ECO mode OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2153 of 6000

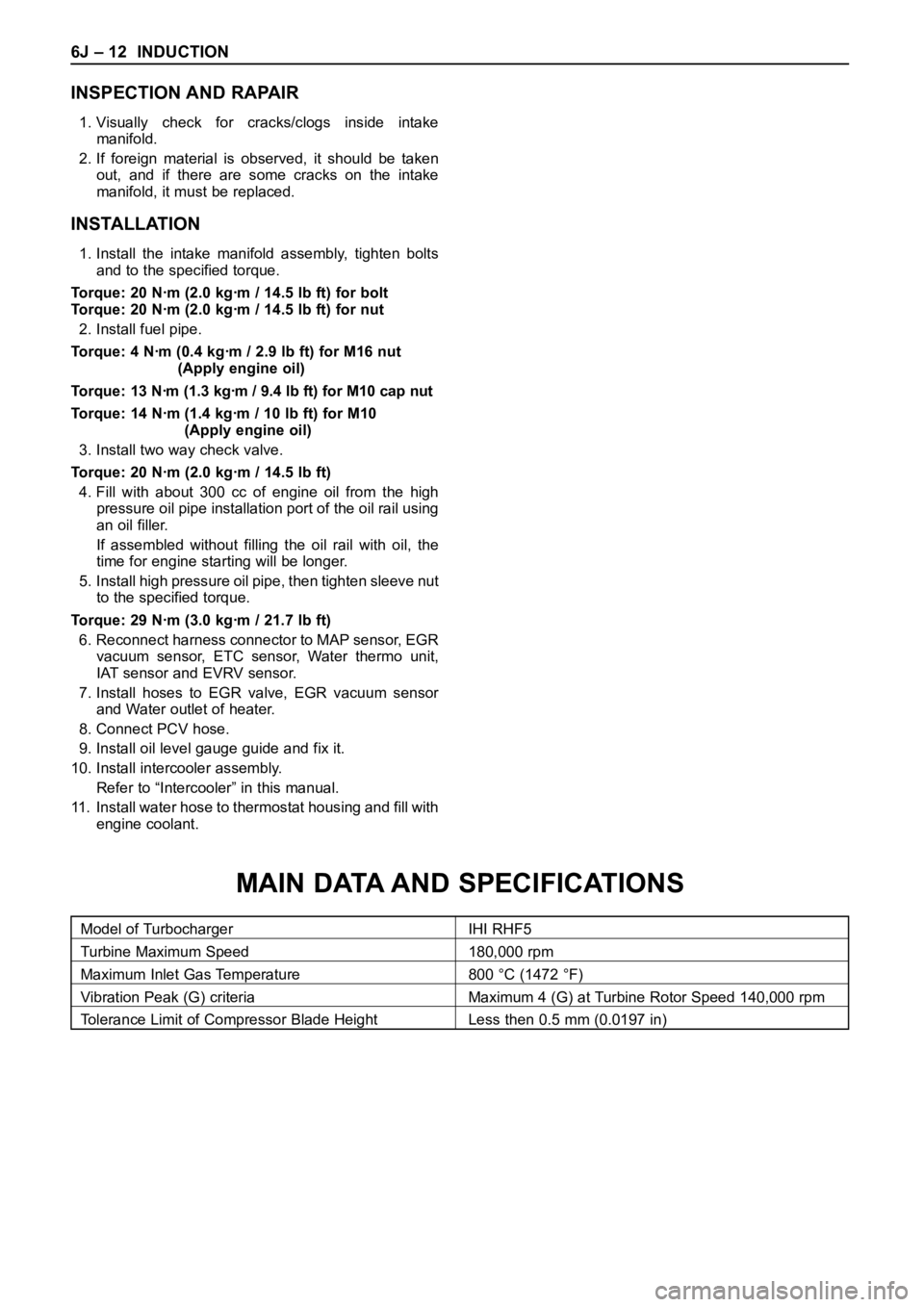

6J – 12 INDUCTION

INSPECTION AND RAPAIR

1. Visually check for cracks/clogs inside intake

manifold.

2. If foreign material is observed, it should be taken

out, and if there are some cracks on the intake

manifold, it must be replaced.

