OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 451 of 6000

DIFFERENTIAL (FRONT) 4A1–14

7. Record the pinion depth code on the head of the

drive pinion.

The number indicates a necessary change in the

pinion mounting distance. A plus number indi-

cates the need for a greater mounting distance

(which can be achieved by decreasing the shim

thickness). A minus number indicates the need

for a smaller mounting distance (which can be

achieved by increasing the shim thickness). If ex-

amination reveals pinion depth code “0”, the pin-

ion is “nominal”.

425RS023

Page 452 of 6000

4A1–15 DIFFERENTIAL (FRONT)

8. Select the shim using the chart;

Pinion marking+10+8+6+4+20–2–4–6–8–10

Dial indicator

reading

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)mm

(Inches)

0.0812.18

(0.0858)

0.0822.18

(0.0858)2.20

(0.0866)

0.0832.18

(0.0858)2.20

(0.0866)2.23

(0.0882)

0.0842.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)

0.0852.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)

0.0862.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)

0.0872.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)

0.0882.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)

0.0892.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)

0.0902.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)

0.0912.18

(0.0858)2.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)

0.0922.20

(0.0866)2.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)

0.0932.24

(0.0882)2.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)

0.0942.26

(0.0890)2.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)

0.0952.28

(0.0898)2.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)

0.0962.32

(0.0914)2.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0972.34

(0.0921)2.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0982.36

(0.0929)2.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0992.38

(0.0937)2.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

02.42

(0.0953)2.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0012.44

(0.0961)2.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0022.46

(0.0969)2.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0032.48

(0.0977)2.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0042.52

(0.0992)2.54

(0.1000)2.56

(0.1008)

0.0052.54

(0.1000)2.56

(0.1008)

0.0062.56

(0.1008)

NOTE: When ordering shims, find the part number in the

parts catalog by using the thickness of shims listed in the

above table.4. Place the shim on the drive pinion, with the chamfered

side turned towards the pinion head then install the

inner bearing onto the pinion using an installer

9–8522–1165–0 and a press.

