check oil OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 524 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–21

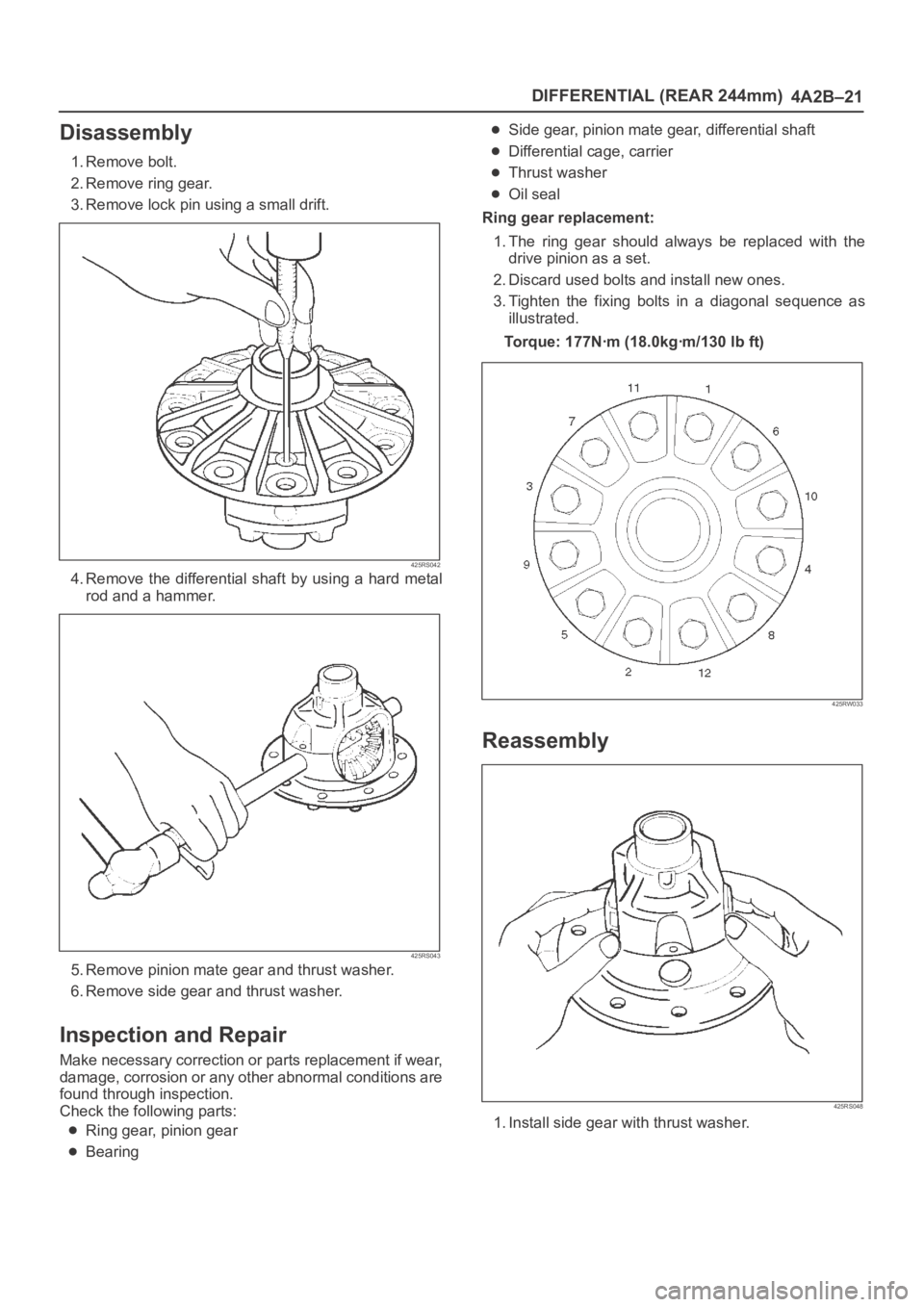

Disassembly

1. Remove bolt.

2. Remove ring gear.

3. Remove lock pin using a small drift.

425RS042

4. Remove the differential shaft by using a hard metal

rod and a hammer.

425RS043

5. Remove pinion mate gear and thrust washer.

6. Remove side gear and thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

Ring gear, pinion gear

Bearing

Side gear, pinion mate gear, differential shaft

Differential cage, carrier

Thrust washer

Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Discard used bolts and install new ones.

3. Tighten the fixing bolts in a diagonal sequence as

illustrated.

Torque: 177Nꞏm (18.0kgꞏm/130 lb ft)

