Back OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3417 of 6000

8J–38EXTERIOR/INTERIOR TRIM

Power Door Mirror System

General Description

The circuit consists of the starter switch, door mirror

control switch, folding switch, defogger switch and door

mirrors on both sides.

The door mirror switch consists of the control switch,

folding switch and defogger switch.

When the control switch is operated with the starter

switch at either “ACC” or “ON” position, the motors

incorporated in the door mirrors on both sides rotates to

allow the horizontal and vertical adjustment of mirror

angles.

The folding switch can be used to fold the mirror and

return it to its original position.

When turning on the door mirror defogger switch with the

starter switch at “ON” position, built-in heater in the mirror

is activated to perform the defogger function.

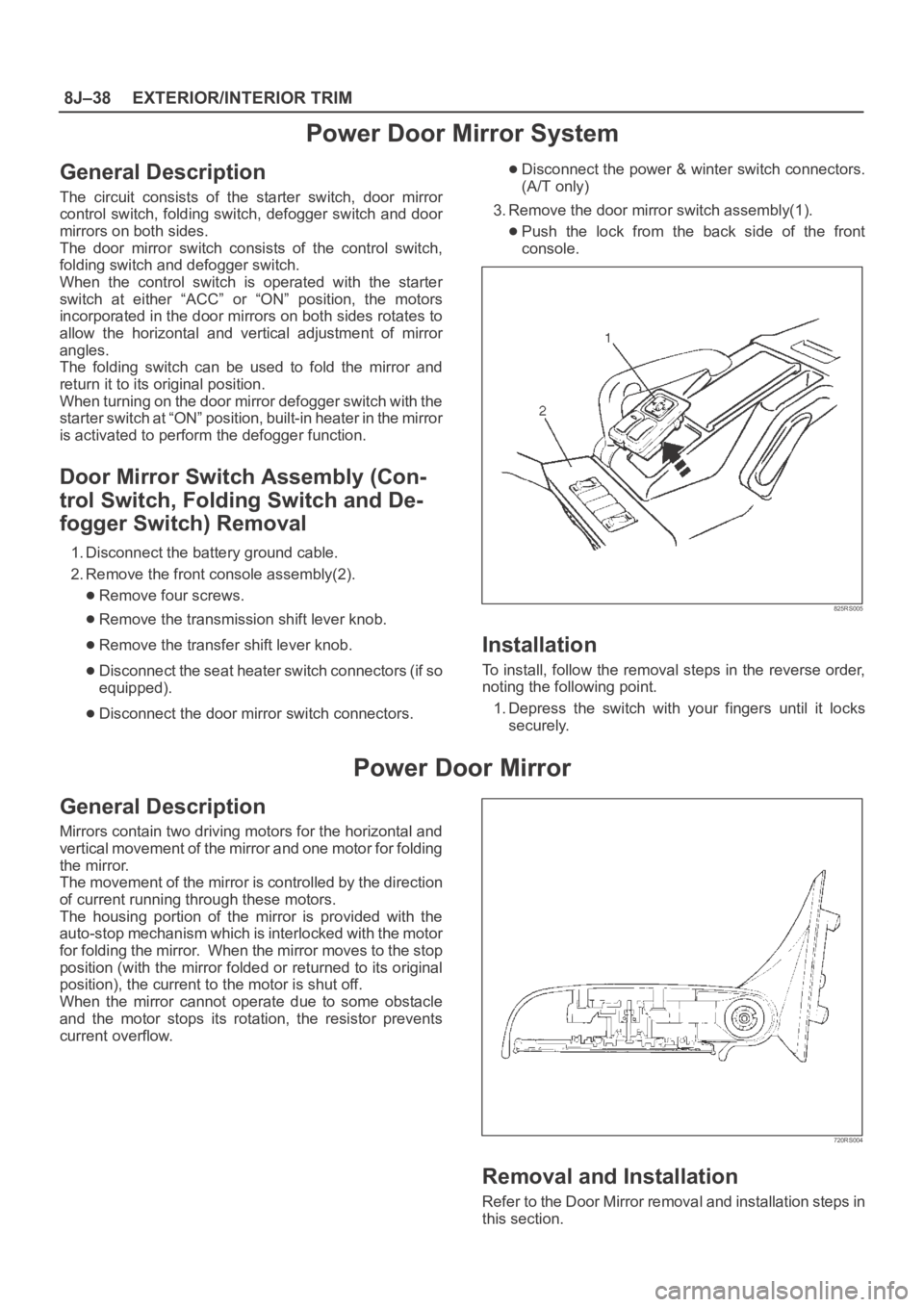

Door Mirror Switch Assembly (Con-

trol Switch, Folding Switch and De-

fogger Switch) Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(2).

