check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2279 of 6000

7A1–34

TRANSMISSION CONTROL SYSTEM (4L30–E)

Diagnostic Aids

Refer to the accompanying chart for the normal range

signals and the illegal combinations.

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as well. Also check for a chafed wire that could short

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.5. This test checks for continuity between each

selected range switch connector terminals.

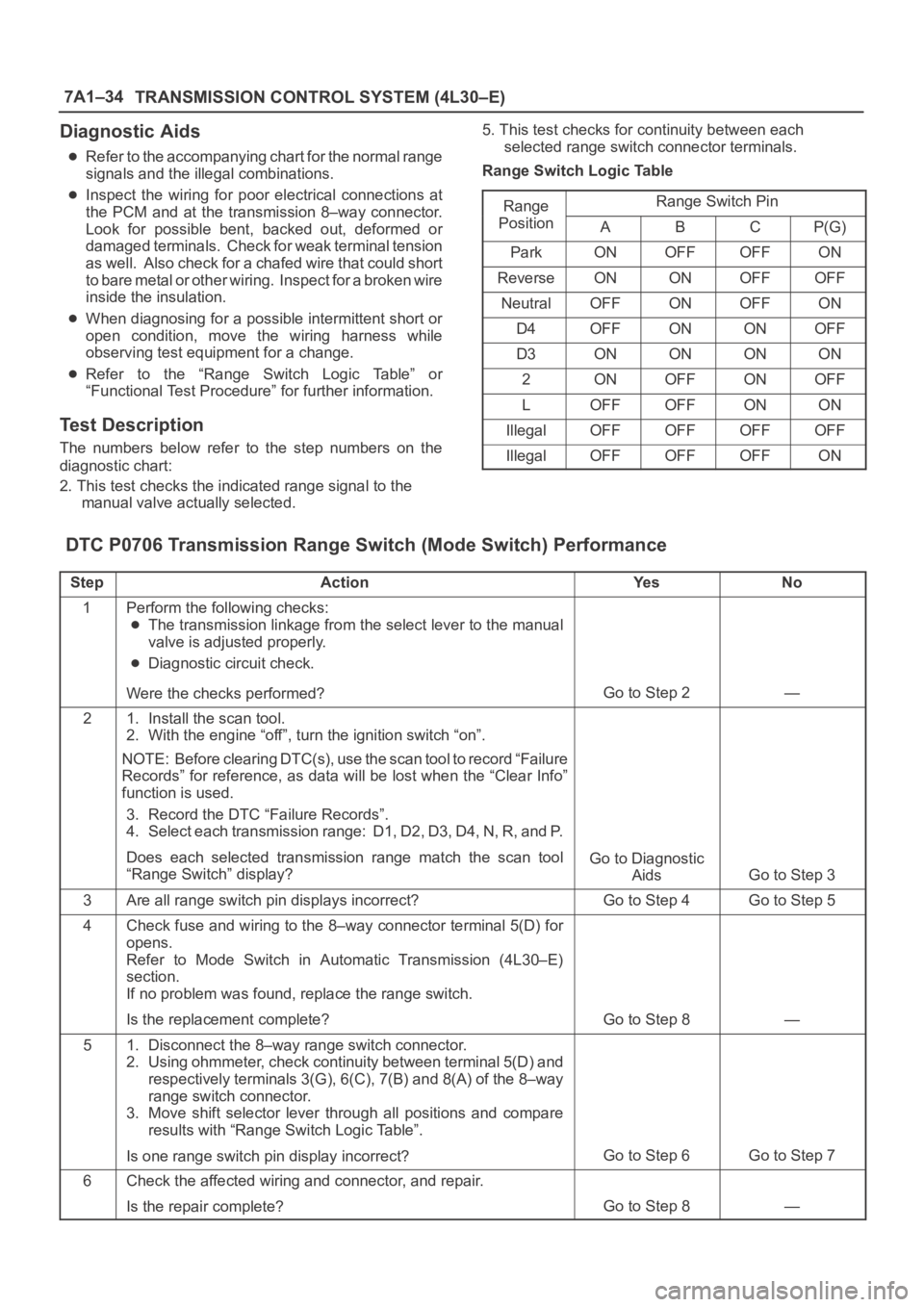

Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0706 Transmission Range Switch (Mode Switch) Performance