Page 453 of 6000

DIFFERENTIAL (FRONT) 4A1–16

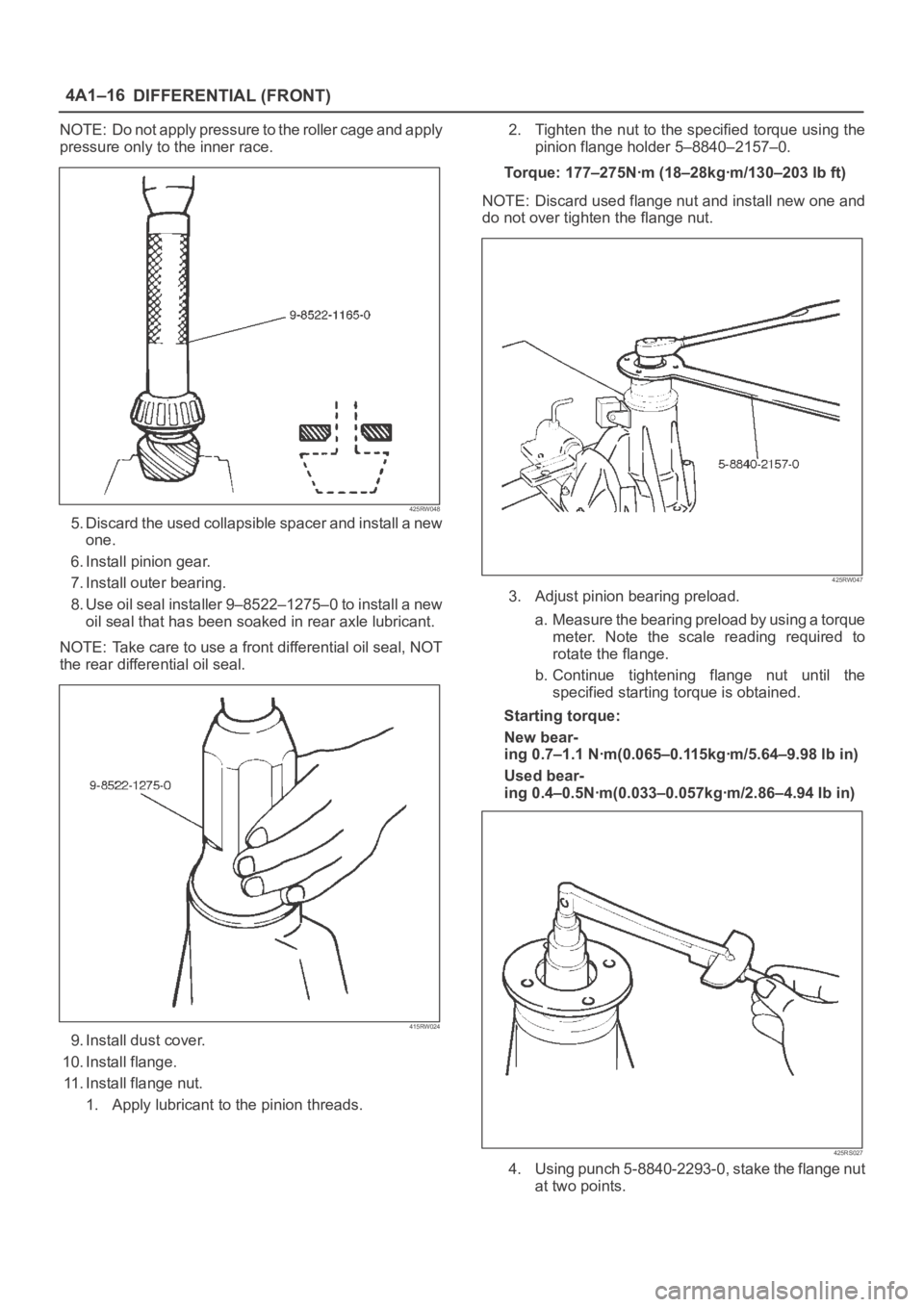

NOTE: Do not apply pressure to the roller cage and apply

pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a new

one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 9–8522–1275–0 to install a new

oil seal that has been soaked in rear axle lubricant.

NOTE: Take care to use a front differential oil seal, NOT

the rear differential oil seal.

415RW024

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque: 177–275Nꞏm (18–28kgꞏm/130–203 lb ft)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

425RW047

3. Adjust pinion bearing preload.

a. Measure the bearing preload by using a torque

meter. Note the scale reading required to

rotate the flange.

b. Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bear-

ing 0.7–1.1 Nꞏm(0.065–0.115kgꞏm/5.64–9.98 lb in)

Used bear-

ing 0.4–0.5Nꞏm(0.033–0.057kgꞏm/2.86–4.94 Ib in)

425RS027

4. Using punch 5-8840-2293-0, stake the flange nut

at two points.

Page 454 of 6000

4A1–17 DIFFERENTIAL (FRONT)

NOTE: When staking, be sure to turn the nut to insure

that there is no change in bearing preload. Make sure of

preload again as instructed in 3).

415RW019

Legend

(1) 1.3mm or less

12. Install adjust shim.

1. Attach the side bearing to the differential

assembly without shims. Support the opposite

side using a pilot to prevent bearing damage.

425RS029

Legend

(1) Drive handle:5–8840–0007–0

(2) Installer:9–8522–1164–0

(3) Pilot:9–8521–1743–0

2. Insert the differential cage assembly with bearing

outer races into the side bearing bores of the

carrier.

425RS030

3. Using two sets of feeler gauges, insert a feeler

stock of sufficient thickness between each

bearing outer race and the carrier to remove all

end play. Make certain the feeler stock is pushed

to the bottom of the bearing bores.

Mount the dial indicator 5–8840–0126–0 on the

carrier so that the indicator stem is at right angles

to a tooth on the ring gear.

