ESP OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2014 of 6000

6E–121 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0341 —CMP Sensor Out of Synchro

StepNo Ye s Va l u e ( s ) Action

101. Check for poor connections at the ECM.

2. If a problem is found, repair it as necessary.

Was a problem found?

—Verify repairGo to Step 11

11Backprobe the ECM connector with a DVM to monitor

voltage on the camshaft position input signal circuit

while cranking the engine with the sensor connected.

(Use rubber band, tape, or an assistant to keep the

DVM lead in contact with the sensor terminal during this

test.)

Does the voltage toggle between the specified values?

4-0 VGo to Step 15Go to Step 12

121. Remove the CMP sensor from the engine front

cover (leave the sensor wiring connected).

2. Place a magnet on the CMP sensor.

(If you use a magnet that is too small to cover the face

of the sensor, test on every part of the sensor face

because only a small area will respond to this test.)

Does the DVM display a voltage near the specified

value?

0 VGo to Step 13Go to Step 14

13Replace the faulty or missing camshaft position sensor

magnet.

Is the action complete?

—Verify repair—

14Replace the camshaft position sensor.

Is the action complete?

—Verify repair—

15Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2017 of 6000

6E–124

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0342 —CMP Sensor No Signal

StepNo Ye s Va l u e ( s ) Action

81. Turn the ignition “OFF.”

2. Disconnect the ECM and connect a DVM to monitor

voltage on the camshaft position signal circuit at the

ECM connector.

3. Ignition “ON.”

4. Monitor the voltage display on the DVM while

repeatedly touching the CMP sensor signal circuit

at the CMP sensor connector with a test light to

ground.

Does the DVM voltage display switch between 0 and

approximately 5 volts when the test light is touched to

the CMP sensor signal circuit?

—Go to Step 12Go to Step 9

91. Ignition “OFF.”

2. Leave the ECM disconnected.

3. Ignition “ON.”

4. Probe the camshaft position signal circuit at the

ECM connector with a test light to B+.

5. If the test light is “ON,” locate and repair the short to

ground in the camshaft position input signal circuit.

Was either circuit shorted to ground?

—Verify repairGo to Step 10

101. Ignition “OFF.”

2. Leave the ECM disconnected.

3. Ignition “ON.”

4. Probe the camshaft position signal circuit with a test

light to ground.

5. If the test light is “ON,” locate and repair the short to

voltage in the camshaft position input signal circuit.

Was the test light “ON”?

—Verify repairGo to Step 11

111. Ignition “OFF,” disconnect the ECM (leave the CMP

sensor disconnected).

2. Ignition “ON,” check the following circuit:

The CMP sensor signal circuit for an open.

3. If a problem is found, repair it as necessary.

Was a problem found?

—Verify repair—

121. Ignition “ON.”

2. Remove the CMP sensor from the engine front

cover (leave the sensor wiring connected).

3. Place a magnet on the CMP sensor. If you use a

magnet that is too small to cover the face of the

sensor, test on every part of the sensor face

because only a small area will respond to this test.

Does the DVM display a voltage near the specified

value?

0 VGo to Step 14Go to Step 13

13Replace the camshaft position sensor.

Is the action complete?

—Verify repair—

141. Reinstall the CMP sensor to the engine front cover.

2. Observe the DVM connected to monitor voltage on

the camshaft position signal circuit while cranking

the engine.

Does the voltage toggle between the specified values?

4-0 VGo to Step 15Go to Step 16

Page 2023 of 6000

6E–130

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1403 (Flash DTC 32)

EGR EVRV Fault

060RW135

Circuit Description

EGR EVRV Circuit has a common power source in

parallel with EGR, VSV, RPCV, and Intake Throttle Motor.

This may cause multiple DTCs. On such occasion, refer

to “Multiple ECM Information sensor DTCs Set”.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged EVRV – Inspect the

wiring harness for damage.

Ensure EVRV is correctly mounted. See On-Vehicle

Service.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart

3. A malfunctioning MAP sensor can set an EGR DTC.

The MAP sensor could send a constant signal which

is not low enough to set a low MAP DTC. The

constant signal from the MAP sensor also may not

be high enough to set a high MAP DTC. This step

verifies that the MAP sensor is responding.