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—

Page 2281 of 6000

7A1–36

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0712 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input

D07RW029

Circuit Description

The TFT sensor is a thermister that controls the signal

voltage to the PCM. The PCM supplies a 5–volt reference

signal to the sensor on circuit RED/BLK–GRN/RED.

When the transmission fluid is cold, the sensor resistance

is high. The PCM detects high signal voltage. As the

transmission fluid temperature increases to the normal

operating temperature of 100

C (212F), the sensor

resistance becomes less and the voltage decreases to

1.5 to 2 volts. With transmission fluid over temperature

and DTC P0218 also set, check the transmission cooling

system.

This DTC detects a continuous short to ground in the TFT

signal circuit or the TFT sensor. This is a type “D” DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

Ignition is “on”.

TFT sensor indicating a voltage less than 0.4 volts.

All conditions met for 20 seconds.

Action Taken When The DTC Sets

Transmission default temperature will be:

80

C (176F) if engine temperature code is set.

100

C (212F) if engine temperature is warm.

80

C (176F) if engine run time is greater than 5

minutes.

21

C (69.8F) if engine run time is less than 5

minutes.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Check harness routing for a potential short to ground

in circuit RED/BLK–GRN/RED. Scan tool TFT

display should rise steadily to about 100

C (212F),

then stabilize.

Inspect the wiring for poor electrical connection at the

PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

The temperature to resistance value scale may be

used to test the TFT sensor at the various

temperature levels to evaluate the possibility of a

“skewed” (mis–scaled) sensor.

A “skewed” sensor could result in delayed garage

shifts or TCC complaints.

Verify customer driving habits, trailer towing, etc.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This test checks for a short to ground or a “skewed”

sensor.

4. This test checks for an internal fault within the

transmission by creating an open.