INSTALLATION

1. Install the intake manifold assembly, tighten bolts

and to the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft) for bolt

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft) for nut

2. Install fuel pipe.

Torque: 4 Nꞏm (0.4 kgꞏm / 2.9 lb ft) for M16 nut

(Apply engine oil)

Torque: 13 Nꞏm (1.3 kgꞏm / 9.4 lb ft) for M10 cap nut

Torque: 14 Nꞏm (1.4 kgꞏm / 10 lb ft) for M10

(Apply engine oil)

3. Install two way check valve.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

5. Install high pressure oil pipe, then tighten sleeve nut

to the specified torque.

Torque: 29 Nꞏm (3.0 kgꞏm / 21.7 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water thermo unit,

IAT sensor and EVRV sensor.

7. Install hoses to EGR valve, EGR vacuum sensor

and Water outlet of heater.

8. Connect PCV hose.

9. Install oil level gauge guide and fix it.

10. Install intercooler assembly.

Refer to “Intercooler” in this manual.

11. Install water hose to thermostat housing and fill with

engine coolant.

Model of Turbocharger IHI RHF5

Turbine Maximum Speed 180,000 rpm

Maximum Inlet Gas Temperature 800 °C (1472 °F)

Vibration Peak (G) criteria Maximum 4 (G) at Turbine Rotor Speed 140,000 rpm

Tolerance Limit of Compressor Blade Height Less then 0.5 mm (0.0197 in)

MAIN DATA AND SPECIFICATIONS

Page 2173 of 6000

7A–19 AUTOMATIC TRANSMISSION (4L30–E)

