check oil OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1031 of 6000

6A–75

ENGINE MECHANICAL

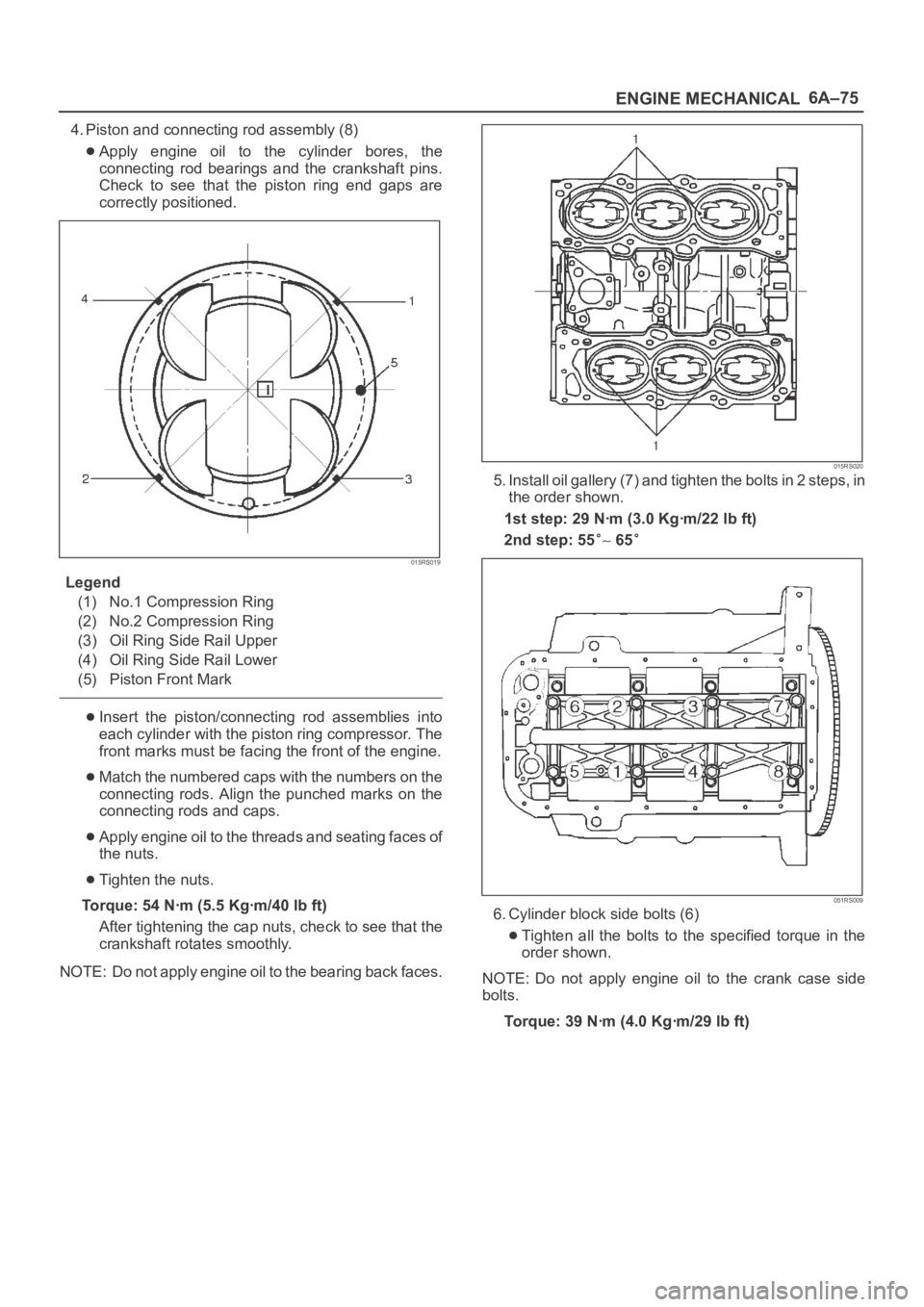

4. Piston and connecting rod assembly (8)

Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins.

Check to see that the piston ring end gaps are

correctly positioned.

015RS019

Legend

(1) No.1 Compression Ring

(2) No.2 Compression Ring

(3) Oil Ring Side Rail Upper

(4) Oil Ring Side Rail Lower

(5) Piston Front Mark

Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor. The

front marks must be facing the front of the engine.

Match the numbered caps with the numbers on the

connecting rods. Align the punched marks on the

connecting rods and caps.

Apply engine oil to the threads and seating faces of

the nuts.

Tighten the nuts.

Torque: 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

After tightening the cap nuts, check to see that the

crankshaft rotates smoothly.

NOTE: Do not apply engine oil to the bearing back faces.

015RS020

5. Install oil gallery (7) and tighten the bolts in 2 steps, in

the order shown.

1st step: 29 Nꞏm (3.0 Kgꞏm/22 lb ft)

2nd step: 55

65

051RS009

6. Cylinder block side bolts (6)

Tighten all the bolts to the specified torque in the

order shown.