Page 2282 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–37

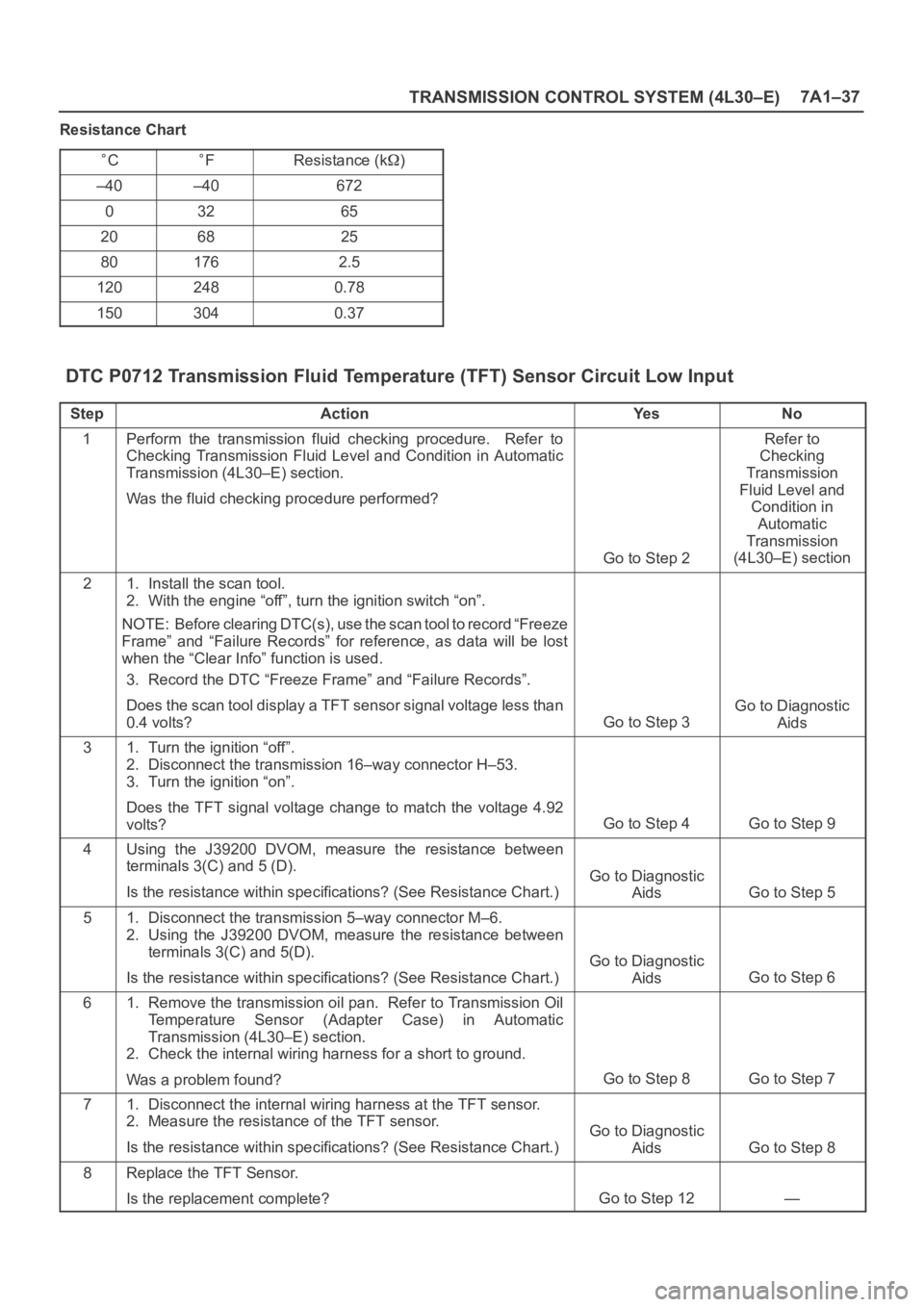

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0712 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input

StepActionYe sNo

1Perform the transmission fluid checking procedure. Refer to

Checking Transmission Fluid Level and Condition in Automatic

Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Freeze

Frame” and “Failure Records” for reference, as data will be lost

when the “Clear Info” function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage less than

0.4 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Turn the ignition “on”.

Does the TFT signal voltage change to match the voltage 4.92

volts?

Go to Step 4Go to Step 9

4Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5 (D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan. Refer to Transmission Oil

Temperature Sensor (Adapter Case) in Automatic

Transmission (4L30–E) section.

2. Check the internal wiring harness for a short to ground.

Was a problem found?

Go to Step 8Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

8Replace the TFT Sensor.

Is the replacement complete?

Go to Step 12—

Page 2284 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–39

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

D07RW029

Circuit Description

The TFT sensor is a thermistor that controls the signal

voltage to the PCM. The PCM supplies a 5–volt reference

signal to the sensor on circuit RED/BLK–GRN/RED.

When the transmission fluid is cold, the sensor resistance

is high and the PCM will sense high signal voltage. As the

transmission fluid temperature warms to the normal

operating temperature of 100

C (212F), the sensor

resistance becomes less and the voltage decreases to

about 1.5 to 2 volts.

This DTC detects a continuous open or short to power in

the TFT signal circuit or the TFT sensor. This is a type “D”

DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

Ignition is “on”.

TFT sensor indicating a voltage greater than 4.86

volts.

All conditions met for 20 seconds.

Action Taken When The DTC Sets

Transmission default temperature will be:

80

C (176F) if engine temperature code is set.

100

C (212F) if engine temperature is warm.

80

C (176F) if engine run time is greater than 5

minutes.

