check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2523 of 6000

7C–14CLUTCH

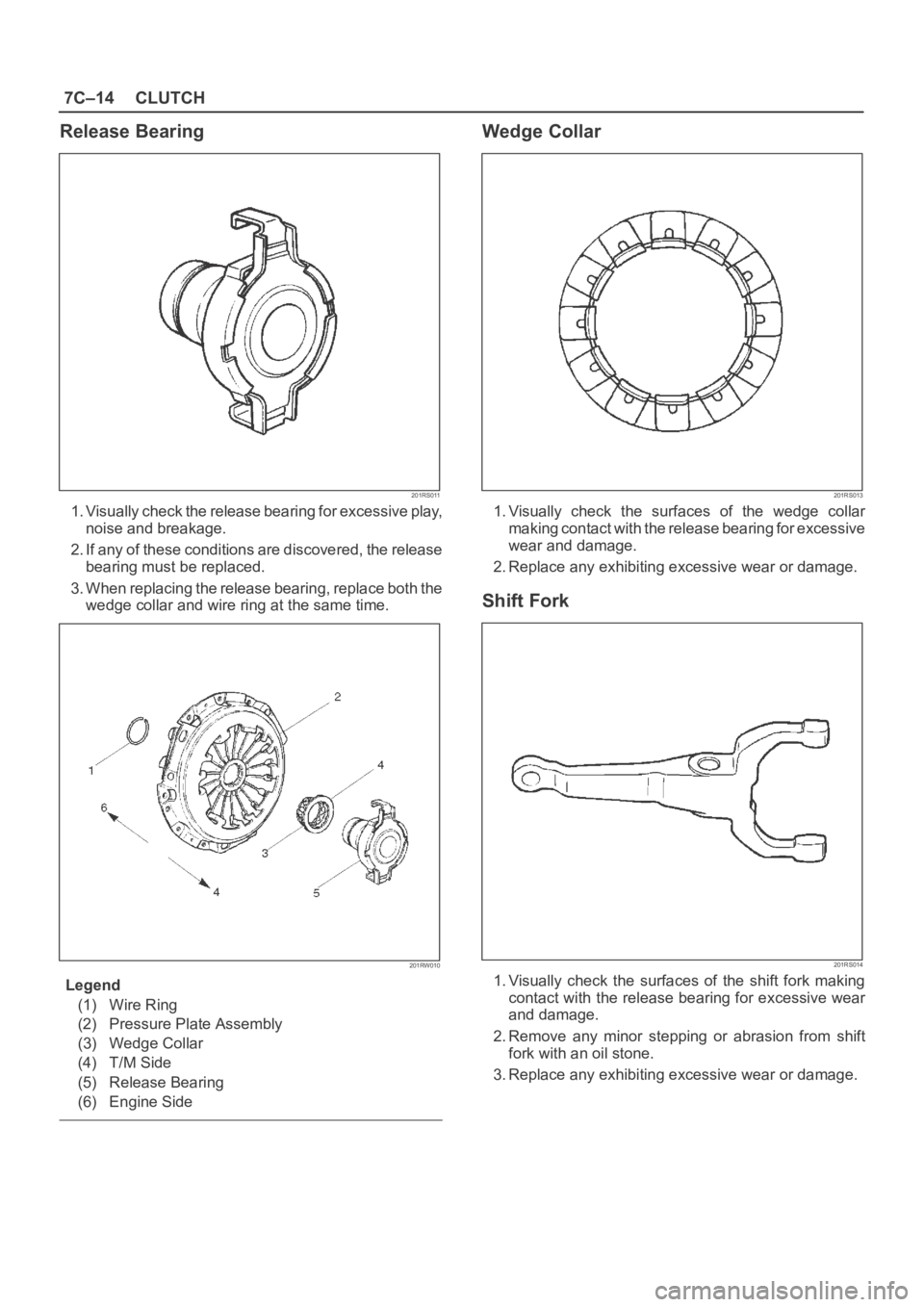

Release Bearing

201RS011

1. Visually check the release bearing for excessive play,

noise and breakage.

2. If any of these conditions are discovered, the release

bearing must be replaced.

3. When replacing the release bearing, replace both the

wedge collar and wire ring at the same time.

201RW010

Legend

(1) Wire Ring

(2) Pressure Plate Assembly

(3) Wedge Collar

(4) T/M Side

(5) Release Bearing

(6) Engine Side

Wedge Collar

201RS013

1. Visually check the surfaces of the wedge collar

making contact with the release bearing for excessive

wear and damage.

2. Replace any exhibiting excessive wear or damage.

Shift Fork

201RS014

1. Visually check the surfaces of the shift fork making

contact with the release bearing for excessive wear

and damage.

2. Remove any minor stepping or abrasion from shift

fork with an oil stone.

