Gas OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1180 of 6000

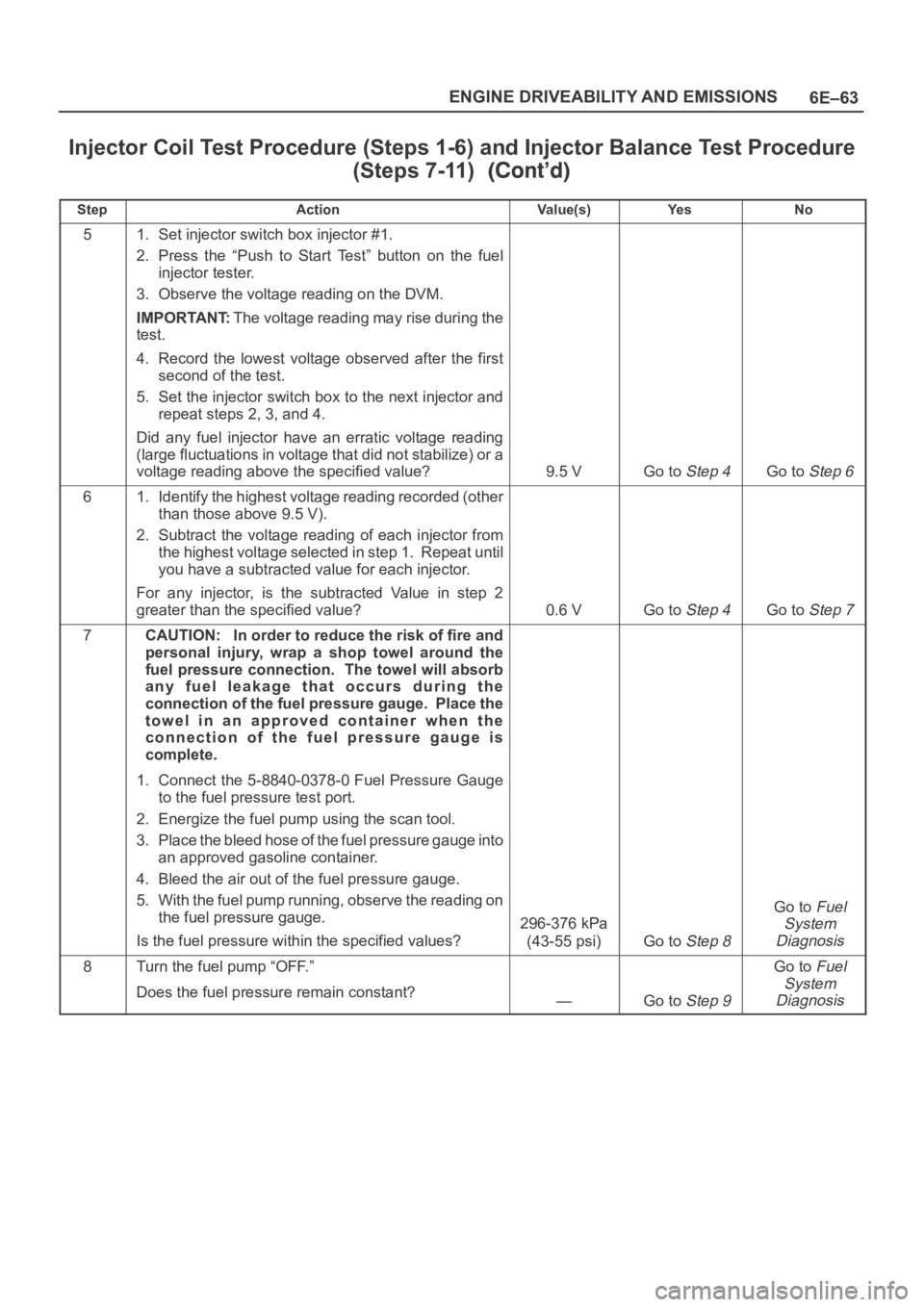

6E–63 ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepNo Ye s Va l u e ( s ) Action

51. Set injector switch box injector #1.

2. Press the “Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT:The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading above the specified value?

9.5 VGo to Step 4Go to Step 6

61. Identify the highest voltage reading recorded (other

than those above 9.5 V).

2. Subtract the voltage reading of each injector from

the highest voltage selected in step 1. Repeat until

you have a subtracted value for each injector.

For any injector, is the subtracted Value in step 2

greater than the specified value?