21

C (69.8F) if engine run time is less than 5

minutes.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connection at the

PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Scan tool displays transmission fluid temperature in

degrees. After transmission is operating, the

temperature should rise steadily to about 100

C

(212

F), then stabilize.

The temperature to resistance value scale may be

used to check the TFT sensor at the various

temperature levels to evaluate the possibility of a

“skewed” (mis–scaled) sensor.

A “skewed” sensor could result in hard shifts or TCC

complaints.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This check verifies problem in the TFT sensor circuit.

4. This test simulates a TFT sensor DTC P0712. If the

PCM recognizes the low signal voltage (high

temperature), and the scan tool displays 146

C

(295

F) or greater, the PCM and wiring are OK.

Page 2285 of 6000

7A1–40

TRANSMISSION CONTROL SYSTEM (4L30–E)

5. This test checks the TFT sensor and internal wiring

harness.

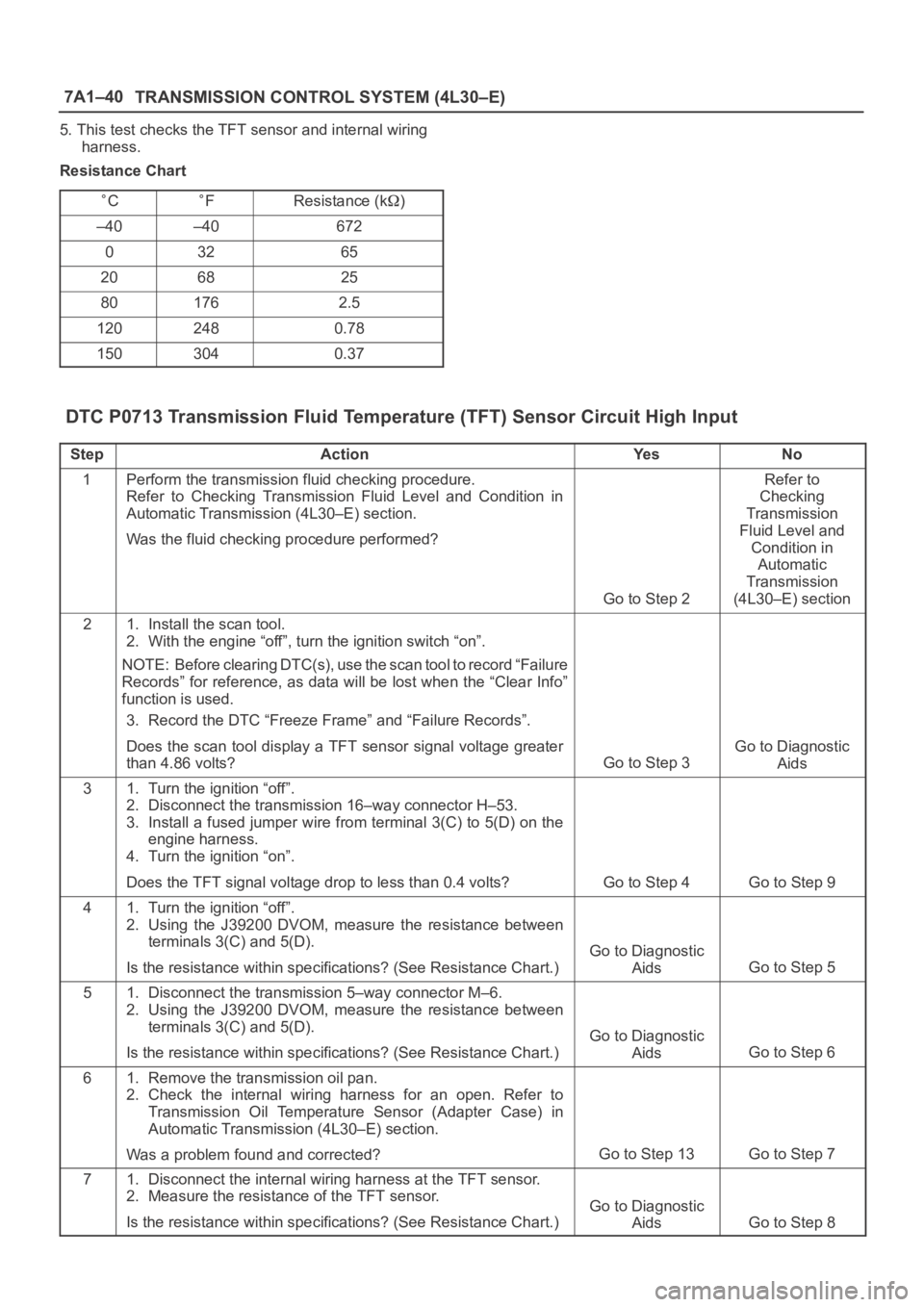

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

StepActionYe sNo

1Perform the transmission fluid checking procedure.

Refer to Checking Transmission Fluid Level and Condition in

Automatic Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage greater

than 4.86 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Install a fused jumper wire from terminal 3(C) to 5(D) on the

engine harness.

4. Turn the ignition “on”.

Does the TFT signal voltage drop to less than 0.4 volts?

Go to Step 4Go to Step 9

41. Turn the ignition “off”.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan.

2. Check the internal wiring harness for an open. Refer to

Transmission Oil Temperature Sensor (Adapter Case) in

Automatic Transmission (4L30–E) section.

Was a problem found and corrected?

