ignition OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4888 of 6000

6E–231 ENGINE DRIVEABILITY AND EMISSIONS

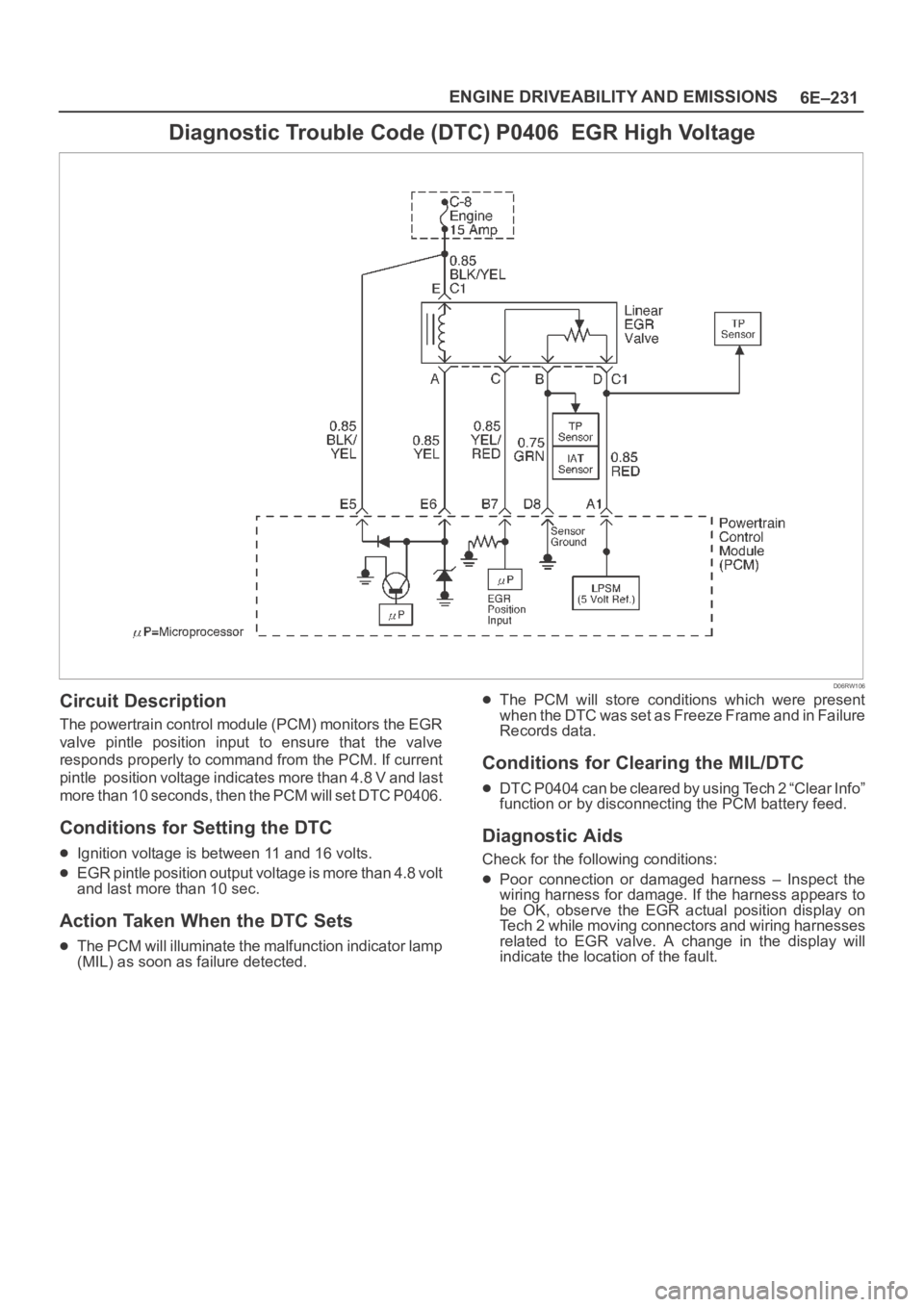

Diagnostic Trouble Code (DTC) P0406 EGR High Voltage

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to command from the PCM. If current

pintle position voltage indicates more than 4.8 V and last

more than 10 seconds, then the PCM will set DTC P0406.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

EGR pintle position output voltage is more than 4.8 volt

and last more than 10 sec.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) as soon as failure detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P0404 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged harness – Inspect the

wiring harness for damage. If the harness appears to

be OK, observe the EGR actual position display on

Tech 2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

Page 4889 of 6000

6E–232

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0406 – EGR High Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “DTC” info for DTC P0406

until the DTC P0406 test runs. Note the result.

Does Tech 2 indicates DTC P0406 failed this ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—Go to Step 4Go to Step 5

4Repair the damaged pin or terminal.

Is the action complete?

—Verify repair

Is the action

complete?

51. Disconnect the EGR harness connector.

2. Ignition “ON”.

3. At the EGR valve, use a DVM to check the voltage

at the 5 volt reference wire (RED).

Did the DVM indicate the specified value?

