ignition OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4404 of 6000

5A–54

BRAKE CONTROL SYSTEM

Chart B-22 RL Speed Sensor Short Circuit (DTC 63)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector

3. Measure the RL speed sensor resistance between EHCU

connector terminals 22 and 23.

Is the resistance between 1.3k and 1.9k ohms?

Go to Step 2Go to Step 3

2Is there play in the sensor/sensor rotor?

Go to Step 4

Repair.

Go to Step 6

3Measure the RL speed sensor resistance at the sensor

connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

4Damage and powdered iron sticking to sensor/sensor ring?

Go to Step 5

Repair.

Go to Step 6

5Is sensor output normal? (Chart C-1-3 or TC-1)?Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h or higher to make sure that the warning light

goes out.

Page 4405 of 6000

5A–55 BRAKE CONTROL SYSTEM

Chart B-23 RR Speed Sensor Short Circuit (DTC 64)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure the RR speed sensor resistance between EHCU

connector terminals 2 and 3.

Is the resistance between 1.3k and 1.9k ohms?

Go to Step 2Go to Step 3

2Is there play in the sensor/sensor rotor?

Go to Step 4

Repair.

Go to Step 6

3Measure the RR speed sensor resistance at the sensor

connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

4Damage and powdered iron sticking to sensor/sensor ring?

Go to Step 5

Repair.

Go to Step 6

5Is sensor output normal? (Chart C-1-4 or TC-1)Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat “Basic

diagnostic flow

chart.”

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h or higher to make sure that the warning light

goes out.

Page 4406 of 6000

5A–56

BRAKE CONTROL SYSTEM

Chart B-24 Sensor Signal Input Abnormality (DTC 65)

StepActionYe sNo

1Using TECH 2?Go to Step 2Go to Step 3

21. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when speed

has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). *1

Is the abnormal sensor condition found?

Replace.

Go to Step 8

Go to Step 3

All the sensors

should follow the

following

flowchart (without

using TECH 2).

3Is there play in sensor/sensor ring?Repair.

Go to Step 8

Go to Step 4

4Is there powdered iron sticking to sensor/sensor ring?Repair.

Go to Step 8

Go to Step 5

5Is there a broken tooth or indentation in sensor ring?Replace sensor

ring.

Go to Step 8

Go to Step 6

6Is there play in wheel bearing?Adjust or repair.

Go to Step 8

Go to Step 7

7Is the check wiring between sensor and EHCU normal?

Replace EHCU.

Go to Step 8

Repair, and

perform system

self-check.

Go to Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat “Basic

diagnostic flow

chart.”

Go to Step 8

Sensor Signal Abnormality Criteria using

TECH 2

1. While driving, the speed of one or two wheels 25% or

more higher than that of the other wheels.

2. The speed of one or two wheels is 10 km/h (6 mph) or

more higher than that of the other wheels.

3. During steady driving, wheel speed changes abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h or higher to make sure that the warning

light goes out.

It is important to verify that the correct tires are installed

on vehicle.