NOTE: Do not apply engine oil to the crank case side

bolts.

Torque: 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

Page 1037 of 6000

6A–81

ENGINE MECHANICAL

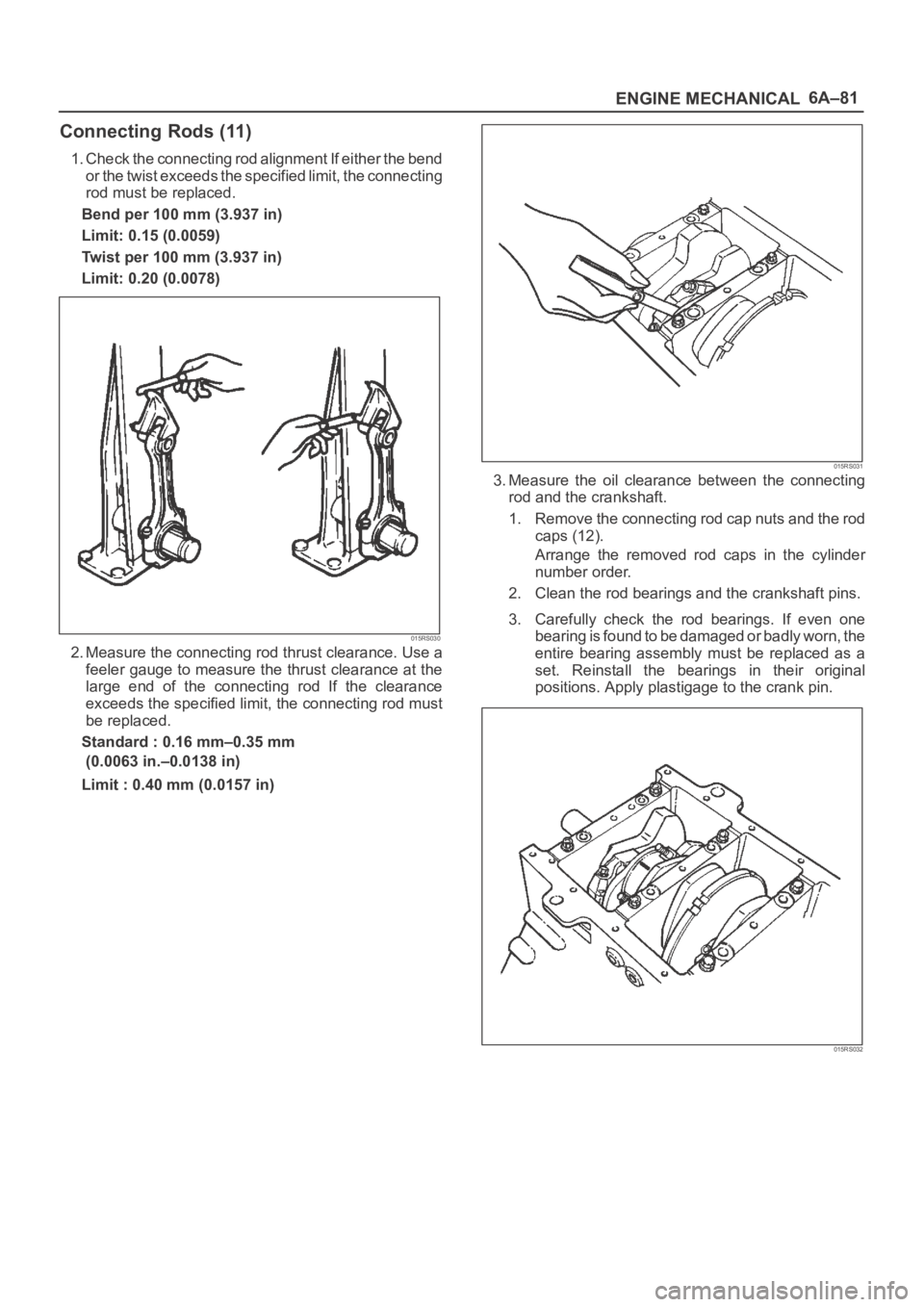

Connecting Rods (11)

1. Check the connecting rod alignment If either the bend

or the twist exceeds the specified limit, the connecting

rod must be replaced.

Bend per 100 mm (3.937 in)

Limit: 0.15 (0.0059)

Twist per 100 mm (3.937 in)

Limit: 0.20 (0.0078)

015RS030

2. Measure the connecting rod thrust clearance. Use a

feeler gauge to measure the thrust clearance at the

large end of the connecting rod If the clearance

exceeds the specified limit, the connecting rod must

be replaced.

Standard : 0.16 mm–0.35 mm

(0.0063 in.–0.0138 in)

Limit : 0.40 mm (0.0157 in)

015RS031

3. Measure the oil clearance between the connecting

rod and the crankshaft.

1. Remove the connecting rod cap nuts and the rod

caps (12).

Arrange the removed rod caps in the cylinder

number order.