4–6 VGo to Step 8Go to Step 6

61. Ignition “ON”.

2. At the PCM connector, backprobe with a DVM at the

5 volt reference for the EGR valve.

Did the DVM indicate the specified value?

4–6 VGo to Step 7Go to Step 16

7Repair the open 5 volt reference circuit

Is the action complete?

—Verify repair—

81. Ignition “OFF”

2. Disconnect the EGR harness.

3. Use a DVM to check for an resistance between D (5

V reference) and B (Sensor Ground) at EGR sensor

terminals.

NOTE: J-35616 Connector Test Adapter Kit may be

useful for gaining access to the recessed pins on the

valve.

Was there measured resistance in range?

5 to 5 KGo to Step 9Go to Step 15

91. Ignition “OFF”.

2. Disconnect the EGR harness.

3. Use a DVM to check for an resistance between B

and C at EGR sensor terminal.

Was there open circuit?

—Go to Step 15Go to Step 10

101. Ignition “OFF”.

2. Disconnect the EGR harness at PCM connector.

3. Use a DVM to check for shorted wire between A1

and B7.

Was there shorted wire?

—Go to Step 14Go to Step 11

Page 4890 of 6000

6E–233 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0406 – EGR High Voltage

StepNo Ye s Va l u e ( s ) Action

111. Ignition “ON”.

2. Use a DVM to backprobe at terminal C of EGR

valve for voltage.

Was measured voltage more than 4.8 V?

more than

4.8 V

Go to Step 12Go to Step 12

121. Ignition “ON”.

2. Stay the EGR harness connected.

3. Check voltage by backproving at PCM B7 terminal.

Was voltage more than 4.8 V?

4.8 VGo to Step 16Go to Step 13

131. Locate short circuit at EGR harness between RED

to RED or GREEN, RED to YEL.

2. Replace EGR harness.

Is the action complete?

—Verify repair—

14Replace EGR harness.

Is the action complete?

—Verify repair—

15Replace the EGR valve.

Does DTC P1404 still fail “specific DTC test on Tech 2?

—Go to Step 16Verify repair

16Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4892 of 6000

6E–235 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0502 – VSS Circuit Low Input

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Does the speedometer work?—Go to Step 10Go to Step 3

31. Disconnect the VSS connector.

2. Ignition “ON.”

3. Using a test light to battery +, probe the connector

ground wire.

Did the light illuminate?

—Go to Step 5Go to Step 4

4Repair the sensor ground.

Is the action complete?

—Verify repair—

51. Ignition “ON,” sensor disconnected.

2. Using a DVM, measure at the VSS connector

between ground and voltage supply.

Was the measurement near the specified value?

Battery

voltage

Go to Step 7Go to Step 6

6Repair the open or short to ground which may have

blown the meter fuse.

Is the action complete?

—Verify repair—

71. Ignition “ON,” VSS disconnected.

2. Using a DVM, measure at the VSS connector

between ground and the wire from the

speedometer.

Was the measurement near the specified value?

7.5-8 VGo to Step 9Go to Step 8

8Check for an open or short circuit between the

speedometer and the VSS.

Was an open or short circuit located?

—Verify repairGo to Step 9

9Replace the speedometer.

Is the action complete?

—Verify repair—

Page 4893 of 6000

6E–236

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0502 – VSS Circuit Low Input

StepNo Ye s Va l u e ( s ) Action

101. Ignition “OFF.”

2. Disconnect the MAF sensor and remove the air

cleaner assembly and filter element to gain access

to the 16-way black connector located immediately

to the rear of the left front headlamp. The connector

attaches the VSS wires from the transmission

harness to the left-side engine harness.

3. Disconnect the black 16-way connector.

4. Select a terminal adapter from kit J 35616 that can

be used with a jumper to supply B+ to the blue wire

with a yellow tracer (transmission side of the

connector).

5. Use another terminal adapter to attach a voltmeter

to the light-green wire with a w h i l e t r a c e r ( n e x t t o t h e

wire in the previous step.)

6. Disconnect the blue connector next to the black

16-way connector, and locate the black/red tracer

wire at one corner of the blue connector. The

black/red wire is the VSS ground. Use a terminal

adapter to attach a jumper to ground to the

black/red VSS ground wire at the transmission side

of the blue connector.

7. Raise the rear wheels off the ground with

transmission in neutral.

Does the DVM toggle back and forth between 0.6 V and

10 V as the wheels (and driveshaft) are rotated?

—Go to Step 11Go to Step 12

11Replace the VSS.

Is the action complete?

—Verify repair—

12Check for an open or short between the PCM and the

speedometer.

Was a problem found?

—Verify repairGo to Step 13

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4894 of 6000

6E–237 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0562 System Voltage Low

D06RW020

Circuit Description

The powertrain control module (PCM) monitors the

system voltage on the ignition feed terminal to the PCM.

A system voltage DTC will set whenever the voltage is

below a calibrated value.

Conditions for Setting the DTC

Ignition “ON.”