Page 2025 of 6000

6E–132

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1404 (Flash DTC 31)

EGR VSV Circuit

060RW135

Circuit Description

The Engine control module (ECM) monitors the EGR

valve input to ensure that the valve responds properly to

commands from the ECM, and to detect a fault if VSV is

stuck open. When the VSV is fixing at closed and opening

the ECM will set DTC P1404.

Diagnostic Aids

Check for the following conditions:

Poor connection or damaged VSV–inspect the wiring

harness for damage.

DTC P1404 – EGR VSV Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON”, engine “OFF”, review and record

scan tool Failure Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a scan tool, monitor “Specific DTC” info for

DTC P1404 until the DTC P1404 test runs. Note the

result.

Does the scan tool indicates DTC P1404 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

Page 2119 of 6000

6E–226

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

0018

Manifold Absolute Pressure (MAP) Sensor

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure. The MAP sensor

signal voltage to the ECM varies from below 2 volts at idle

(high vacuum) to above 4 volts.

The MAP sensor is used to determine the following:

Boost pressure for injector control.

Barometric pressure (BARO).

If the ECM detects a voltage that is lower than the

possible range of the MAP sensor, DTC P0107 will be set.

A signal voltage higher than the possible range of the

sensor will set DTC P0108. An intermittent low or high

voltage will set DTC P1107 or DTC P1106, respectively.

The ECM can detect a shifted MAP sensor. The ECM

compares the MAP sensor signal to a calculated MAP

based on throttle position and various engine load factors.

If the ECM detects a MAP signal that varies excessively

above or below the calculated value, DTC P0106 will set.

Engine Control Module (ECM)

The engine control module (ECM) is located in the engine

room.

The ECM constantly observes the information from

various sensors. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. It can recognize

operational problems, alert the driver through the MIL

(Service Engine Soon lamp), and store diagnostic trouble

codes (DTCs). DTCs identify the problem areas to aid the

technician in making repairs.

ECM Function

The ECM supplies 5, 12 and 110 volts to power various

sensors or switches. The power is supplied through

resistances in the ECM which are so high in value that a

test light will not light when connected to the circuit. In

some cases, even an ordinary shop voltmeter will not give

an accurate reading because its resistance is too low.

Therefore, a digital voltmeter with at least 10 megohms

input impedance is required to ensure accurate voltage

readings. The ECM controls output circuits such as theinjectors, glow relays, etc., by controlling the ground or

the power feed circuit through transistors or through

either of the following two devices:

Output Driver Module (ODM)

Quad Driver Module (QDM)

ECM Components

The ECM is designed to maintain exhaust emission levels

to government mandated standards while providing

excellent driveability and fuel efficiency. The ECM

monitors numerous engine and vehicle functions via

electronic sensors such as the crankshaft position (CKP)

sensor, and vehicle speed sensor (VSS). The ECM also

controls certain engine operations through the following:

Fuel injector control

Rail pressure control

ECM Voltage Description

The ECM supplies a buffered voltage to various switches

and sensors. It can do this because resistance in the

ECM is so high in value that a test light may not illuminate

when connected to the circuit. An ordinary shop

voltmeter may not give an accurate reading because the

voltmeter input impedance is too low. Use a 10-megohm

input impedance digital voltmeter to assure accurate

voltage readings.

The input/output devices in the ECM include

analog-to-digital converters, signal buffers, counters,

and special drivers. The ECM controls most components

with electronic switches which complete a ground circuit

when turned “ON.” These switches are arranged in

groups of 4 and 7, called either a surface-mounted quad

driver module (QDM), which can independently control up

to 4 output terminals, or QDMs which can independently

control up to 7 outputs. Not all outputs are always used.

ECM Input/Outputs

Inputs – Operating Conditions Read

Air Conditioning “ON” or “OFF”

Engine Coolant Temperature

Crankshaft Position

Electronic Ignition

Manifold Absolute Pressure

Battery Voltage

Intake Throttle Position

Vehicle Speed

Fuel Temperature

Oil Temperature

Intake Air Temperature

EGR boost pressure

Oil rail pressure

Camshaft Position

Accelerator position

Outputs – Systems Controlled

Exhaust Gas Recirculation (EGR)

Injector Control

QWS

Page 2126 of 6000

ENGINE EXHAUST 6F – 3

ON-VEHICLE SERVICE

FRONT EXHAUST PIPE

Rattles and noise vibrations in the exhaust system are

usually caused by misalignment of parts. When aligning

the system, leave all bolts or nuts loose until all parts

are properly aligned; then tighten, working from front to

rear.

