engine oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2300 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–55

DTC P0748 Pressure Control Solenoid (PCS) (Force Motor) Circuit Electrical

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. While the engine is operating, put the transmission in Park.

5. Using the scan tool, apply 0.1 amp through 1.0 amp while

observing “PC Ref. Current” and “PC Act. Current”.

Is the “PC Act. Current” reading always within 0.16 amp?

Go to Diagnostic

Aids

Go to Step 2

21. Turn the ignition “off”.

2. Disconnect the transmission 5–way connector M–6.

3. Using the J39200 DVOM, measure the resistance between

terminals M6–2(B) and M6–1(E).

Is the resistance within 3–7 ohms?

Go to Step 6Go to Step 3

31. Remove the transmission oil pan. Refer to Solenoid (Adapter

Case Valve Body) in Automatic Transmission (4L30–E)

section.

2. Disconnect the internal wiring harness at the PCS.

3. Measure the resistance of the PCS.

Is the resistance within 3–7 ohms?

Go to Step 5Go to Step 4

4Replace the PCS.

Is the replacement complete?

Go to Step 9—

5Repair the internal wiring harness for an open.

Is the repair complete?

Go to Step 9—

6Inspect/repair circuits J3–E4, M6–2(B), J3–E3, and M6–1(E).

Was a problem found?

Go to Step 9Go to Step 7

7Inspect/repair circuits J3–E4, M6–2(B), J3–E3, and M6–1(E) for

a short to ground or poor connections.

Was a problem found?

Go to Step 9Go to Step 8

8Replace the PCM. Refer to Powertrain Control Module (PCM) in

Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 9—

91. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

The PCS duty cycle is not at its electrical high or low limit.

2. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 2312 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–67

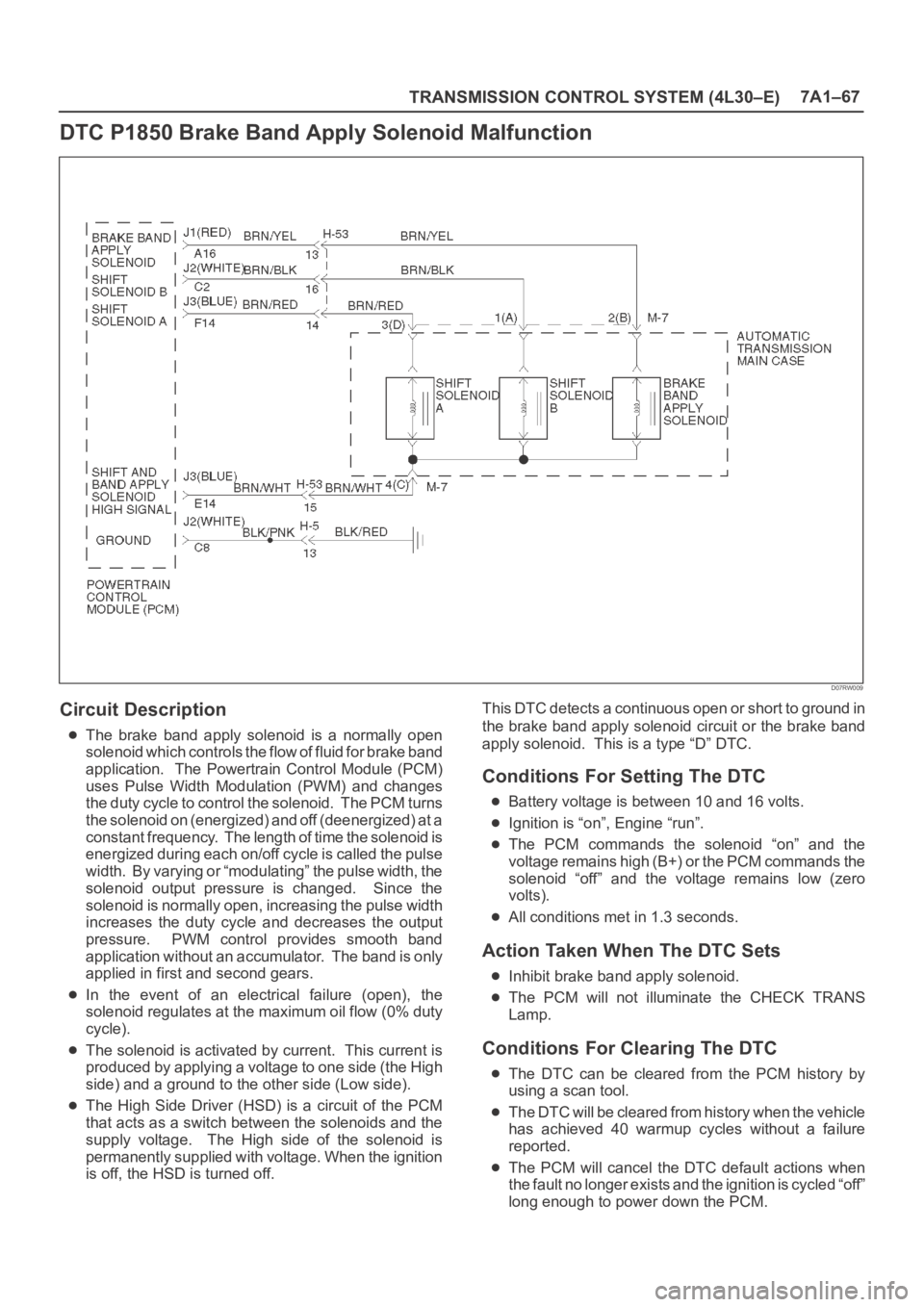

DTC P1850 Brake Band Apply Solenoid Malfunction

D07RW009

Circuit Description

The brake band apply solenoid is a normally open

solenoid which controls the flow of fluid for brake band

application. The Powertrain Control Module (PCM)

uses Pulse Width Modulation (PWM) and changes

the duty cycle to control the solenoid. The PCM turns

the solenoid on (energized) and off (deenergized) at a

constant frequency. The length of time the solenoid is

energized during each on/off cycle is called the pulse

width. By varying or “modulating” the pulse width, the

solenoid output pressure is changed. Since the

solenoid is normally open, increasing the pulse width

increases the duty cycle and decreases the output

pressure. PWM control provides smooth band

application without an accumulator. The band is only

applied in first and second gears.