3. Replace any exhibiting excessive wear or damage.

Page 2529 of 6000

7C–20CLUTCH

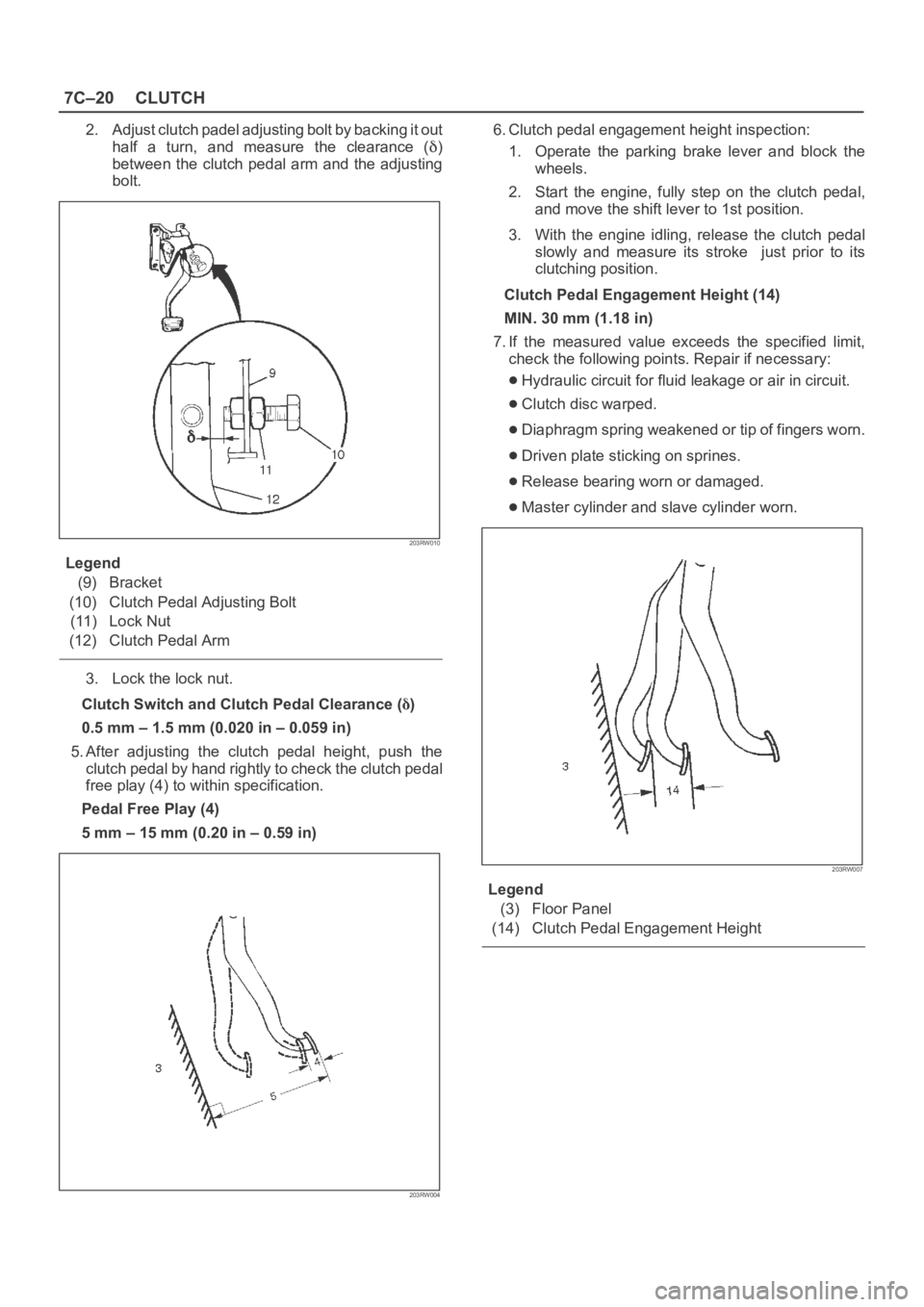

2. Adjust clutch padel adjusting bolt by backing it out

half a turn, and measure the clearance (

)

between the clutch pedal arm and the adjusting

bolt.

203RW010

Legend

(9) Bracket

(10) Clutch Pedal Adjusting Bolt

(11) Lock Nut

(12) Clutch Pedal Arm

3. Lock the lock nut.

Clutch Switch and Clutch Pedal Clearance (

)

0.5 mm – 1.5 mm (0.020 in – 0.059 in)

5. After adjusting the clutch pedal height, push the

clutch pedal by hand rightly to check the clutch pedal

free play (4) to within specification.

Pedal Free Play (4)

5 mm – 15 mm (0.20 in – 0.59 in)

203RW004

6. Clutch pedal engagement height inspection:

1. Operate the parking brake lever and block the

wheels.

2. Start the engine, fully step on the clutch pedal,

and move the shift lever to 1st position.

3. With the engine idling, release the clutch pedal

slowly and measure its stroke just prior to its

clutching position.

Clutch Pedal Engagement Height (14)

MIN. 30 mm (1.18 in)

7. If the measured value exceeds the specified limit,

check the following points. Repair if necessary:

Hydraulic circuit for fluid leakage or air in circuit.

Clutch disc warped.

Diaphragm spring weakened or tip of fingers worn.

Driven plate sticking on sprines.

Release bearing worn or damaged.

Master cylinder and slave cylinder worn.