Remove four screws.

Remove the transmission shift lever knob.

Remove the transfer shift lever knob.

Disconnect the seat heater switch connectors (if so

equipped).

Disconnect the door mirror switch connectors.

Disconnect the power & winter switch connectors.

(A/T only)

3. Remove the door mirror switch assembly(1).

Push the lock from the back side of the front

console.

825RS005

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Depress the switch with your fingers until it locks

securely.

Power Door Mirror

General Description

Mirrors contain two driving motors for the horizontal and

vertical movement of the mirror and one motor for folding

the mirror.

The movement of the mirror is controlled by the direction

of current running through these motors.

The housing portion of the mirror is provided with the

auto-stop mechanism which is interlocked with the motor

for folding the mirror. When the mirror moves to the stop

position (with the mirror folded or returned to its original

position), the current to the motor is shut off.

When the mirror cannot operate due to some obstacle

and the motor stops its rotation, the resistor prevents

current overflow.

720RS004

Removal and Installation

Refer to the Door Mirror removal and installation steps in

this section.

Page 3449 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–12

Deployed Air Bag Assembly (Driver Side)

“You should wear gloves and glasses. After the air bag

assembly has been deployed, the surface of the air bag

may contain solid particulate. This solid particulate

c o n s i s t s p r i m a r i l y o f b y p r oducts of the chemical reaction,

Potassium Chloride and copper metal dust. Compounds

of Potassium Borate, Strontium Chloride, Copper

Chloride, and Ammonium Chloride may be found in

amounts of about 1% (each) of the total particulate.”

Deployed Pretensioner Seat Belt.

You should wear gloves and safety glasses. After the

pretensioner seat belt has been deployed, the surface of

the pretensioner seat belt cylinder may heating up.

Air Bag Assembly and/or Pretensioner

Seat Belt Scrapping Procedure.

During the cause of vehicle’s useful life, certain situations

may arise which will necessitate the disposal of a live air

bag and/or pretensioner seat belt. (This information

covers proper procedures for disposing of a live air bag

assembly and/or pretensioner seat belt.)

Before a live air bag assembly can be dispose off, it must

be deployed.

A live air bag assembly and/or pretensioner seat belt

must not be disposed of though normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDPLOYED AIR

BAG ASSEMBLY MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF LOCAL

LAW.

In situations which require deployment of a live air bag

assembly, deployment may be accomplished inside or

outside the vehicle. The method employed depends

upon the final disposition of the particular vehicle, as

noted in “Deployment Outside Vehicle” and “Deployment

Inside Vehicle” in this section.

Cautions About Air Bag Deployment And

Disposal

Failure to follow proper procedures could result in

erroneous air bag deployment which may cause personal

injury be sure to follow proper procedures.

1. Turn off (Lock) the ignition switch and disconnect the

minus terminal of the battery, then start the work 15 or

more sec later. (Air bag is designed to work by the

back-up power source even if the battery power

source is cut off at vehicle collision).

2. Be sure not to disassemble the air bag.

3. Do not give an impact to the air bag and bring the air

bag close to magnet. (The air bag could deploy

unexpectedly).4. Place the air bag with its trim cover up.

5. Do not let the air bag deploy directly on the floor. (The

air bag may be blown off 2

3 m (6.5 or 10 feet)).

6. Be sure to install the air bag firmly to a deployment

tool (fixing tool).

7. Set a battery 10 m (33 feet) or more away from the air

bag.

8. Before disconnecting air bag harness, ground the

worker by touching the vehicle outer panel with bare

hand.

9. When connecting or disconnecting the harness, do

not work just in front of the air bag.

10. As deployment gives rise to big sound, warn the

people around against it. Further, try to reduce the

sound by covering the steering wheel or tires, and

shut the vehicle windows in case of deployment

inside the vehicle.