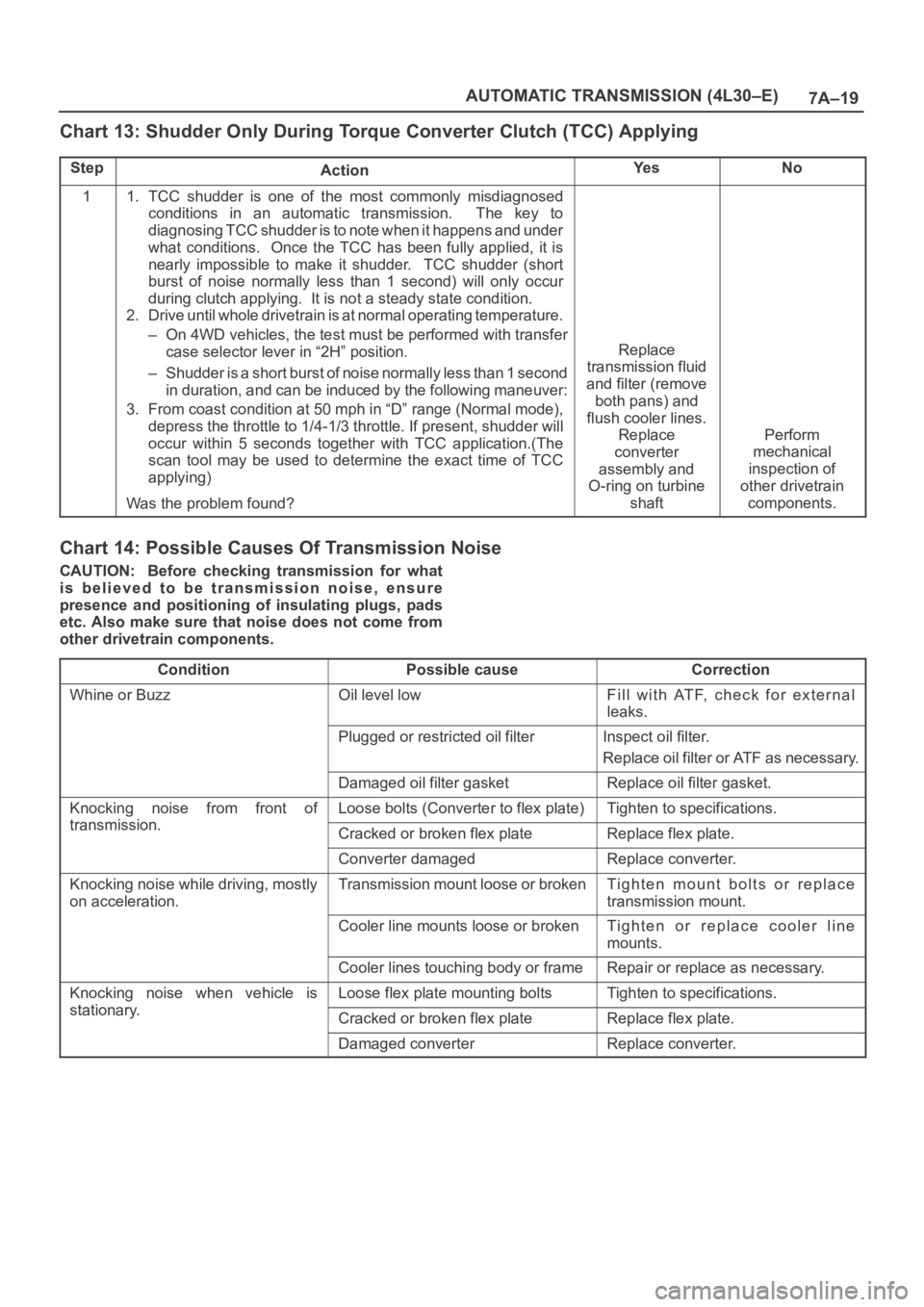

Chart 13: Shudder Only During Torque Converter Clutch (TCC) Applying

StepActionYe sNo

11. TCC shudder is one of the most commonly misdiagnosed

conditions in an automatic transmission. The key to

diagnosing TCC shudder is to note when it happens and under

what conditions. Once the TCC has been fully applied, it is

nearly impossible to make it shudder. TCC shudder (short

burst of noise normally less than 1 second) will only occur

during clutch applying. It is not a steady state condition.

2. Drive until whole drivetrain is at normal operating temperature.

– On 4WD vehicles, the test must be performed with transfer

case selector lever in “2H” position.

– Shudder is a short burst of noise normally less than 1 second

in duration, and can be induced by the following maneuver:

3. From coast condition at 50 mph in “D” range (Normal mode),

depress the throttle to 1/4-1/3 throttle. If present, shudder will

occur within 5 seconds together with TCC application.(The

scan tool may be used to determine the exact time of TCC

applying)

Was the problem found?

Replace

transmission fluid

and filter (remove

both pans) and

flush cooler lines.

Replace

converter

assembly and

O-ring on turbine

shaft

Perform

mechanical

inspection of

other drivetrain

components.

Chart 14: Possible Causes Of Transmission Noise

CAUTION: Before checking transmission for what

is believed to be transmission noise, ensure

presence and positioning of insulating plugs, pads

etc. Also make sure that noise does not come from

other drivetrain components.

Condition

Possible causeCorrection

Whine or BuzzOil level lowFill with ATF, check for external

leaks.

Plugged or restricted oil filterInspect oil filter.

Replace oil filter or ATF as necessary.

Damaged oil filter gasketReplace oil filter gasket.

Knocking noise from front of

transmission

Loose bolts (Converter to flex plate)Tighten to specifications.

transmission.Cracked or broken flex plateReplace flex plate.

Converter damagedReplace converter.

Knocking noise while driving, mostly

on acceleration.Transmission mount loose or brokenTighten mount bolts or replace

transmission mount.

Cooler line mounts loose or brokenTighten or replace cooler line

mounts.

Cooler lines touching body or frameRepair or replace as necessary.

Knocking noise when vehicle is

stationary

Loose flex plate mounting boltsTighten to specifications.

stationary.Cracked or broken flex plateReplace flex plate.

Damaged converterReplace converter.