203RW007

Legend

(3) Floor Panel

(14) Clutch Pedal Engagement Height

Page 2568 of 6000

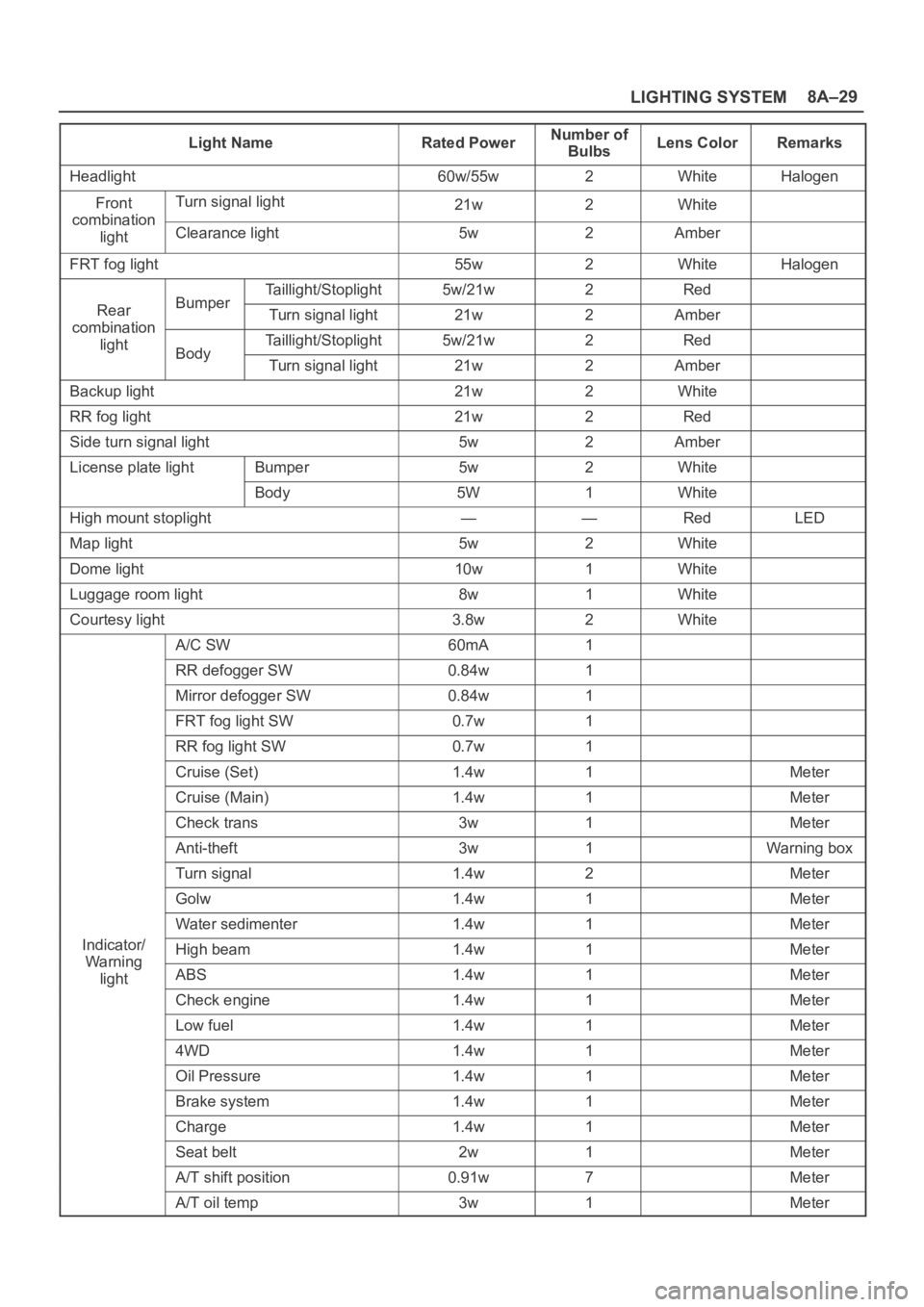

LIGHTING SYSTEM8A–29

Light NameRated PowerNumber of

BulbsLens ColorRemarks

Headlight60w/55w2WhiteHalogen

FrontTurn signal light21w2Whitecombination

lightClearance light5w2Amber

FRT fog light55w2WhiteHalogen

Taillight/Stoplight5w/21w2Red

RearBumperTurn signal light21w2Ambercombination

lightTaillight/Stoplight5w/21w2RedBodyTurn signal light21w2Amber

Backup light21w2White

RR fog light21w2Red

Side turn signal light5w2Amber

License plate lightBumper5w2White

Body5W1White

High mount stoplight——RedLED

Map light5w2White

Dome light10w1White

Luggage room light8w1White

Courtesy light3.8w2White

A/C SW60mA1

RR defogger SW0.84w1

Mirror defogger SW0.84w1

FRT fog light SW0.7w1

RR fog light SW0.7w1

Cruise (Set)1.4w1Meter

Cruise (Main)1.4w1Meter

Check trans3w1Meter

Anti-theft3w1Warning box

Turn signal1.4w2Meter

Golw1.4w1Meter

Water sedimenter1.4w1Meter

Indicator/High beam1.4w1MeterWa rnin g

lightABS1.4w1Meter

Check engine1.4w1Meter

Low fuel1.4w1Meter

4WD1.4w1Meter

Oil Pressure1.4w1Meter

Brake system1.4w1Meter

Charge1.4w1Meter

Seat belt2w1Meter

A/T shift position0.91w7Meter

A/T oil temp3w1Meter