11. As deployment generates smoke, select a well

ventilated place. (In case of deployment indoors,

avoid deployment just under a fire alarm, smoke

sensor, and fluorescent lamps).

12. Be careful not to inhale the smoke after deployment.

13. If part of the vehicle glass is damaged, cover the

vehicle with a car cover to prevent the glass from

braking at the time of deployment.

14. Do not touch the air bag immediately after

deployment, since it remains hot for 30 minutes.

15. Do not water the air bag immediately after

deployment.

16. Wear safety glasses and gloves throughout the work

and wash the glasses and gloves after the work.

17. Do not reuse the removed air bag for another vehicle.

(Deployment characteristic is different with vehicle

types).

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

air bag assembly is replaced. Deployment and disposal

of a malfunctioning air bag assembly is, of course, subject

to any required retention period.

For deployment of a live (undeployed) air bag assembly

outside the vehicle, the deployment procedure must be

followed exactly. Always wear safety glasses during this

deployment procedure until a deployed air bag assembly

is scrapped or until an undeployed air bag assembly is

shipped. Before performing the procedures you should

be familiar with servicing the SRS and with proper

handling of the air bag assembly. Procedures should be

read fully before they are performed.

The following procedure requires use of 5–8840–2468–0

SRS deployment harness with appropriate pigtail

adapter. Do not attempt procedure without

5–8840–2468–0 adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

