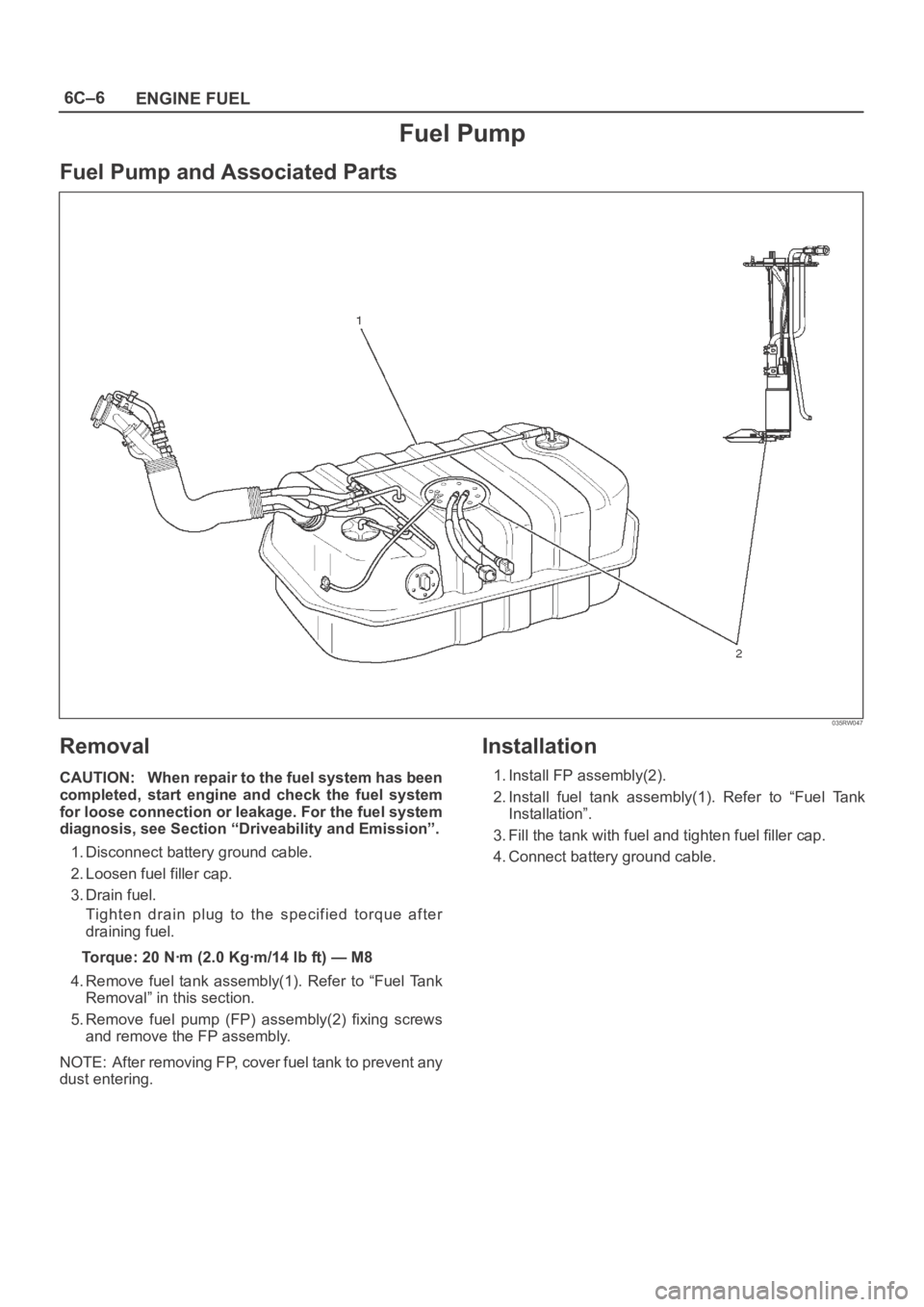

Fuel Pump

Fuel Pump and Associated Parts

035RW047

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

1. Disconnect battery ground cable.

2. Loosen fuel filler cap.

3. Drain fuel.

Tighten drain plug to the specified torque after

draining fuel.

Torque: 20 Nꞏm (2.0 Kgꞏm/14 lb ft) — M8

4. Remove fuel tank assembly(1). Refer to “Fuel Tank

Removal” in this section.

5. Remove fuel pump (FP) assembly(2) fixing screws

and remove the FP assembly.

NOTE: After removing FP, cover fuel tank to prevent any

dust entering.

Installation

1. Install FP assembly(2).

2. Install fuel tank assembly(1). Refer to “Fuel Tank

Installation”.

3. Fill the tank with fuel and tighten fuel filler cap.

4. Connect battery ground cable.

Page 1074 of 6000

6C–7

ENGINE FUEL

Fuel Pump Relay

General Description

In order to control the FP operation, the FP relay is

provided. When the starter switch is turned to “ON”

position, the FP relay operates the FP for 2 seconds.When it is turned to “START” position, the Power Train

Control Module (PCM) receives the reference pulse from

the Ignition Control Module and it operates the relay,

again causing the FP to feed fuel.