Page 4497 of 6000

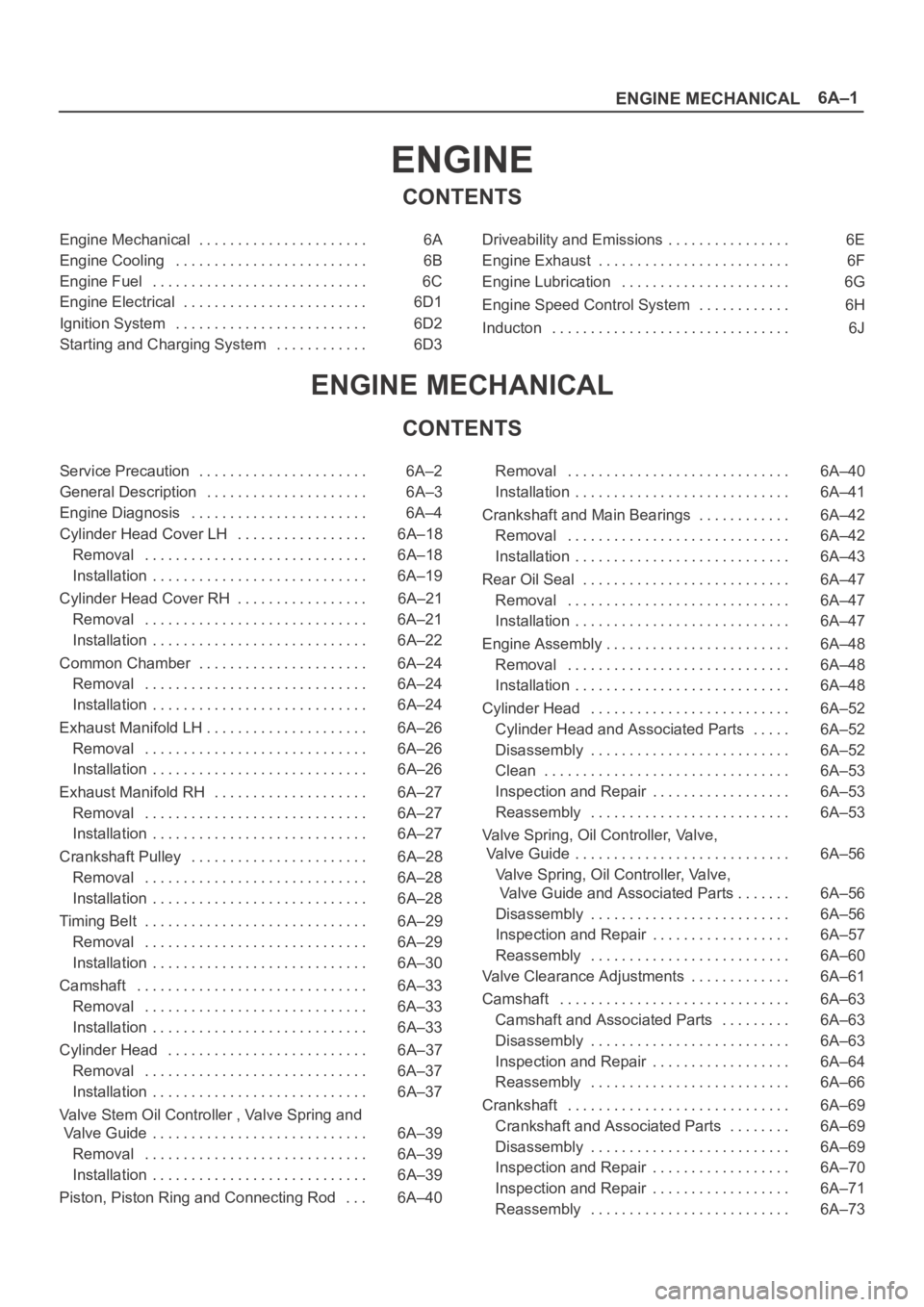

6A–1

ENGINE MECHANICAL

ENGINE

CONTENTS

Engine Mechanical 6A. . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 6B. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel 6C. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Electrical 6D1. . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6D2. . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Charging System 6D3. . . . . . . . . . . . Driveability and Emissions 6E. . . . . . . . . . . . . . . .

Engine Exhaust 6F. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication 6G. . . . . . . . . . . . . . . . . . . . . .

Engine Speed Control System 6H. . . . . . . . . . . .

Inducton 6J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MECHANICAL

CONTENTS

Service Precaution 6A–2. . . . . . . . . . . . . . . . . . . . . .

General Description 6A–3. . . . . . . . . . . . . . . . . . . . .

Engine Diagnosis 6A–4. . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover LH 6A–18. . . . . . . . . . . . . . . . .