2. Clean the rod bearings and the crankshaft pins.

3. Carefully check the rod bearings. If even one

bearing is found to be damaged or badly worn, the

entire bearing assembly must be replaced as a

set. Reinstall the bearings in their original

positions. Apply plastigage to the crank pin.

015RS032

Page 1039 of 6000

6A–83

ENGINE MECHANICAL

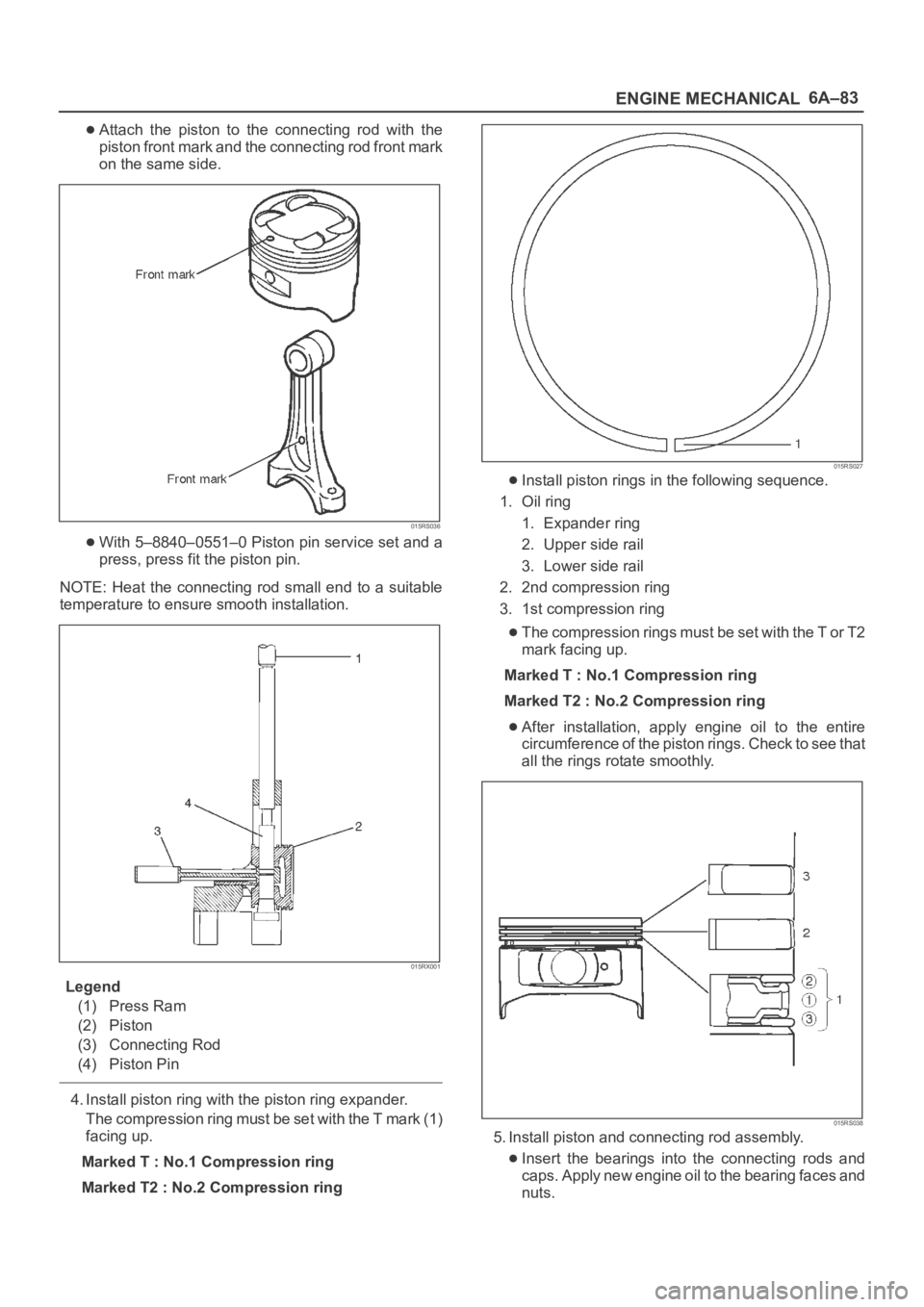

Attach the piston to the connecting rod with the

piston front mark and the connecting rod front mark

on the same side.

015RS036

With 5–8840–0551–0 Piston pin service set and a

press, press fit the piston pin.

NOTE: Heat the connecting rod small end to a suitable

temperature to ensure smooth installation.

015RX001

Legend

(1) Press Ram

(2) Piston

(3) Connecting Rod

(4) Piston Pin

4. Install piston ring with the piston ring expander.

The compression ring must be set with the T mark (1)

facing up.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

015RS027

Install piston rings in the following sequence.

1. Oil ring

1. Expander ring

2. Upper side rail

3. Lower side rail

2. 2nd compression ring

3. 1st compression ring

The compression rings must be set with the T or T2

mark facing up.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

After installation, apply engine oil to the entire

circumference of the piston rings. Check to see that

all the rings rotate smoothly.