Page 3465 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–28

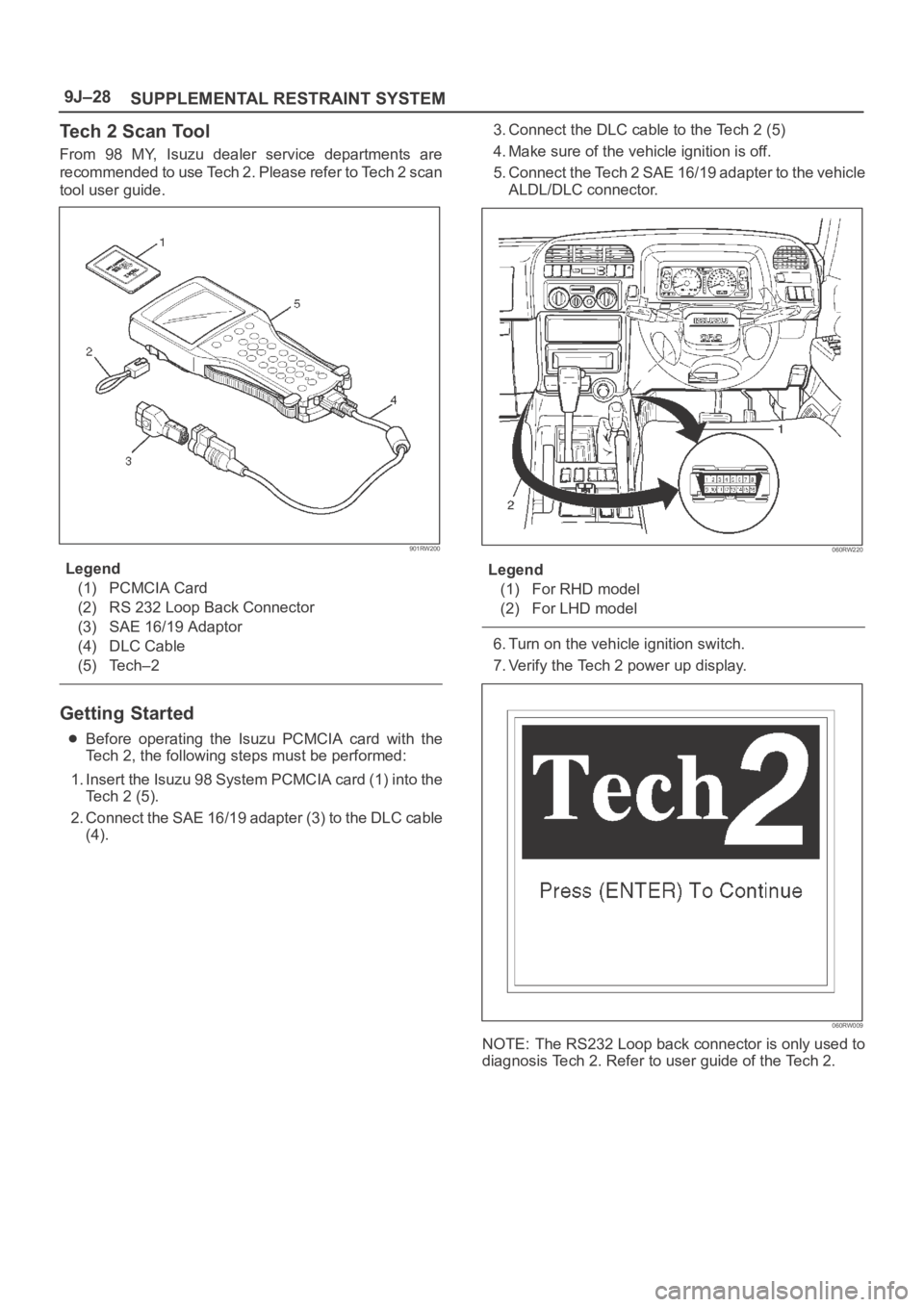

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments are

recommended to use Tech 2. Please refer to Tech 2 scan

tool user guide.

901RW200

Legend

(1) PCMCIA Card

(2) RS 232 Loop Back Connector

(3) SAE 16/19 Adaptor

(4) DLC Cable

(5) Tech–2

Getting Started

Before operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1. Insert the Isuzu 98 System PCMCIA card (1) into the

Tech 2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC cable

(4).3. Connect the DLC cable to the Tech 2 (5)

4. Make sure of the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the vehicle

ALDL/DLC connector.

060RW220

Legend

(1) For RHD model

(2) For LHD model

6. Turn on the vehicle ignition switch.

7. Verify the Tech 2 power up display.

060RW009

NOTE: The RS232 Loop back connector is only used to

diagnosis Tech 2. Refer to user guide of the Tech 2.

Page 3561 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

1A HEATING AND VENTILATION

1B AIR CONDITIONING

1D COMPRESSOR OVERHAUL

HOME

1A

1B

1D

Page 3562 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

00 SERVICE INFORMATION

2A FRONT END ALIGNMENT

HOME

00

2A

Page 3563 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

3C FRONT SUSPENSION

3D REAR SUSPENSION; COIL SPRING

3E WHEELS AND TIRES

HOME

3C

3D

3E

Page 3564 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

4A1 DIFFERENTIAL (FRONT)

4A2A DIFFERENTIAL (Rear 220mm)

4A2B DIFFERENTIAL (REAR 244mm)

4B1 DRIVELINE CONTROL SYSTEM (SHIFT ON

THE FLY)

4B2 DRIVELINE CONTROL SYSTEM (TOD)

4C DRIVE SHAFT SYSTEM

4D1 TRANSFER CASE (STANDARD TYPE)

4D2 TRANSFER CASE (TOD)