In the event of an electrical failure (open), the

solenoid regulates at the maximum oil flow (0% duty

cycle).

The solenoid is activated by current. This current is

produced by applying a voltage to one side (the High

side) and a ground to the other side (Low side).

The High Side Driver (HSD) is a circuit of the PCM

that acts as a switch between the solenoids and the

supply voltage. The High side of the solenoid is

permanently supplied with voltage. When the ignition

is off, the HSD is turned off.This DTC detects a continuous open or short to ground in

the brake band apply solenoid circuit or the brake band

apply solenoid. This is a type “D” DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

Ignition is “on”, Engine “run”.

The PCM commands the solenoid “on” and the

voltage remains high (B+) or the PCM commands the

solenoid “off” and the voltage remains low (zero

volts).

All conditions met in 1.3 seconds.

Action Taken When The DTC Sets

Inhibit brake band apply solenoid.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Page 2316 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–71

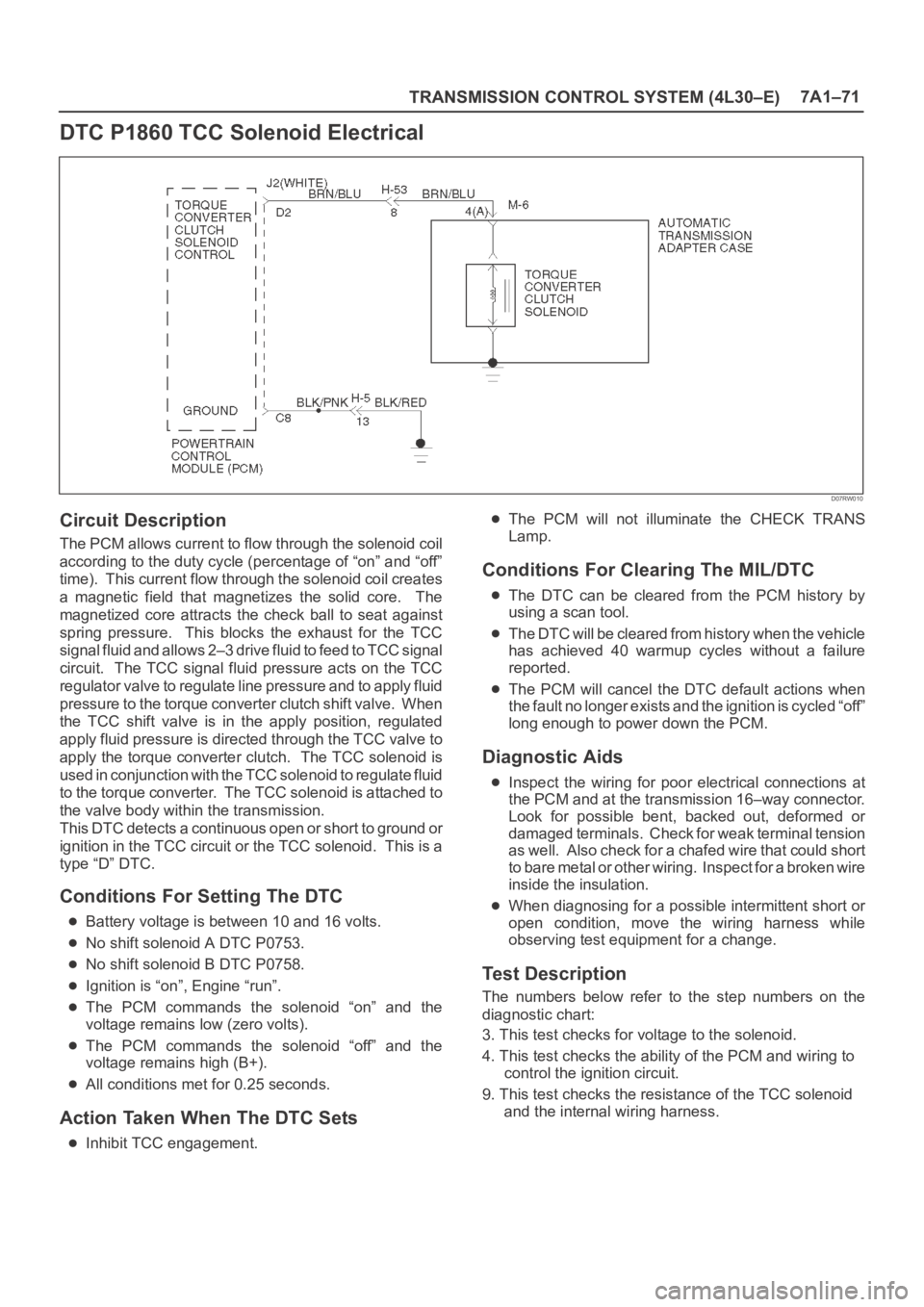

DTC P1860 TCC Solenoid Electrical

D07RW010

Circuit Description

The PCM allows current to flow through the solenoid coil

according to the duty cycle (percentage of “on” and “off”