Go to Step 13Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

Page 2288 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–43

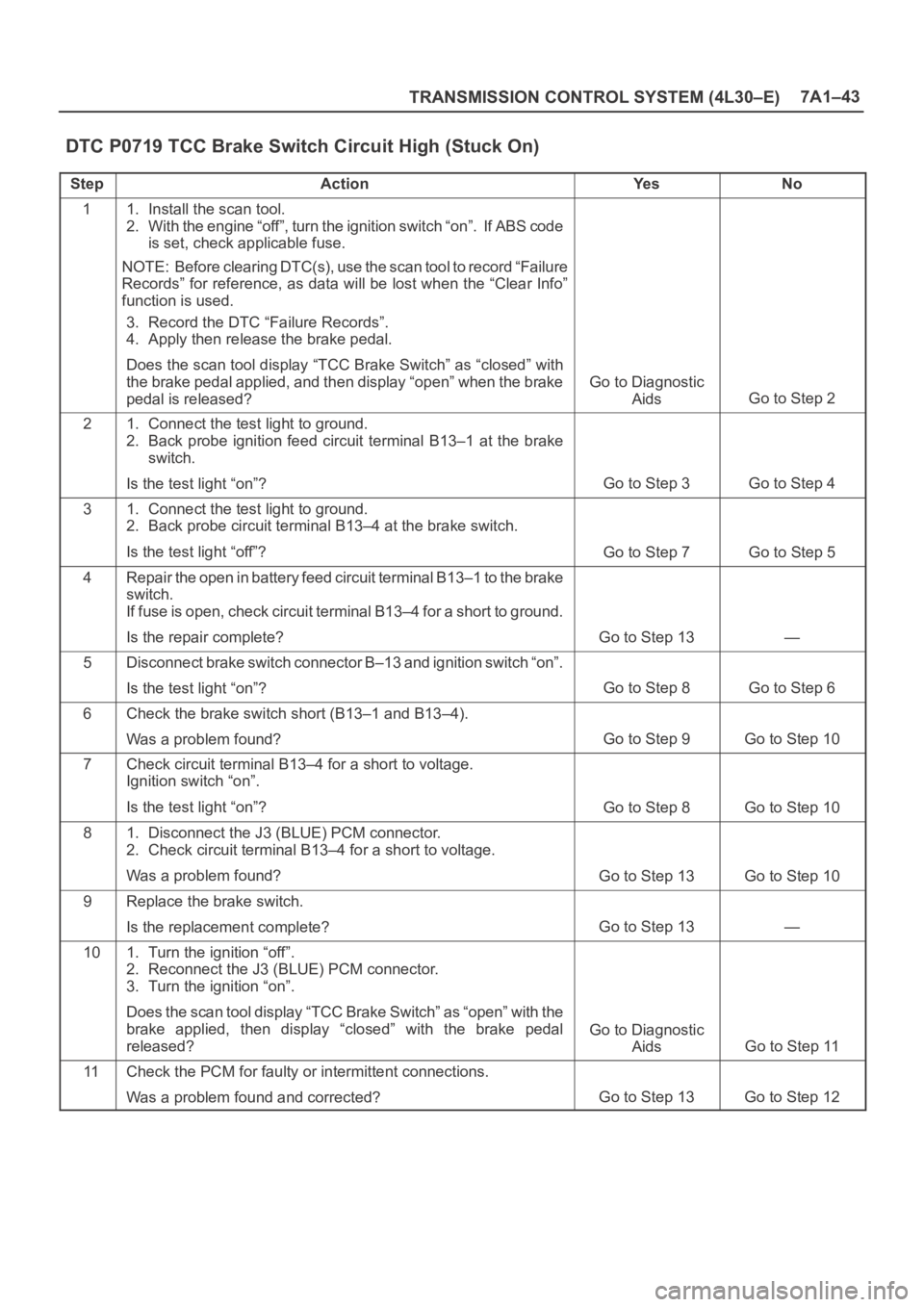

DTC P0719 TCC Brake Switch Circuit High (Stuck On)

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”. If ABS code

is set, check applicable fuse.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Apply then release the brake pedal.

Does the scan tool display “TCC Brake Switch” as “closed” with

the brake pedal applied, and then display “open” when the brake

pedal is released?

Go to Diagnostic

Aids

Go to Step 2

21. Connect the test light to ground.

2. Back probe ignition feed circuit terminal B13–1 at the brake

switch.

Is the test light “on”?

Go to Step 3Go to Step 4

31. Connect the test light to ground.

2. Back probe circuit terminal B13–4 at the brake switch.

Is the test light “off”?

Go to Step 7Go to Step 5

4Repair the open in battery feed circuit terminal B13–1 to the brake

switch.

If fuse is open, check circuit terminal B13–4 for a short to ground.

Is the repair complete?

Go to Step 13—

5Disconnect brake switch connector B–13 and ignition switch “on”.

Is the test light “on”?

Go to Step 8Go to Step 6

6Check the brake switch short (B13–1 and B13–4).

Was a problem found?

Go to Step 9Go to Step 10