015RS038

5. Install piston and connecting rod assembly.

Insert the bearings into the connecting rods and

caps. Apply new engine oil to the bearing faces and

nuts.

Page 1042 of 6000

6A–86

ENGINE MECHANICAL

11. Remove rear oil seal retainer assembly.

12. Remove main bearing cap.

13. Remove crankshaft.

14. Remove cylinder block.

Inspection and Repair

1. Remove the cylinder head gasket and any other

material adhering to the upper surface of the cylinder

block. Be very careful not to allow any material to

accidentally drop into the cylinder block. Be very

careful not to scratch the cylinder block.

2. Carefully remove the oil pump, rear oil seal retainer,

and crankcase assembly installation surface seal.

3. Wipe the cylinder block clean.

4. Visually inspect the cylinder block. If necessary, use a

flaw detector to perform a dye penetrate and

hydraulic (or air pressure) test. If cracking or other

damage is discovered, the cylinder block must either

be repaired or replaced.

Flatness

1. Using a straight–edge and feeler gauge, check that

the upper surface of the cylinder block is not warped.

CAUTION: Be very careful not to allow any material

to accidentally drop into the upper surface of the

cylinder block. Be very careful not to scratch the

upper surface of the cylinder block.

2. The cylinder block must be reground or replaced if the

warpage exceeds the limit.

Warpage

Limit : 0.15 mm (0.0059 in)

Maximum repairable limit: 0.15 mm (0.0059 in)

012RS004

Cylinder Bore

Use a cylinder gauge to measure the cylinder bore

diameter in both the axial and thrust directions. Each

measurement should be made at six points.CAUTION: Be very careful not to allow any material

to accidentally drop into the upper surface of the

cylinder block. Be very careful not to scratch the

upper surface of the cylinder block.

Cylinder Bore Inside Diameter

Limit : 93.530 (3.6823)

If the measurement exceed the specified limit, the

cylinder block must be replaced.

Diameter

Grade A : 93.400 mm–93.410 mm

(3.6772 in–3.6776 in)

Grade B : 93.411 mm–93.420 mm

(3.6776 in–3.6779 in)

Grade C : 93.421 mm–93.430 mm

(3.6780 in–3.6783 in)

012RS005

NOTE: For information on piston diameter, please refer

to the section ”Inspection of the Piston and Connecting

Rod Assembly” in this manual.

The ”Grade” mark (1) is stamped at the position

illustrated.

Page 1044 of 6000

6A–88

ENGINE MECHANICAL

015RW001

4. Install flywheel

1. Thoroughly clean and remove the oil from the

threads of crankshaft.

2. Remove the oil from the crankshaft and flywheel

mounting faces.

3. Mount the flywheel on the crankshaft and then

install the washer.

4. Holding the crankshaft stationary, tighten the

flywheel bolts in the order shown.

Torque: 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

NOTE: Do not reuse the bolts and do not apply oil or

thread lock to the bolts.

015RS018

5. Install piston and connecting rod assembly.

Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins.

NOTE: Do not apply engine oil to the bearing back faces.

Check to see that the piston ring end gaps are

correctly positioned.

015RS019

Legend

(1) No.1 Compression Ring

(2) No.2 Compression Ring

(3) Oil Ring Side Rail Upper

(4) Oil Ring Side Rail Lower

(5) Piston Front Mark

Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

The front marks (1) must be facing the front of the

engine.

015RS020

6. Install oil gallery and tighten the bolts in 2 steps in the

order shown.

1st step : 29 Nꞏm (3.0 Kgꞏm/22 lb ft)

