battery OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 974 of 6000

6A–18

ENGINE MECHANICAL

Cylinder Head Cover LH

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from faucet bottom of radiator.

3. Remove engine cover from the dowels on the

common chamber.

F06RW018

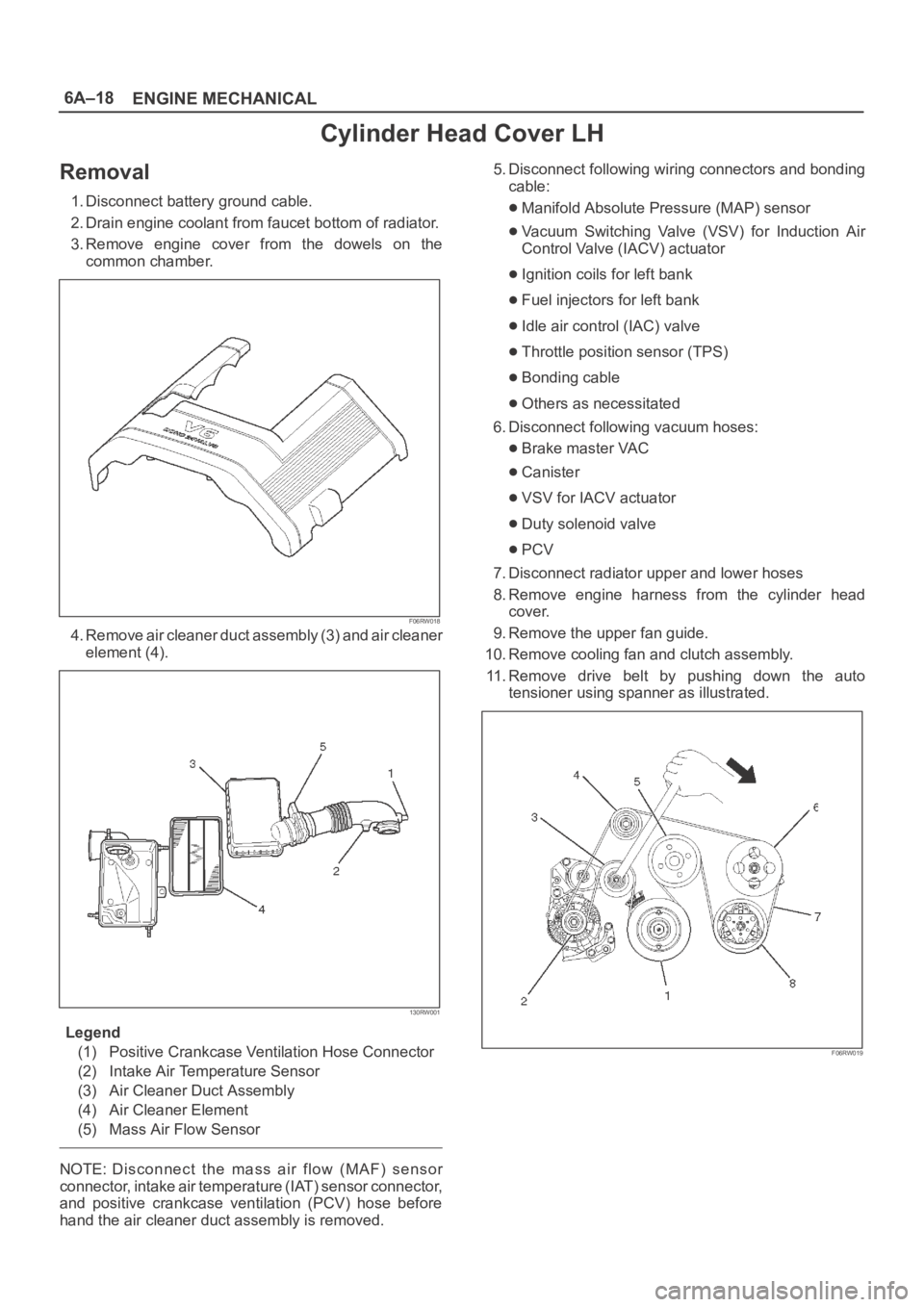

4. Remove air cleaner duct assembly (3) and air cleaner

element (4).

130RW001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

NOTE: Disconnect the mass air flow (MAF) sensor

connector, intake air temperature (IAT) sensor connector,

and positive crankcase ventilation (PCV) hose before

hand the air cleaner duct assembly is removed.5. Disconnect following wiring connectors and bonding

cable:

Manifold Absolute Pressure (MAP) sensor

Vacuum Switching Valve (VSV) for Induction Air

Control Valve (IACV) actuator

Ignition coils for left bank

Fuel injectors for left bank

Idle air control (IAC) valve

Throttle position sensor (TPS)

Bonding cable

Others as necessitated

6. Disconnect following vacuum hoses:

Brake master VAC

Canister

VSV for IACV actuator

Duty solenoid valve

PCV

7. Disconnect radiator upper and lower hoses

8. Remove engine harness from the cylinder head

cover.