Page 2601 of 6000

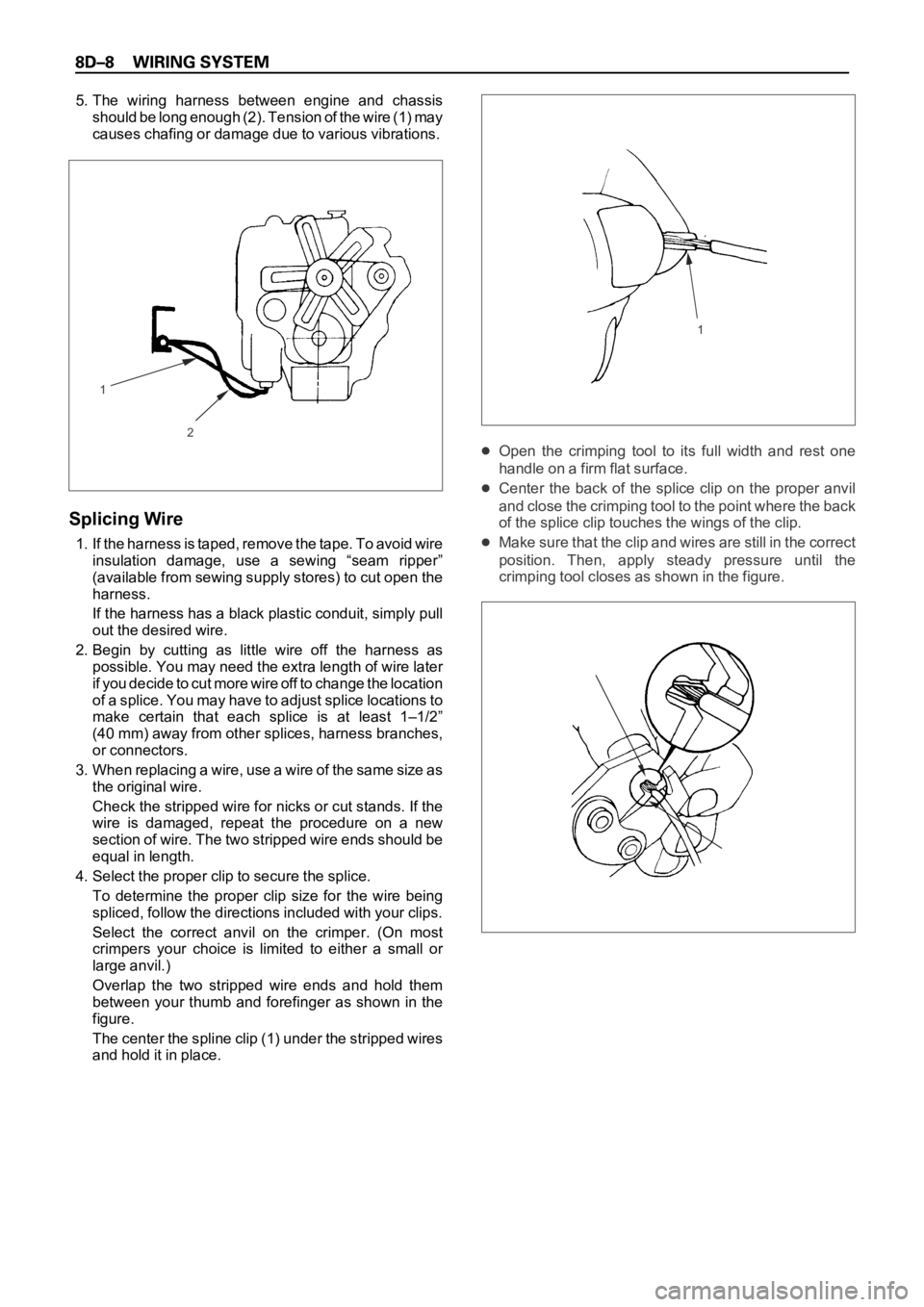

5. The wiring harness between engine and chassis

should be long enough (2). Tension of the wire (1) may

causes chafing or damage due to various vibrations.

Splicing Wire

1. If the harness is taped, remove the tape. To avoid wire

insulation damage, use a sewing “seam ripper”

(available from sewing supply stores) to cut open the

harness.

If the harness has a black plastic conduit, simply pull

out the desired wire.

2. Begin by cutting as little wire off the harness as

possible. You may need the extra length of wire later

if you decide to cut more wire off to change the location

of a splice. You may have to adjust splice locations to

make certain that each splice is at least 1–1/2”

(40 mm) away from other splices, harness branches,

or connectors.

3 . W h e n r e p l a c i n g a w i r e , u s e a w i r e o f t h e s a m e s i z e a s

the original wire.

Check the stripped wire for nicks or cut stands. If the

wire is damaged, repeat the procedure on a new

section of wire. The two stripped wire ends should be

equal in length.

4. Select the proper clip to secure the splice.

To determine the proper clip size for the wire being

spliced, follow the directions included with your clips.