0.6 VGo to Step 4Go to Step 7

7CAUTION: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the

fuel pressure connection. The towel will absorb

any fuel leakage that occurs during the

connection of the fuel pressure gauge. Place the

towel in an approved container when the

connection of the fuel pressure gauge is

complete.

1. Connect the 5-8840-0378-0 Fuel Pressure Gauge

to the fuel pressure test port.

2. Energize the fuel pump using the scan tool.

3. Place the bleed hose of the fuel pressure gauge into

an approved gasoline container.

4. Bleed the air out of the fuel pressure gauge.

5. With the fuel pump running, observe the reading on

the fuel pressure gauge.

Is the fuel pressure within the specified values?

296-376 kPa

(43-55 psi)

Go to Step 8

Go to Fuel

System

Diagnosis

8Turn the fuel pump “OFF.”

Does the fuel pressure remain constant?

—Go to Step 9

Go to Fuel

System

Diagnosis

Page 1182 of 6000

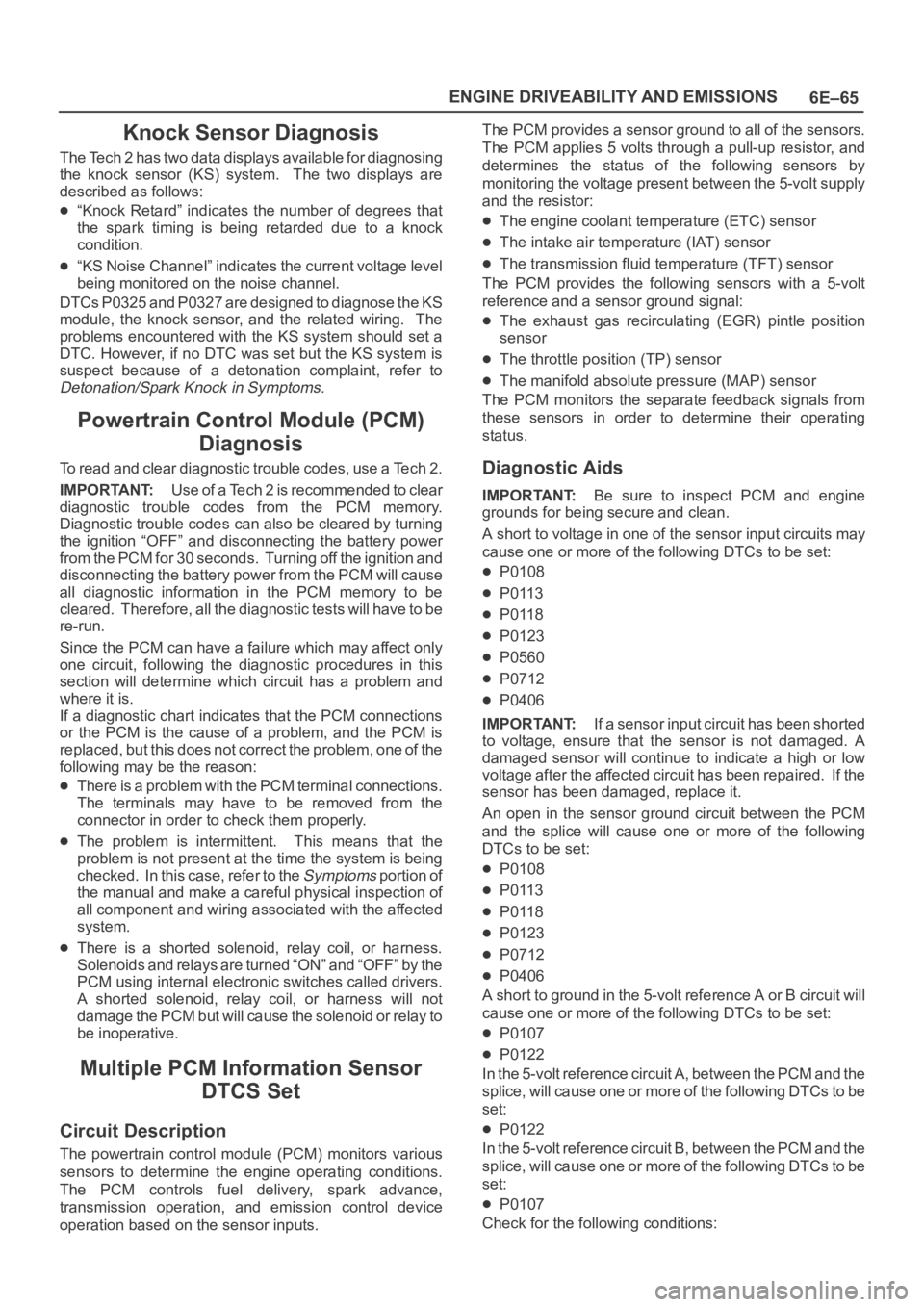

6E–65 ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor Diagnosis

The Tech 2 has two data displays available for diagnosing

the knock sensor (KS) system. The two displays are

described as follows:

“Knock Retard” indicates the number of degrees that

the spark timing is being retarded due to a knock

condition.