425RW049

Page 455 of 6000

DIFFERENTIAL (FRONT) 4A1–18

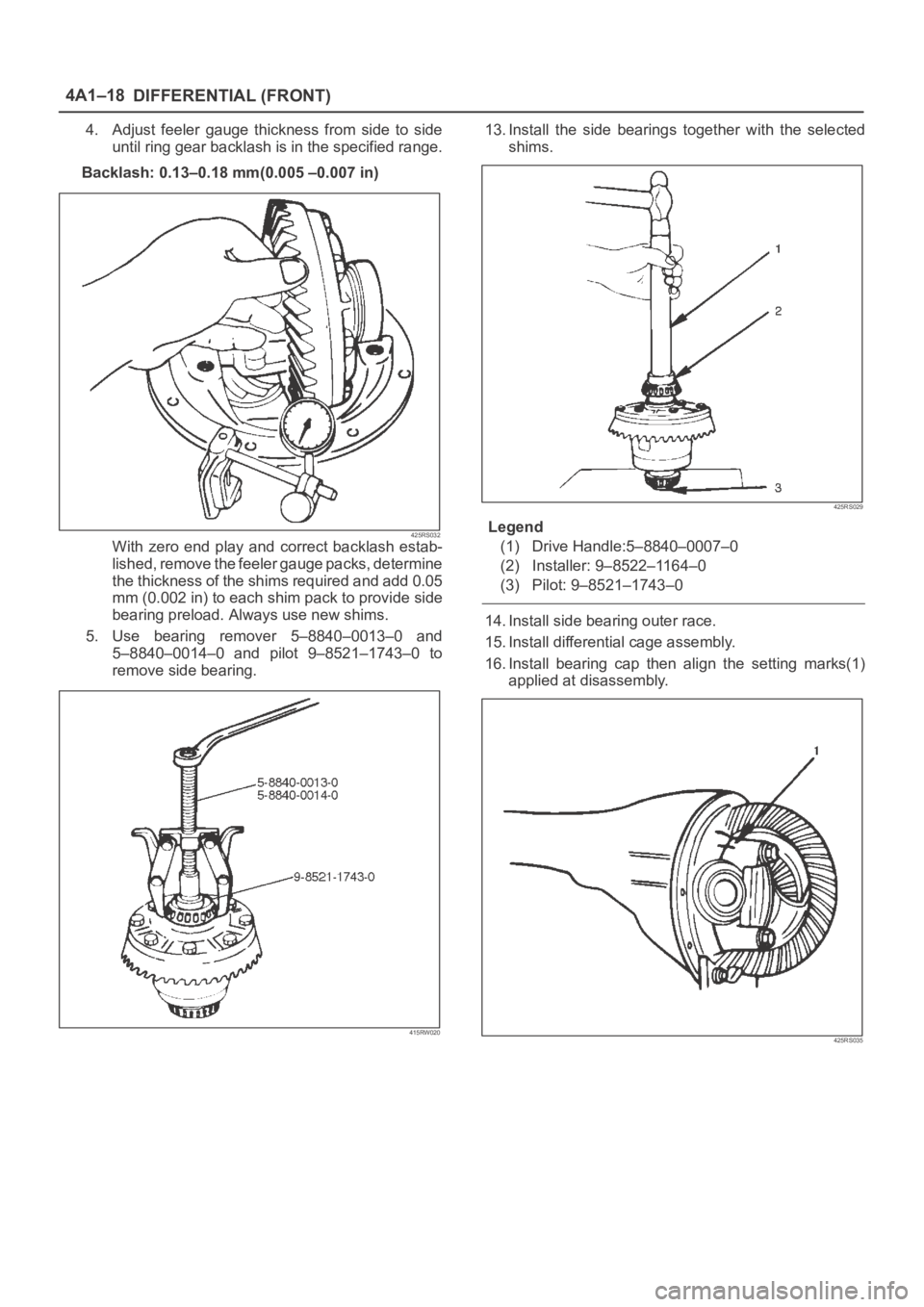

4. Adjust feeler gauge thickness from side to side

until ring gear backlash is in the specified range.