Page 2178 of 6000

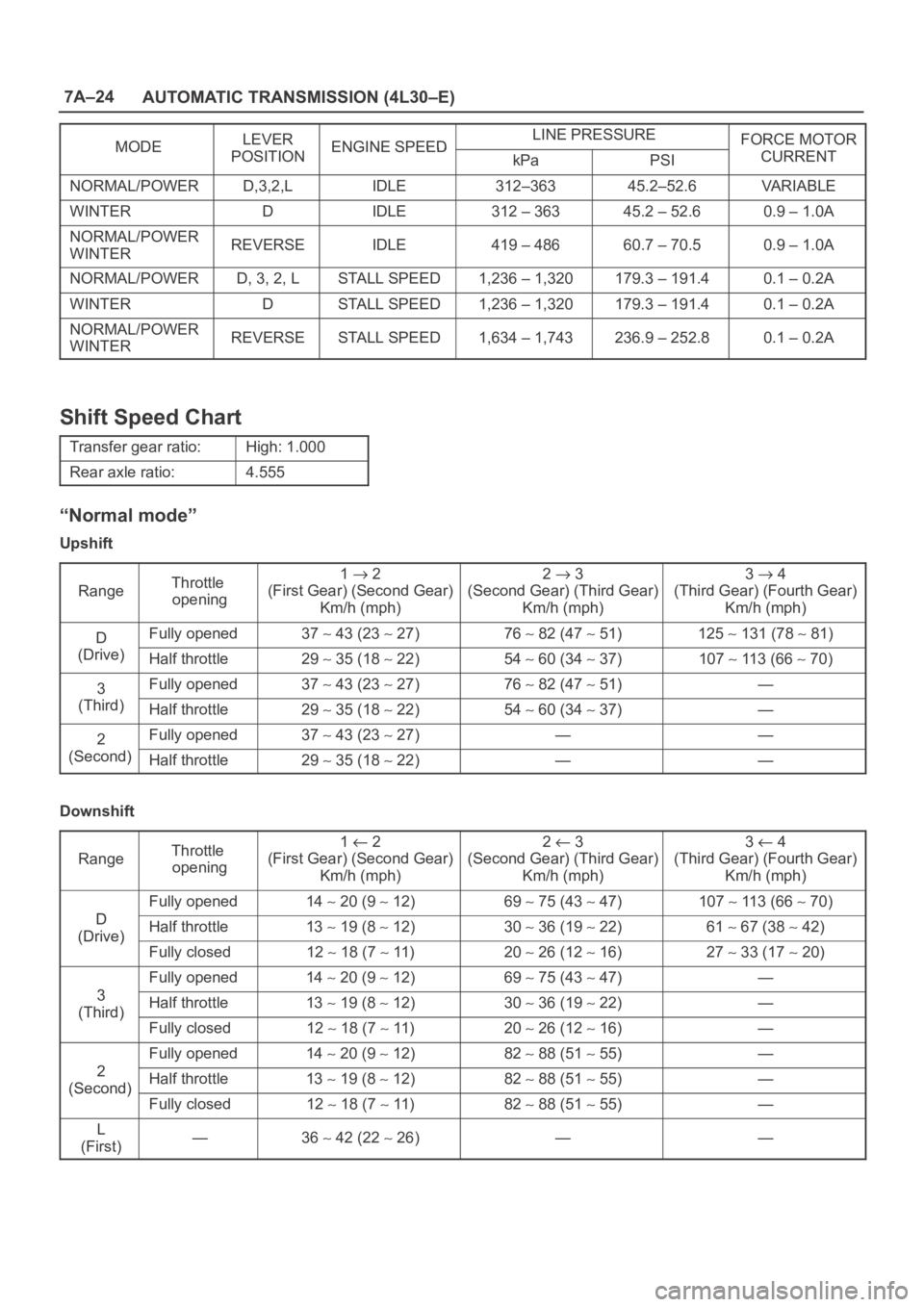

7A–24

AUTOMATIC TRANSMISSION (4L30–E)

MODELEVERENGINE SPEEDLINE PRESSUREFORCE MOTORMODEPOSITIONENGINE SPEEDkPaPSICURRENT

NORMAL/POWERD,3,2,LIDLE312–36345.2–52.6VA R I A B L E

WINTERDIDLE312 – 36345.2 – 52.60.9 – 1.0A

NORMAL/POWER

WINTERREVERSEIDLE419 – 48660.7 – 70.50.9 – 1.0A

NORMAL/POWERD, 3, 2, LSTALL SPEED1,236 – 1,320179.3 – 191.40.1 – 0.2A

WINTERDSTALL SPEED1,236 – 1,320179.3 – 191.40.1 – 0.2A

NORMAL/POWER

WINTERREVERSESTALL SPEED1,634 – 1,743236.9 – 252.80.1 – 0.2A

Shift Speed Chart

Transfer gear ratio:High: 1.000

Rear axle ratio:4.555

“Normal mode”

Upshift

Range

Throttle

opening1 2

(First Gear) (Second Gear)

Km/h (mph)2 3

(Second Gear) (Third Gear)

Km/h (mph)3 4

(Third Gear) (Fourth Gear)

Km/h (mph)

DFully opened37 43 (23 27)76 82 (47 51)125 131 (78 81)

(Drive)Half throttle29 35 (18 22)54 60 (34 37)107 113 (66 70)

3Fully opened37 43 (23 27)76 82 (47 51)—

(Third)Half throttle29 35 (18 22)54 60 (34 37)—

2Fully opened37 43 (23 27)——

(Second)Half throttle29 35 (18 22)——

Downshift

Range

Throttle

opening1 2

(First Gear) (Second Gear)

Km/h (mph)2 3

(Second Gear) (Third Gear)

Km/h (mph)3 4

(Third Gear) (Fourth Gear)

Km/h (mph)