System voltage is below 11.5 volts for 15 minutes.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store as Failure Records conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

A history DTC P0562 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC P0562 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

Page 4895 of 6000

6E–238

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0562 – System Voltage Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Using a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/Char

ging

41. Ignition “OFF.”

2. Disconnect the PCM connector at the PCM.

3. Using a DVM, measure the battery voltage at the

PCM connector A-4.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the PCM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the PCM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4896 of 6000

6E–239 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0563 System Voltage High

Circuit Description

The powertrain control module (PCM) monitors the

system voltage on the ignition feed terminals to the PCM.

A system voltage DTC will set whenever the voltage is

above a calibrated value.

Conditions for Setting the DTC

Ignition “ON.”

System voltage is above 16 volts for 15 minutes.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store as Failure Records only conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

A history DTC P0563 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC P0563 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

DTC P0563 – System Voltage High

StepActionVa l u e ( s )Ye sNo

1Was the “ON-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage less than the specified value?

11 . 5 VGo to Step 3Go to Step 4

31. Charge the battery and clean the battery terminals.

2. Clean the battery ground cable connection if

corrosion is indicated.

Is the battery voltage less than the specified value?

11 . 5 V

Replace

battery

Go to Step 4

41. Turn “OFF” all the accessories.

2. Install a Tech 2.

3. Select the ignition voltage parameter on the Tech 2.

4. Start the engine and raise the engine RPM to the

specified value.

Is the voltage more than 2.5 volts greater than the

measurement taken in step 2 or 3?

2000 RPM

Go to

Starting/Char

ging

Go to Step 5

5Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98 model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4898 of 6000

6E–241 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1154 HO2S Circuit Transition Time Ratio

Bank 2 Sensor 1

060RW190

Circuit Description

The powertrain control module (PCM) monitors the

heated oxygen sensor (HO2S) activity for 90 seconds

after “closed loop” and stoichiometric operation have

been enabled. During the monitor period the PCM counts

the number of times that the HO2S responds from

rich-to-lean and from lean-to-rich and adds the amount of

time it took to complete all transitions. With this

information, an average time for all transitions can be

determined. The PCM then divides the rich-to-lean

average by the lean-to-rich average to obtain a ratio. If

the HO2S transition time ratio is not within this range,

DTC P1154 will be set, indicating that the oxygen sensor

is not responding as expected to changes in exhaust

oxygen content.

Conditions for Setting the DTC

No related DTCs.

Engine coolant temperature (ETC) is above 50C

(122F) for automatic transmission; 75C (167F) for

manual transmission.

The engine is operating in “closed loop.”

The engine has been running at least one minute.

Canister purge duty cycle is greater than 2%.

Engine speed is between 1500 RPM and 3000 RPM.

Mass air flow is between 9 g/second and 42 g/second.

Above conditions are present for a 3-second

monitoring period.

90 seconds after “closed loop” and stoichiometric

operation have been enabled, Bank 2 HO2S 1

transition ratio between lean to rich and rich to lean is

less than 0.44 or greater than 3.8.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

”Open loop” fuel control will be in effect.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1154 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

A multifunction in the HO2S heater ignition feed or ground

circuit may cause a DTC P1154 to set. Check HO2S

heater circuitry for intermittent faults or poor connections.

If connections and wiring are OK and DTC P1154

continues to set, replace the Bank 2 HO2S 1.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

Page 4899 of 6000

6E–242

ENGINE DRIVEABILITY AND EMISSIONS

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. A condition that affects other heated oxygen sensors

indicates probable contamination. To avoid

damaging replacement sensors, correct the

condition which caused the contamination before

replacing the affected sensors.5. This step checks for conditions which may cause the

heated oxygen sensor to appear faulty. Correct any

of the described conditions if present.

8. To avoid damaging replacement sensors, correct the

condition which caused the contamination before

replacing the affected sensors.

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2IMPORTANT:If any other DTCs are set (except P1133

and/or P1134), refer to those DTCs before proceeding

with this diagnostic chart.

1. Idle the engine at operating temperature.

2. Operate the vehicle within parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P1154 until the DTC P1154 test runs.

Note the test result.

Does Tech 2 indicate DTC failed this ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

3Did Tech 2 also indicate P1133, and/or P1134 test

failed?

—Go to Step 17Go to Step 4

4Check for leaks at the pipe joints.

Are the joints leaking?

—Go to Step 5Go to Step 6

5Tighten the U-bolt nuts at the leaking joints.

Is your action complete?

—Go to Step 2—

6Check for gaskets that are damaged or improperly

installed.

Are there damaged or misaligned gaskets?

—Go to Step 7Go to Step 8

71. Replace the damaged gaskets.

2. Align the connections.

3. Tighten the connections.

Is your action complete?

—Go to Step 2—

8Check for loose exhaust flange connections.

Are the flange connections loose?

—Go to Step 9Go to Step 10

9Tighten the stud nuts or bolts to specifications.

Is your action complete?

—Go to Step 2—

10Check for burned or corroded exhaust pipes.

Are the exhaust pipes burned or corroded?

—Go to Step 11Go to Step 12

11Replace the exhaust pipes, as required.

Is your action complete?

—Go to Step 2—