1. Check connections for looseness or damage,

especially for exhaust gas leakage.

2. Check clamps and rubbers for weakness, cracks or

damage.3. If any part of the converter heat shield is damaged

or dented to the extent that it contacts the catalyst,

repair or replace.

4. Check for dents or damage and for any holes or

cracks caused by corrosion.

3

2 1

Legend

(1) Front exhaust pipe

(2) Center exhaust pipe

(3) Mounting rubber

150RW071

Page 2181 of 6000

7A–27 AUTOMATIC TRANSMISSION (4L30–E)

Changing Transmission Fluid

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A. Repeated short trips

B. Driving on rough roads

C. Driving on dusty roads

D. Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km.)

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge the

right time for ATF replacement.

The remaining life percentage is calculated from ATF’S

heat history. When it is close to 0%, ATF replacement is

recommended.

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw (2) and drain

fluid.

3. Tighten drain screw (2).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

4. Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON

–III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached.6. Add transmission fluid until it flows out over the overfill

screw opening, then close the overfill screw (1).

To r q u e : 3 8 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

242RW003

Selector Lever

Inspection

1. Make sure that when the shifter control lever is shifted

from “P” to “L”, a “clicking” can be felt at each shift

position. Make sure that the gear corresponds to that

of the position plate indicator.

2. Check to see if the shifter lever can be shifted as

shown in illustration.

C07RW009

Page 2190 of 6000

7A–36

AUTOMATIC TRANSMISSION (4L30–E)

Solenoid (Main Case Valve Body)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Remove transfer and exhaust protectors.

4. Drain fluid.

5. Remove exhaust pipe and disconnect oxygen sensor

connector.

6. Support transfer case with a jack and remove third

crossmember.

7. Remove sixteen 10 mm screws, main case oil pan,

magnet, and gasket.

8. Remove three 13 mm screws, oil filter.

9. Disconnect wiring harness from band control

solenoid and shift solenoids. Pull only on connectors,

not on wiring harness.

10. Remove spring pin for shift solenoid A, shift solenoid

B, and band control solenoid respectively, using

suitable pliers taking care not to damage solenoids.

210RW010

244RW003

11. Remove shift solenoid A, shift solenoid B, band

control solenoid, and gaskets from main case valve

body. Do not pull on wiring harness. Remove

solenoids by grasping the metal tip.

Installation

1. Install shift solenoid A, shift solenoid B, band control

solenoid with new gaskets to main case valve body

respectively.

2. Carefully install spring pin with hammer to avoid

damage to valve body, etc.

243RW004

3. Connect wiring harness to solenoids.

4. Install oil filter with a new gasket and the three 13 mm

screws. Tighten the screws to the specified torque.

To r q u e : 2 0 N

m (2.0 kgꞏm/15 lb ft)

5. Install magnet, main case oil pan with new gasket,

sixteen 10 mm screws. Tighten the screws to the

specified torque.

To r q u e : 11 N

m (1.1 kgꞏm/96 lb in)

6. Install third crossmember and rear mount nuts.

Tighten the nuts and bolts to the specified torque.

Third crossmember bolt: 50 N

m

(5.1 kgꞏm/37 lb ft)

Rear mount nut: 50 N

m (5.1 kgꞏm/37 lb ft)

7. Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque:

43 N

m(4.4kgꞏm/32lbft)

8. Install the transfer and exhaust protectors. Tighten

the bolts to the specified torque.

Torque: 37 N

m (3.8 kgꞏm/27 lb ft)

9. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

10. Connect the battery ground cable.

Page 2266 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–21

NOTE: To use the DTC again to identify a problem, you

will need to reproduce the fault or the problem. This may

require a new test drive or just turning the ignition on (this

depends on the nature of the fault).

1. IF you have a Tech2:

1. Connect the Tech2 if it is still not connected

GOTHROUGH Tech2 OBD II CONNECTION.

2. Push “F4” and answer “Yes” to the question “Do

you really want to clear the codes?”

a. When a malfunction remains as it is the Tech2

displays “4L30E CODES NOT CLEARED”. This

means that the problem is still there or that the

recovery was not done. Please GOTO DTC

CHECK.

b. When a malfunction has been repaired and the

recovery is done. The Tech2 displays “4L30E

CODES CLEARED”.