9. Remove the upper fan guide.

10. Remove cooling fan and clutch assembly.

11. Remove drive belt by pushing down the auto

tensioner using spanner as illustrated.

F06RW019

Page 977 of 6000

6A–21

ENGINE MECHANICAL

Cylinder Head Cover RH

Removal

1. Disconnect battery ground cable.

2. Remove battery from the vehicle.

3. Drain engine coolant from faucet bottom of radiator.

4. Remove engine cover from the dowels on the

common chamber.

F06RW018

5. Remove air cleaner duct assembly (3) and air cleaner

element (4).

130RW001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

NOTE: Disconnect the mass air flow (MAF) sensor

connector, intake air temperature (IAT) sensor connector,

and positive crankcase ventilation (PCV) hose before

hand the air cleaner duct assembly is removed.

6. Disconnect following wiring connectors and bonding

cable:

Exhaust Gas Recirculation (EGR) valve

Fuel injectors for right bank

Ignition coils for right bank

Bonding cable

Othres as necessitated

7. Disconnect radiator upper and lower hoses.

8. Remove engine harness from the cylinder head

cover.

9. Remove the upper fan guide.

10. Remove cooling fan and clutch assembly.

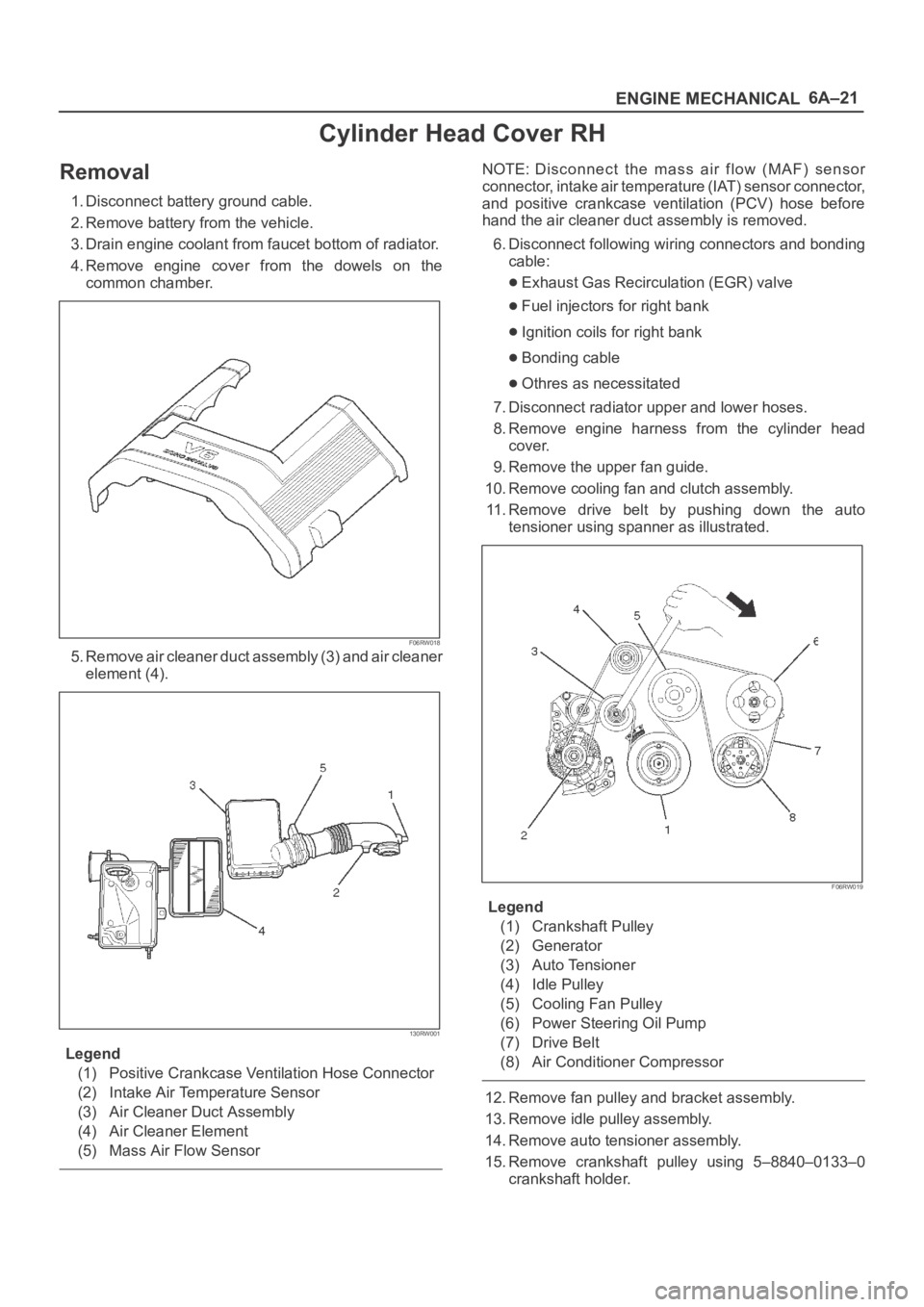

11. Remove drive belt by pushing down the auto

tensioner using spanner as illustrated.