7Check circuit terminal B13–4 for a short to voltage.

Ignition switch “on”.

Is the test light “on”?

Go to Step 8Go to Step 10

81. Disconnect the J3 (BLUE) PCM connector.

2. Check circuit terminal B13–4 for a short to voltage.

Was a problem found?

Go to Step 13Go to Step 10

9Replace the brake switch.

Is the replacement complete?

Go to Step 13—

101. Turn the ignition “off”.

2. Reconnect the J3 (BLUE) PCM connector.

3. Turn the ignition “on”.

Does the scan tool display “TCC Brake Switch” as “open” with the

brake applied, then display “closed” with the brake pedal

released?

Go to Diagnostic

Aids

Go to Step 11

11Check the PCM for faulty or intermittent connections.

Was a problem found and corrected?

Go to Step 13Go to Step 12

Page 2290 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–45

DTC P0722 Transmission Output Speed Sensor (OSS) Low Input

D07RW006

Circuit Description

Output speed information is provided to the PCM by the

OSS, which is a permanent magnet (PM) generator. The

PM generator produces a pulsing AC voltage. The AC

voltage level and number of pulses increases as the

speed of the vehicle increases. The PCM then converts

the pulsing voltage to output speed, which is used for

calculations. The vehicle speed can be displayed with a

scan tool.