time). This current flow through the solenoid coil creates

a magnetic field that magnetizes the solid core. The

magnetized core attracts the check ball to seat against

spring pressure. This blocks the exhaust for the TCC

signal fluid and allows 2–3 drive fluid to feed to TCC signal

circuit. The TCC signal fluid pressure acts on the TCC

regulator valve to regulate line pressure and to apply fluid

pressure to the torque converter clutch shift valve. When

the TCC shift valve is in the apply position, regulated

apply fluid pressure is directed through the TCC valve to

apply the torque converter clutch. The TCC solenoid is

used in conjunction with the TCC solenoid to regulate fluid

to the torque converter. The TCC solenoid is attached to

the valve body within the transmission.

This DTC detects a continuous open or short to ground or

ignition in the TCC circuit or the TCC solenoid. This is a

type “D” DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

No shift solenoid A DTC P0753.

No shift solenoid B DTC P0758.

Ignition is “on”, Engine “run”.

The PCM commands the solenoid “on” and the

voltage remains low (zero volts).

The PCM commands the solenoid “off” and the

voltage remains high (B+).

All conditions met for 0.25 seconds.

Action Taken When The DTC Sets

Inhibit TCC engagement.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The MIL/DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This test checks for voltage to the solenoid.

4. This test checks the ability of the PCM and wiring to

control the ignition circuit.

9. This test checks the resistance of the TCC solenoid

and the internal wiring harness.

Page 2360 of 6000

7B–42MANUAL TRANSMISSION

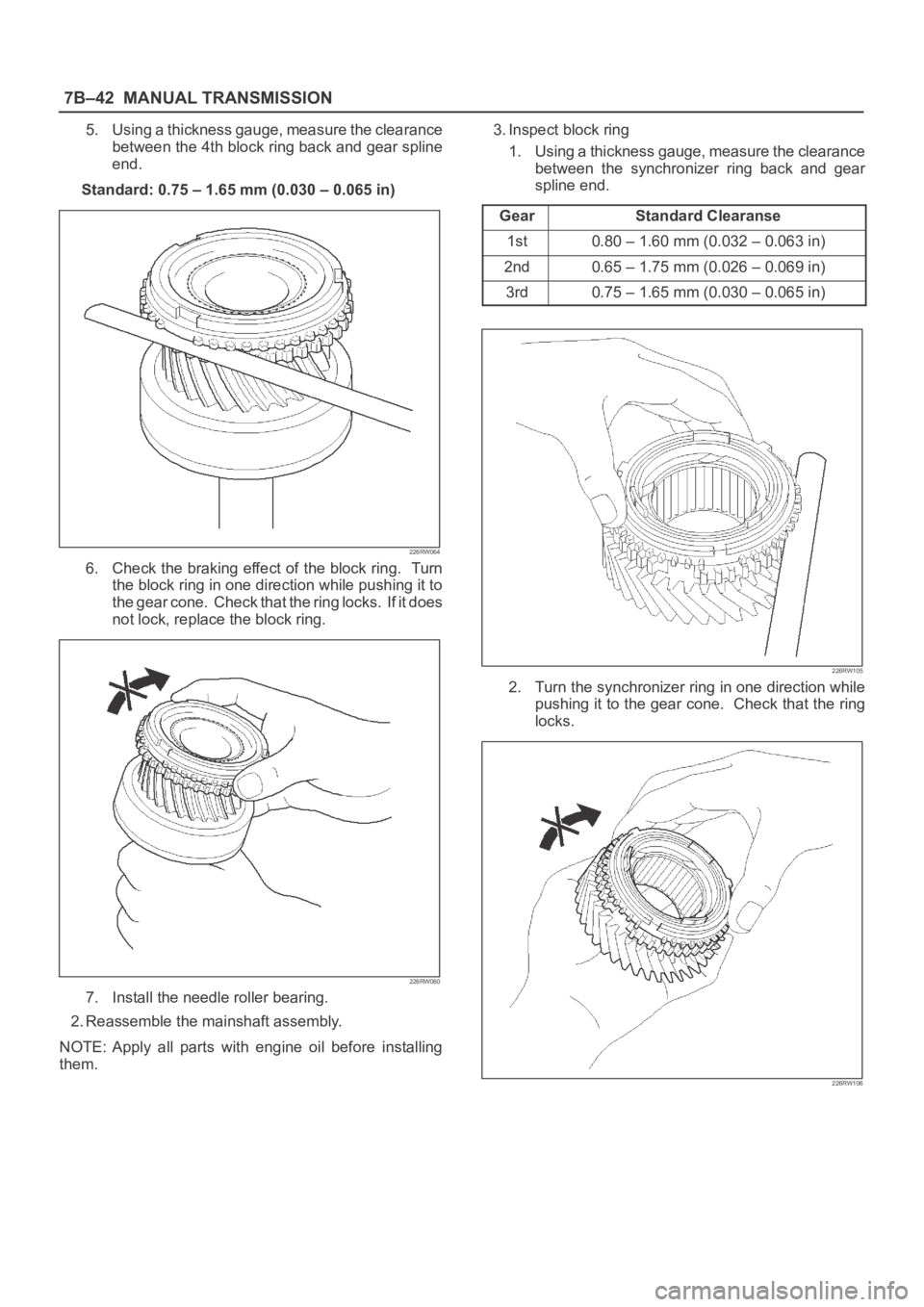

5. Using a thickness gauge, measure the clearance

between the 4th block ring back and gear spline

end.