Backlash: 0.13–0.18 mm(0.005 –0.007 in)

425RS032With zero end play and correct backlash estab-

lished, remove the feeler gauge packs, determine

the thickness of the shims required and add 0.05

mm (0.002 in) to each shim pack to provide side

bearing preload. Always use new shims.

5. Use bearing remover 5–8840–0013–0 and

5–8840–0014–0 and pilot 9–8521–1743–0 to

remove side bearing.

415RW020

13. Install the side bearings together with the selected

shims.

425RS029

Legend

(1) Drive Handle:5–8840–0007–0

(2) Installer: 9–8522–1164–0

(3) Pilot: 9–8521–1743–0

14. Install side bearing outer race.

15. Install differential cage assembly.

16. Install bearing cap then align the setting marks(1)

applied at disassembly.

425RS035

Page 456 of 6000

4A1–19 DIFFERENTIAL (FRONT)

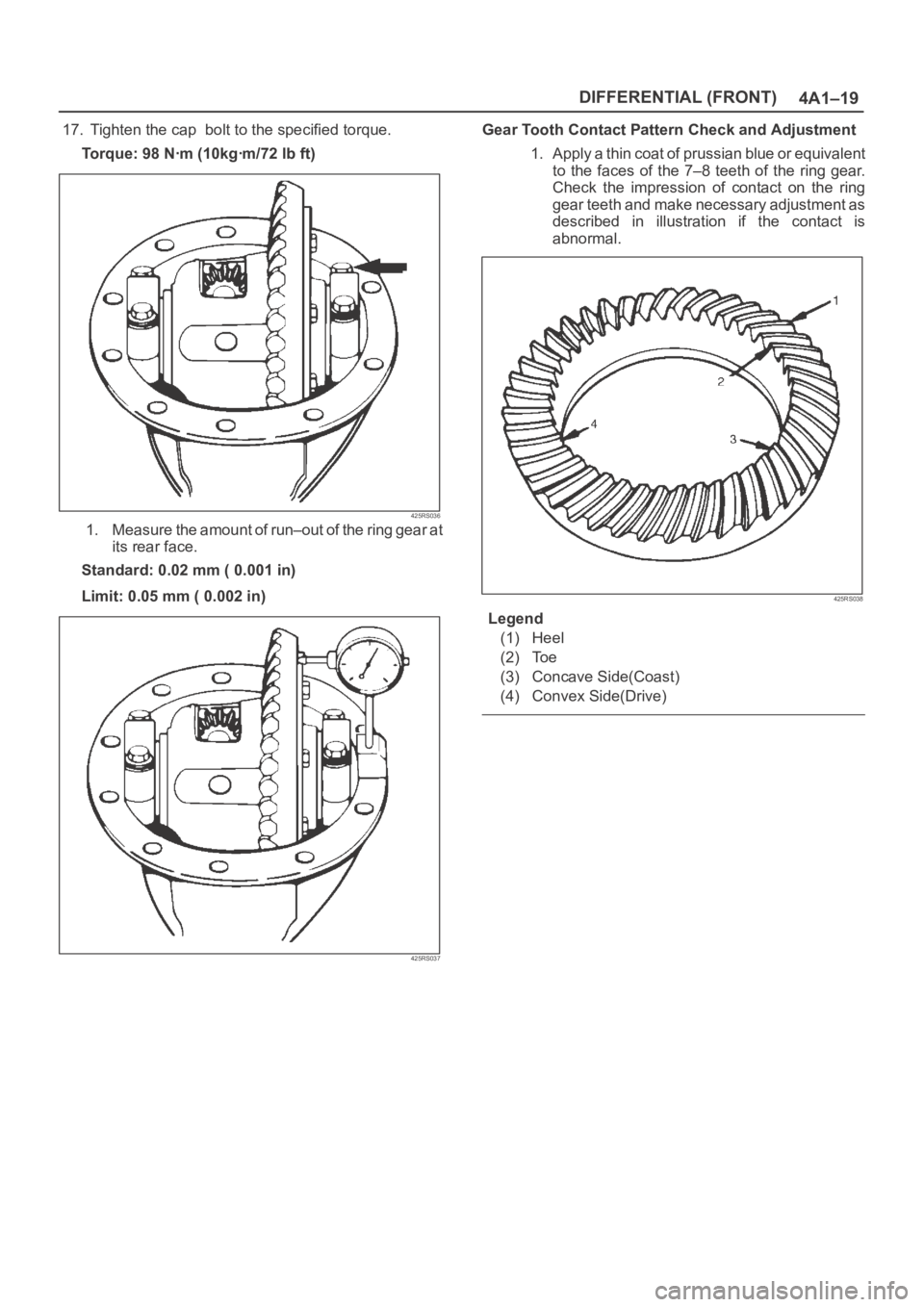

17. Tighten the cap bolt to the specified torque.

To r q u e : 9 8 N ꞏm ( 1 0 k g ꞏm / 7 2 l b f t )

425RS036

1. Measure the amount of run–out of the ring gear at

its rear face.

Standard: 0.02 mm ( 0.001 in)

Limit: 0.05 mm ( 0.002 in)

425RS037

Gear Tooth Contact Pattern Check and Adjustment

1. Apply a thin coat of prussian blue or equivalent

to the faces of the 7–8 teeth of the ring gear.

Check the impression of contact on the ring

gear teeth and make necessary adjustment as

described in illustration if the contact is

abnormal.

425RS038

Legend

(1) Heel

(2) Toe

(3) Concave Side(Coast)

(4) Convex Side(Drive)