This DTC detects a low output speed when there is a high

engine speed in a drive gear range. This is a type “C”

DTC.

Conditions For Setting The DTC

No MAP DTCs P0107 or P0108, P0106, P1106,

P1107.

No TPS DTCs P0122 or P0123.

Not in Park or Neutral.

TP angle is greater than 10%.

Engine vacuum is between 0 and 70kPa.

Engine speed is between 3,000 and 7,000 rpm.

Transmission output speed is less than 0 rpm.

All conditions met for 5 seconds.

Action Taken When The DTC Sets

Fixed to 4th gear.

Maximum line pressure.

Inhibit TCC engagement.

The PCM will illuminate the CHECK TRANS Lamp.

Conditions For Clearing The MIL/DTC

The PCM will turn off the CHECK TRANS Lamp after

three consecutive ignition cycles without a failure

reported.

The DTC can be cleared from the PCM history by

using a scan tool. The DTC will be cleared from

history when the vehicle has achieved 40 warmup

cycles without a failure reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

An OSS DTC P0722 will set when no output speed is

at detected at start off.

Inspect the wiring for poor electrical connection at the

PCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

5. This test checks the OSS circuit.

6. This test checks the integrity of the OSS.

8. This test checks the 5–volt and ground circuit of the

PCM.

Page 2291 of 6000

7A1–46

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0722 Transmission Output Speed Sensor (OSS) Low Input

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Raise the drive wheels.

5. Start the engine.

6. Place the transmission in any drive range.

With the drive wheels rotating, does the “Trans Output Speed”

increase with the drive wheel speed?

Go to Diagnostic

Aids

Go to Step 2

2Does the speedometer work?Go to Step 3Go to Step 4

3Check for the most current and/or incorrect calibration.

Is the calibration current?

Go to Step 16Go to Step 4

41. Turn the ignition “off”.

2. Disconnect the J3 (BLUE) PCM connector.

3. Using the J39200 DVOM, measure the resistance between

harness connector terminals J3–E1 and J3–E2.

Is the reading 3,000 ohms?

Go to Step 5Go to Step 6

51. Select AC volts.

2. Rotate the rear wheels, ensuring the driveshaft is turning.

Is the voltage greater than 0.5 volts?

Go to Step 7Go to Step 8

6Inspect circuits RED and WHT for a poor connection or an open

circuit.

Was a problem found?

Go to Step 17Go to Step 8

71. Reconnect the J3 (BLUE) PCM connector.

2. Disconnect the OSS harness from the OSS.

3. With the engine “off”, turn the ignition “on”.

4. Using the J 39200 DVOM, measure the voltage at the OSS

harness connector terminals M15–1 and M15–2.

Is the reading between 4.0 to 5.1 volts?

Go to Step 16Go to Step 10

81. Remove the OSS.

2. Check the output shaft speed sensor rotor for damage or

misalignment. Refer to Speed Sensor (Extension Housing) in

Automatic Transmission (4L30–E) section.

Was a problem found?

Go to Step 17Go to Step 9

9Replace the OSS.

Is the replacement complete?

Go to Step 17—

10Was the reading in step 8 less than 4.0 volts?Go to Step 12Go to Step 11

11Was the reading in Step 8 greater than 5.1 volts?Go to Step 15—

12Using the J 39200 DVOM to chassis ground, measure the voltage

on circuit RED.

Is the reading between 4.0 to 5.1 volts?

Go to Step 13Go to Step 14

13Repair the open in circuit WHT.

Is the repair complete?

Go to Step 17—

14Check circuit RED for a short to ground or open.

Was a problem found and corrected?

Go to Step 17Go to Step 16

Page 2293 of 6000

7A1–48

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0723 Transmission Output Speed Sensor (OSS) Intermittent

D07RW006

Circuit Description

Output speed information is provided to the PCM by the

OSS, which is a permanent magnet (PM) generator. The

PM generator produces a pulsing AC voltage. The AC

voltage level and number of pulses increases as the

speed of the vehicle increases. The PCM then converts

the pulsing voltage to output speed, which is used for

calculations. The vehicle speed can be displayed with a

scan tool.