Standard: 0.75 – 1.65 mm (0.030 – 0.065 in)

226RW064

6. Check the braking effect of the block ring. Turn

the block ring in one direction while pushing it to

the gear cone. Check that the ring locks. If it does

not lock, replace the block ring.

226RW060

7. Install the needle roller bearing.

2. Reassemble the mainshaft assembly.

NOTE: Apply all parts with engine oil before installing

them.3. Inspect block ring

1. Using a thickness gauge, measure the clearance

between the synchronizer ring back and gear

spline end.

Gear

Standard Clearanse

1st0.80–1.60mm (0.032–0.063in)

2nd0.65–1.75mm (0.026–0.069in)

3rd0.75–1.65mm (0.030–0.065in)

226RW105

2. Turn the synchronizer ring in one direction while

pushing it to the gear cone. Check that the ring

locks.

226RW106

Page 2386 of 6000

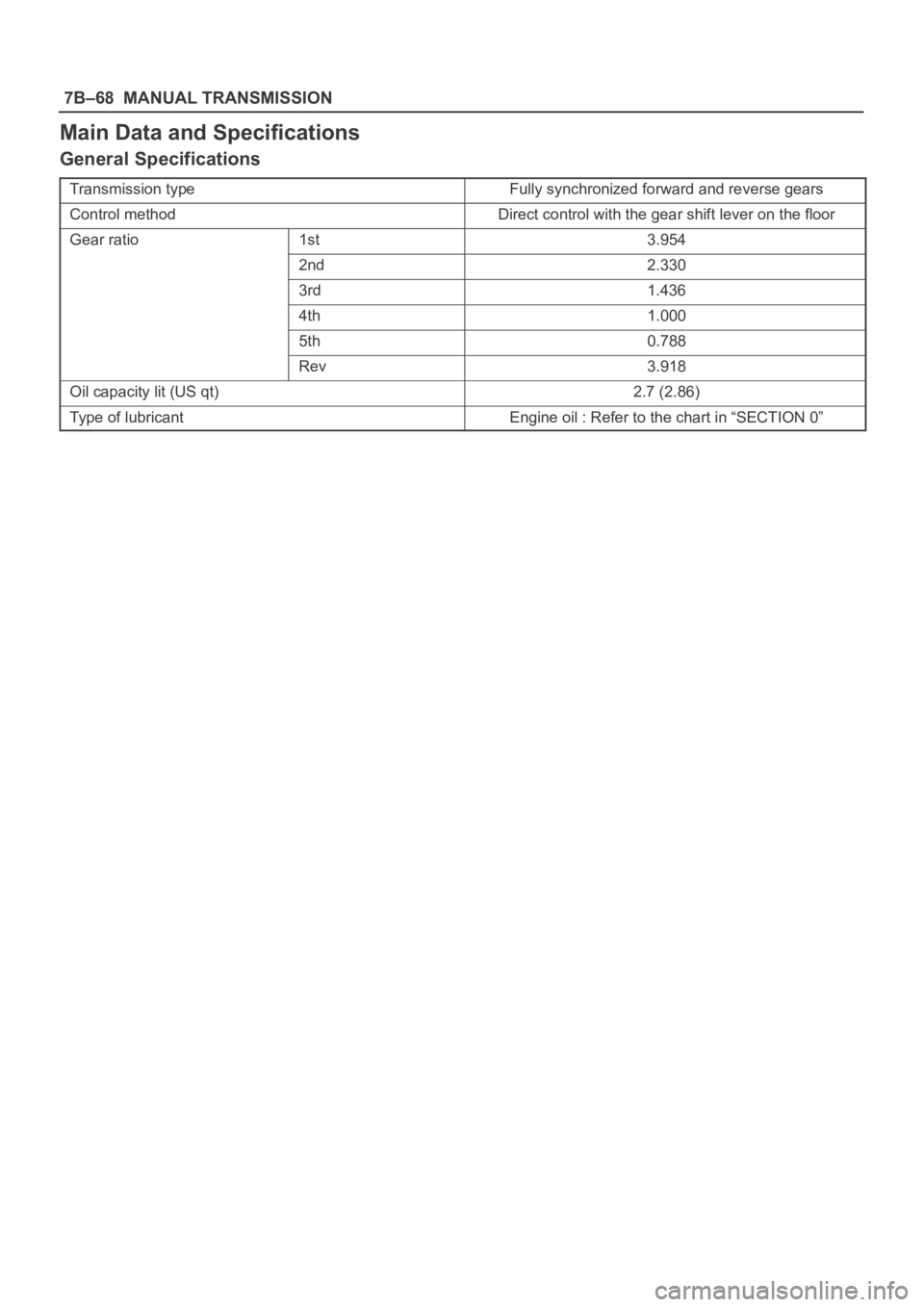

7B–68MANUAL TRANSMISSION

Main Data and Specifications

General Specifications

Transmission typeFully synchronized forward and reverse gears

Control methodDirect control with the gear shift lever on the floor

Gear ratio1st3.954

2nd2.330

3rd1.436

4th1.000

5th0.788

Rev3.918

Oil capacity lit (US qt)2.7 (2.86)

Type of lubricantEngine oil : Refer to the chart in “SECTION 0”