HOME

4A1

4A2A

4A2B

4B1

4B2

4C

4D1

4D2

Page 3565 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

5A BRAKE CONTROL SYSTEM

5B ANTI-LOCK BRAKE SYSTEM

5C POWER ASSISTED BRAKE SYSTEM

5D PARKING BRAKES

HOME

5A

5B

5C

5D

Page 3566 of 6000

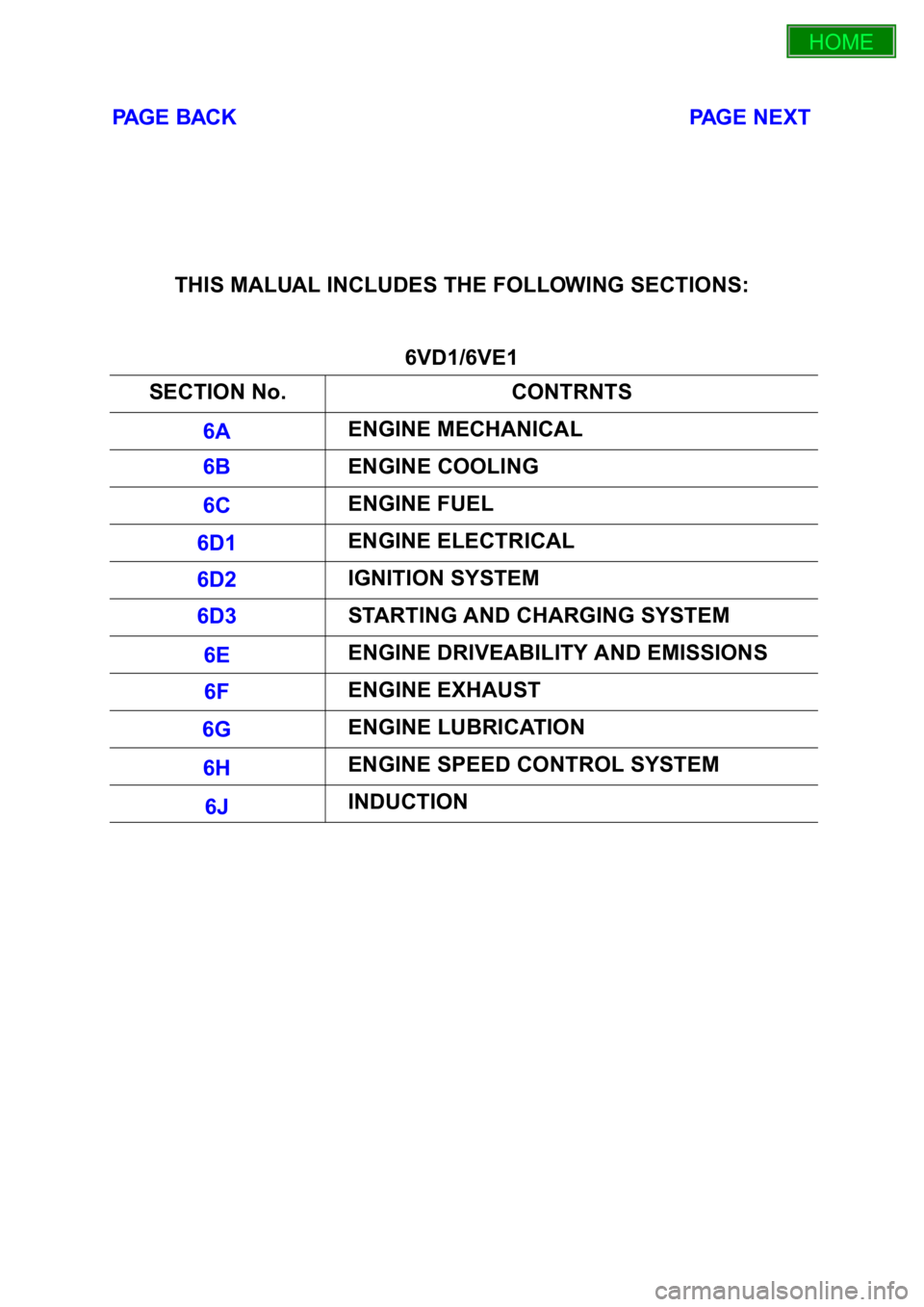

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

6VD1/6VE1

SECTION No. CONTRNTS

6A ENGINE MECHANICAL

6B ENGINE COOLING

6C ENGINE FUEL

6D1 ENGINE ELECTRICAL

6D2 IGNITION SYSTEM

6D3 STARTING AND CHARGING SYSTEM

6E ENGINE DRIVEABILITY AND EMISSIONS

6F ENGINE EXHAUST

6G ENGINE LUBRICATION

6H ENGINE SPEED CONTROL SYSTEM