F06RW019

Legend

(1) Crankshaft Pulley

(2) Generator

(3) Auto Tensioner

(4) Idle Pulley

(5) Cooling Fan Pulley

(6) Power Steering Oil Pump

(7) Drive Belt

(8) Air Conditioner Compressor

12. Remove fan pulley and bracket assembly.

13. Remove idle pulley assembly.

14. Remove auto tensioner assembly.

15. Remove crankshaft pulley using 5–8840–0133–0

crankshaft holder.

Page 980 of 6000

6A–24

ENGINE MECHANICAL

Common Chamber

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner duct assembly.

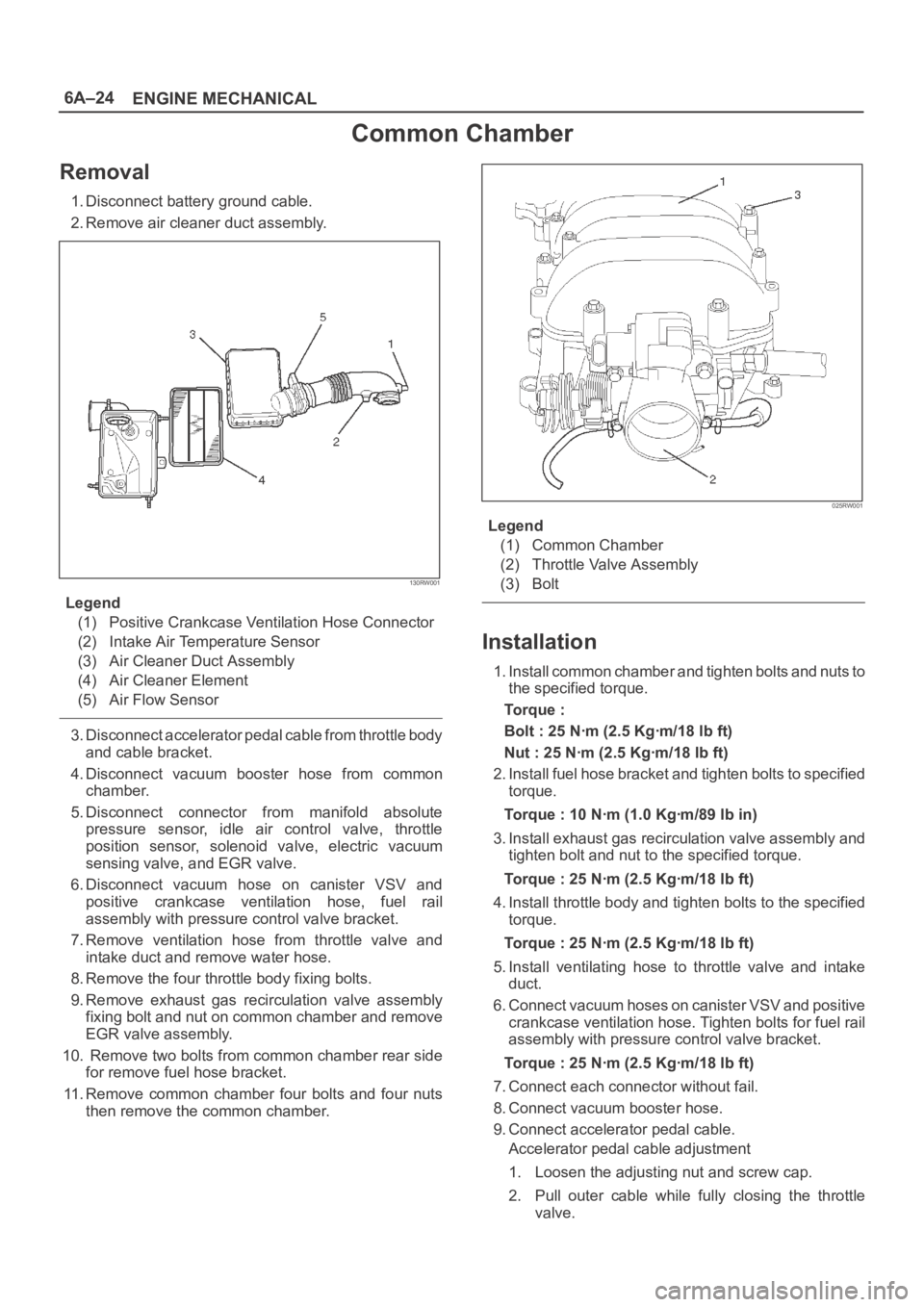

130RW001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Air Flow Sensor

3. Disconnect accelerator pedal cable from throttle body

and cable bracket.