425RW033

Reassembly

425RS048

1. Install side gear with thrust washer.

Page 577 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–6

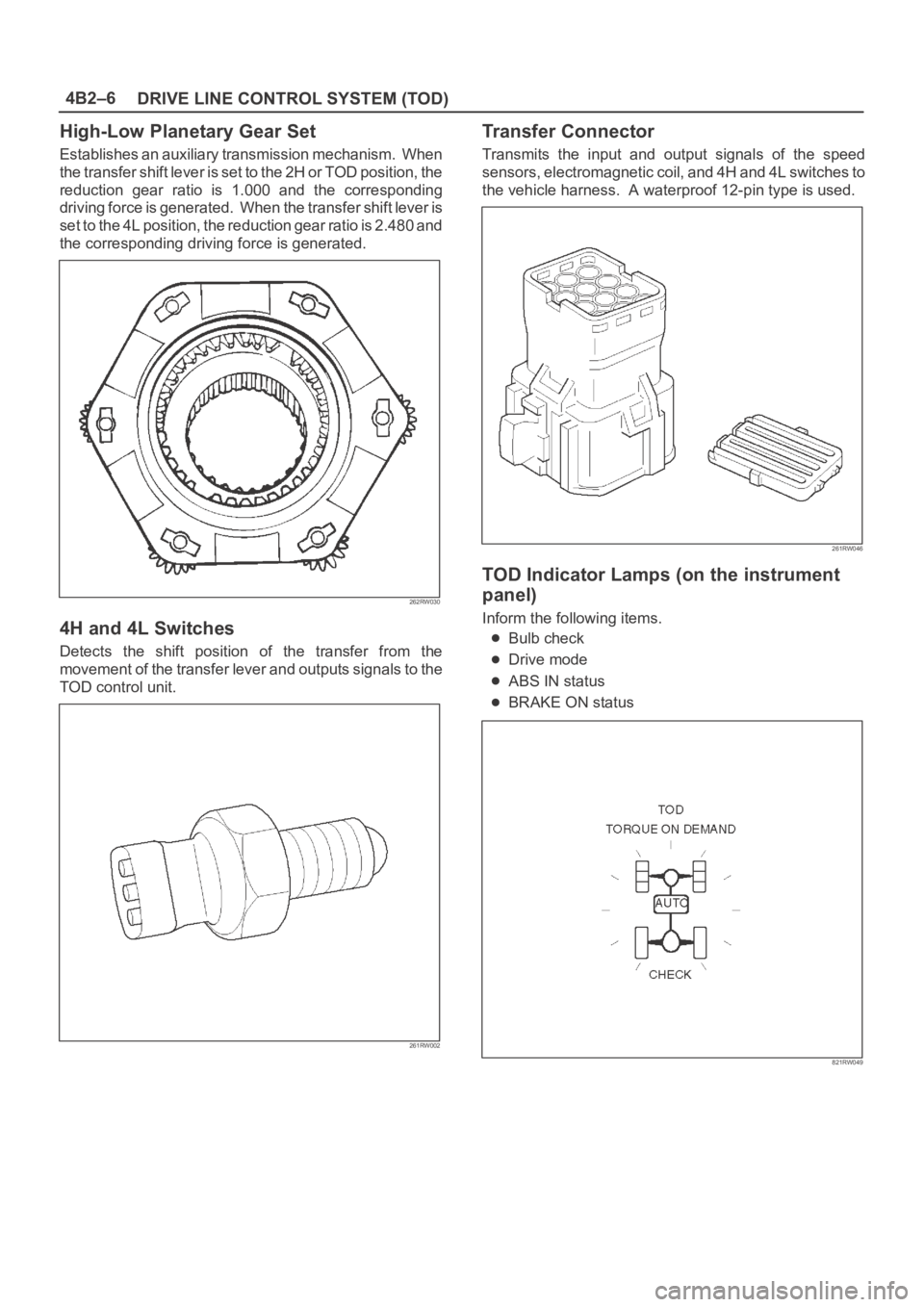

High-Low Planetary Gear Set

Establishes an auxiliary transmission mechanism. When

the transfer shift lever is set to the 2H or TOD position, the

reduction gear ratio is 1.000 and the corresponding

driving force is generated. When the transfer shift lever is

set to the 4L position, the reduction gear ratio is 2.480 and

the corresponding driving force is generated.

262RW030

4H and 4L Switches

Detects the shift position of the transfer from the

movement of the transfer lever and outputs signals to the

TOD control unit.

261RW002

Transfer Connector

Transmits the input and output signals of the speed

sensors, electromagnetic coil, and 4H and 4L switches to

the vehicle harness. A waterproof 12-pin type is used.

261RW046

TOD Indicator Lamps (on the instrument

panel)

Inform the following items.