2nd step : 55

65

Page 1059 of 6000

6B–6

ENGINE COOLING

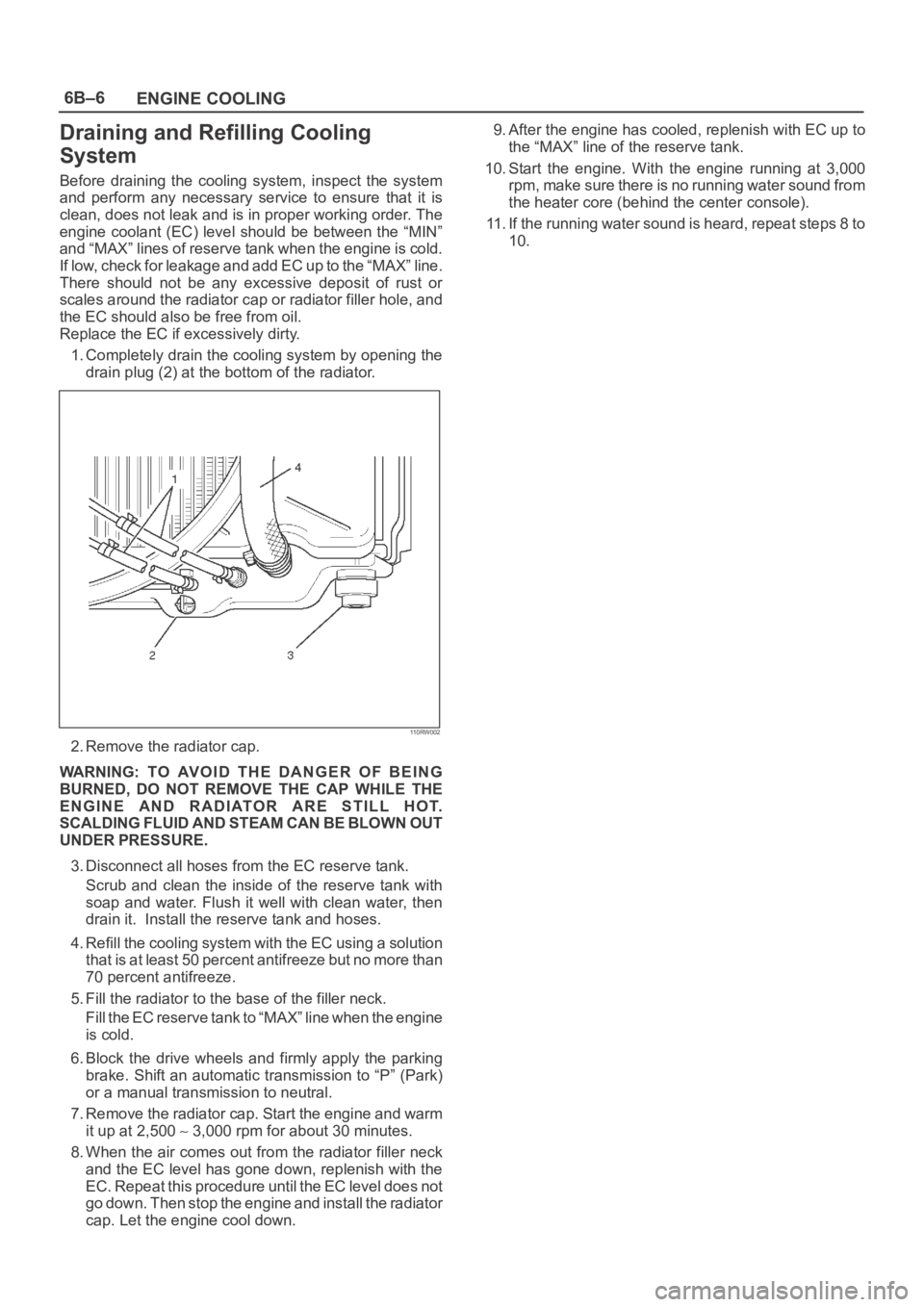

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to “MAX” line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to “P” (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500

3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the “MAX” line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.