D

Fully opened14 20 (9 12)69 75 (43 47)107 113 (66 70)

D

(Drive)Half throttle13 19 (8 12)30 36 (19 22)61 67 (38 42)(Drive)

Fully closed12 18 (7 11)20 26 (12 16)27 33 (17 20)

3

Fully opened14 20 (9 12)69 75 (43 47)—

3

(Third)Half throttle13 19 (8 12)30 36 (19 22)—(Third)

Fully closed12 18 (7 11)20 26 (12 16)—

2

Fully opened14 20 (9 12)82 88 (51 55)—

2

(Second)Half throttle13 19 (8 12)82 88 (51 55)—(Second)

Fully closed12 18 (7 11)82 88 (51 55)—

L

(First)—36 42 (22 26)——

Page 2179 of 6000

7A–25 AUTOMATIC TRANSMISSION (4L30–E)

“Power mode”

Upshift

Range

Throttle

opening1 2

(First Gear) (Second Gear)

Km/h (mph)2 3

(Second Gear) (Third Gear)

Km/h (mph)3 4

(Third Gear) (Fourth Gear)

Km/h (mph)

DFully opened41 47 (25 29)79 85 (49 53)125 131 (78 81)

(Drive)Half throttle36 42 (22 26)69 75 (43 47)11 9 125 (74 78)

3Fully opened41 47 (25 29)79 85 (49 53)—

(Third)Half throttle36 42 (22 26)69 75 (43 47)—

2Fully opened41 47 (25 29)——

(Second)Half throttle36 42 (22 26)——

Downshift

Range

Throttle

opening1 2

(First Gear) (Second Gear)

Km/h (mph)2 3

(Second Gear) (Third Gear)

Km/h (mph)3 4

(Third Gear) (Fourth Gear)

Km/h (mph)

D

Fully opened28 34 (17 21)70 76 (43 47)11 5 121 (71 75)

D

(Drive)Half throttle20 26 (12 16)46 52 (29 32)90 96 (56 60)(Drive)

Fully closed12 18 (7 11)22 28 (14 17)43 50 (27 31)

3

Fully opened28 34 (17 21)70 76 (43 47)—

3

(Third)Half throttle20 26 (12 16)46 52 (29 32)—(Third)

Fully closed12 18 (7 11)22 28 (14 17)—

2

Fully opened28 34 (17 21)82 88 (51 55)—

2

(Second)Half throttle20 26 (12 16)82 88 (51 55)—(Second)

Fully closed12 18 (7 11)82 88 (51 55)—

L

(First)—36 42 (22 26)——

“Winter mode”

D range, winter mode ON OFF27 33 Km/h (17 20 mph)

Page 2231 of 6000

7A–77 AUTOMATIC TRANSMISSION (4L30–E)

Main Data And Specification

General Specifications

Remarks

ModelTHM 4L30–E

EngineV6 3.2L 6VD1DOHC

Ty p eAutomatic four speed overdrive in

4th gear lock–up clutch torque con-

verter

Shift controlHydraulic

Control systemsShift patternElectronicControl systemsShift qualityElectronic

Lock–up clutchElectronic

1st2.856

2nd1.618

Gear ratio3rd1.000

4th (O/D)0.723

Reverse2.000

Gear setNoiseless, high torque capability

Oil usedNameAT F D E X R O N–IIIOil usedQ’ty liter (qt)8.6 (9.1)

Torque converter2,100 150Stall speed (rpm)

