ignition OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2016 of 6000

6E–123 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0342 —CMP Sensor No Signal

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “Specific DTC” information

for DTC P0342 until the DTC P0342 test runs.

5. Note test result.

Does the Tech 2 indicate DTC P0342 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Ignition “ON.”

2. Disconnect the CMP sensor.

3. Measure the voltage between the sensor feed

circuit and the sensor ground circuit at the CMP

sensor harness connector.

Does the voltage measure near the specified value?

4-6 VGo to Step 7Go to Step 4

41. Ignition “OFF,” disconnect the ECM and the CMP

sensor.

2. Check for poor connections at the camshaft

position sensor.

3. If a problem is found, repair it as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check for poor connections at the ECM.

2. If a problem is found, repair it as necessary.

Was a problem found?

—Verify repair Go to Step 6

61. Check the following circuits between the ECM and

the CMP sensor:

The sensor feed circuit. Open or short to

ground?

The sensor ground circuit. Open or short to

voltage?

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair—

71. Ignition “ON,” engine “OFF.”

2. Measure the voltage between the CMP sensor

signal circuit and the sensor ground circuit at the

CMP sensor harness connector.

Does the voltage measure near the specified value?

4-6 VGo to Step 8Go to Step 9

Page 2017 of 6000

6E–124

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0342 —CMP Sensor No Signal

StepNo Ye s Va l u e ( s ) Action

81. Turn the ignition “OFF.”

2. Disconnect the ECM and connect a DVM to monitor

voltage on the camshaft position signal circuit at the

ECM connector.

3. Ignition “ON.”

4. Monitor the voltage display on the DVM while

repeatedly touching the CMP sensor signal circuit

at the CMP sensor connector with a test light to

ground.

Does the DVM voltage display switch between 0 and

approximately 5 volts when the test light is touched to

the CMP sensor signal circuit?

—Go to Step 12Go to Step 9

91. Ignition “OFF.”

2. Leave the ECM disconnected.

3. Ignition “ON.”

4. Probe the camshaft position signal circuit at the

ECM connector with a test light to B+.

5. If the test light is “ON,” locate and repair the short to

ground in the camshaft position input signal circuit.

Was either circuit shorted to ground?

—Verify repairGo to Step 10

101. Ignition “OFF.”

2. Leave the ECM disconnected.

3. Ignition “ON.”

4. Probe the camshaft position signal circuit with a test

light to ground.

5. If the test light is “ON,” locate and repair the short to

voltage in the camshaft position input signal circuit.

Was the test light “ON”?

—Verify repairGo to Step 11

111. Ignition “OFF,” disconnect the ECM (leave the CMP

sensor disconnected).

2. Ignition “ON,” check the following circuit:

The CMP sensor signal circuit for an open.

3. If a problem is found, repair it as necessary.

Was a problem found?

—Verify repair—

121. Ignition “ON.”

2. Remove the CMP sensor from the engine front

cover (leave the sensor wiring connected).

3. Place a magnet on the CMP sensor. If you use a

magnet that is too small to cover the face of the

sensor, test on every part of the sensor face

because only a small area will respond to this test.

Does the DVM display a voltage near the specified

value?

0 VGo to Step 14Go to Step 13

13Replace the camshaft position sensor.

Is the action complete?

—Verify repair—

141. Reinstall the CMP sensor to the engine front cover.

2. Observe the DVM connected to monitor voltage on

the camshaft position signal circuit while cranking

the engine.

Does the voltage toggle between the specified values?