Bulb check

Drive mode

ABS IN status

BRAKE ON status

821RW049

Page 601 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–30

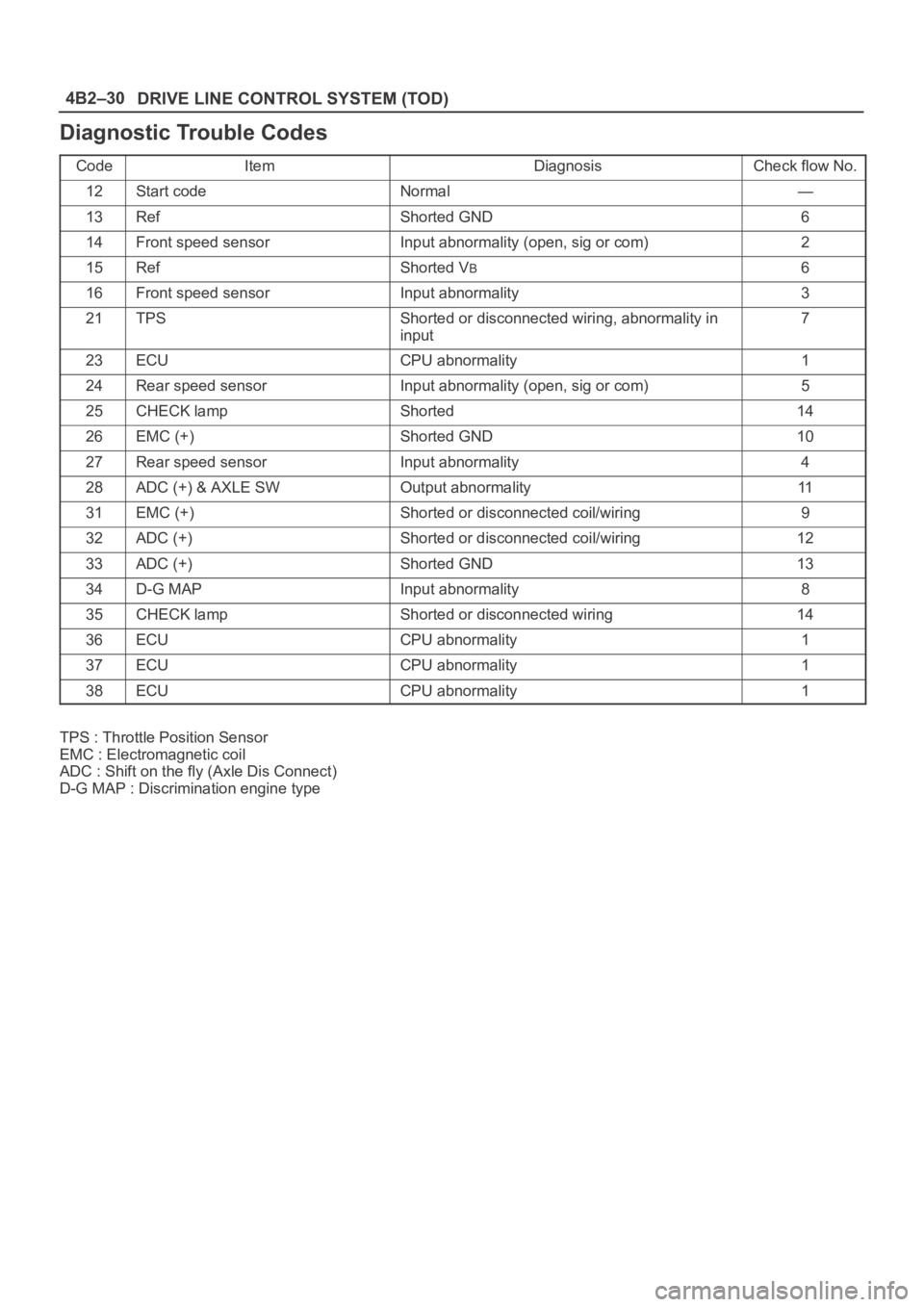

Diagnostic Trouble Codes

CodeItemDiagnosisCheck flow No.

12Start codeNormal—

13RefShorted GND6

14Front speed sensorInput abnormality (open, sig or com)2

15RefShorted VB6

16Front speed sensorInput abnormality3

21TPSShorted or disconnected wiring, abnormality in

input7

23ECUCPU abnormality1

24Rear speed sensorInput abnormality (open, sig or com)5

25CHECK lampShorted14

26EMC (+)Shorted GND10

27Rear speed sensorInput abnormality4

28ADC (+) & AXLE SWOutput abnormality11

31EMC (+)Shorted or disconnected coil/wiring9

32ADC (+)Shorted or disconnected coil/wiring12

33ADC (+)Shorted GND13

34D-G MAPInput abnormality8

35CHECK lampShorted or disconnected wiring14

36ECUCPU abnormality1

37ECUCPU abnormality1

38ECUCPU abnormality1

TPS : Throttle Position Sensor

EMC : Electromagnetic coil

ADC : Shift on the fly (Axle Dis Connect)