Reverse clutchRC4

Second clutchC26Number of discsThird clutchC36Number of discs

Brake bandDouble wrap

Fourth clutchC42Number of discsOverrun clutchOC1Number of discs

OverdriveOFW10Number of rollers

PrincipalPFW26Number of sprags

Input sun gear30

Pinion gear19

Ravigneaux plan-Long pinion23g

etary gear setRing gear90

Long pinion19Number of teeth

Output sun gear46

Odi l

Sun gear31

Overdrive plane-

tary gear setPinion gear24tary gear set

Ring gear81

Page 2254 of 6000

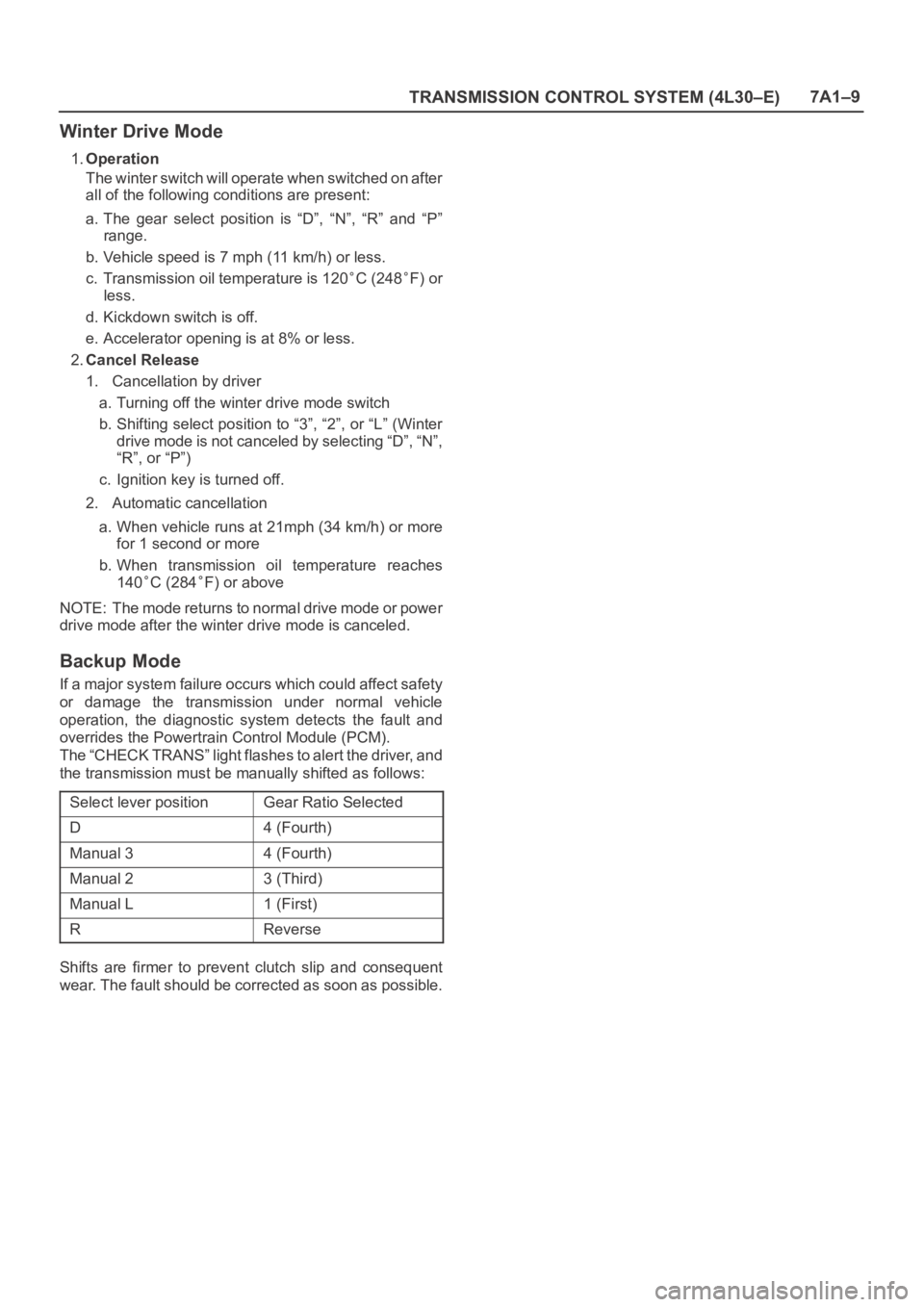

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–9

Winter Drive Mode

1.Operation

The winter switch will operate when switched on after

all of the following conditions are present:

a. The gear select position is “D”, “N”, “R” and “P”

range.

b. Vehicle speed is 7 mph (11 km/h) or less.

c. Transmission oil temperature is 120

C (248F) or

less.

d. Kickdown switch is off.

e. Accelerator opening is at 8% or less.

2.Cancel Release

1. Cancellation by driver

a. Turning off the winter drive mode switch

b. Shifting select position to “3”, “2”, or “L” (Winter

drive mode is not canceled by selecting “D”, “N”,

“R”, or “P”)

c. Ignition key is turned off.

2. Automatic cancellation

a. When vehicle runs at 21mph (34 km/h) or more

for 1 second or more

b. When transmission oil temperature reaches

140

C (284F) or above

NOTE: The mode returns to normal drive mode or power

drive mode after the winter drive mode is canceled.

Backup Mode

If a major system failure occurs which could affect safety

or damage the transmission under normal vehicle

operation, the diagnostic system detects the fault and

overrides the Powertrain Control Module (PCM).