2. IF you have no Tech2:

To clear the DTC, remove Fuse “Stop, A/T CONT”

(C–14, 15A) for at least 10 seconds.

DTC Check

1. Diagnostic Trouble Codes (DTC) have been identified

by Tech2.

2. You have written the list of the DTCs. The order of the

malfunctions has no meanings for this PCM. Usually

only one or two malfunctions should be set for a given

problem.

3. Check directly the DTCs you identified. The DTCs are

sorted by number. Refer to Diagnostic Trouble Code

(DTC) Identification in this section.

PCM Precaution

The PCM can be damaged by:

1. Electrostatic discharge

2. The short circuit of some terminals to voltage or to

ground.

Electrostatic Discharge Damage Description:

1. Electronic components used to control systems are

often designed to carry very low voltage, and are very

susceptible to damage caused by electrostatic

discharge. It is possible for less than 100 volts of

static electricity to cause damage to some electronic

components. By comparison, it takes as much as

4,000 volts for a person to even feel the zap of a static

discharge.2. There are several ways for a person to become

statically charged. The most common methods of

charging are by friction and induction. An example of

charging by friction is a person sliding across a car

seat, in which a charge of as much as 25,000 volts

can build up. Charging by induction occurs when a

person with well insulated shoes stands near a highly

charged object and momentarily touches ground.

Charges for the same polarity are drained off, leaving

the person highly charged with the opposite polarity.

Static charges of either type can cause damage,

therefore, it is important to use care when handling

and testing electronic components.

NOTICE: To prevent possible electrostatic

discharge damage:

1. Do not touch the PCM connector pins or soldered

components on the PCM circuit board.

2. Be sure to follow the guidelines listed below if

servicing any of these electronic components:

3. Do not open the replacement part package until it is

time to install the part.

4. Avoid touching electrical terminals of the part.

5. Before removing the part from its package, ground

the package to a known good ground on the vehicle.

6. Always touch a known good ground before handling

the part. This step should be repeated before

installing the part if the part has been handled while

sliding across the seat, while sitting down from a

standing position or while walking some distance.

Information On PCM

1. The Powertrain Control Module (PCM) is located in

the center console and is the control center of the

electronic transmission control system.

2. The PCM must be maintained at a temperature below

185

F (85C) at all times. This is most essential if the

vehicle is put through a paint baking process. The

PCM will become inoperative if its temperature

exceeds 85

C (185F). Therefore, it is

recommended that the PCM be removed or that

temporary insulation be placed around the PCM

during the time the vehicle is in a paint oven or other

high temperature process.

3. The PCM is designed to process the various inputs

and then respond by sending the appropriate

electrical signals to control transmission upshift,

downshift, shift feel and torque converter clutch

engagement.

4. The PCM constantly interprets information from the

various sensors, and controls the systems that affect

transmission and vehicle performance. By analyzing

operational problems, the PCM is able to perform a

diagnostic function by displaying DTC(s) and aid the

technician in making repairs.