D-G MAP : Discrimination engine type

Page 617 of 6000

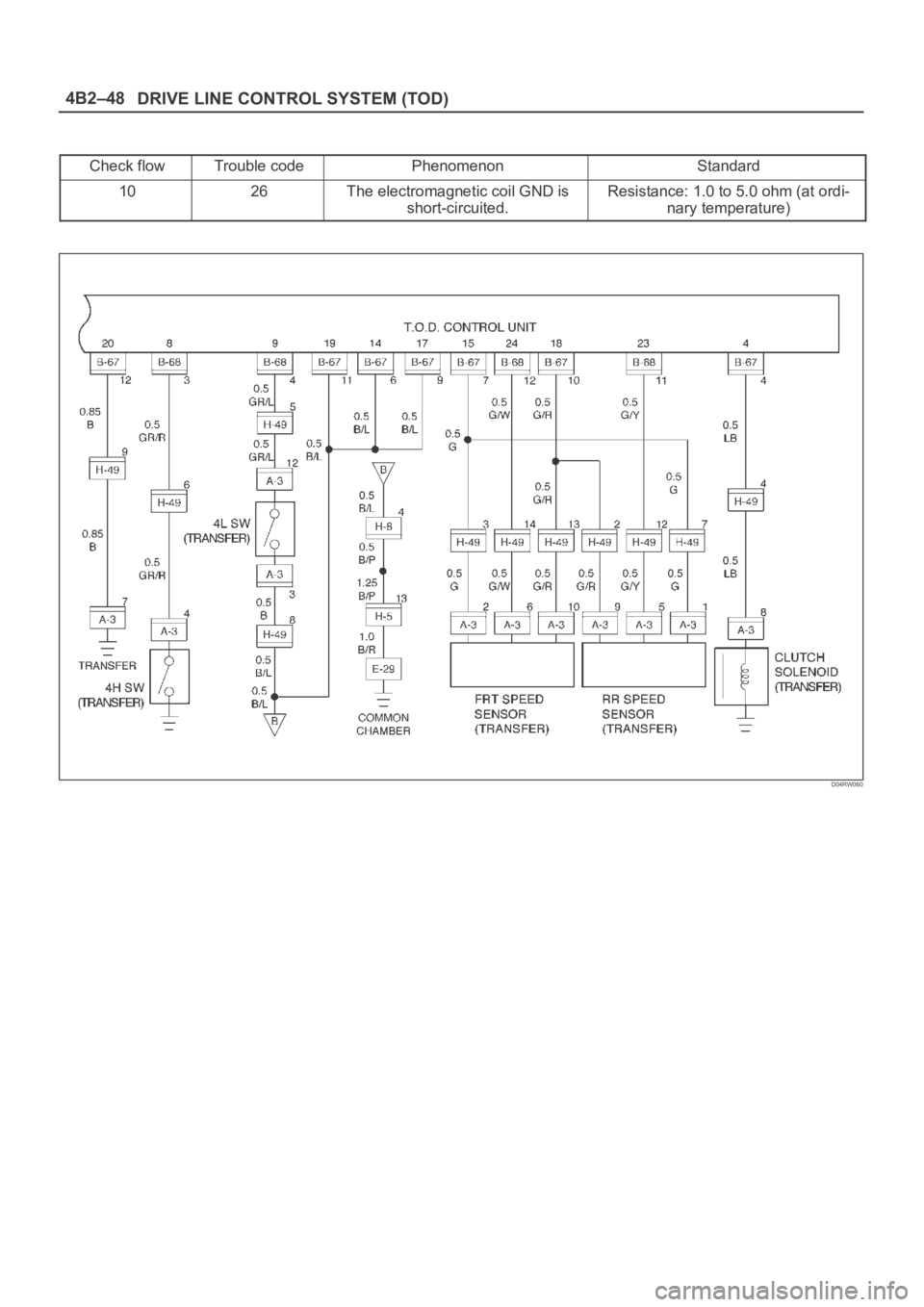

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–46

Check flowTrouble codePhenomenonStandard

931The electromagnetic coil is broken.—

D04RW060

Page 618 of 6000

4B2–47 DRIVE LINE CONTROL SYSTEM (TOD)