Page 2517 of 6000

7C–8CLUTCH

Diagnosis

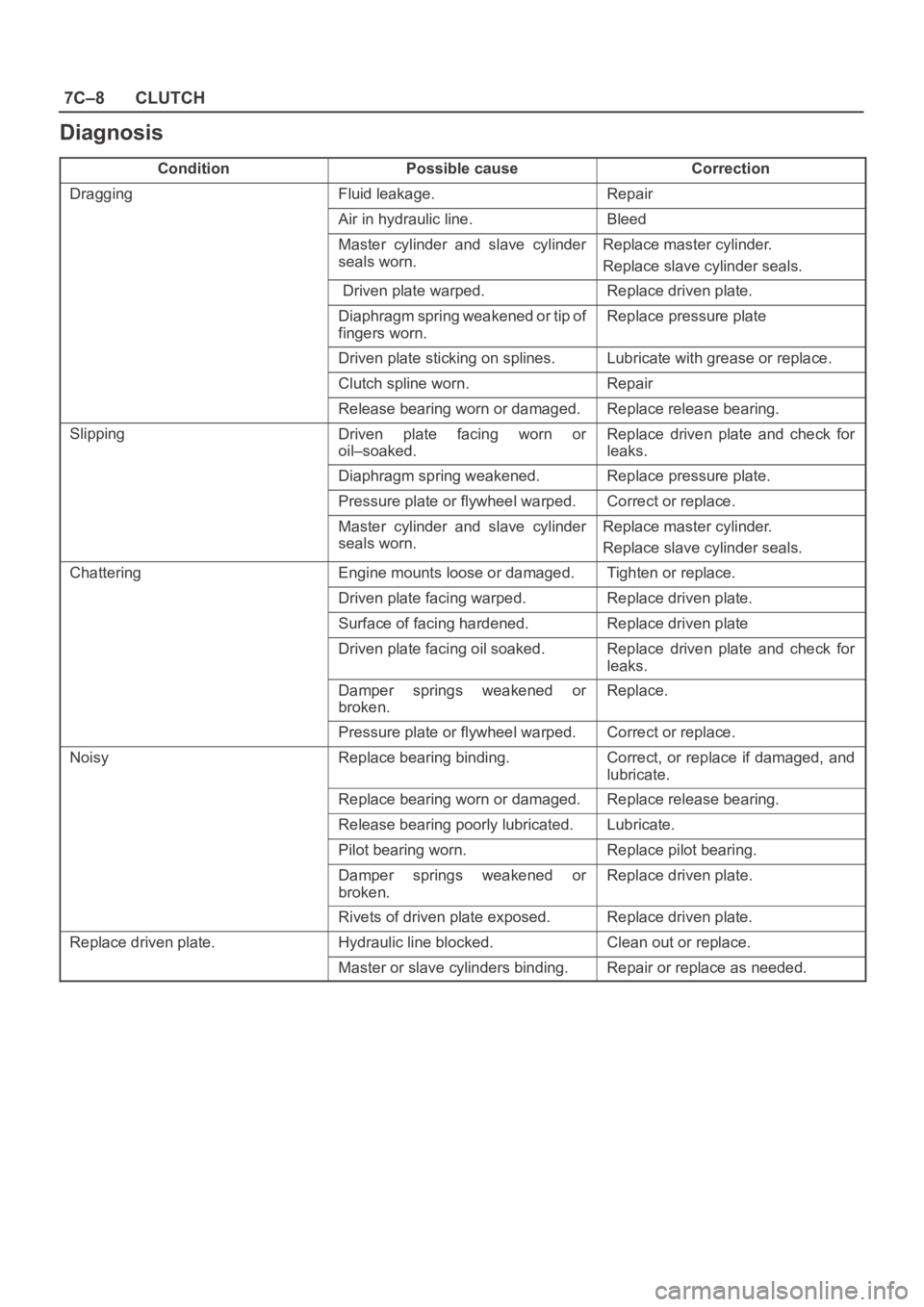

ConditionPossible causeCorrection

DraggingFluid leakage.Repair

Air in hydraulic line.Bleed

Master cylinder and slave cylinder

seals worn. Replace master cylinder.

Replace slave cylinder seals.

Driven plate warped.Replace driven plate.

Diaphragm spring weakened or tip of

fingers worn. Replace pressure plate

Driven plate sticking on splines.Lubricate with grease or replace.

Clutch spline worn. Repair

Release bearing worn or damaged.Replace release bearing.

SlippingDriven plate facing worn or

oil–soaked.Replace driven plate and check for

leaks.

Diaphragm spring weakened.Replace pressure plate.

Pressure plate or flywheel warped.Correct or replace.

Master cylinder and slave cylinder

seals worn.Replace master cylinder.

Replace slave cylinder seals.

ChatteringEngine mounts loose or damaged.Tighten or replace.

Driven plate facing warped.Replace driven plate.

Surface of facing hardened.Replace driven plate

Driven plate facing oil soaked. Replace driven plate and check for

leaks.

Damper springs weakened or

broken. Replace.

Pressure plate or flywheel warped.Correct or replace.

NoisyReplace bearing binding.Correct, or replace if damaged, and

lubricate.

Replace bearing worn or damaged. Replace release bearing.

Release bearing poorly lubricated. Lubricate.

Pilot bearing worn.Replace pilot bearing.

Damper springs weakened or

broken.Replace driven plate.

Rivets of driven plate exposed.Replace driven plate.

Replace driven plate.Hydraulic line blocked.Clean out or replace.

Master or slave cylinders binding.Repair or replace as needed.