Page 1064 of 6000

ENGINE COOLING6B–11

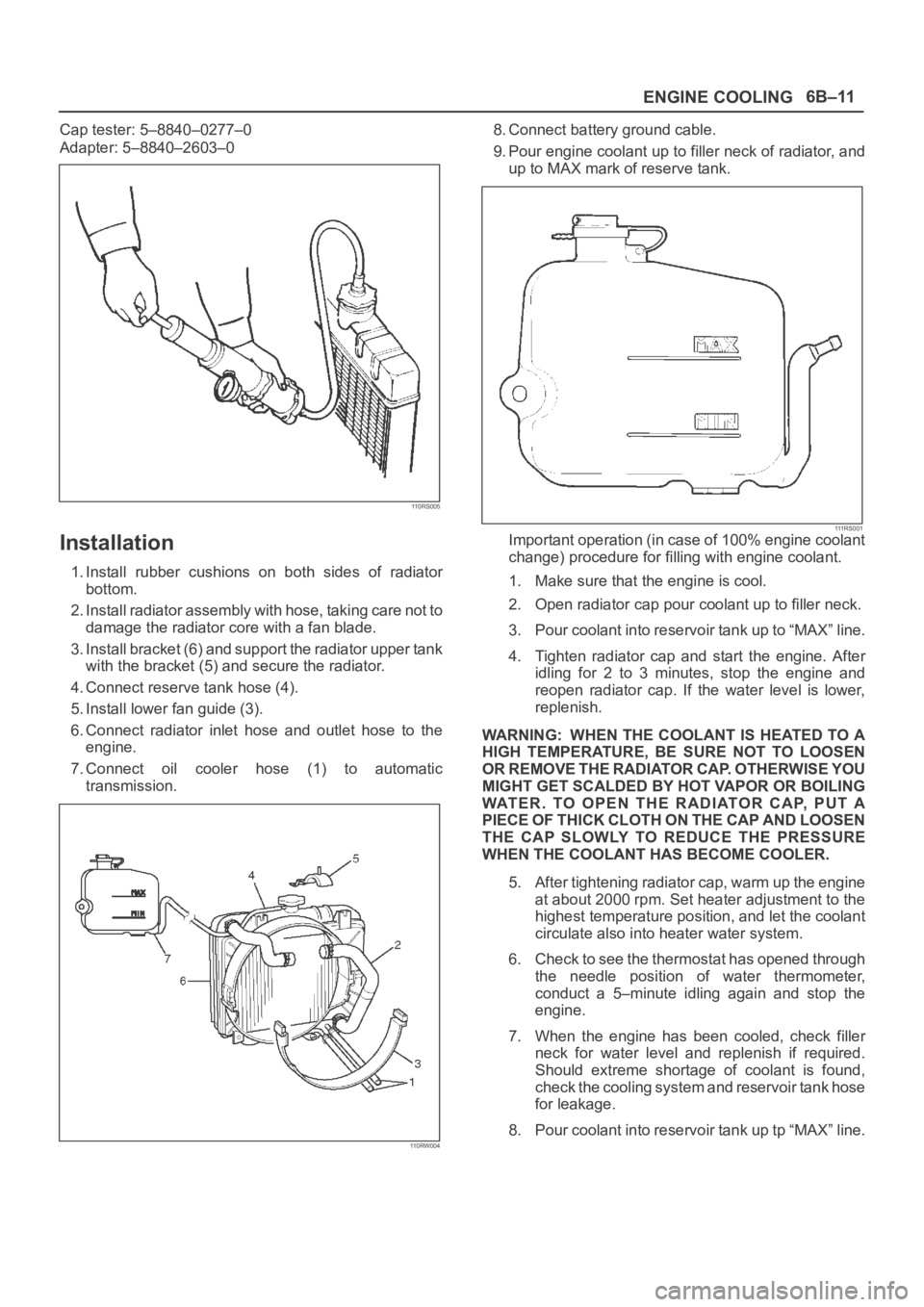

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

Installation

1. Install rubber cushions on both sides of radiator

bottom.

2. Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3. Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4. Connect reserve tank hose (4).

5. Install lower fan guide (3).

6. Connect radiator inlet hose and outlet hose to the

engine.

7. Connect oil cooler hose (1) to automatic

transmission.

110RW004

8. Connect battery ground cable.

9. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111 R S 0 0 1Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

1. Make sure that the engine is cool.

2. Open radiator cap pour coolant up to filler neck.

3. Pour coolant into reservoir tank up to “MAX” line.

4. Tighten radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING: WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

5. After tightening radiator cap, warm up the engine

at about 2000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

6. Check to see the thermostat has opened through

the needle position of water thermometer,

conduct a 5–minute idling again and stop the

engine.

7. When the engine has been cooled, check filler

neck for water level and replenish if required.

Should extreme shortage of coolant is found,

check the cooling system and reservoir tank hose

for leakage.