4. Disconnect vacuum booster hose from common

chamber.

5. Disconnect connector from manifold absolute

pressure sensor, idle air control valve, throttle

position sensor, solenoid valve, electric vacuum

sensing valve, and EGR valve.

6. Disconnect vacuum hose on canister VSV and

positive crankcase ventilation hose, fuel rail

assembly with pressure control valve bracket.

7. Remove ventilation hose from throttle valve and

intake duct and remove water hose.

8. Remove the four throttle body fixing bolts.

9. Remove exhaust gas recirculation valve assembly

fixing bolt and nut on common chamber and remove

EGR valve assembly.

10. Remove two bolts from common chamber rear side

for remove fuel hose bracket.

11. Remove common chamber four bolts and four nuts

then remove the common chamber.

025RW001

Legend

(1) Common Chamber

(2) Throttle Valve Assembly

(3) Bolt

Installation

1. Install common chamber and tighten bolts and nuts to

the specified torque.

To r q u e :

Bolt : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

Nut : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

2. Install fuel hose bracket and tighten bolts to specified

torque.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

3. Install exhaust gas recirculation valve assembly and

tighten bolt and nut to the specified torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

4. Install throttle body and tighten bolts to the specified

torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

5. Install ventilating hose to throttle valve and intake

duct.

6. Connect vacuum hoses on canister VSV and positive

crankcase ventilation hose. Tighten bolts for fuel rail

assembly with pressure control valve bracket.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

7. Connect each connector without fail.

8. Connect vacuum booster hose.

9. Connect accelerator pedal cable.

Accelerator pedal cable adjustment

1. Loosen the adjusting nut and screw cap.

2. Pull outer cable while fully closing the throttle

valve.

Page 982 of 6000

6A–26

ENGINE MECHANICAL

Exhaust Manifold LH

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner duct assembly.

130RW001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

3. Remove exhaust front pipe three stud nuts from

exhaust side and two nuts from rear end of exhaust

front pipe.

150RW062

Legend

(1) Exhaust Front Pipe LH

4. Remove heat protector two fixing bolts then the heat

protector.5. Remove a bolt on engine LH side for air conditioner

(A/C) compressor bracket and loosen two bolts for

A/C compressor then move A/C compressor to front

side.

6. Remove exhaust manifold eight fixing nuts and

remove exhaust manifold from the engine.

Installation

1. Install exhaust manifold and tighten exhaust manifold

fixing nuts to the specified torque with new nuts.

Torque: 57 Nꞏm (5.8 Kgꞏm/42 lb ft)

2. Install heat protector.

3. Install exhaust front pipe and tighten three stud nuts

and two nuts to the specified torque.

To r q u e :

Stud nuts: 67 Nꞏm (6.8 Kgꞏm/49 lb ft)

Nuts: 43 Nꞏm (4.4 Kgꞏm/32 lb ft)

150RW062

Legend

(1) Exhaust Front Pipe LH

4. Set A/C compressor to normal position and tighten

two bolts and a bolt to the specified torque.

Torque : 40 Nꞏm (4.1 Kgꞏm/30 lb ft)

5. Install air cleaner duct assembly.

Page 983 of 6000

6A–27

ENGINE MECHANICAL

Exhaust Manifold RH

Removal

1. Disconnect battery ground cable.

2. Remove torsion bar. Refer to removal procedure in

Front Suspension section.

3. Remove exhaust front pipe three stud nuts and two

nuts then disconnect exhaust front pipe.

150RW061

Legend

(1) Exhaust Front Pipe RH

(2) O

2 Sensor (for IGM)

4. Remove heat protector two fixing bolts then the heat

protector.