Select the correct anvil on the crimper. (On most

crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them

between your thumb and forefinger as shown in the

figure.

The center the spline clip (1) under the stripped wires

and hold it in place.

Open the crimping tool to its full width and rest one

handle on a firm flat surface.

Center the back of the splice clip on the proper anvil

and close the crimping tool to the point where the back

of the splice clip touches the wings of the clip.

Make sure that the clip and wires are still in the correct

position. Then, apply steady pressure until the

crimping tool closes as shown in the figure.

2

11

Page 2992 of 6000

WIRING SYSTEM 8D–399

1. Check to see if the battery voltage is normal.

2. Check to see if the fuse is normal.

3. Replace the anti–theft & keyless entry control unit with one reserved for test. If a trouble recurs even after replacing

the control unit, find out the cause of the trouble by referring to “System check procedure” and the following list.

ITEM MALFUNCTION POSSIBLE CAUSE DETECTING METHOD REMARKS

ANTI–THEFT

indicator light

does not flash

ANTI–THEFT

indicator light

does not turn off.

(Steadily on)

When door is

opened by pulling

up locking knob,

alarm does not

operate

Alarm does not

stop. Indicator light

does not change

to fully ON

condition, or does

not come on at

all.Burnt out indicator

light bulb possible.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system. Defective contact of door switch,

or open circuit in door switch

wiring.

Short circuit in the detect switch.

Engine hood, doors and tailgate

are not fully closed and locked.

Defective door switch, or short

circuit in switch wiring.

Defective tamper switch, or short

circuit in wiring.

Defective lock switch, or short

circuit in wiring.

Defective engine hood switch, or

short circuit in wiring.

Defective tailgate switch, or short

circuit in wiring.

Defective control unit.

Poor contact of lock switch, or

open circuit in wiring.

Broken wire in wiring to headlight

and horn, or a blown fuse.

Defective contact of detect

switch, or damaged switch wiring.With door open, dome light and

courtesy light do not come on.

Check the control unit connector.

Check to see if doors are closed

and locked.

Dome light and courtesy light

remain lit on after closing doors.

Check the control unit connector.

Check the control unit connector.

Check the control unit connector.

Luggage room light remains lit

after closing tailgate.

Check alarm operation (See No.

46 of “System check procedure”),

possible cause is a poor contact

of lock switch of an open circuit in

wiring.

Check to see if headlights go out.

Check the control unit connector.