Page 2523 of 6000

7C–14CLUTCH

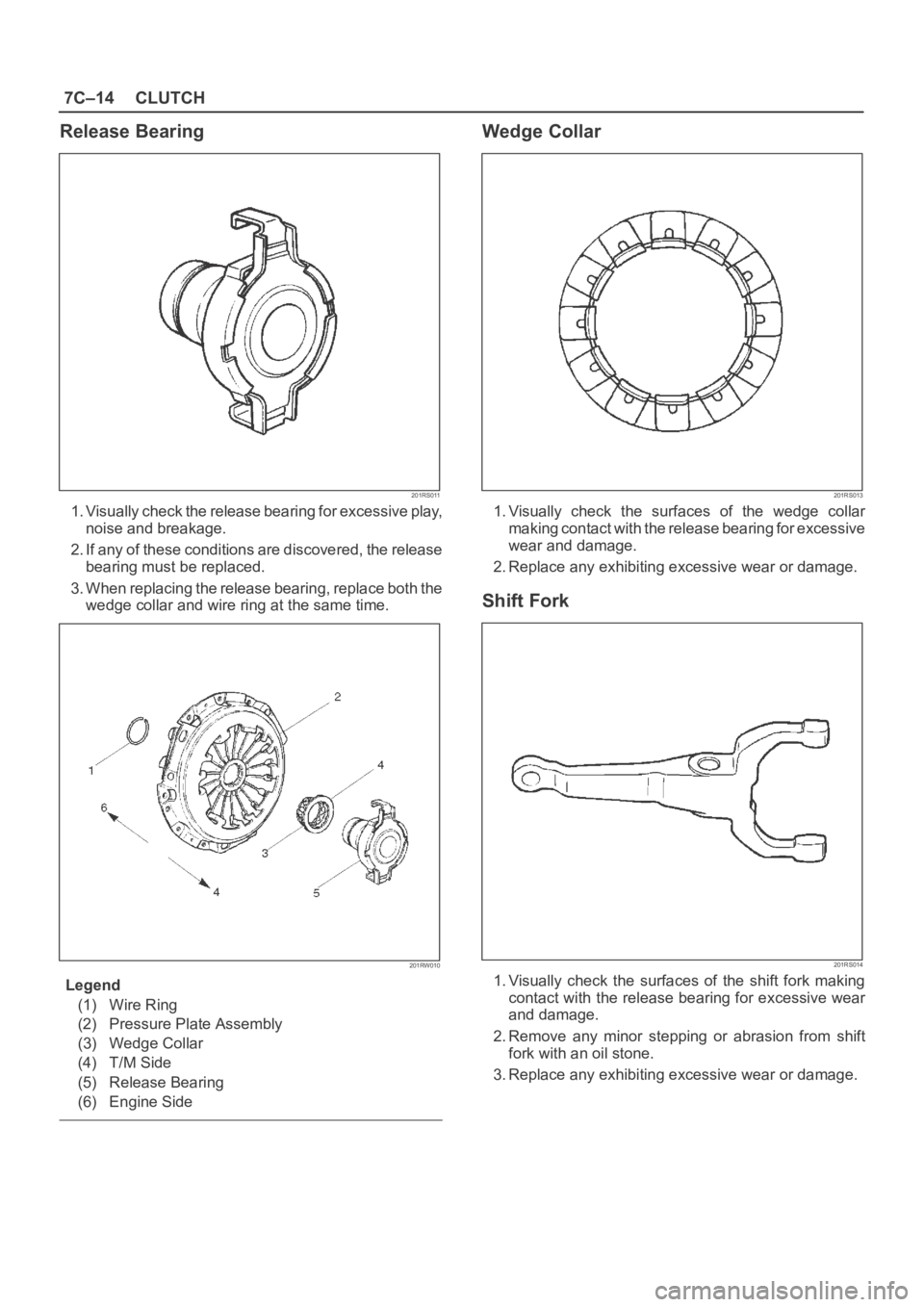

Release Bearing

201RS011

1. Visually check the release bearing for excessive play,

noise and breakage.

2. If any of these conditions are discovered, the release

bearing must be replaced.

3. When replacing the release bearing, replace both the

wedge collar and wire ring at the same time.

201RW010

Legend

(1) Wire Ring

(2) Pressure Plate Assembly

(3) Wedge Collar

(4) T/M Side

(5) Release Bearing

(6) Engine Side

Wedge Collar

201RS013

1. Visually check the surfaces of the wedge collar

making contact with the release bearing for excessive

wear and damage.

2. Replace any exhibiting excessive wear or damage.

Shift Fork

201RS014

1. Visually check the surfaces of the shift fork making

contact with the release bearing for excessive wear

and damage.

2. Remove any minor stepping or abrasion from shift

fork with an oil stone.