“KS Noise Channel” indicates the current voltage level

being monitored on the noise channel.

DTCs P0325 and P0327 are designed to diagnose the KS

module, the knock sensor, and the related wiring. The

problems encountered with the KS system should set a

DTC. However, if no DTC was set but the KS system is

suspect because of a detonation complaint, refer to

Detonation/Spark Knock in Symptoms.

Powertrain Control Module (PCM)

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

There is a problem with the PCM terminal connections.

The terminals may have to be removed from the

connector in order to check them properly.

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms p o r t i o n o f

the manual and make a careful physical inspection of

all component and wiring associated with the affected

system.

There is a shorted solenoid, relay coil, or harness.

S o l e n o i d s a n d r e l a y s a r e t u r n e d “ O N ” a n d “ O F F ” b y t h e

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay to

be inoperative.

Multiple PCM Information Sensor

DTCS Set

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

The engine coolant temperature (ETC) sensor

The intake air temperature (IAT) sensor

The transmission fluid temperature (TFT) sensor

The PCM provides the following sensors with a 5-volt

reference and a sensor ground signal:

The exhaust gas recirculating (EGR) pintle position

sensor

The throttle position (TP) sensor

The manifold absolute pressure (MAP) sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

IMPORTANT:Be sure to inspect PCM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

P0108

P0113

P0118

P0123

P0560

P0712

P0406

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

P0108

P0113

P0118

P0123

P0712

P0406

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

P0107

P0122

In the 5-volt reference circuit A, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0122

In the 5-volt reference circuit B, between the PCM and the

splice, will cause one or more of the following DTCs to be

set:

P0107

Check for the following conditions:

Page 1185 of 6000

6E–68

ENGINE DRIVEABILITY AND EMISSIONS

Exhaust Gas Recirculation (EGR)

Diagnosis (For except EXPORT and

SOUTH AFRICA)

Pintle position error diagnosis is covered by DTC P0402,

P0404, P1404, P0405, P0406. If EGR diagnostic trouble

codes P0402, P0404, P1404, P0405, P0406 are

encountered, refer to the DTC charts.

Engine Tech 2 Data Definitions and

Ranges

A/C CLUTCH – Tech 2 Displays ON or OFF –

Indicates whether the PCM has commanded the A/C

clutch ON. Used in A/C system diagnostic.

A/C REQUEST — Tech 2 Displays YES or NO —

Indicates the state of the A/C request input circuit from the

HVAC controls. The PCM uses the A/C request signal to

determine whether A/C compressor operation is being

requested.

AIR/FUEL RATIO — Tech 2 Range 0.0-25.5 —

Air/fuel ratio indicates the PCM commanded value. In

closed loop, the air/fuel ratio should normally be

displayed around “14.2-14.7.” A lower air/fuel ratio

indicates a richer commanded mixture, which may be

seen during power enrichment or TWC protection modes.

A higher air/fuel ratio indicates a leaner commanded

mixture. This can be seen during deceleration fuel mode.

BAROMETRIC PRESSURE — Tech 2 Range 10-105

kPa/0.00-5.00 Volts —

The barometric pressure reading is determined from the

MAP sensor signal monitored during key up and wide

open throttle (WOT) conditions. The barometric pressure

is used to compensate for altitude differences and is

normally displayed around “61-104” depending on

altitude and barometric pressure.

CHECK TRANS LAMP — AUTO TRANSMISSION —

Indicates the need to check for a DTC with the Tech 2

when the lamp is flashing 0.2 seconds ON and 0.2

seconds OFF.

CMP ACT. COUNTER – Cam Position Activity

DECEL FUEL MODE — Tech 2 Display ACTIVE or

INACTIVE —

“ACTIVE” displayed indicates that the PCM has detected

conditions appropriate to operate in deceleration fuel

mode. The PCM will command the deceleration fuel

mode when it detects a closed throttle position while the

vehicle is traveling over 20 mph. While in the deceleration

fuel delivered by entering open loop and decreasing the

injector pulse width.