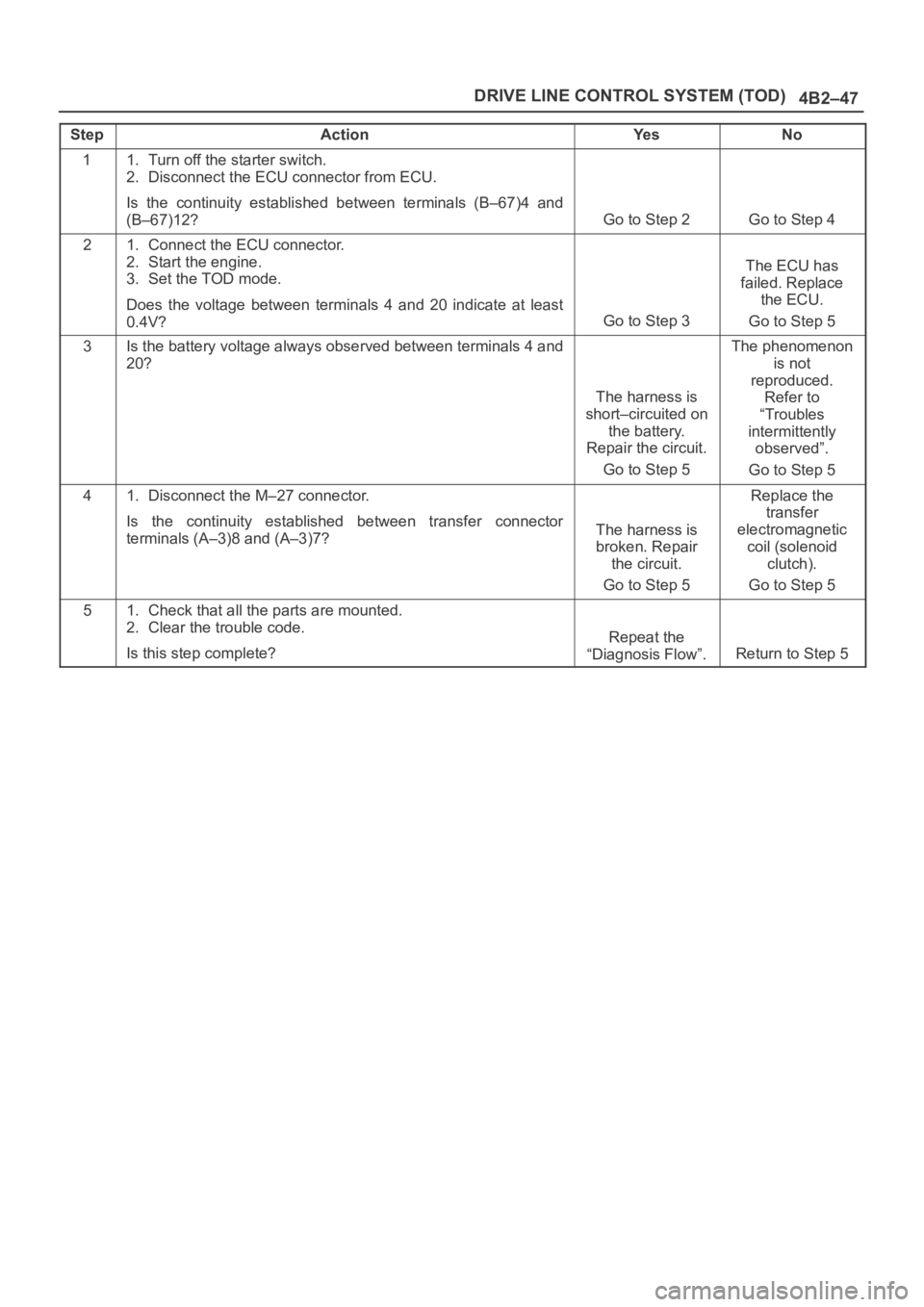

StepActionYe sNo

11. Turn off the starter switch.

2. Disconnect the ECU connector from ECU.

Is the continuity established between terminals (B–67)4 and

(B–67)12?

Go to Step 2Go to Step 4

21. Connect the ECU connector.

2. Start the engine.

3. Set the TOD mode.

Does the voltage between terminals 4 and 20 indicate at least

0.4V?

Go to Step 3

The ECU has

failed. Replace

the ECU.

Go to Step 5

3Is the battery voltage always observed between terminals 4 and

20?

The harness is

short–circuited on

the battery.

Repair the circuit.

Go to Step 5

The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 5

41. Disconnect the M–27 connector.

Is the continuity established between transfer connector

terminals (A–3)8 and (A–3)7?

The harness is

broken. Repair

the circuit.

Go to Step 5

Replace the

transfer

electromagnetic

coil (solenoid

clutch).

Go to Step 5

51. Check that all the parts are mounted.

2. Clear the trouble code.

Is this step complete?

Repeat the

“Diagnosis Flow”.