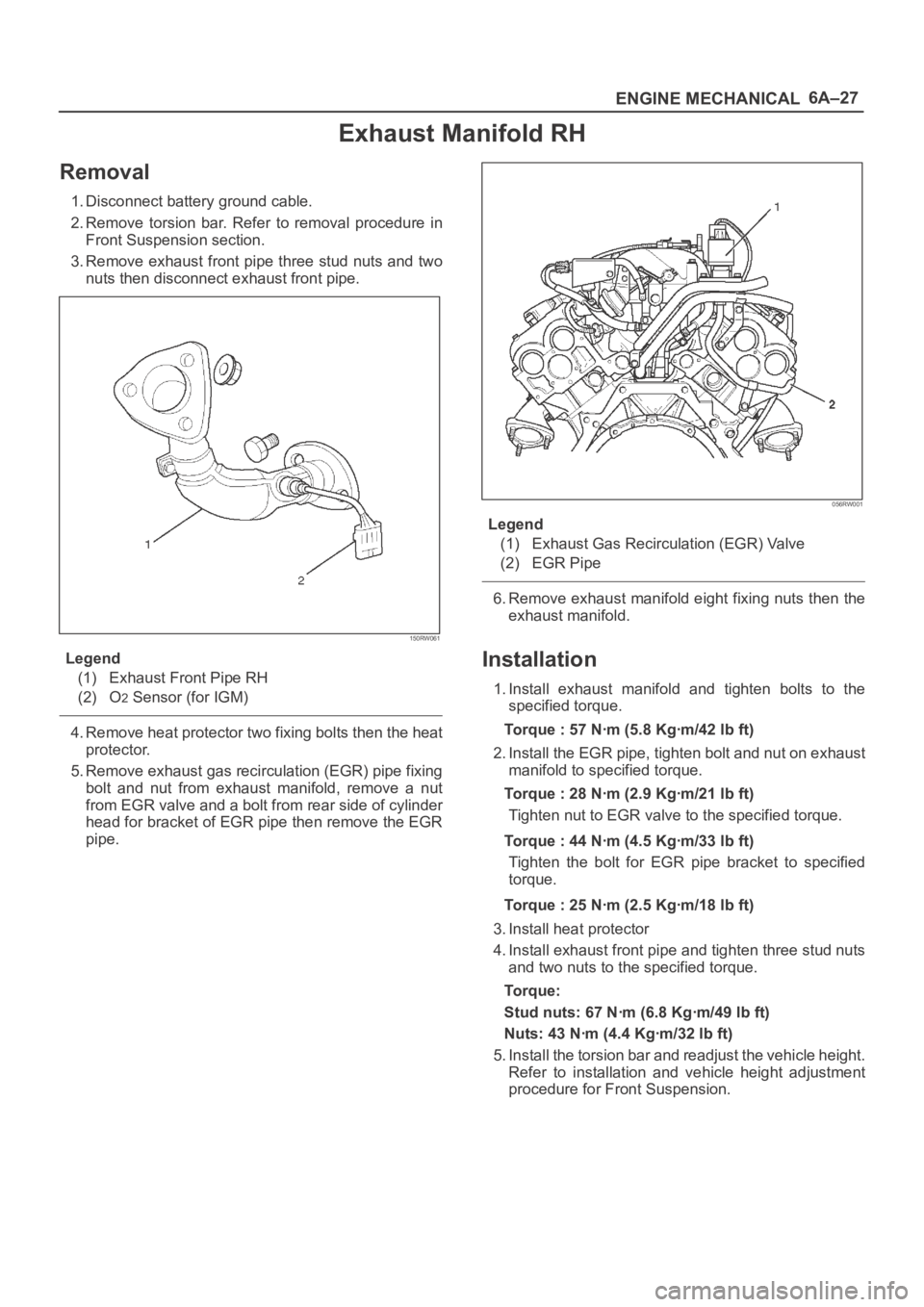

5. Remove exhaust gas recirculation (EGR) pipe fixing

bolt and nut from exhaust manifold, remove a nut

from EGR valve and a bolt from rear side of cylinder

head for bracket of EGR pipe then remove the EGR

pipe.

056RW001

Legend

(1) Exhaust Gas Recirculation (EGR) Valve

(2) EGR Pipe

6. Remove exhaust manifold eight fixing nuts then the

exhaust manifold.

Installation

1. Install exhaust manifold and tighten bolts to the

specified torque.

Torque : 57 Nꞏm (5.8 Kgꞏm/42 lb ft)

2. Install the EGR pipe, tighten bolt and nut on exhaust

manifold to specified torque.

Torque : 28 Nꞏm (2.9 Kgꞏm/21 lb ft)

Tighten nut to EGR valve to the specified torque.

Torque : 44 Nꞏm (4.5 Kgꞏm/33 lb ft)

Tighten the bolt for EGR pipe bracket to specified

torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

3. Install heat protector

4. Install exhaust front pipe and tighten three stud nuts

and two nuts to the specified torque.

To r q u e :

Stud nuts: 67 Nꞏm (6.8 Kgꞏm/49 lb ft)

Nuts: 43 Nꞏm (4.4 Kgꞏm/32 lb ft)

5. Install the torsion bar and readjust the vehicle height.

Refer to installation and vehicle height adjustment

procedure for Front Suspension.

Page 984 of 6000

6A–28

ENGINE MECHANICAL

Crankshaft Pulley

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner assembly.