3. Replace any exhibiting excessive wear or damage.

Page 2568 of 6000

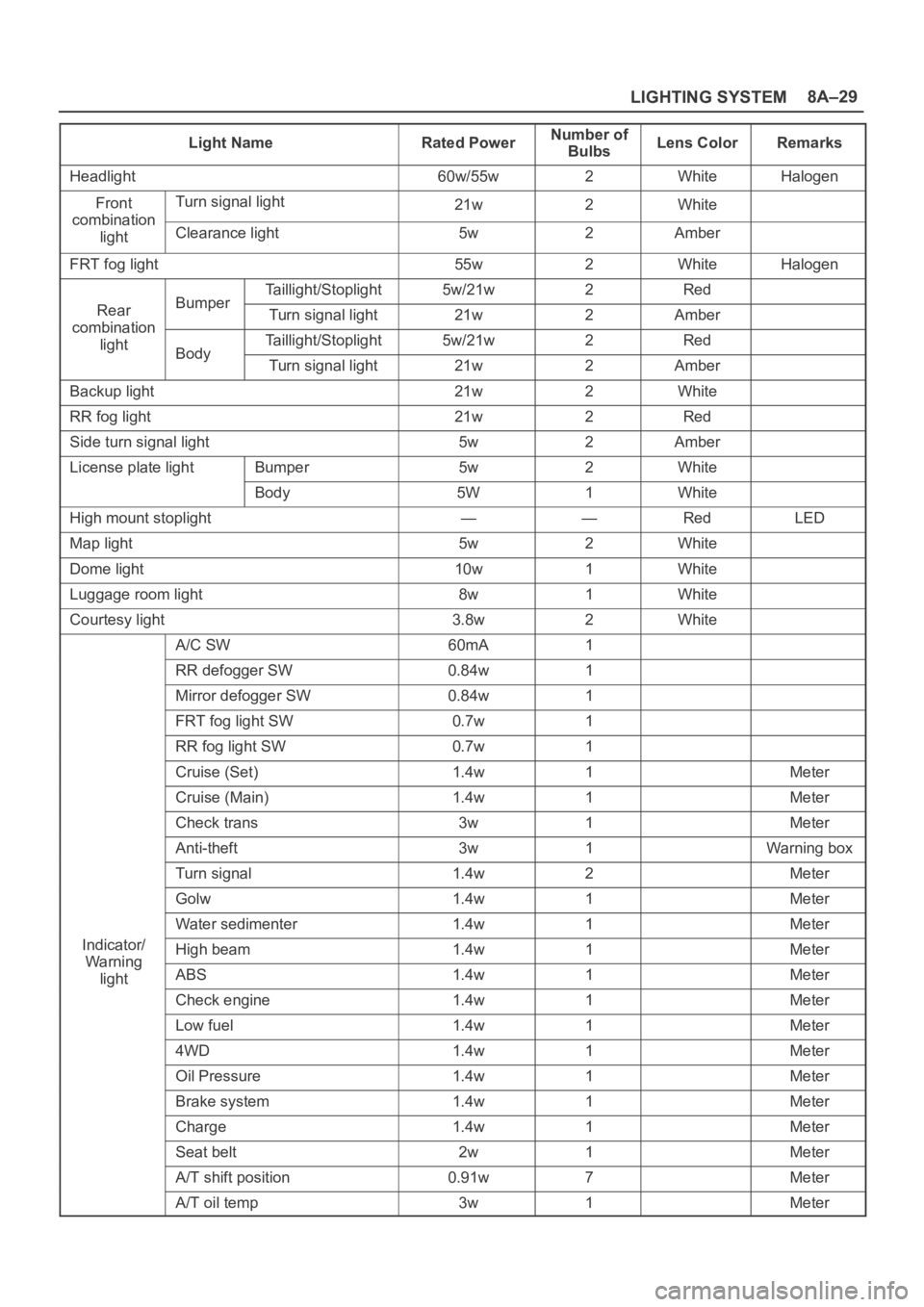

LIGHTING SYSTEM8A–29

Light NameRated PowerNumber of

BulbsLens ColorRemarks

Headlight60w/55w2WhiteHalogen

FrontTurn signal light21w2Whitecombination

lightClearance light5w2Amber

FRT fog light55w2WhiteHalogen

Taillight/Stoplight5w/21w2Red

RearBumperTurn signal light21w2Ambercombination

lightTaillight/Stoplight5w/21w2RedBodyTurn signal light21w2Amber

Backup light21w2White

RR fog light21w2Red

Side turn signal light5w2Amber

License plate lightBumper5w2White

Body5W1White

High mount stoplight——RedLED

Map light5w2White

Dome light10w1White

Luggage room light8w1White

Courtesy light3.8w2White

A/C SW60mA1

RR defogger SW0.84w1

Mirror defogger SW0.84w1

FRT fog light SW0.7w1

RR fog light SW0.7w1

Cruise (Set)1.4w1Meter

Cruise (Main)1.4w1Meter

Check trans3w1Meter

Anti-theft3w1Warning box

Turn signal1.4w2Meter

Golw1.4w1Meter

Water sedimenter1.4w1Meter

Indicator/High beam1.4w1MeterWa rnin g

lightABS1.4w1Meter

Check engine1.4w1Meter

Low fuel1.4w1Meter

4WD1.4w1Meter

Oil Pressure1.4w1Meter

Brake system1.4w1Meter

Charge1.4w1Meter

Seat belt2w1Meter

A/T shift position0.91w7Meter

A/T oil temp3w1Meter

Page 2650 of 6000

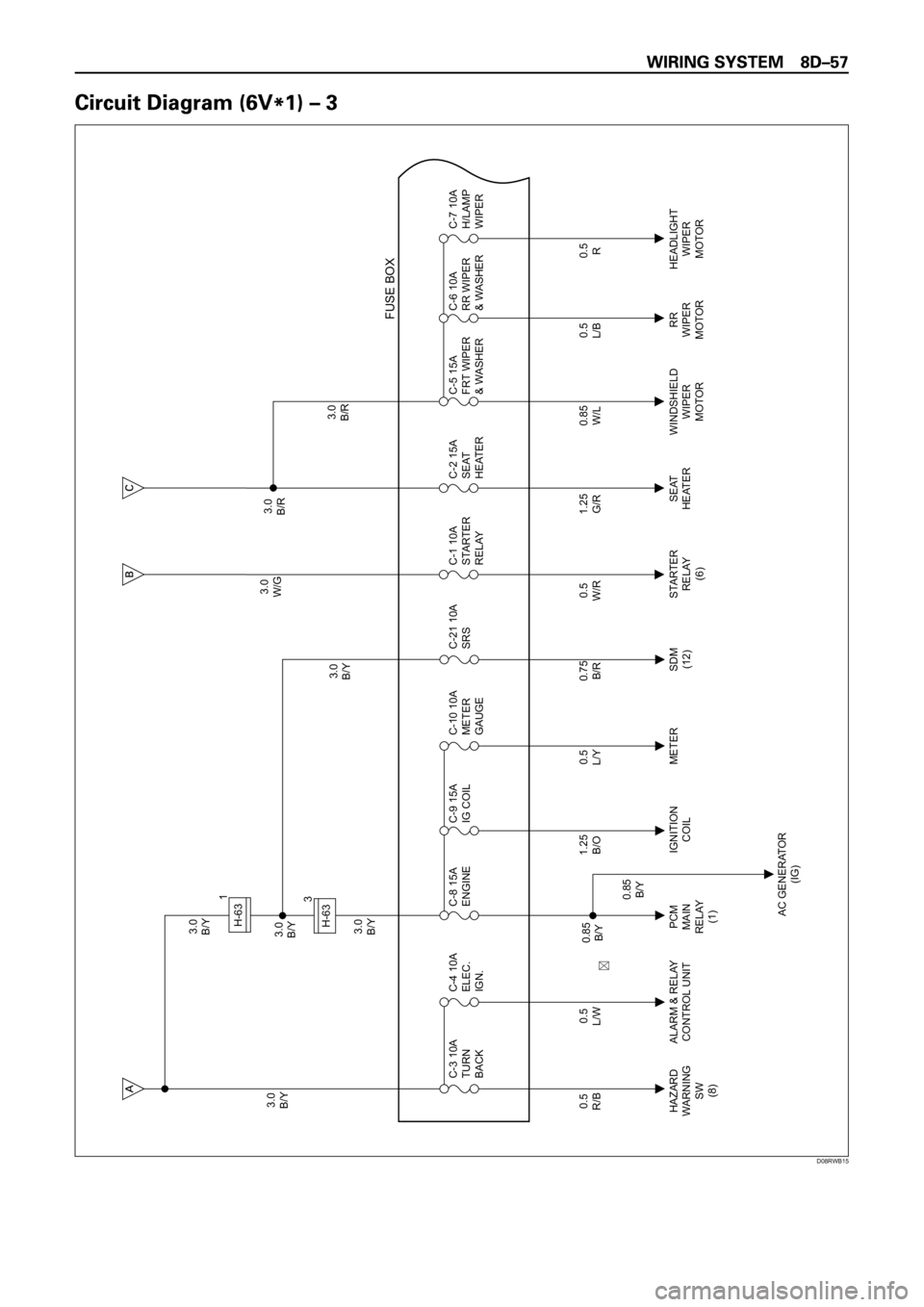

3.0

B/Y3.0

B/Y

3.0

B/Y3.0