Check the control unit connector. A

C

D

E B

Page 2993 of 6000

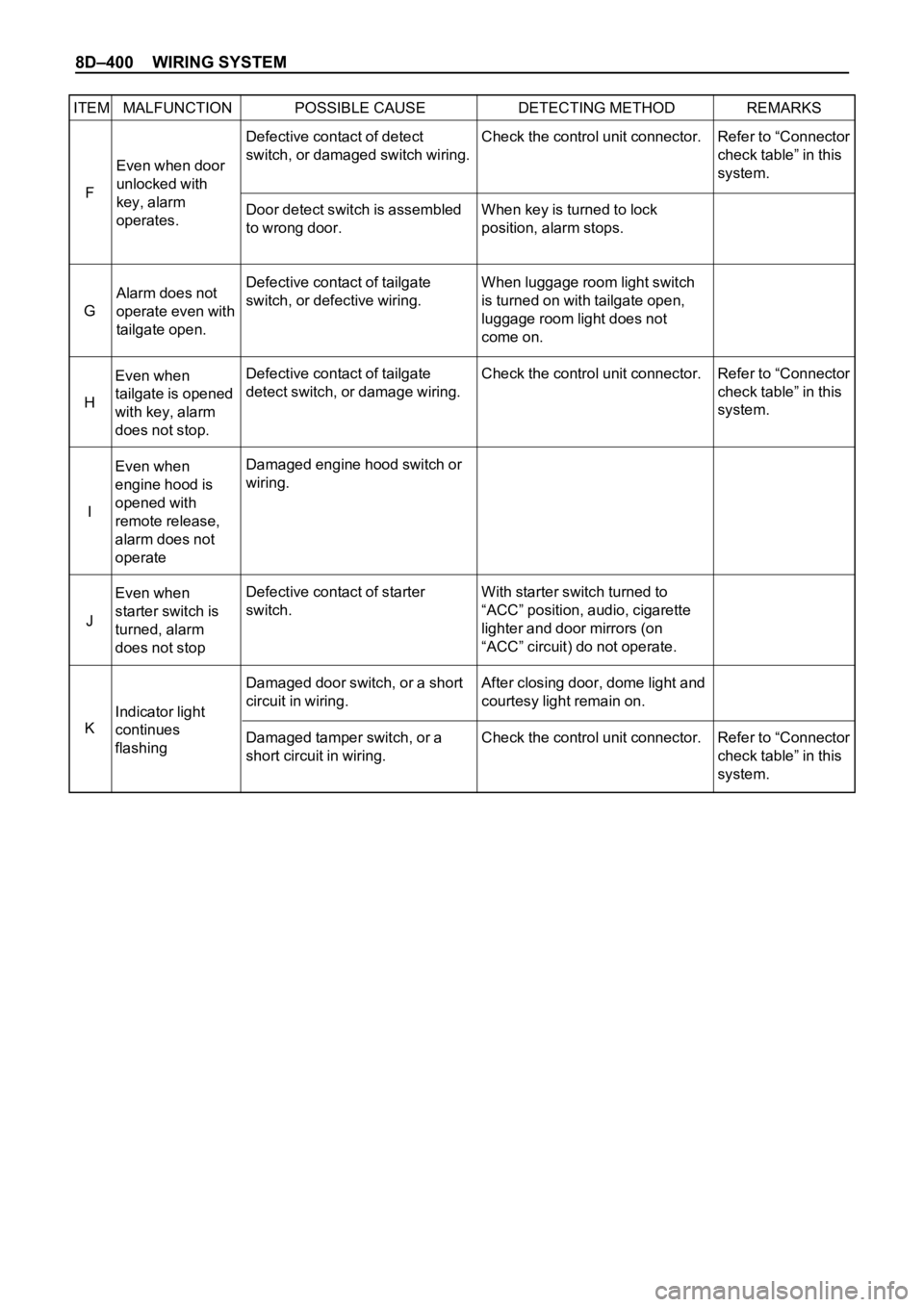

8D–400 WIRING SYSTEM

ITEM MALFUNCTION POSSIBLE CAUSE DETECTING METHOD REMARKS

Even when door

unlocked with

key, alarm

operates.

Alarm does not

operate even with

tailgate open.

Even when

tailgate is opened

with key, alarm

does not stop.

Even when

engine hood is

opened with

remote release,

alarm does not

operate

Even when

starter switch is

turned, alarm

does not stop

Indicator light

continues

flashingRefer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system. Defective contact of detect

switch, or damaged switch wiring.

Door detect switch is assembled

to wrong door.

Defective contact of tailgate

switch, or defective wiring.

Defective contact of tailgate

detect switch, or damage wiring.

Damaged engine hood switch or

wiring.

Defective contact of starter

switch.

Damaged door switch, or a short

circuit in wiring.

Damaged tamper switch, or a

short circuit in wiring.Check the control unit connector.

When key is turned to lock

position, alarm stops.

When luggage room light switch

is turned on with tailgate open,

luggage room light does not

come on.

Check the control unit connector.

With starter switch turned to

“ACC” position, audio, cigarette

lighter and door mirrors (on

“ACC” circuit) do not operate.

After closing door, dome light and

courtesy light remain on.