DESIRED EGR POS. — Tech 2 Range 0%-100% —

Represents the EGR pintle position that the PCM is

commanding.

DESIRED IDLE — Tech 2 Range 0-3187 RPM —

The idle speed that the PCM is commanding. The PCM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.ECT — (Engine Coolant Temperature) Tech 2

Range –40

C to 151C (–40F to 304F) —

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the PCM. The PCM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as temperature changes.

When the sensor is cold (high resistance), the PCM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the PCM will interpret

the lower voltage as a warm engine.

EGR DUTY CYCLE — Tech 2 Range 0%-100% —

Represents the EGR valve driver PWM signal from the

PCM. A duty cycle of 0% indicates that no EGR flow is

being commanded; a 100% duty cycle indicates

maximum EGR flow commanded.

EGR FEEDBACK — Tech 2 Range 0.00-5.00 Volts —

Indicates the EGR pintle position sensor signal voltage

being monitored by the PCM. A low voltage indicates a

fully extended pintle (closed valve); a voltage near 5 volts

indicates a retracted pintle (open valve).

ENGINE LOAD — Tech 2 Range 0%-100% —

Engine load is calculated by the PCM from engine speed

and MAF sensor readings. Engine load should increase

with an increase in RPM or air flow.

ENGINE RUN TIME — Tech 2 Range

00:00:00-99:99:99 Hrs:Min:Sec —

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED — Range 0-9999 RPM —

Engine speed is computed by the PCM from the 58X

reference input. It should remain close to desired idle

under various engine loads with engine idling.

FUEL PUMP — Tech 2 Displays ON or OFF —

Indicates the PCM commanded state of the fuel pump

relay driver circuit.

FUEL TRIM CELL — Tech 2 Range 0-21 —

The fuel trim cell is dependent upon engine speed and

MAF sensor readings. A plot of RPM vs. MAF is divided

into 22 cells. Fuel trim cell indicates which cell is currently

active.

FUEL TRIM LEARN — Tech 2 Displays NO or YES

—

When conditions are appropriate for enabling long term

fuel trim corrections, fuel trim learn will display “YES.”

This indicates that the long term fuel trim is responding to

the short term fuel trim. If the fuel trim learn displays

“NO,” then long term fuel trim will not respond to changes

in short term fuel trim.

HO2S BANK 1, SEN. 1 — Tech 2 Range 0-1132 mV

—

Represents the fuel control exhaust oxygen sensor

output voltage. Should fluctuate constantly within a range

between 10 mV (lean exhaust) and 1000 mV (rich

exhaust) while operating in closed loop.