Return to Step 5

Page 619 of 6000

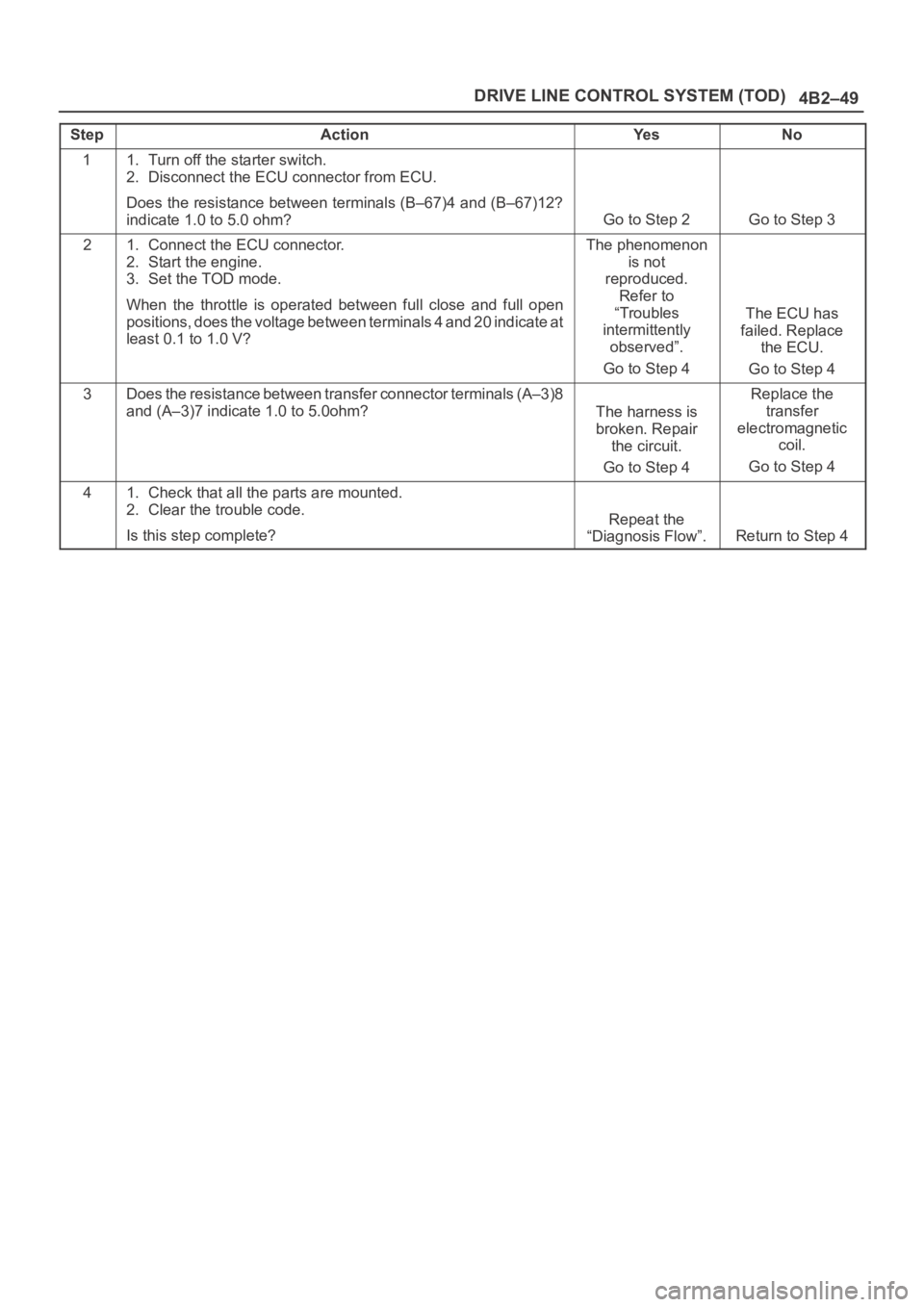

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–48

Check flowTrouble codePhenomenonStandard

1026The electromagnetic coil GND is

short-circuited.Resistance: 1.0 to 5.0 ohm (at ordi-

nary temperature)

D04RW060

Page 620 of 6000

4B2–49 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

11. Turn off the starter switch.

2. Disconnect the ECU connector from ECU.

Does the resistance between terminals (B–67)4 and (B–67)12?

indicate 1.0 to 5.0 ohm?

Go to Step 2Go to Step 3

21. Connect the ECU connector.

2. Start the engine.

3. Set the TOD mode.

When the throttle is operated between full close and full open

positions, does the voltage between terminals 4 and 20 indicate a t

least 0.1 to 1.0 V?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 4

The ECU has

failed. Replace

the ECU.

Go to Step 4

3Does the resistance between transfer connector terminals (A–3)8

and (A–3)7 indicate 1.0 to 5.0ohm?

The harness is

broken. Repair

the circuit.

Go to Step 4

Replace the

transfer

electromagnetic

coil.

Go to Step 4

41. Check that all the parts are mounted.

2. Clear the trouble code.

Is this step complete?

Repeat the

“Diagnosis Flow”.