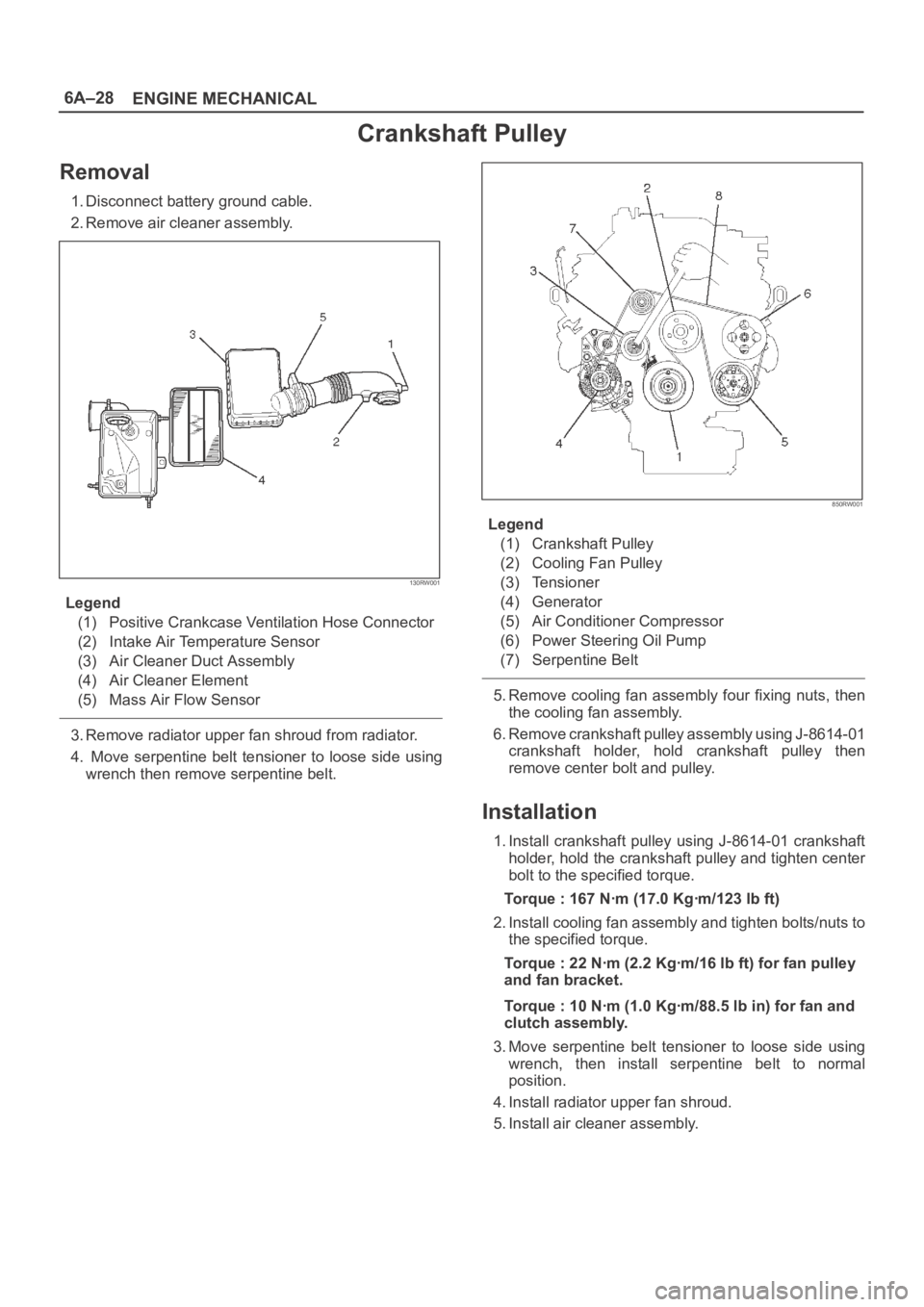

130RW001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

3. Remove radiator upper fan shroud from radiator.

4. Move serpentine belt tensioner to loose side using

wrench then remove serpentine belt.

850RW001

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Serpentine Belt

5. Remove cooling fan assembly four fixing nuts, then

the cooling fan assembly.

6. Remove crankshaft pulley assembly using J-8614-01

crankshaft holder, hold crankshaft pulley then

remove center bolt and pulley.

Installation

1. Install crankshaft pulley using J-8614-01 crankshaft

holder, hold the crankshaft pulley and tighten center

bolt to the specified torque.

Torque : 167 Nꞏm (17.0 Kgꞏm/123 lb ft)

2. Install cooling fan assembly and tighten bolts/nuts to

the specified torque.

Torque : 22 Nꞏm (2.2 Kgꞏm/16 lb ft) for fan pulley

and fan bracket.

Torque : 10 Nꞏm (1.0 Kgꞏm/88.5 lb in) for fan and

clutch assembly.

3. Move serpentine belt tensioner to loose side using

wrench, then install serpentine belt to normal

position.

4. Install radiator upper fan shroud.

5. Install air cleaner assembly.

Page 985 of 6000

6A–29

ENGINE MECHANICAL

Timing Belt

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner assembly.

3. Remove radiator upper fan shroud from radiator.

4. Move drive belt tensioner to loose side using wrench

then remove drive belt.

850RW001

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Drive Belt

5. Remove cooling fan assembly four nuts, then the

cooling fan assembly.