Intermittent Conditions

If the Tech2 displays a diagnostic trouble code as

intermittent, or if after a test drive a DTC does not

reappear though the detection conditions for this DTC are

present, the problem is most likely a faulty electrical

Page 2276 of 6000

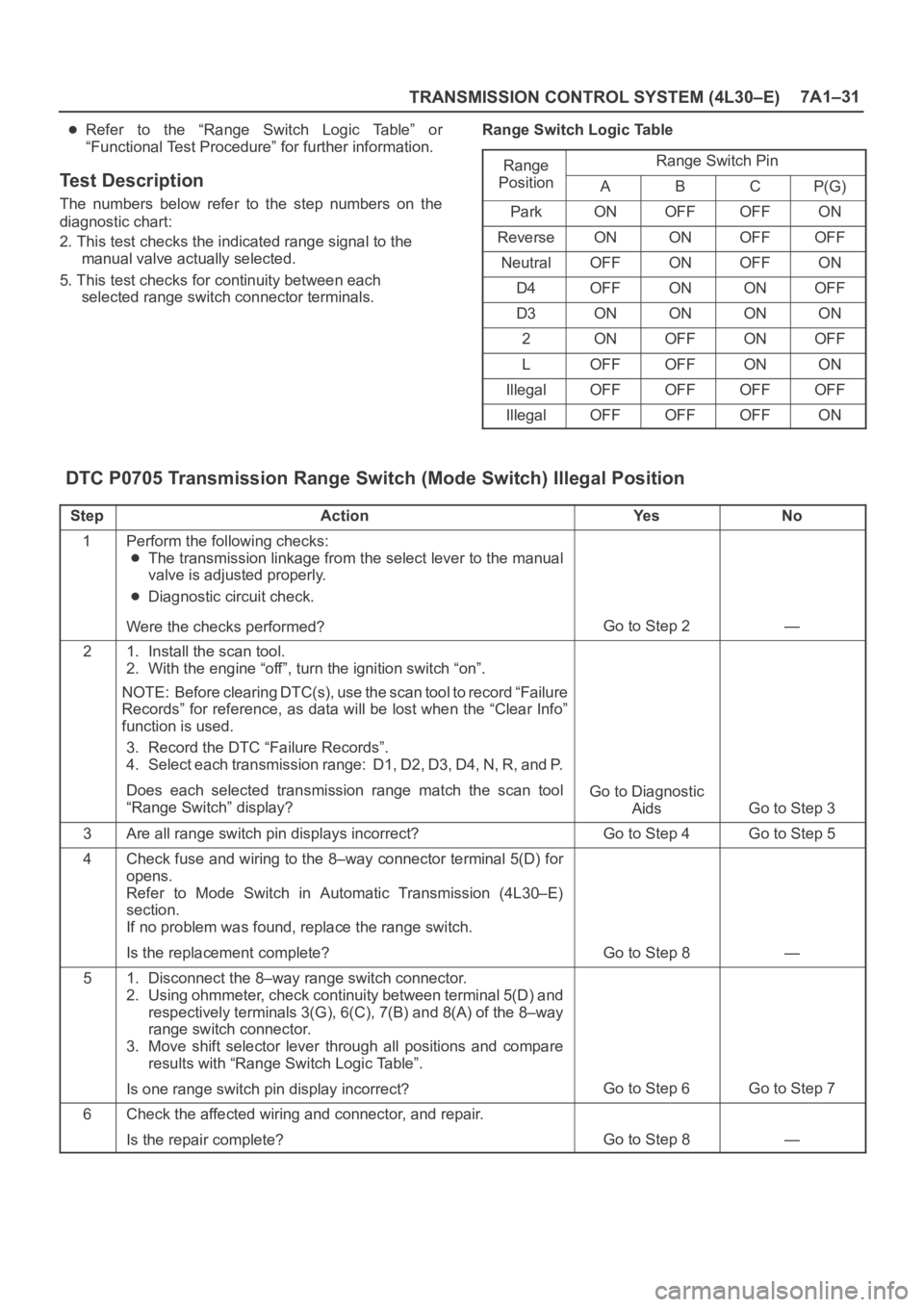

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–31

Refer to the “Range Switch Logic Table” or

“Functional Test Procedure” for further information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.

5. This test checks for continuity between each

selected range switch connector terminals.Range Switch Logic Table

Range

Range Switch Ping

PositionABCP(G)

ParkONOFFOFFON

ReverseONONOFFOFF

NeutralOFFONOFFON

D4OFFONONOFF

D3ONONONON

2ONOFFONOFF

LOFFOFFONON

IllegalOFFOFFOFFOFF

IllegalOFFOFFOFFON

DTC P0705 Transmission Range Switch (Mode Switch) Illegal Position

StepActionYe sNo

1Perform the following checks:

The transmission linkage from the select lever to the manual

valve is adjusted properly.

Diagnostic circuit check.

Were the checks performed?

Go to Step 2—

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Select each transmission range: D1, D2, D3, D4, N, R, and P.

Does each selected transmission range match the scan tool

“Range Switch” display?

Go to Diagnostic

Aids

Go to Step 3

3Are all range switch pin displays incorrect?Go to Step 4Go to Step 5

4Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete?

Go to Step 8—

51. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectively terminals 3(G), 6(C), 7(B) and 8(A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table”.

Is one range switch pin display incorrect?

Go to Step 6Go to Step 7

6Check the affected wiring and connector, and repair.

Is the repair complete?

Go to Step 8—