B/Y3.0

W/G3.0

B/R

3.0

B/R 3.0

B/Y

0.5

R/B

HAZARD

WARNING

SW

(8)PCM

MAIN

RELAY

(1)IGNITION

COILMETER STARTER

RELAY

(6)SEAT

HEATERWINDSHIELD

WIPER

MOTORRR

WIPER

MOTORHEADLIGHT

WIPER

MOTOR

AC GENERATOR

(IG) ALARM & RELAY

CONTROL UNIT C-3 10A

TURN

BACK

0.5

L/WC-4 10A

ELEC.

IGN.

0.5

L/YC-10 10A

METER

GAUGE

0.5

W/RC-1 10A

STARTER

RELAY

0.85

W/LC-5 15A

FRT WIPER

& WASHERC-6 10A

RR WIPER

& WASHERC-7 10A

H/LAMP

WIPER

FUSE BOX

1.25

B/OC-9 15A

IG COIL C-8 15A

ENGINE

0.5

L/B

0.85

B/Y

0.85

B/Y

0.5

R

0.75

B/R

SDM

(12)C-21 10A

SRS

1.25

G/RC-2 15A

SEAT

HEATER

H-631

3

H-63

��

D08RWB15

Page 3004 of 6000

D08RW722

3C-3910

H-42

0.5

B/R0.5

B/R 0.5

B/R

B

D

C

A

FENDER-RH

H-104

M-10

2

A

I 0.5

L/Y0.5

L/Y0.5

L/Y

1M-109

H-103

H-9

0.5

LG/W0.5

LG/W

0.5

LG/W0.5

LG/W 0.5

LG/W0.5

R/W

SPEEDO-

METER

RESET

SWTACHOMETERENGINE

COOLANT

TEMPERATURE

GAUGEFUEL

GAUGEOIL

PRESSURE

GAUGE FUSE C-15

3M-10125

H-9

11

H-10

VEHICLE

SPEED SENSOR

I-10

0.5

Y/B0.5

Y/B0.5

Y/B

1

E-191 4

H-24

11

H-6

I-10

2H-8

PCM

(D7)CRUISE CONTROL

UNIT(9)0.5

B/R

15H-9

PCM

(C10)9

I-9

0.5

Y/R

14

H-2520

I-10

ENGINE

COOLANT

TEMPERATURE

UNIT

0.5

Y/G0.5

Y/V0.5

Y/B

1

E-217 19

H-9

10

H-6

I-10

OIL

PRESSURE

UNIT

8I-10METER

ODO/TRIP

METER