6. Remove cooling fan drive pulley assembly.

7. Remove idle pulley assembly.

8. Remove serpentine belt tensioner assembly.

9. Remove power steering pump assembly.

10. Remove crankshaft pulley assembly using

5–8840–0133–0 crankshaft holder, hold crankshaft

pulley remove center bolt, then the pulley.

11. Remove right side timing belt cover then left side

timing belt cover.

12. Remove lower timing belt cover

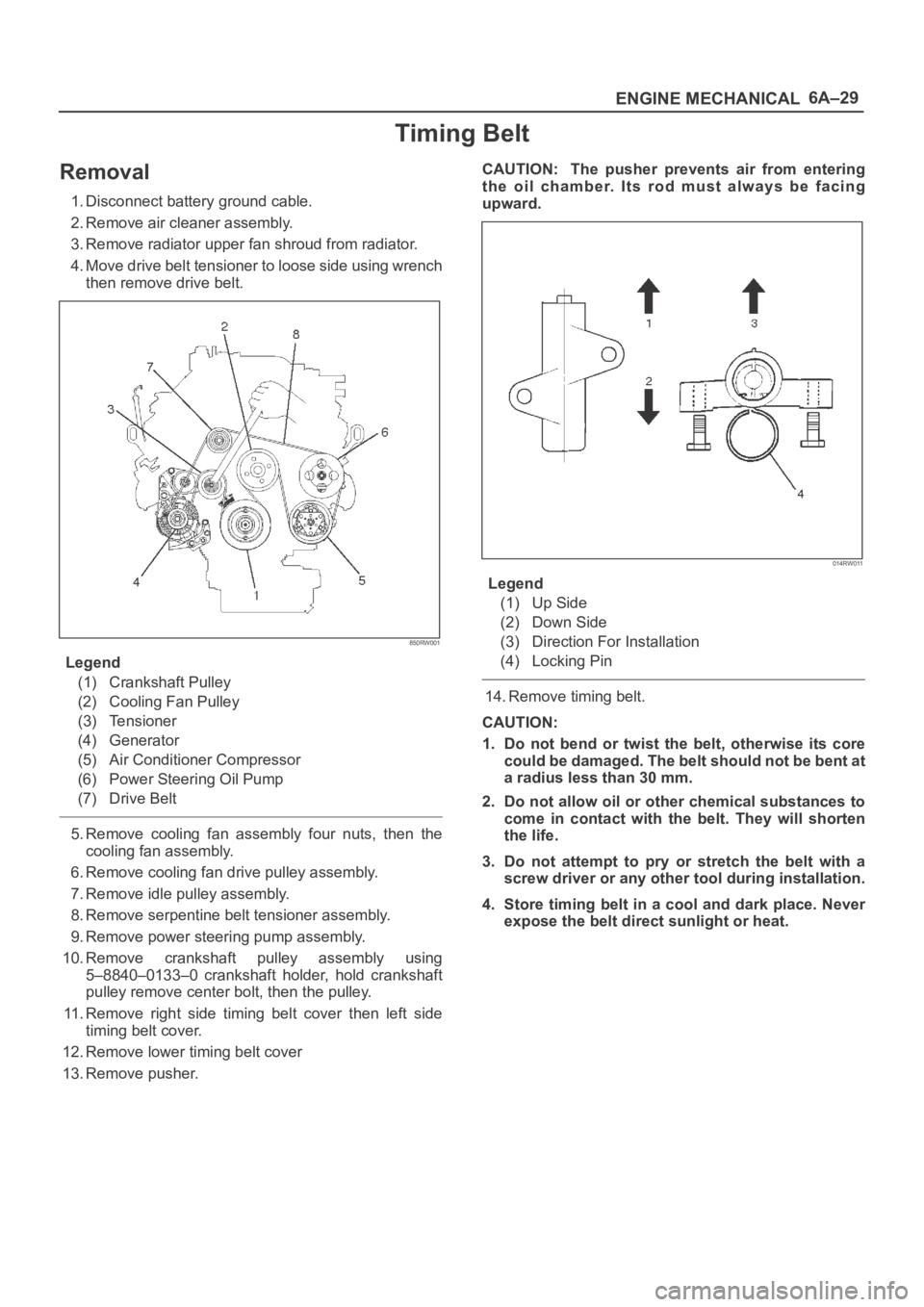

13. Remove pusher.CAUTION: The pusher prevents air from entering

the oil chamber. Its rod must always be facing

upward.

014RW011

Legend

(1) Up Side

(2) Down Side

(3) Direction For Installation

(4) Locking Pin

14. Remove timing belt.

CAUTION:

1. Do not bend or twist the belt, otherwise its core

could be damaged. The belt should not be bent at

a radius less than 30 mm.

2. Do not allow oil or other chemical substances to

come in contact with the belt. They will shorten

the life.

3. Do not attempt to pry or stretch the belt with a

screw driver or any other tool during installation.

4. Store timing belt in a cool and dark place. Never

expose the belt direct sunlight or heat.