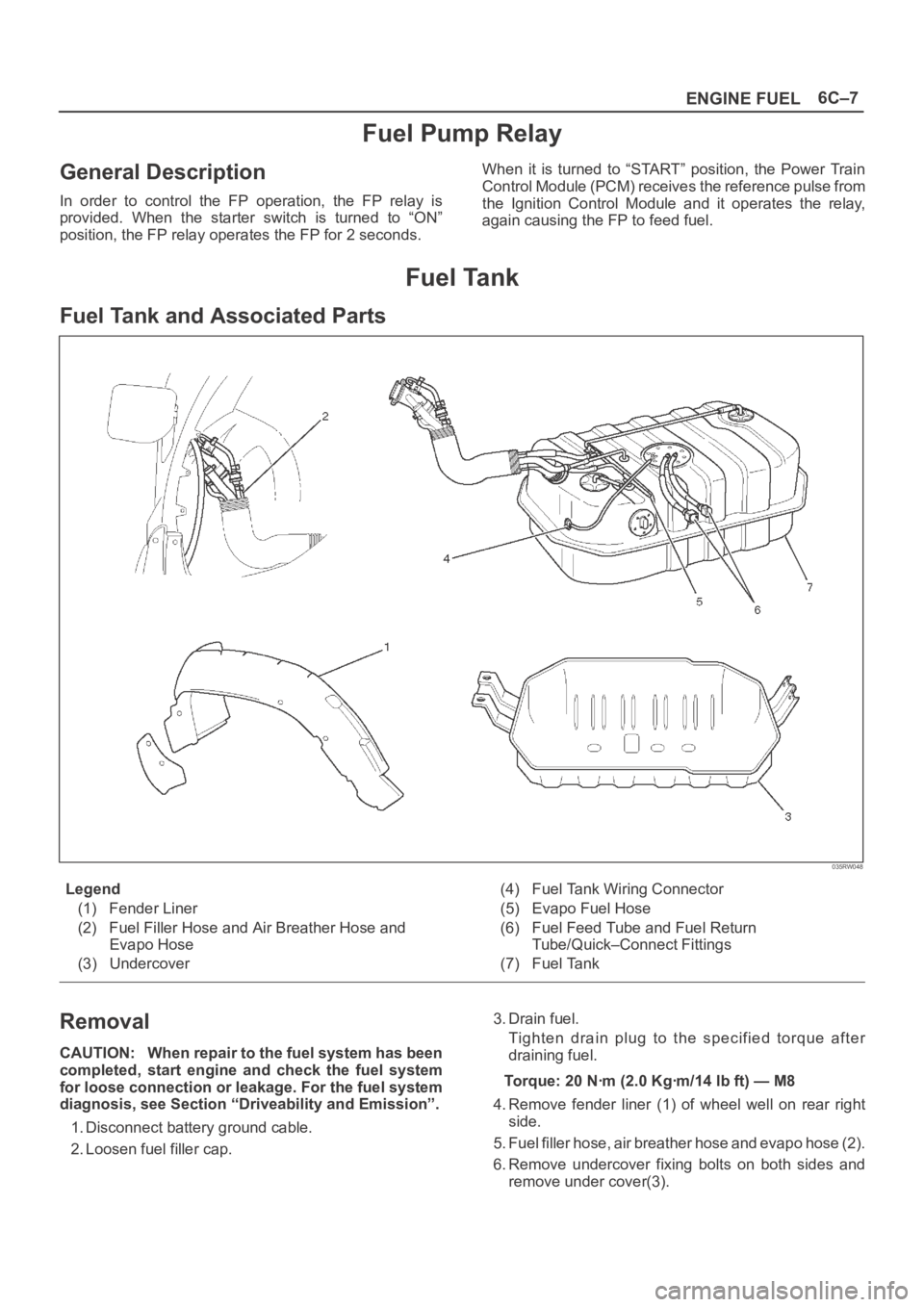

Fuel Tank

Fuel Tank and Associated Parts

035RW048

Legend

(1) Fender Liner

(2) Fuel Filler Hose and Air Breather Hose and

Evapo Hose

(3) Undercover(4) Fuel Tank Wiring Connector

(5) Evapo Fuel Hose

(6) Fuel Feed Tube and Fuel Return

Tube/Quick–Connect Fittings

(7) Fuel Tank

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

1. Disconnect battery ground cable.

2. Loosen fuel filler cap.3. Drain fuel.

Tighten drain plug to the specified torque after

draining fuel.

Torque: 20 Nꞏm (2.0 Kgꞏm/14 lb ft) — M8

4. Remove fender liner (1) of wheel well on rear right

side.

5. Fuel filler hose, air breather hose and evapo hose (2).

6. Remove undercover fixing bolts on both sides and

remove under cover(3).