The “CHECK TRANS” light flashes to alert the driver, and

the transmission must be manually shifted as follows:

Select lever position

Gear Ratio Selected

D4 (Fourth)

Manual 34 (Fourth)

Manual 23 (Third)

Manual L1 (First)

RReverse

Shifts are firmer to prevent clutch slip and consequent

wear. The fault should be corrected as soon as possible.

Page 2267 of 6000

7A1–22

TRANSMISSION CONTROL SYSTEM (4L30–E)

connection or loose wiring. Terminals and grounds should

always be the prime suspect. Intermittents rarely occur

inside sophisticated electronic components such as the

PCM.

Use the DTC information to understand which wires and

sensors are involved.

When an intermittent problem is encountered, check

suspect circuits for:

1. Poor terminal to wire connection.

2. Terminals not fully seated in the connector body

(backed out).

3. Improperly formed or damaged terminals.

4. Loose, dirty, or corroded ground connections:

HINT: Any time you have an intermittent in more than

one circuit, check whether the circuits share a

common ground connection.

5. Pinched or damaged wires.

6. Electro–Magnetic Interference (EMI):

HINT: Check that all wires are properly routed away

from spark plug wires, distributor wires, coil, and

generator. Also check for improperly installed

electrical options, such as lights, 2–way radios, etc.Use the F3 SNAPSHOT mode of the Tech2 to help isolate

the cause of an intermittent fault. The snapshot mode will

record information before and after the problem occurs.

Set the snapshot to “trigger” on the suspect DTC. If you

notice the reported symptom during the test drive, trigger

the snapshot manually.

After the snapshot has been triggered, command the

Tech2 to play back the flow of data recorded from each of

the various sensors. Signs of an intermittent fault in a

sensor circuit are sudden unexplainable jump in data

values out of the normal range.

Transmission And PCM Identification

The chart below contains a list of all important information

concerning rear axle ratio, Powertrain Control Module

(PCM), and transmission identification.

VEHICLE

Rr axlePCMTRANSMISSION

Ty p eEngine

Rr axle

RatioISUZU Parts No.Calibration

CodeIsuzu Part No.Model Code

Isuzu /

Trooper3.2L V64.555

8–16254–949–0

8–16254–749–0

8–16253–989–0

G208–96018–272–3FP (4X4)

Page 2270 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–25

DTC P0218 Transmission Fluid Over Temperature

D07RW029

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a

thermister that controls the signal voltage to the PCM.

The PCM supplies a 5–volt reference to the sensor on

circuit RED/BLK–GRN/RED. When the transmission fluid

is cold, the sensor resistance is high and the PCM will

sense high signal voltage. As the fluid temperature

warms to a normal transmission operating temperature of

100

C (212F), the sensor resistance becomes less and

the voltage decreases to 1.5 to 2.0 volts.

This DTC detects a high transmission temperature for a

long period of time. This is a type “D” DTC.

Conditions For Setting The DTC

No TFT DTCs P0712 or P0713.

TFT is greater than 135C (275F).

All conditions met for 21 seconds.

Action Taken When The DTC Sets

Hot mode TCC Shift Pattern.

The PCM will not illuminate the CHECK TRANS

Lamp.

ATF Lamp ON. (TFT is greater than 145C (293F).)

Disable E–side TCC OFF request.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warm–up cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed, or

damaged terminals. Check for weak terminal tension

as well.

Also check for a chafed wire that could short to bare

metal or other wiring. Inspect for a broken wire inside

the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Check harness routing for a potential short to ground

in circuit RED/BLK–GRN/RED.

Scan tool TFT sensor temperature should rise

steadily to about 100

C (212F), then stabilize.

Check for a “skewed” (mis–scaled) sensor by

comparing the TFT sensor temperature to the

ambient temperature after a vehicle cold soak. A

“skewed” sensor can cause delayed garage shifts or

TCC complaints.

Check for a possible torque converter stator problem.

Verify customer driving habits, trailer towing, etc.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart.

3. This test checks for a “skewed” sensor or shorted

circuit.

4. This test simulates a TFT DTC P0713.

Page 2275 of 6000

7A1–30

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

D07RW031

Circuit Description

The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

lever position: P, R, N, D 3, 2 or L. The selector lever

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

The range switch is also used to provide the

information P or N to the engine crank wiring. The

engine can be cranked only if connector M–25

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

The range switch is also used to provide the backup

lamp power in reverse. This is why the range switch is

supplied through a 10A fuse (C–3). This fuse can

burn due to a short circuit in the backup lamp.