Page 989 of 6000

6A–33

ENGINE MECHANICAL

Camshaft

Removal

1. Disconnect battery ground cable.

2. Remove crankshaft pulley.

Refer to removal procedure for Crankshaft Pulley in

this manual.

3. Remove timing belt.

Refer to removal procedure for Timing Belt in this

manual.

4. Remove cylinder head cover LH.

Refer to removal procedure for Cylinder Head

Cover LH in this manual.

5. Remove cylinder head cover RH.

Refer to removal procedure for Cylinder Head

Cover RH in this manual.

6. Remove twenty fixing bolts from inlet and exhaust

camshaft bracket on one side bank, then camshaft

brackets.

014RW027

7. Remove camshaft assembly.

8. Remove fixing bolt for camshaft drive gear pulley.

9. Remove three fixing bolts from camshaft drive gear

retainer, then camshaft drive gear assembly.

014RW026

Legend

(1) Right Bank

(2) Left Bank

(3) Timing Mark on Retainer

Installation

1. Install camshaft drive gear assembly and tighten

three bolts to the specified torque.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

2. Tighten bolt for camshaft drive gear assembly pulley

to the specified torque.

Torque : 98 Nꞏm (10.0 Kgꞏm/72 lb ft)

3. Tighten sub gear setting bolt.

1. Use the 5–8840–2443–0 gear spring lever to turn

sub gear to right direction until it aligns with the M5

bolt hole between camshaft driven gear and sub

gear.

2. Tighten the M5 bolt to a suitable torque to prevent

the sub gear from moving.

Page 993 of 6000

6A–37

ENGINE MECHANICAL

Cylinder Head

Removal

1. Remove engine hood.

2. Disconnect battery ground cable.

3. Drain radiator coolant.

4. Drain engine oil.

5. Remove crankshaft pulley.

Refer to removal procedure for Crankshaft Pulley in

this manual.

6. Remove timing belt.

Refer to removal procedure for Timing Belt in this

manual.

7. Remove cylinder head cover LH.

Refer to removal procedure for Cylinder Head

Cover LH in this manual.

8. Remove cylinder head cover RH.

Refer to removal procedure for Cylinder Head

Cover RH in this manual.

9. Remove common chamber.

Refer to removal procedure for Common Chamber

in this manual.

10. Remove cylinder head assembly.

1. Loosen eights bolts for tight cylinder head.

2. Remove cylinder head assembly.

014RW028

Legend

(1) Cylinder Head

(2) Cylinder Head Bolt

(3) Camshaft

Installation

1. Install cylinder head assembly to cylinder block.

1. Put cylinder head gasket on the cylinder block.NOTE: There is discrimination mark “R” for right bank

and “L” for left bank on the cylinder head gasket as shown

in the illustration.

Do not reuse cylinder head gasket.

011RW005

2. Align dowel pin hole to dowel pin on the cylinder

block.

3. Tighten two bolts temporarily by hand to prevent

the cylinder head assembly from moving.

4. Using 9–8511–4209–0 cylinder head bolt wrench,

tighten bolts in numerical order as shown in the

illustration to the specified torque.

NOTE: Do not reuse cylinder head bolts.

Do not apply any lubricant to the cylinder head bolts.

To r q u e :

Temporary : 29 Nꞏm (3.0 Kgꞏm/21 lb ft)

Final : 64 Nꞏm (6.5 Kgꞏm/47 lb ft)

014RW029

Page 995 of 6000

6A–39

ENGINE MECHANICAL

Valve Stem Oil Controller , Valve Spring and Valve Guide

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

Drain engine coolant.

3. Remove cylinder head assembly.

Refer to removal procedure for Cylinder Head in

this manual.

4. Remove camshaft.

Refer to removal procedure for Camshaft in this

manual.

5. Remove tappets with shim.

NOTE: Do not damage shim surface.

6. Remove valve springs using 5–8840–2446–0 valve

spring compressor and 5–8840–2547–0 valve spring

compressor adapter then remove upper valve spring

seat and lower seat.

014RW042

7. Remove oil controller using 5–8840–0623–0 oil

controller remover, remove each valve stem oil

controller.

8. Remove valve guide using 5–8840–2549–0 valve

guide replacer.

Installation

1. Install valve guide using 5–8840–2442–0 valve guide

installer.

2. Install oil controller using 5–8840–0624–0 oil

controller installer.

3. Install lower valve spring seat, valve spring and upper

valve spring seat then put split collars on the upper

spring seat, using 5–8840–2446–0 valve spring

compressor and 5–8840–2547–0 valve spring

compressor adapter to install the split collars.

014RW042

4. Install tappet with shim.

5. Install camshaft assembly.

Refer to installation procedure for Camshaft in this

manual.

6. Install cylinder head assembly.

Refer to installation procedure for Cylinder Head in

this manual.

7. Fill engine oil until full level.

8. Fill engine coolant.