Removal 6A–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover RH 6A–21. . . . . . . . . . . . . . . . .

Removal 6A–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Chamber 6A–24. . . . . . . . . . . . . . . . . . . . . .

Removal 6A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold LH 6A–26. . . . . . . . . . . . . . . . . . . . .

Removal 6A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold RH 6A–27. . . . . . . . . . . . . . . . . . . .

Removal 6A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Pulley 6A–28. . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 6A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Stem Oil Controller , Valve Spring and

Valve Guide 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Connecting Rod 6A–40. . . Removal 6A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 6A–42. . . . . . . . . . . .

Removal 6A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 6A–48. . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–52. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Associated Parts 6A–52. . . . .

Disassembly 6A–52. . . . . . . . . . . . . . . . . . . . . . . . . .

Clean 6A–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–53

. . . . . . . . . . . . . . . . . .

Reassembly 6A–53. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide 6A–56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide and Associated Parts 6A–56. . . . . . .

Disassembly 6A–56. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–57. . . . . . . . . . . . . . . . . .

Reassembly 6A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Clearance Adjustments 6A–61. . . . . . . . . . . . .

Camshaft 6A–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft and Associated Parts 6A–63. . . . . . . . .

Disassembly 6A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–64. . . . . . . . . . . . . . . . . .

Reassembly 6A–66. . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 6A–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Associated Parts 6A–69. . . . . . . .

Disassembly 6A–69. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–70. . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–71. . . . . . . . . . . . . . . . . .

Reassembly 6A–73. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4500 of 6000

6A–4

ENGINE MECHANICAL

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble — Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5–8840–0607–0, start the engine,

a n d c h e c k i f a s p a r k i s g e n e r a t e d in t h e s p a r k p l u g t e s t e r.

Before starting the engine, make sure that the spark plugtester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the igniton coil is

broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to “Electronic Fuel Injection”

section

Page 4501 of 6000

6A–5

ENGINE MECHANICAL

4. Engine Lacks Compression

Condition

Possible causeCorrection

Engine lacks compressionSpark plug loosely fitted or spark

plug gasket defectiveTighten to specified torque or replace

gasket

Valve timing incorrectAdjust

Cylinder head gasket defectiveReplace gasket

Valve incorrectly seatedLap valve

Valve stem seizedReplace valve and valve guide

Valve spring weakened or brokenReplace

Cylinder or piston rings wornOverhaul engine

Piston ring seizedOverhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking speed

is approximately 300 rpm.7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle reaches

the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

Page 4502 of 6000

6A–6

ENGINE MECHANICAL

Rough Engine Idling or Engine Stalling

ConditionPossible causeCorrection

Trouble in fuel injection systemIdle air control valve defectiveReplace

Throttle shutting off incompleteCorrect or replace

Throttle position sensor circuit open

or shortedCorrect or replace

Fuel injector circuits open or shortedCorrect or replace

Fuel injectors damagedReplace

Fuel pump relay defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or poor connectionsCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature Sensor

circuit open or poor connectionsCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Intake Air Temperature sensor circuit

open or poor connectionsCorrect or replace

Intake Air Temperature sensor

defectiveReplace

Knock Sensor (KS) cable broken or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or groundCorrect or replace

KS Module defectiveReplace

Vehicle Speed Sensor circuit open or

shortedCorrect or replace

Vehicle Speed Sensor defectiveReplace

Trouble in emission control systemPowertrain Control Module defectiveReplace

Exhaust Gas Recirculation Valve

circuit open or poor connectionsCorrect or replace

Exhaust Gas Recirculation Valve

faultyReplace

Canister purge valve circuit open or

poor connectionsCorrect or replace

Canister purge valve defectiveReplace

Evaporative Emission Canister

Purge control valve defectiveReplace

Trouble in ignition systemRefer to “Hard Start”

Page 4503 of 6000

6A–7

ENGINE MECHANICAL

Condition CorrectionPossible cause

OthersEngine lacks compressionRefer to “Hard Start”