This DTC detects a low output speed when there is a high

engine speed in a drive gear range. This is a type “C”

DTC.

Conditions For Setting The DTC

In Park or Neutral:

Transmission output speed change is greater than

10,000 rpm.

Conditions met for 6 seconds.

Engine running time is greater than 2 seconds.

Not in Park or Neutral:

Transmission output speed change is greater than

512 rpm.

Conditions met for 0.075 seconds

Engine running time is greater than 2 seconds.

Engine vacuum is less than 70 kPa.

Output speed is greater than 1,380 rpm for 1 second.

NORAW–NOLAST < 60 rpm for 6 seconds.

NORAW: Latest raw data of output shaft speed.

NOLAST: Filtered pervious data of output speed.

Action Taken When The DTC Sets

Fixed to 4th gear.

Maximum line pressure.

Inhibit TCC engagement.

The PCM will illuminate the CHECK TRANS Lamp.

Conditions For Clearing The MIL/DTC

The PCM will turn off the CHECK TRANS Lamp after

three consecutive ignition cycles without a failure

reported.

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

A OSS DTC P0723 will set when output speed has

been detected and is lost.

Inspect the wiring for poor electrical connection at the

PCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

5. This test checks the OSS circuit.

6. This test checks the integrity of the OSS.

8. This test checks the 5–volt and ground circuit of the

PCM.

Page 2294 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–49

DTC P0723 Transmission Output Speed Sensor (OSS) Intermittent

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Raise the drive wheels.

5. Start the engine.

6. Place the transmission in any drive range.

With the drive wheels rotating, does the “Trans Output Speed”

increase with the drive wheel speed?

Go to Diagnostic

Aids

Go to Step 2

2Does the speedometer work?Go to Step 3Go to Step 4

3Check for the most current and/or incorrect calibration.

Is the calibration current?

Go to Step 16Go to Step 4

41. Turn the ignition “off”.

2. Disconnect the J3 (BLUE) PCM connector.

3. Using the J39200 DVOM, measure the resistance between

harness connector terminals J3–E1 and J3–E2.

Is the reading 3,000 ohms?

Go to Step 5Go to Step 6

51. Select AC volts.

2. Rotate the rear wheels, ensuring the driveshaft is turning.

Is the voltage greater than 0.5 volts?

Go to Step 7Go to Step 8

6Inspect circuits RED and WHT for a poor connection or an open

circuit.

Was a problem found?

Go to Step 17Go to Step 8

71. Reconnect the J3 (BLUE) PCM connector.

2. Disconnect the OSS harness from the OSS.

3. With the engine “off”, turn the ignition “on”.

4. Using the J 39200 DVOM, measure the voltage at the OSS

harness connector terminals M15–1 and M15–2.

Is the reading between 4.0 to 5.1 volts?

Go to Step 16Go to Step 10

81. Remove the OSS.

2. Check the output shaft speed sensor rotor for damage or

misalignment. Refer to Speed Sensor (Extension Housing) in

Automatic Transmission (4L30–E) section.

Was a problem found?

Go to Step 17Go to Step 9

9Replace the OSS.

Is the replacement complete?

Go to Step 17—

10Was the reading in step 8 less than 4.0 volts?Go to Step 12Go to Step 11

11Was the reading in Step 8 greater than 5.1 volts?Go to Step 15—

12Using the J 39200 DVOM to chassis ground, measure the voltage

on circuit RED.

Is the reading between 4.0 to 5.1 volts?

Go to Step 13Go to Step 14

13Repair the open in circuit WHT.

Is the repair complete?

Go to Step 17—

14Check circuit RED for a short to ground or open.

Was a problem found and corrected?

Go to Step 17Go to Step 16