Page 457 of 6000

DIFFERENTIAL (FRONT) 4A1–20

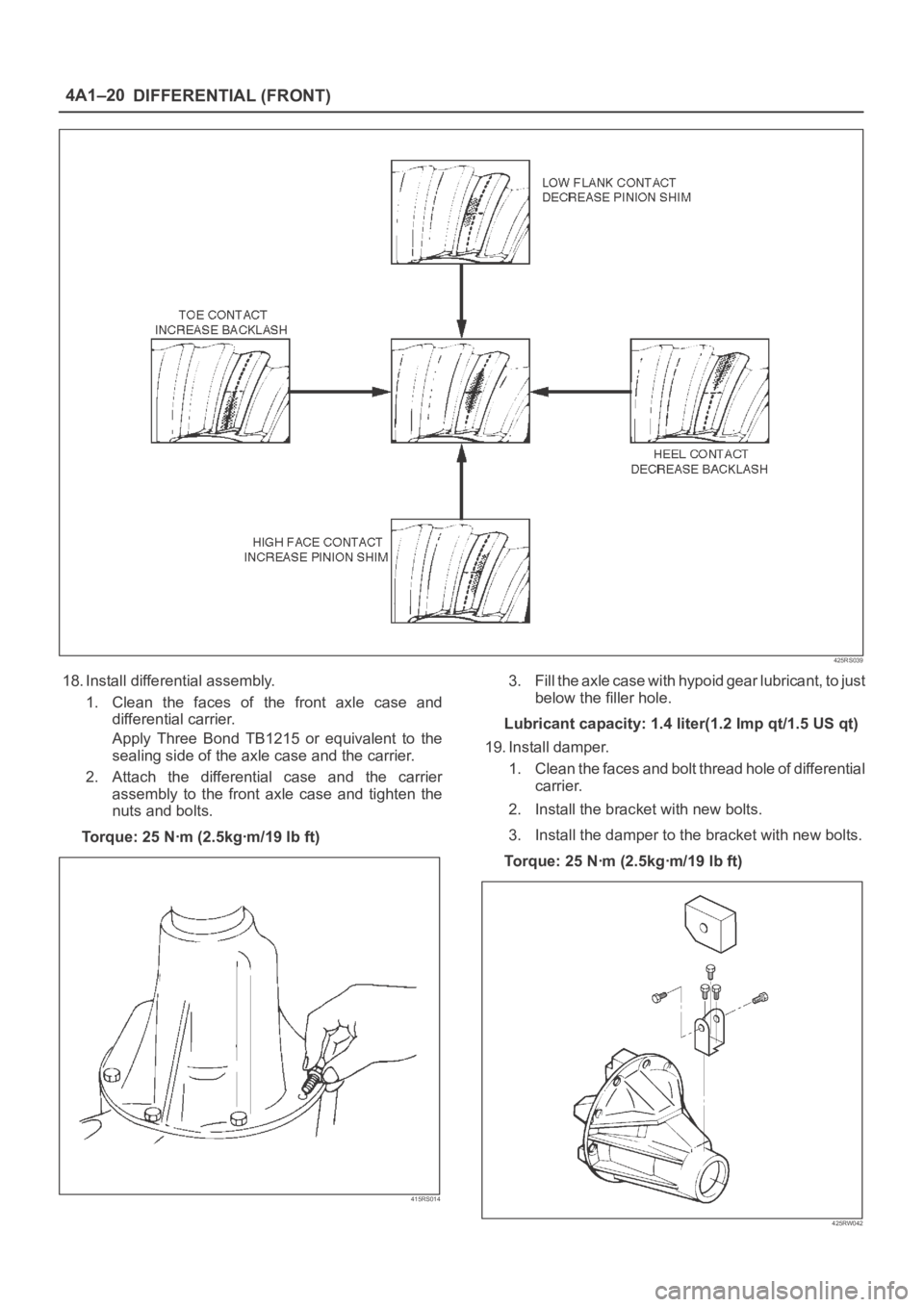

425RS039

18. Install differential assembly.

1. Clean the faces of the front axle case and

differential carrier.

Apply Three Bond TB1215 or equivalent to the

sealing side of the axle case and the carrier.

2. Attach the differential case and the carrier

assembly to the front axle case and tighten the

nuts and bolts.

To r q u e : 2 5 N ꞏm ( 2 . 5 k g ꞏm / 1 9 l b f t )

415RS014

3. Fill the axle case with hypoid gear lubricant, to just

below the filler hole.

Lubricant capacity: 1.4 liter(1.2 Imp qt/1.5 US qt)

19. Install damper.

1. Clean the faces and bolt thread hole of differential

carrier.

2. Install the bracket with new bolts.

3. Install the damper to the bracket with new bolts.

Torque: 25 Nꞏm (2.5kgꞏm/19 lb ft)

425RW042

Page 458 of 6000

4A1–21 DIFFERENTIAL (FRONT)

Differential Cage Assembly

Disassembled View

415RS015

Legend

(1) Pinion Gear

(2) Thrust Washer

(3) Side Gear

(4) Cross Pin(5) Ring Gear

(6) Bolt

(7) Differential Cage

(8) Lock Pin

Disassembly

1. Remove bolt.

2. Remove ring gear.

3. Remove lock pin, break staking on the lock pin, using

a 5 mm (0.20 in) diameter drill.