This DTC detects when a fuse is open or the range switch

circuit does not work. This is a type “D” DTC.

Conditions For Setting The DTC

Range switch illegal positions met for 5 seconds.

Action Taken When The DTC Sets

Default to D position.

Inhibit torque management.

Maximum line pressure.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Refer to accompanying chart for the normal range

signals and the illegal combinations.

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Page 2276 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–31

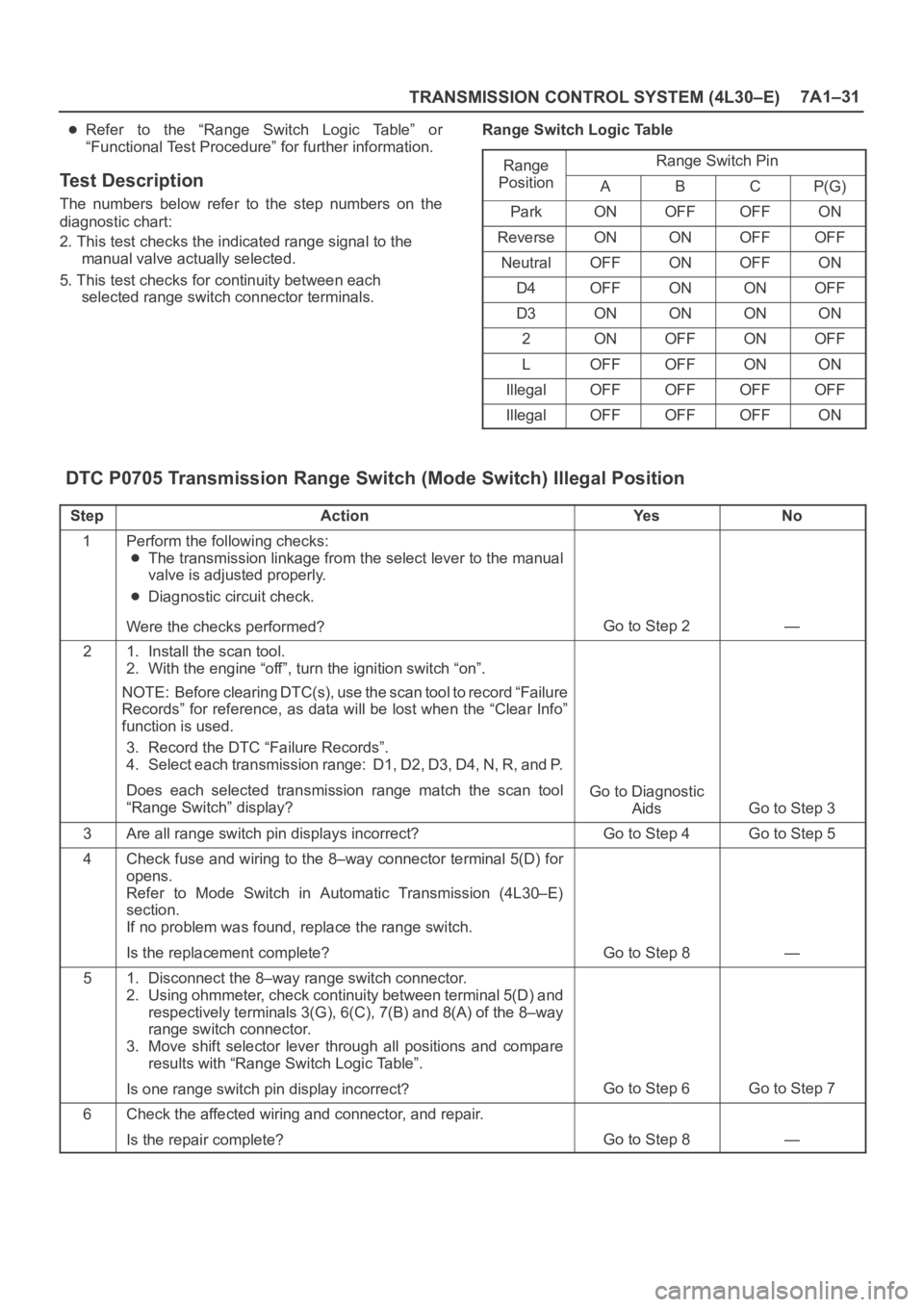

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.

5. This test checks for continuity between each

selected range switch connector terminals.Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—