Check the control unit connector. F

G

H

I

J

K

Page 2994 of 6000

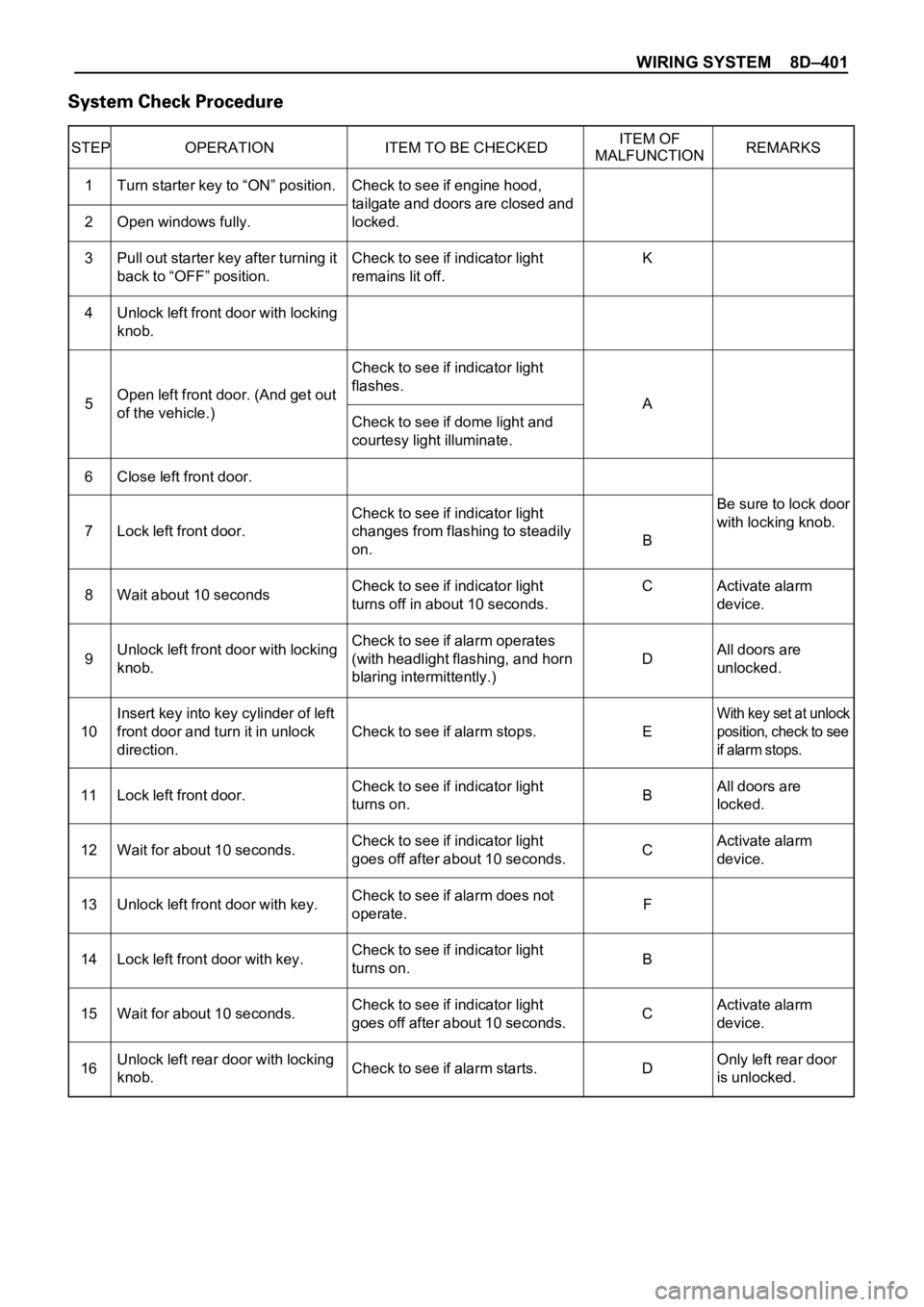

WIRING SYSTEM 8D–401

STEP OPERATION ITEM TO BE CHECKEDITEM OF

REMARKS

MALFUNCTION

Be sure to lock door

with locking knob.

Activate alarm

device.

All doors are

unlocked.

With key set at unlock

position, check to see

if alarm stops.

All doors are

locked.

Activate alarm

device.

Activate alarm

device.

Only left rear door

is unlocked. Check to see if engine hood,

tailgate and doors are closed and

locked.

Check to see if indicator light

remains lit off.

Check to see if indicator light

flashes.

Check to see if dome light and

courtesy light illuminate.

Check to see if indicator light

changes from flashing to steadily

on.

Check to see if indicator light

turns off in about 10 seconds.

Check to see if alarm operates

(with headlight flashing, and horn

blaring intermittently.)

Check to see if alarm stops.

Check to see if indicator light

turns on.

Check to see if indicator light

goes off after about 10 seconds.

Check to see if alarm does not

operate.

Check to see if indicator light

turns on.

Check to see if indicator light

goes off after about 10 seconds.

Check to see if alarm starts. Turn starter key to “ON” position.

Open windows fully.

Pull out starter key after turning it

back to “OFF” position.

Unlock left front door with locking

knob.

Open left front door. (And get out

of the vehicle.)

Close left front door.

Lock left front door.

Wait about 10 seconds

Unlock left front door with locking

knob.

Insert key into key cylinder of left

front door and turn it in unlock

direction.

Lock left front door.

Wait for about 10 seconds.

Unlock left front door with key.

Lock left front door with key.

Wait for about 10 seconds.