8. Pour coolant into reservoir tank up tp “MAX” line.

Page 1077 of 6000

6C–10

ENGINE FUEL

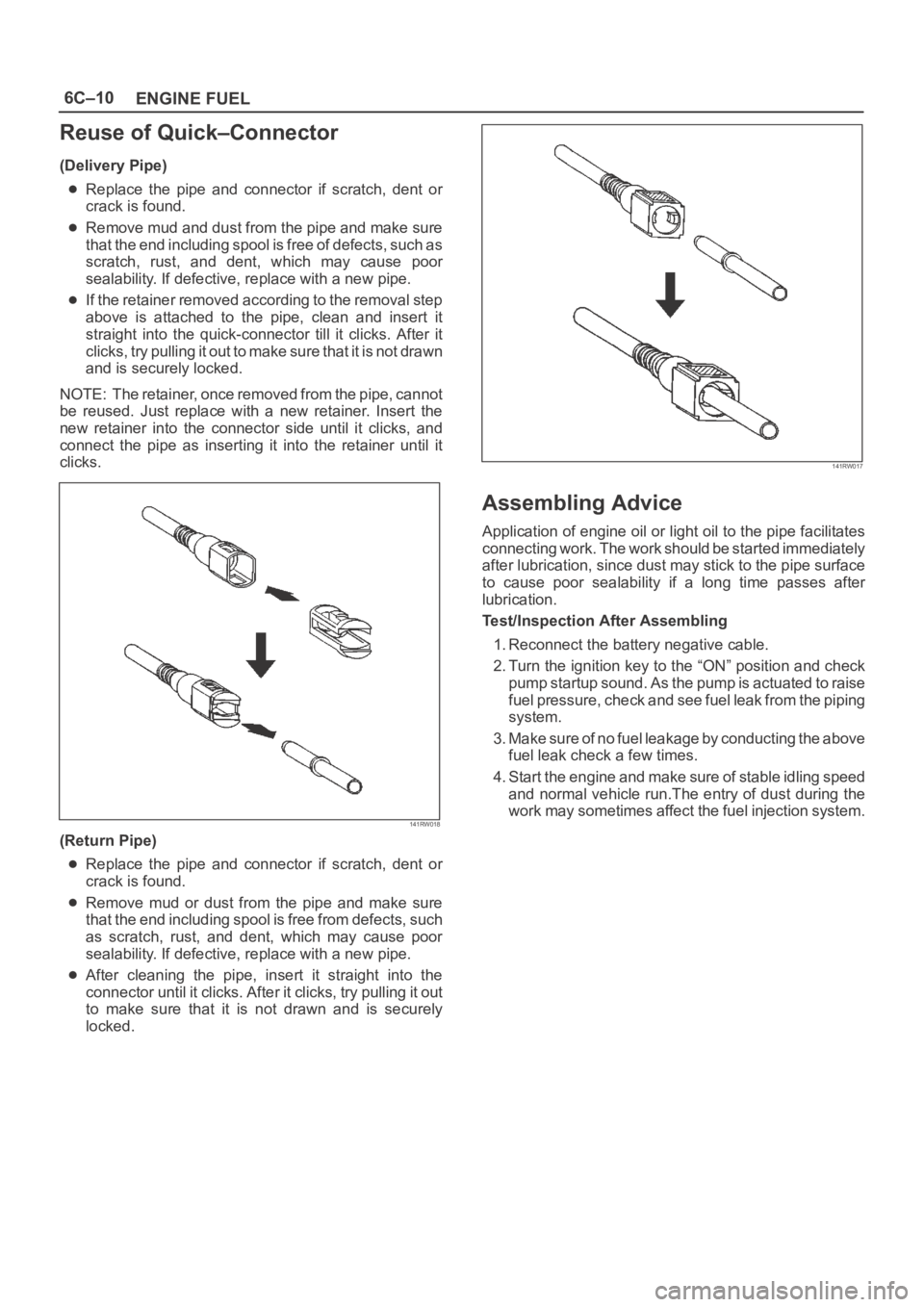

Reuse of Quick–Connector

(Delivery Pipe)

Replace the pipe and connector if scratch, dent or

crack is found.

Remove mud and dust from the pipe and make sure

that the end including spool is free of defects, such as

scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

If the retainer removed according to the removal step

above is attached to the pipe, clean and insert it

straight into the quick-connector till it clicks. After it

clicks, try pulling it out to make sure that it is not drawn

and is securely locked.

NOTE: The retainer, once removed from the pipe, cannot

be reused. Just replace with a new retainer. Insert the

new retainer into the connector side until it clicks, and

connect the pipe as inserting it into the retainer until it

clicks.

141RW018

(Return Pipe)

Replace the pipe and connector if scratch, dent or

crack is found.

Remove mud or dust from the pipe and make sure

that the end including spool is free from defects, such

as scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

After cleaning the pipe, insert it straight into the

connector until it clicks. After it clicks, try pulling it out

to make sure that it is not drawn and is securely

locked.

141RW017

Assembling Advice

Application of engine oil or light oil to the pipe facilitates

connecting work. The work should be started immediately

after lubrication, since dust may stick to the pipe surface

to cause poor sealability if a long time passes after

lubrication.

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Turn the ignition key to the “ON” position and check

pump startup sound. As the pump is actuated to raise

fuel pressure, check and see fuel leak from the piping

system.

3. Make sure of no fuel leakage by conducting the above

fuel leak check a few times.

4. Start the engine and make sure of stable idling speed

and normal vehicle run.The entry of dust during the

work may sometimes affect the fuel injection system.

Page 1088 of 6000

6D2–3

IGNITION SYSTEM

Ignition Coil

Removal

1. Disconnect battery ground cable.

2. Ignition coil connector and ignition coil.

Disconnect three connector from ignition coil.

Remove harness bracket bolt on cylinder head

cover.

Remove fixing bolts on ignition coil.

060RW121

Legend

(1) Ignition Coil Connector

(2) Bolt

(3) Ignition Coil Assembly

Inspection and Repair

Check the ignition coil assembly for insulation. Check

terminals for corrosion or damage, and replace as

necessary.

Measuring resistance of ignition coil assembly.

Terminal No.

Limit

1 to 2Without 0 ohm or infinity

maximum ohm.

1 to 3Same as above

2 to 3Same as above

Measure resistance of ignition coil assembly, and replace

the ignition coil assembly if its value exceeds the

standard.

060RW006

Installation

1. Install the ignition coil assembly (3).

Connect ignition coil connector (1) and ignition coil

(3), then tighten bolt (2) to the specified torque.

Torque: 4 Nꞏm (0.4 Kgꞏm/35 lb in)