Valve incorrectly seatedLap valve

Air Cleaner Filter cloggedReplace filter element

Valve timing incorrectReadjust

Idle air control valve brokenReplace

Fast idle solenoid defectiveReplace

Positive Crankcase Ventilation valve

defective or cloggedReplace

Rough Engine Running

ConditionPossible causeCorrection

Engine misfires periodicallyIgnition coil layer shortedReplace

Spark plugs foulingClean or install hotter type plug

Spark plug(s) insulator nose leakingReplace

Fuel injector(s) defectiveReplace

Powertrain control module faultyReplace

Engine knocks periodicallySpark plugs running too hotInstall colder type spark plugs

Powertrain control module faultyReplace

Engine lacks powerSpark plugs fouledClean

Fuel injectors defectiveReplace

Mass Airflow Sensor or Intake

Airflow Sensor circuit defectiveCorrect or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defectiveCorrect or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defectiveCorrect or replace

Powertrain Control Module faultyReplace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defectiveCorrect or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defectiveCorrect or replace

Knock Sensor or Knock Sensor

circuits defectiveCorrect or replace

Knock Sensor Module or Knock

Sensor Module circuits defectiveCorrect or replace

Page 4506 of 6000

6A–10

ENGINE MECHANICAL

Engine Lacks Power

ConditionPossible causeCorrection

Trouble in fuel systemFuel Pressure Control Valve not

working normallyReplace

Fuel injector cloggedClean or replace

Fuel pipe cloggedClean

Fuel filter clogged or fouledReplace

Fuel pump drive circuit not working

normallyCorrect or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuitClean or replace

Water in fuel systemClean

Inferior quality fuel in fuel systemUse fuel of specified octane rating

Powertrain Control Module supplied

poor voltageCorrect circuit

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Mass Airflow Sensor not working

normallyReplace

Manifold Absolute Pressure Sensor

not working normallyReplace

Intake Air Temperature Sensor not

working normallyReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Powertrain Control Module defectiveReplace

Trouble in intake or exhaust systemAir Cleaner Filter cloggedReplace filter element

Air duct kinked or flattenedCorrect or replace

Ignition failure————Refer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequateInstall spark plugs of adequate heat

range

Ignition coil defectiveReplace

Page 4509 of 6000

6A–13

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine knockingPreignition due to use of spark plugs

of inadequate heat rangeInstall Spark Plugs of adequate heat

range

Carbon deposits in combustion

chambersClean

Fuel too low in octane ratingReplace fuel

Wide Open Throttle enrichment

system failureRefer to Section 6E

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Engine overheatingRefer to “Engine Lacks Power”

OthersWater pump defectiveReplace

Drive belt slippingReplace auto tentioner or drive belt

Abnormal Combustion

ConditionPossible causeCorrection

Trouble in fuel systemFuel pressure control valve defectiveReplace

Fuel filter cloggedReplace

Fuel pump cloggedClean or replace

Fuel tank or fuel pipe cloggedClean or replace

Fuel injector cloggedClean or replace

Fuel pump relay defectiveReplace

Power supply cable for fuel pump

broken or poor connectionsReconnect, correct or replace

Mass Airflow (MAF) sensor circuit

open or defectiveCorrect or replace

MAF Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or shortedCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature (ECT)

Sensor circuit open or shortedCorrect or replace

ECT Sensor defectiveReplace

Throttle Position Sensor adjustment

incorrectReadjust

Throttle Position Sensor defectiveReplace

Throttle Position Sensor connector

poor connectionsReconnect

Vehicle Speed Sensor cable poor

connections or defectiveCorrect or replace

Vehicle Speed Sensor loosely fixedFix tightly

Vehicle Speed Sensor in wrong

contact or defectiveReplace

Powertrain Control Module cable

poor connections or defectiveCorrect or replace