Unlock left rear door with locking

knob.K

A

B

C

D

E

B

C

F

B

C

D 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 2997 of 6000

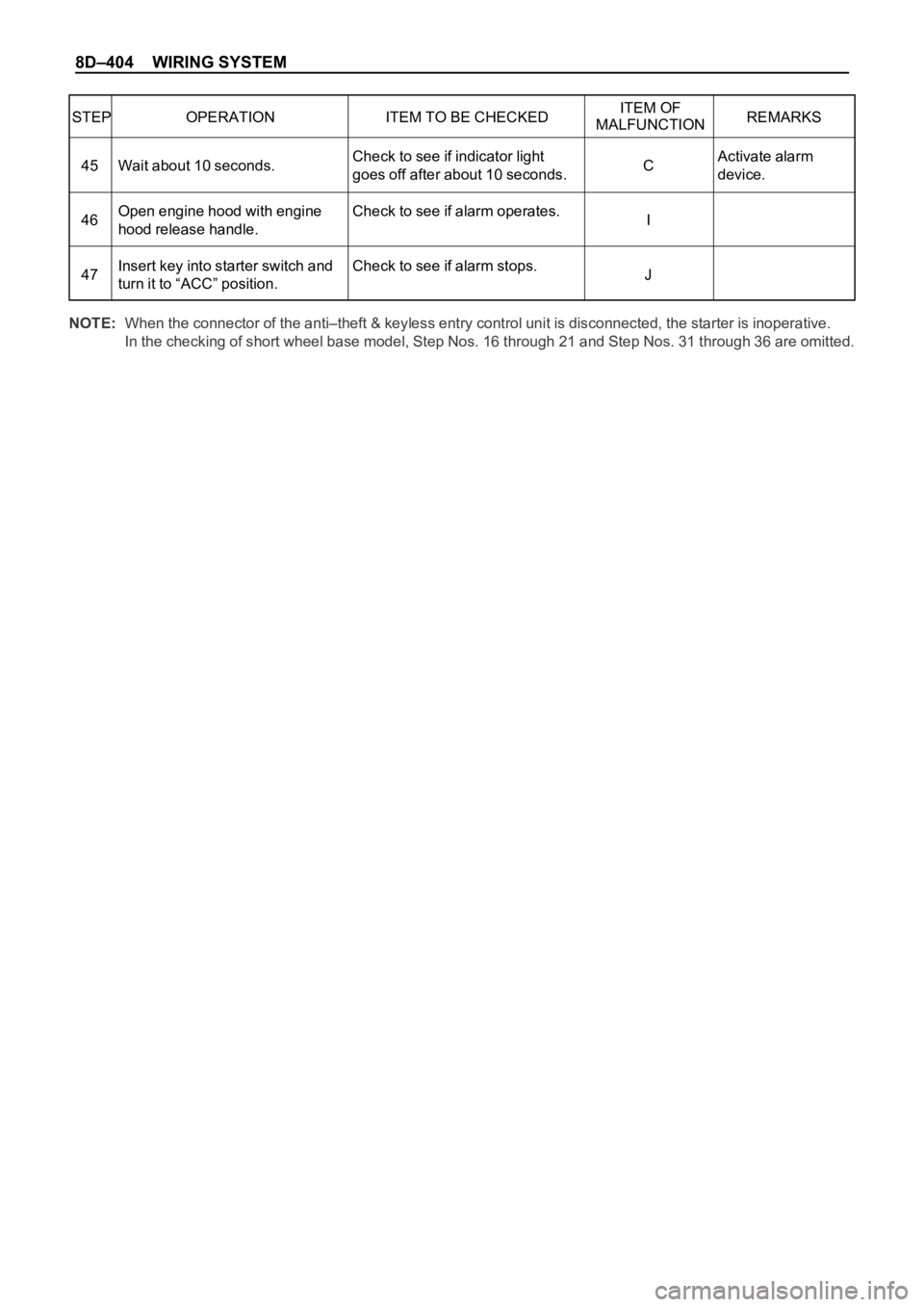

8D–404 WIRING SYSTEM

STEP OPERATION ITEM TO BE CHECKEDITEM OF

REMARKS

MALFUNCTION

Activate alarm

device. Check to see if indicator light

goes off after about 10 seconds.

Check to see if alarm operates.

Check to see if alarm stops. Wait about 10 seconds.

Open engine hood with engine

hood release handle.

Insert key into starter switch and

turn it to “ACC” position.C

I

J 45

46

47

NOTE:When the connector of the anti–theft & keyless entry control unit is disconnected, the starter is inoperative.

In the checking of short wheel base model, Step Nos. 16 through 21 and Step Nos. 31 through 36 are omitted.

Page 2998 of 6000

WIRING SYSTEM 8D–405

TERMINAL

CONNECTIONCHECK

OPERATIONCIRCUIT

NO. ITEM CONDITION

1 FRT door switch–LH, RH ContinuityOpen door Continuity

Close door No continuity

2 RR door switch–LH, RH ContinuityOpen door Continuity

Close door No continuity

3— — – –

4 Door lock key switch–LH, RH Continuity Lock with key Continuity

5 FRT door lock switch–LH, RH Continuity Lock Continuity

6 Tailgate switch ContinuityOpen tailgate Continuity

Close tailgate No continuity

8 Anti–theft horn Voltage – Approx. 12V

10 Battery Voltage – Approx. 12V

11 Door switch ContinuityUnlock with locking knob Continuity

Lock with locking knob No continuity

12 Engine hood switch ContinuityOpen engine hood Continuity

Close engine hood No continuity

13 Detect switch ContinuityUnlock with key Continuity

Lock with key No continuity

14 Door lock key switch Continuity Unlock Continuity

15 FRT door lock switch–LH, RH Continuity Unlock Continuity

16 Tamper switch Continuity – No continuity

17 Ground Continuity – Continuity

18 Starter switch Voltage Starter switch “ACC” Approx. 12V

19 Indicator light Voltage – Approx. 12V

20 Dome light Voltage Dome light “DOOR” position Approx. 12V

21 Anti-theft relay Voltage – Approx. 12V

22 Starter relay VoltageMode switch “P” or “N” Approx. 12V

Clutch pedal depressed Approx. 12V

Check the anti–theft & keyless entry control unit harness side connector B–20 by using a circuit tester.

Page 3186 of 6000

METER AND GAUGE8E–9

Meter Assembly–Gasoline W/O TOD–2

Connector No. I–9

Te r m i n a lFunction

1A/T oil temp warning light

2Seat belt warning light

3Check trans warning light

4Brake warning light

5Check engine warning light

6Charge warning light

7Cigarette lighter illumination light

8Illumination controller

9Tachometer

10D position (A/T)

11—

12A/T shift indicator control unit

13—

142 position (A/T)

15Starter switch

16Cruise set indicator light

17Cruise main indicator light

184WD indicator light

19Ground (Gauge)

20—

21Winter drive indicator light

22Oil pressure warning light

23—

24Air bag warning light

25Power drive indicator light

26—

27—

28Turn signal indicator light (Left)

29—

30Ground

Connector No. I–10

Te r m i n a lFunction

1Turn signal indicator light (Right)

2L position (A/T)

3R position (A/T)

4Engine coolant temperature gauge

5Speedometer

6—

7—

8Battery (+)

9—

10Rear fog light

11P position (A/T)

12N position (A/T)

133 position (A/T)

14High-beam indicator light (–)

15High-beam indicator light (+)

16ABS indicator light

17—

18Fuel warning light

19Oil pressure gauge

20Fuel gauge

21—

22—