4-0 VGo to Step 15Go to Step 16

Page 2020 of 6000

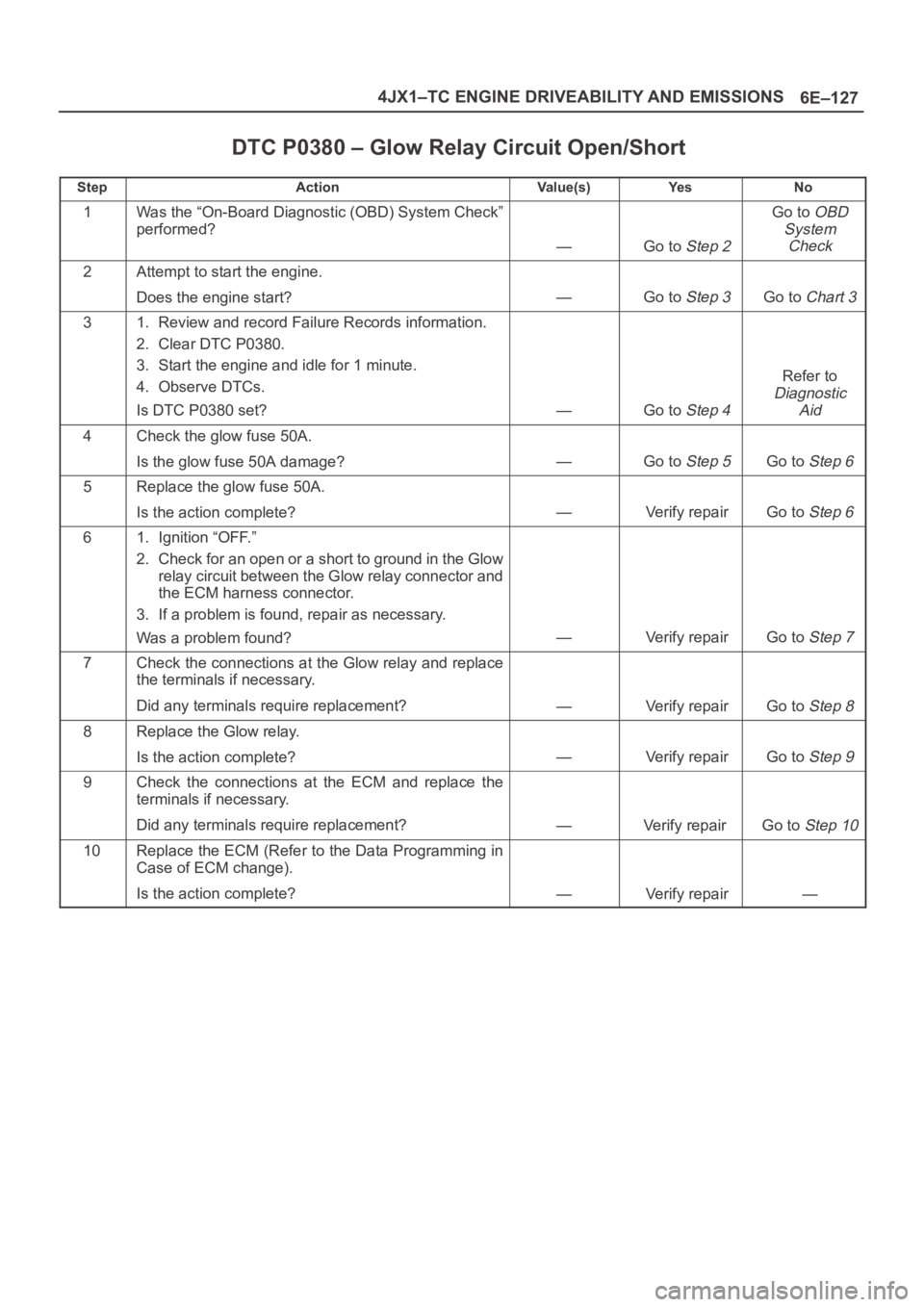

6E–127 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0380 – Glow Relay Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Chart 3

31. Review and record Failure Records information.

2. Clear DTC P0380.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P0380 set?

—Go to Step 4

Refer to

Diagnostic

Aid

4Check the glow fuse 50A.

Is the glow fuse 50A damage?

—Go to Step 5Go to Step 6

5Replace the glow fuse 50A.

Is the action complete?

—Verify repairGo to Step 6

61. Ignition “OFF.”

2. Check for an open or a short to ground in the Glow

relay circuit between the Glow relay connector and

the ECM harness connector.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

7Check the connections at the Glow relay and replace

the terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 8

8Replace the Glow relay.

Is the action complete?

—Verify repairGo to Step 9

9Check the connections at the ECM and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repair Go to Step 10

10Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2022 of 6000

6E–129 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0381 – Glow Lamp Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Review and record Failure Records information.

2. Clear DTC P0381.

3. Observe DTCs.

Is DTC P0381 set?

—Go to Step 3

Refer to

Diagnostic

Aid

31. Ignition “OFF.”

2. Remove the Meter assembly.

3. Check for an open or a short to ground in the Glow

Lamp circuit.

4. If a problem is found, repair as necessary.

(On electric bulb of the Glow Lamp, The Glow Lamp

harness circuit)

Was a problem found?

—

Refer to the

Meter in

Electric

section 8

Go to Step 4

4Check the connections at the ECM and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repair Go to Step 5

5Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2024 of 6000

6E–131 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1403 – EGR EVRV Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the EVRV circuit.

Was the EVRV circuit darmage?

—

Replace the

EVRV circuit

Go to Step 3

31. Start the engine.

2. Monitor the MAP signal with a scan tool while idling.

3. While idling, jab the accelerator pedal about halfway

down and immediately let the engine return to idle.

Did the MAP value on the scan tool show an immediate

large change?

—Go to Step 5Go to Step 4

4Replace the MAP sensor.

Is the action complete?

—Verify repair—

51. Inspect the exhaust system for modification of

original installed parts or leaks.

2. If a problem was found, repair exhaust system as

necessary.

Was a condition present that required repair?

—Go to Step 8Go to Step 6

61. Remove the EGR valve.

2. Visually and physically inspect the pintle, valve

passages and the adapter for excessive deposits or

any kind of a restriction.

3. If a problem is found, clean or replace EGR system

components as necessary.