Return to Step 4

Page 626 of 6000

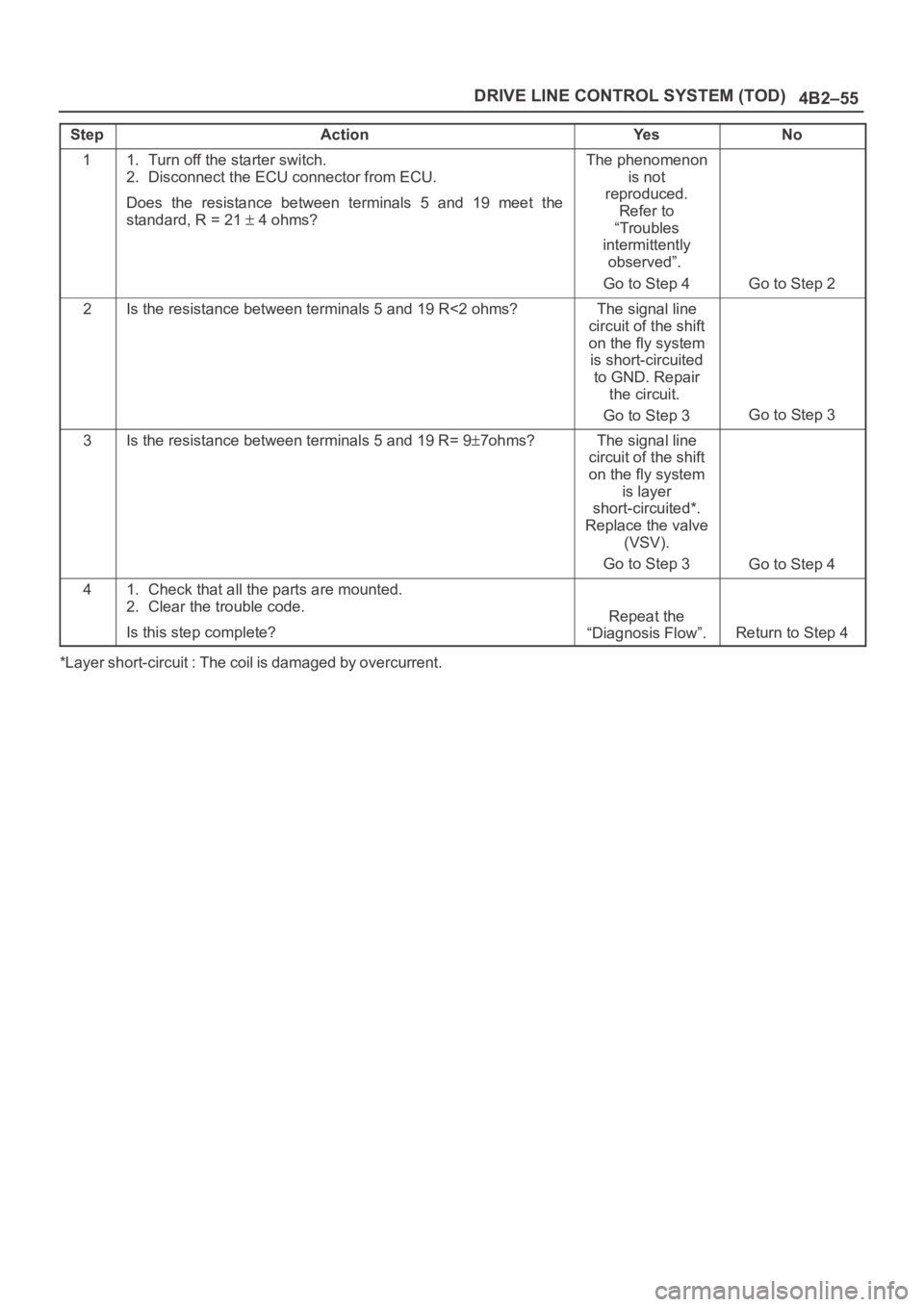

4B2–55 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

11. Turn off the starter switch.

2. Disconnect the ECU connector from ECU.

Does the resistance between terminals 5 and 19 meet the

standard, R = 21

4 ohms?

The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 4

Go to Step 2

2Is the resistance between terminals 5 and 19 R<2 ohms?The signal line

circuit of the shift

on the fly system

is short-circuited

to GND. Repair

the circuit.

Go to Step 3

Go to Step 3

3Is the resistance between terminals 5 and 19 R= 97ohms?The signal line

circuit of the shift

on the fly system

is layer

short-circuited*.

Replace the valve

(VSV).

Go to Step 3

Go to Step 4

41. Check that all the parts are mounted.

2. Clear the trouble code.

Is this step complete?

Repeat the

“Diagnosis Flow”.

Return to Step 4

*Layer short-circuit : The coil is damaged by overcurrent.