425RS042

Page 459 of 6000

DIFFERENTIAL (FRONT) 4A1–22

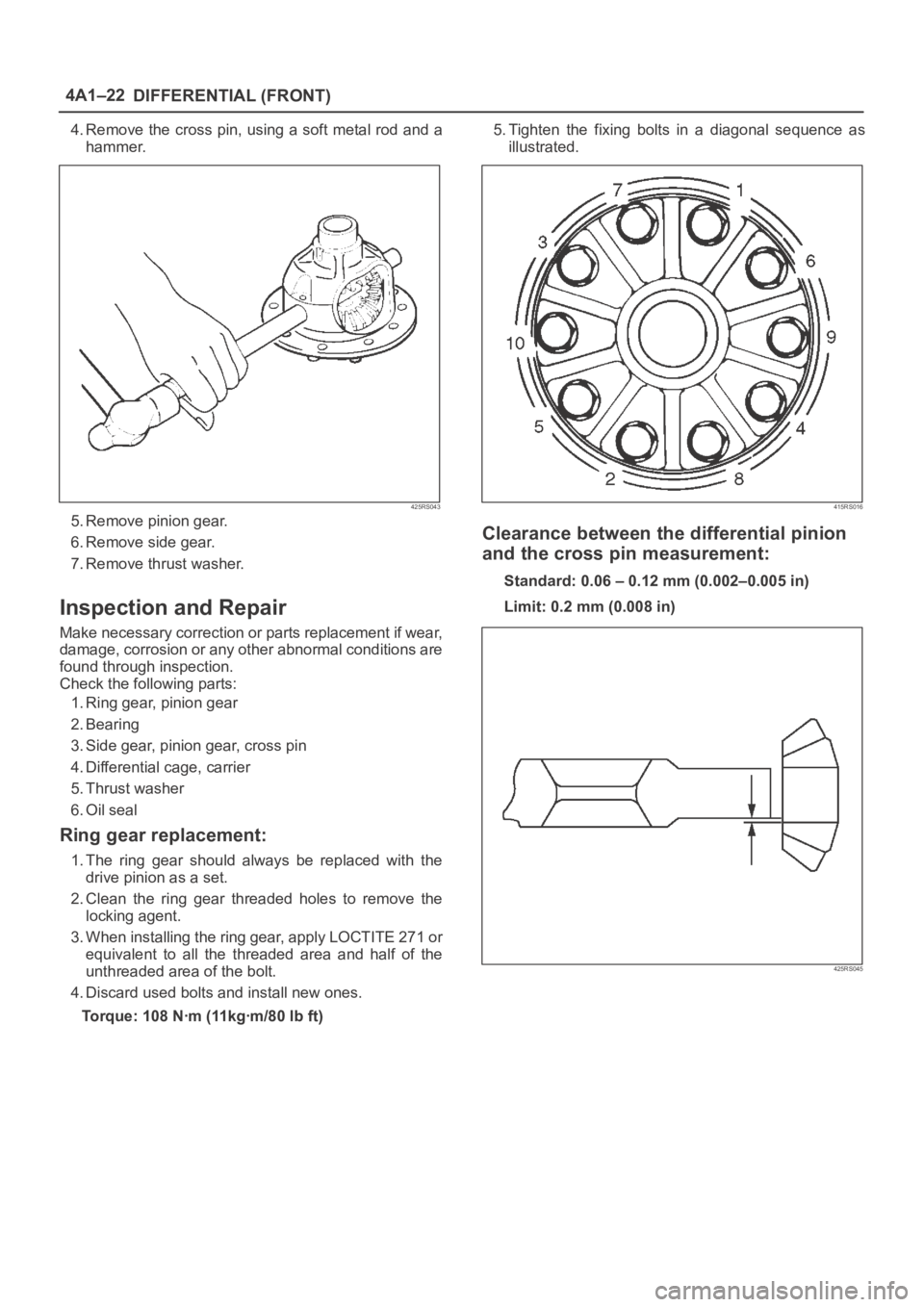

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

4. Discard used bolts and install new ones.

Torque: 108 Nꞏm (11kgꞏm/80 lb ft)5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RS016

Clearance between the differential pinion

and the cross pin measurement:

Standard: 0.06 – 0.12 mm (0.002–0.005 in)

Limit: 0.2 mm (0.008 in)

425RS045

Page 460 of 6000

4A1–23 DIFFERENTIAL (FRONT)