Was a condition present that required repair?

—Go to Step 8Go to Step 7

71. Inspect the EGR passages for a blockage caused

by excessive deposits or other damage.

2. If a problem is found, correct the condition as

necessary.

Was a condition present that required repair?

—Go to Step 8

Refer to

Diagnostic

Aids

81. Review and record the scan tool Failure Records

data.

2. Clear DTC and monitor the scan tool System Info

Screen while operating the vehicle as specified in

“Diagnostic Aids.”

3. Using a scan tool, monitor “DTC” info for DTC

P1403 until the DTC P1403 test runs.

4. Note the test result.

Does the scan tool indicate DTC P1403 failed this

ignition?

—

Go to the last

step

completed in

this

diagnostic

chart

Repair

complete

Page 2025 of 6000

6E–132

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1404 (Flash DTC 31)

EGR VSV Circuit

060RW135

Circuit Description

The Engine control module (ECM) monitors the EGR

valve input to ensure that the valve responds properly to

commands from the ECM, and to detect a fault if VSV is

stuck open. When the VSV is fixing at closed and opening

the ECM will set DTC P1404.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged VSV–inspect the wiring

harness for damage.

DTC P1404 – EGR VSV Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON”, engine “OFF”, review and record

scan tool Failure Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a scan tool, monitor “Specific DTC” info for

DTC P1404 until the DTC P1404 test runs. Note the

result.

Does the scan tool indicates DTC P1404 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

Page 2028 of 6000

6E–135 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0405 – EGR Pressure Sensor Low Voltage

StepNo Ye s Va l u e ( s ) Action

31. Turn off the ignition switch.

2. Remove the sensor connector connection.

3. Jumper between harness pins “red” and “blue”

wires.

4. Turn on the ignition switch “ON”.

Is the EGR pressure sensor voltage reading above the

specified value?

4 VGo to Step 5Go to Step 4

41. Turn off the ignition switch.

2. Remove the jumper wire.

3. Connect the relay & solenoid checker

(5-8840-0386-0) to the battery voltage, then check

the EGR pressure sensor signal circuit (blue wire).

4. Turn on the ignition switch.

Is the value displayed on the Tech 2 above the specified

value?

4 VGo to Step 6Go to Step 7

5Check the terminal connection at the EGR pressure

sensor and repair or replace terminal if necessary.

Is the action complete?

—Verify repair—

6Repair the 5V power circuit (red) harness or Replace

the ECM (Refer to the Data Programming in Case of

ECM change).

Is the action complete?

—Verify repair—

7Repair the signal circuit (blue) harness or Replace the

ECM (Refer to the Data Programming in Case of ECM

change).

Is the action complete?

—Verify repair—

Page 2030 of 6000

6E–137 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1405 – EGR EVRV Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Review and record Failure Records information.

2. Clear DTC P1405.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P1405 set?

—Go to Step 3

Refer to

Diagnostic

Aid

31. Ignition “OFF.”

2. Disconnect the EVRV.

3. Check for an open or a short to ground in the EVRV

circuit between the EVRV connector and the ECM

harness connector.

4. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 4

4Check the connections at the EVRV and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 5

5Check the connections at the ECM and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repair Go to Step 6

6Replace the EVRV.

Is the action complete?

—Verify repairGo to Step 7

7Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2031 of 6000

6E–138

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0406 (Flash DTC 26)

EGR Pressure Sensor High Voltage

060RW134

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) as soon as failure detected.

The ECM will store conditions which were present

w h e n t h e D T C w a s s e t a s F r e e z e F r a m e a n d i n F a i l u r e

Records data.

Conditions for Clearing the MIL/DTC

DTC P0404 can be cleared by using the scan tool

“Clear Info” function or by disconnecting the ECM

battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

wiring harness for damage.

DTC P0406 – EGR Pressure Sensor High Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Put the engine into an idling status.

Is the EGR pressure sensor voltage value displayed on

the Tech 2 above the specified value?

4 VGo to Step 3Go to Step 4

31. Turn off the ignition switch.

2. Remove the sensor connector connection.

3. Turn on the ignition switch “ON”.

Is the EGR pressure sensor voltage value displayed on

the Tech 2 below the specified value?

1 VGo to Step 5Go to Step 6

Page 2034 of 6000

6E–141 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0475 – EXH #1 VSV Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.” Review and record

Tech 2 Failure Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor the “ DTC” info for DTC

P0475.

Does the Tech 2 indicate DTC P0475 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Ignition “OFF.”

2. Disconnect the EXH #1 VSV connectors.

3. Check the EXH #1 VSV circuit for a short to ground.

Is the EXH #1 VSV circuit shorted to ground?

—Verify repairGo to Step 4

4Replace the EXH #1 VSV.

Is the action complete?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.” Review and record

Tech 2 Failure Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor the “ DTC” info for DTC

P0475.

Does the Tech 2 indicate DTC P0475 failed this

ignition?

—Go to Step 6—

6Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—