Page 659 of 6000

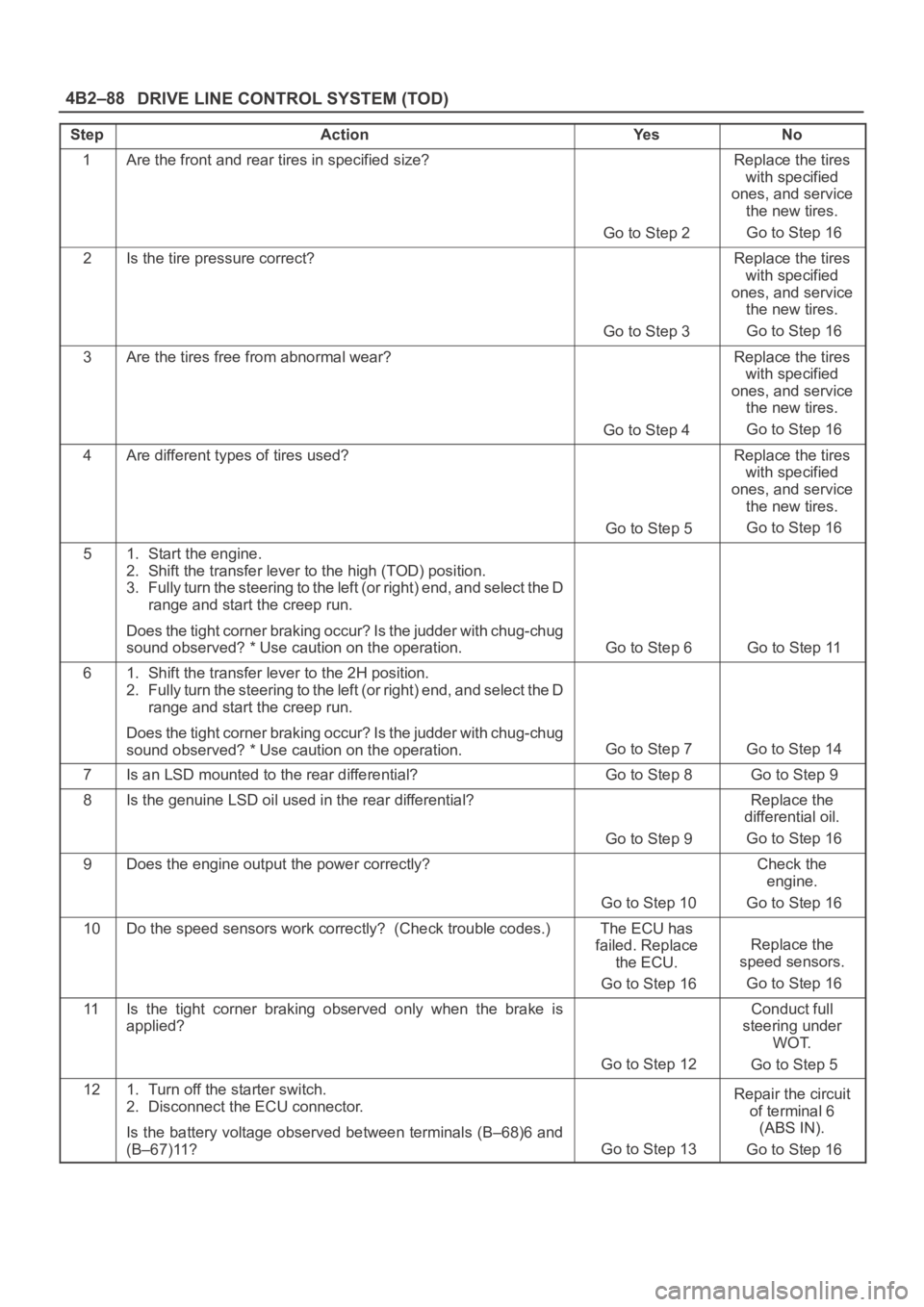

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 671 of 6000

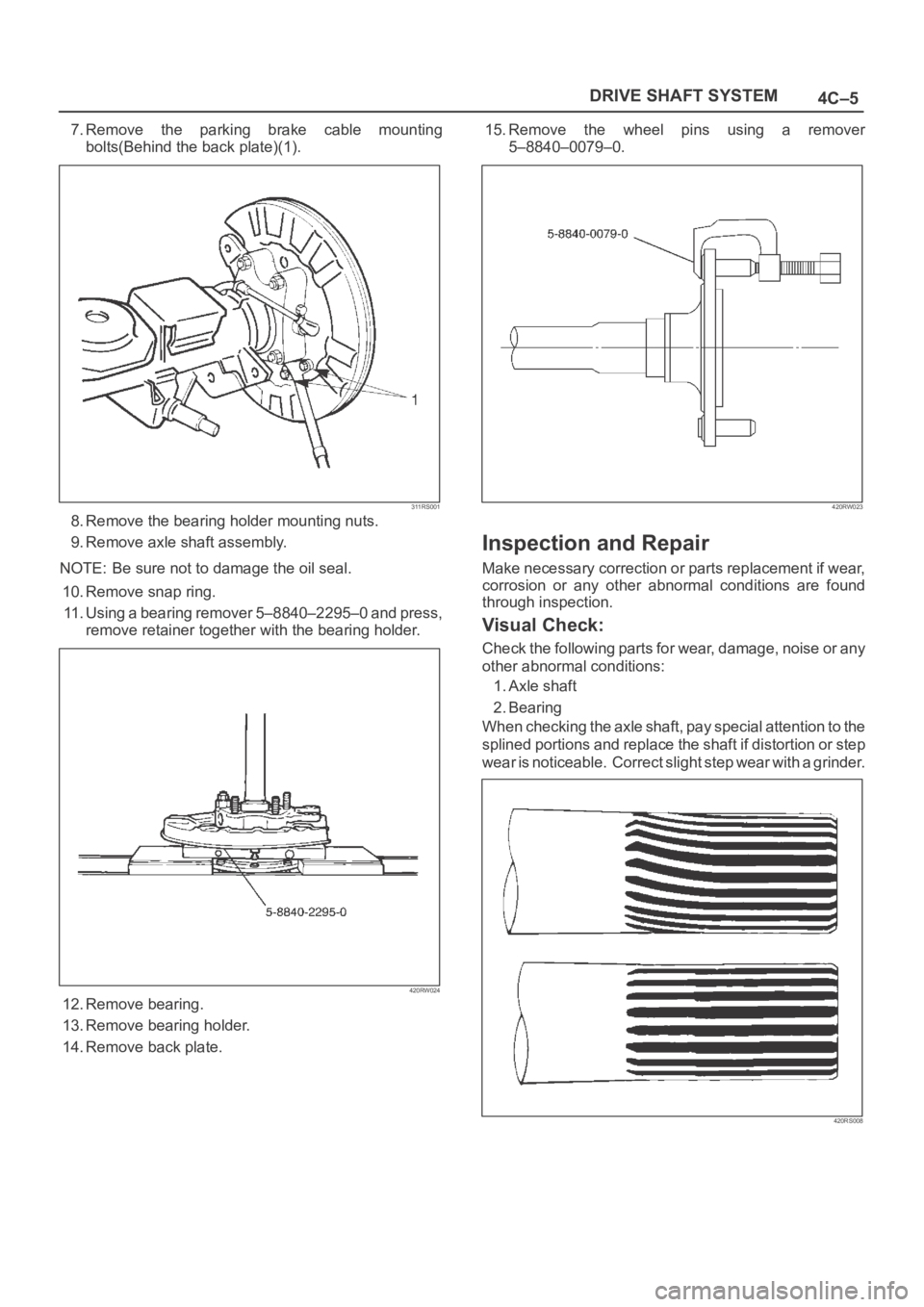

4C–5 DRIVE SHAFT SYSTEM

7.Remove the parking brake cable mounting

bolts(Behind the back plate)(1).

311RS001

8. Remove the bearing holder mounting nuts.

9. Remove axle shaft assembly.

NOTE: Be sure not to damage the oil seal.

10. Remove snap ring.

11. Using a bearing remover 5–8840–2295–0 and press,

remove retainer together with the bearing holder.

420RW024

12. Remove bearing.

13. Remove bearing holder.

14. Remove back plate.15. Remove the wheel pins using a remover

5–8840–0079–0.

420RW023

Inspection and Repair

Make necessary correction or parts replacement if wear,

corrosion or any other abnormal conditions are found

through inspection.

Visual Check:

Check the following parts for wear, damage, noise or any

other abnormal conditions:

1. Axle shaft

2. Bearing

When checking the axle shaft, pay special attention to the

splined portions and replace the shaft if distortion or step

wear is noticeable. Correct slight step wear with a grinder.

420RS008