060RW121

2. Connect battery ground cable.

Page 1089 of 6000

6D2–4

IGNITION SYSTEM

Spark Plug

Removal

1. Remove spark plugs.

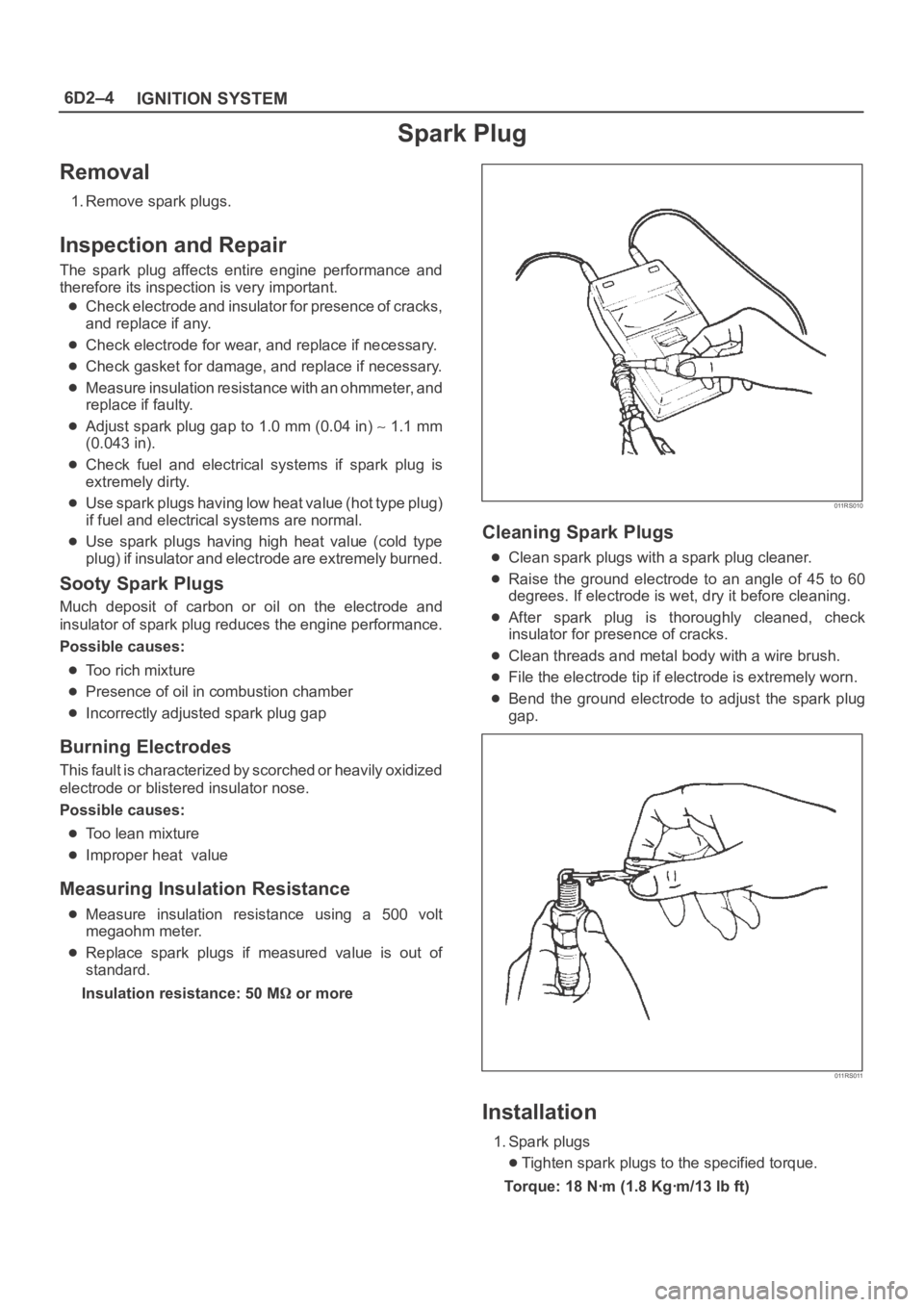

Inspection and Repair

The spark plug affects entire engine performance and

therefore its inspection is very important.

Check electrode and insulator for presence of cracks,

and replace if any.

Check electrode for wear, and replace if necessary.

Check gasket for damage, and replace if necessary.

Measure insulation resistance with an ohmmeter, and

replace if faulty.

Adjust spark plug gap to 1.0 mm (0.04 in) 1.1 mm

(0.043 in).

Check fuel and electrical systems if spark plug is

extremely dirty.

Use spark plugs having low heat value (hot type plug)

if fuel and electrical systems are normal.

Use spark plugs having high heat value (cold type

plug) if insulator and electrode are extremely burned.

Sooty Spark Plugs

Much deposit of carbon or oil on the electrode and

insulator of spark plug reduces the engine performance.

Possible causes:

Too rich mixture

Presence of oil in combustion chamber

Incorrectly adjusted spark plug gap

Burning Electrodes

This fault is characterized by scorched or heavily oxidized

electrode or blistered insulator nose.

Possible causes:

Too lean mixture

Improper heat value

Measuring Insulation Resistance

Measure insulation resistance using a 500 volt

megaohm meter.

Replace spark plugs if measured value is out of

standard.

Insulation resistance: 50 M

or more

011RS010

Cleaning Spark Plugs

Clean spark plugs with a spark plug cleaner.

Raise the ground electrode to an angle of 45 to 60

degrees. If electrode is wet, dry it before cleaning.

After spark plug is thoroughly cleaned, check

insulator for presence of cracks.

Clean threads and metal body with a wire brush.

File the electrode tip if electrode is extremely worn.

Bend the ground electrode to adjust the spark plug

gap.

011RS011

Installation

1. Spark plugs

Tighten spark plugs to the specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)