6J INDUCTION

HOME

6A

6B

6C

6D1

6D2

6D3

6E

6F

6G

6H

6J

Page 3567 of 6000

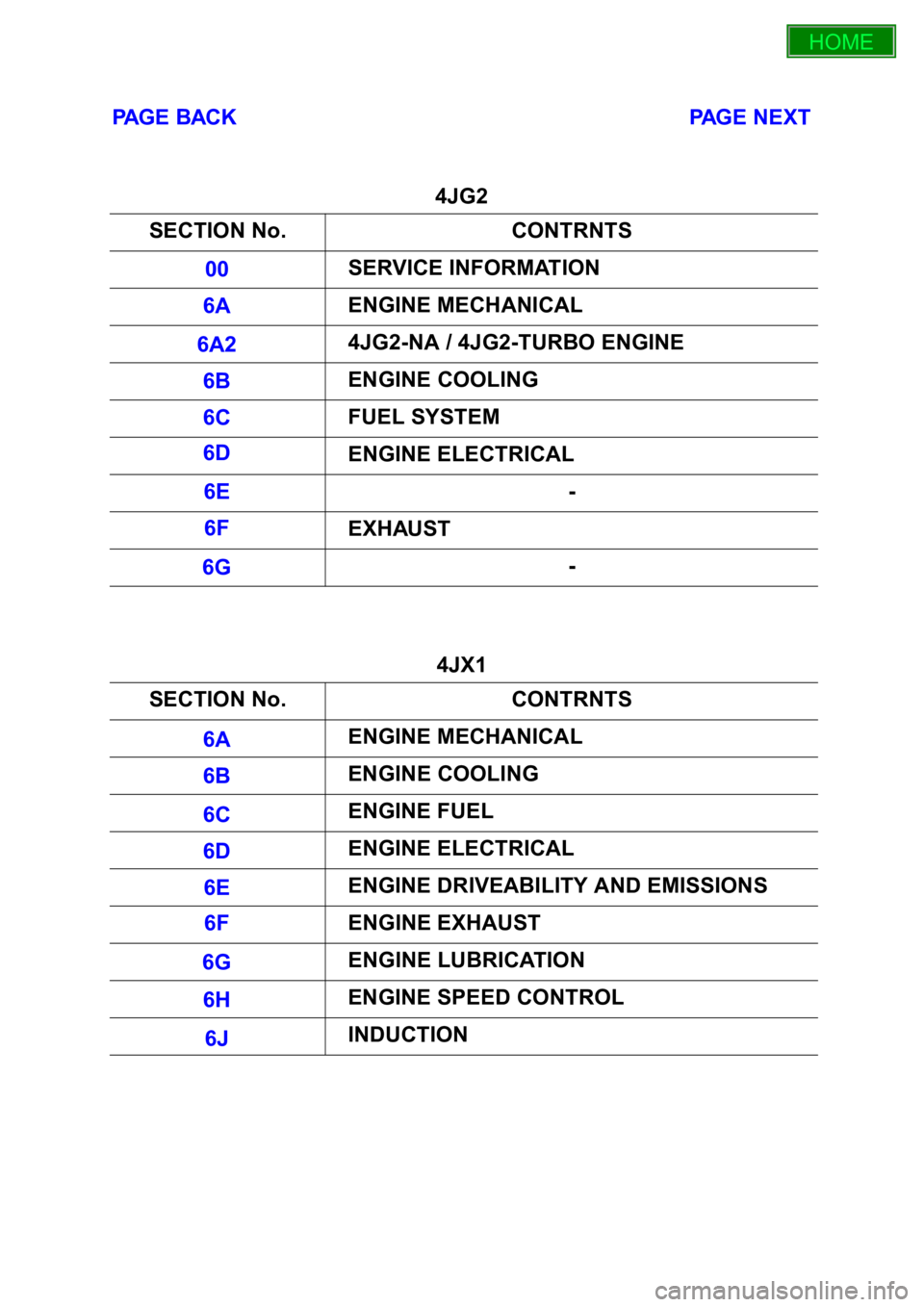

PAGE BACK PAGE NEXT

4JG2

4JX1 SECTION No. CONTRNTS

00 SERVICE INFORMATION

6A ENGINE MECHANICAL

6A2 4JG2-NA / 4JG2-TURBO ENGINE

6B ENGINE COOLING

6C FUEL SYSTEM

6D ENGINE ELECTRICAL

6E -

6F EXHAUST

6G -

SECTION No. CONTRNTS

6A ENGINE MECHANICAL

6B ENGINE COOLING

6C ENGINE FUEL

6D ENGINE ELECTRICAL

6E ENGINE DRIVEABILITY AND EMISSIONS

6F ENGINE EXHAUST

6G ENGINE LUBRICATION

6H ENGINE SPEED CONTROL

6J INDUCTION

HOME

00

6A

6A2

6B

6C

6D

6E

6F

6G

6A

6B

6C

6D

6E

6F

6G

6H

6J