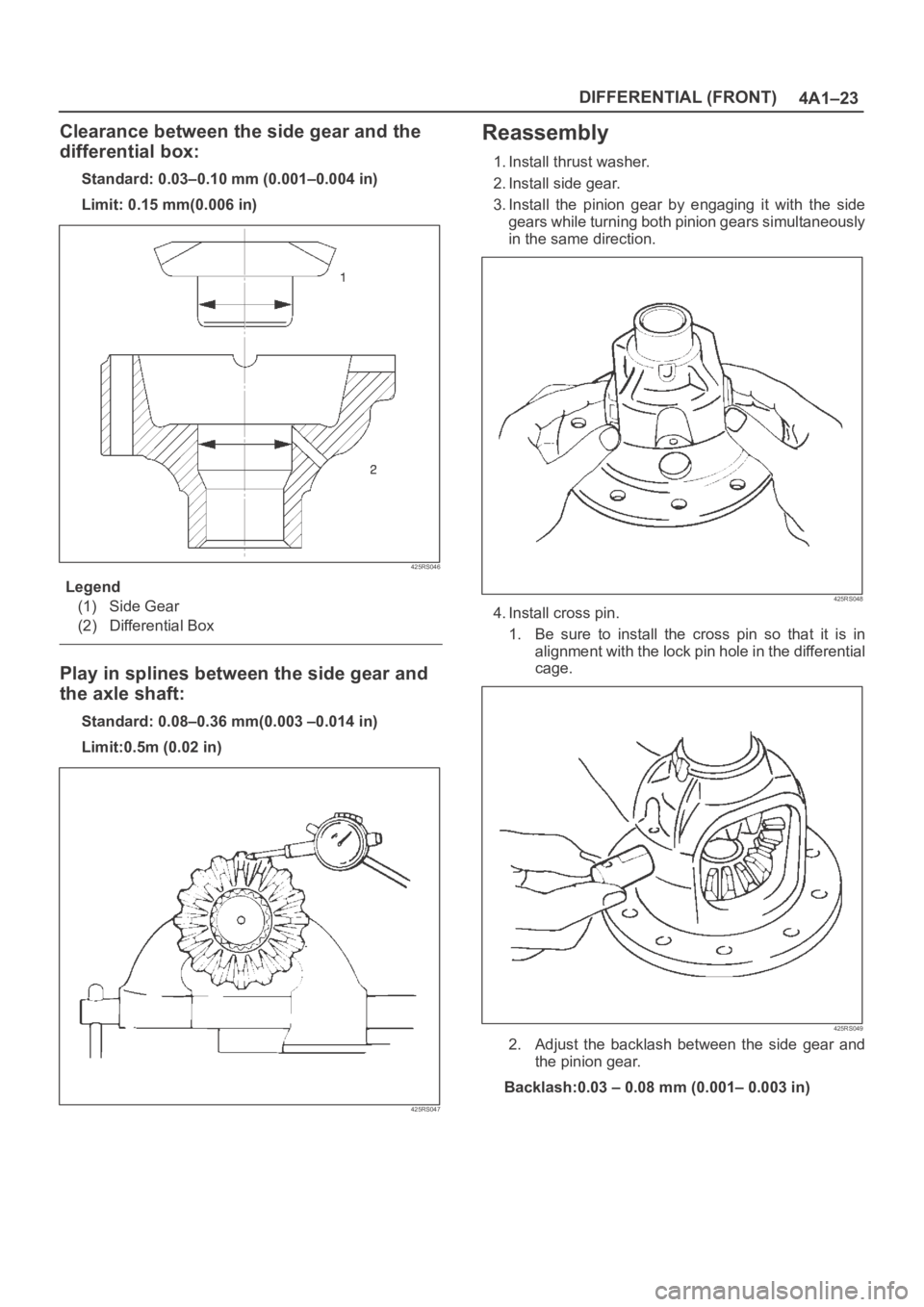

Clearance between the side gear and the

differential box:

Standard: 0.03–0.10 mm (0.001–0.004 in)

Limit: 0.15 mm(0.006 in)

425RS046

Legend

(1) Side Gear

(2) Differential Box

Play in splines between the side gear and

the axle shaft:

Standard: 0.08–0.36 mm(0.003 –0.014 in)

Limit:0.5m (0.02 in)

425RS047

Reassembly

1. Install thrust washer.

2. Install side gear.

3. Install the pinion gear by engaging it with the side

gears while turning both pinion gears simultaneously

in the same direction.

425RS048

4. Install cross pin.

1. Be sure to install the cross pin so that it is in

alignment with the lock pin hole in the differential

cage.

425RS049

2. Adjust the backlash between the side gear and

the pinion gear.

Backlash:0.03 – 0.08 mm (0.001– 0.003 in)