Page 1199 of 6000

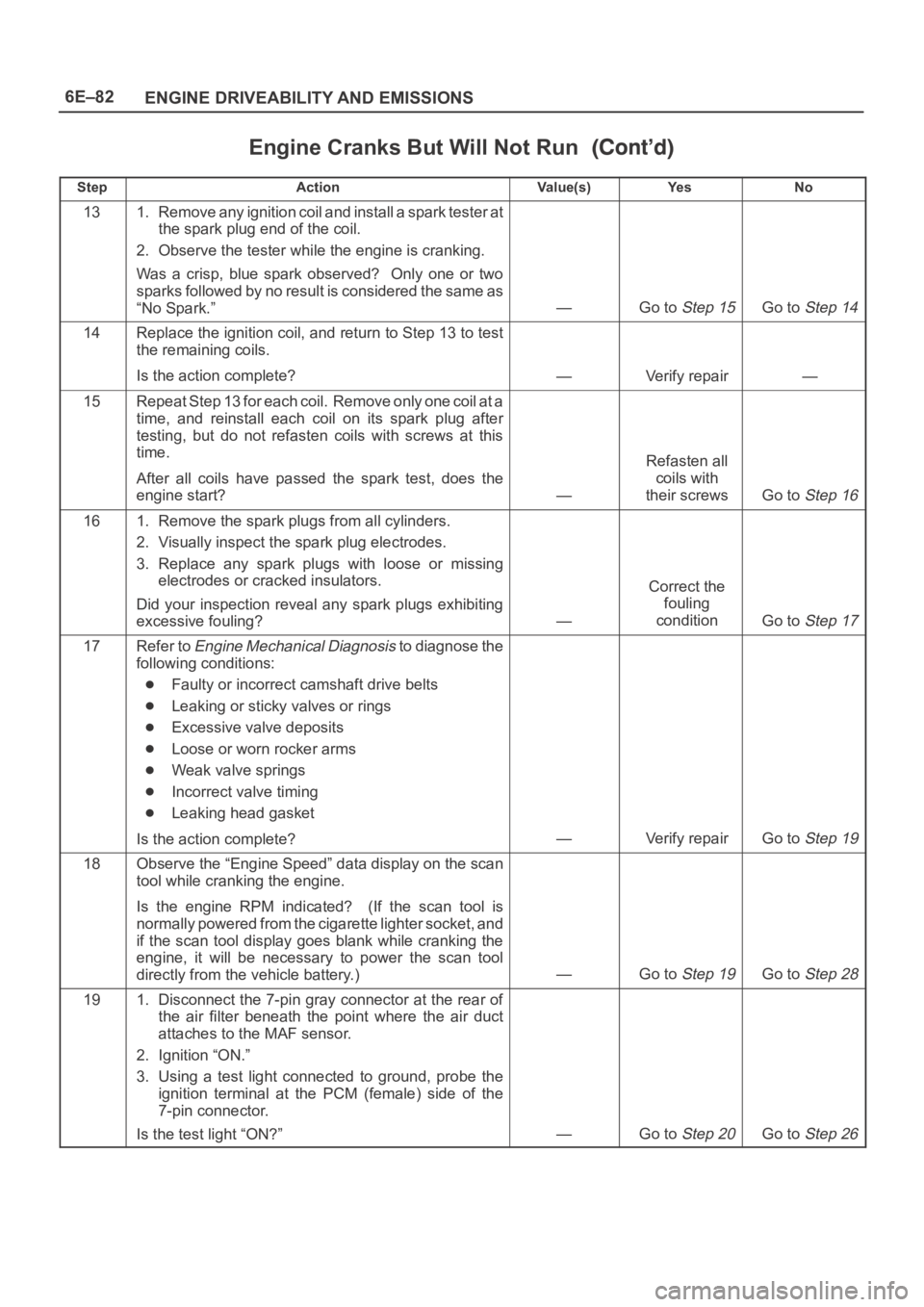

6E–82

ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

StepNo Ye s Va l u e ( s ) Action

131. Remove any ignition coil and install a spark tester at

the spark plug end of the coil.

2. Observe the tester while the engine is cranking.

Was a crisp, blue spark observed? Only one or two

sparks followed by no result is considered the same as

“No Spark.”

—Go to Step 15Go to Step 14

14Replace the ignition coil, and return to Step 13 to test

the remaining coils.

Is the action complete?

—Verify repair—

15Repeat Step 13 for each coil. Remove only one coil at a

time, and reinstall each coil on its spark plug after

testing, but do not refasten coils with screws at this

time.

After all coils have passed the spark test, does the

engine start?

—

Refasten all

coils with

their screws

Go to Step 16

161. Remove the spark plugs from all cylinders.

2. Visually inspect the spark plug electrodes.

3. Replace any spark plugs with loose or missing

electrodes or cracked insulators.

Did your inspection reveal any spark plugs exhibiting

excessive fouling?

—

Correct the

fouling

condition

Go to Step 17

17Refer to Engine Mechanical Diagnosis to diagnose the

following conditions:

Faulty or incorrect camshaft drive belts

Leaking or sticky valves or rings

Excessive valve deposits

Loose or worn rocker arms

Weak valve springs

Incorrect valve timing

Leaking head gasket

Is the action complete?

—Verify repairGo to Step 19

18Observe the “Engine Speed” data display on the scan

tool while cranking the engine.

Is the engine RPM indicated? (If the scan tool is

normally powered from the cigarette lighter socket, and

if the scan tool display goes blank while cranking the

engine, it will be necessary to power the scan tool

directly from the vehicle battery.)

—Go to Step 19Go to Step 28

191. Disconnect the 7-pin gray connector at the rear of

the air filter beneath the point where the air duct

attaches to the MAF sensor.

2. Ignition “ON.”

3. Using a test light connected to ground, probe the

ignition terminal at the PCM (female) side of the

7-pin connector.

Is the test light “ON?”

—Go to Step 20Go to Step 26

Page 1208 of 6000

6E–91 ENGINE DRIVEABILITY AND EMISSIONS

Fuel System Diagnosis

StepNo Ye s Va l u e ( s ) Action

10Locate and repair the loss of vacuum to the fuel

pressure regulator.

Is the action complete?

—Verify repair—

11Replace the fuel pressure regulator.

Is the action complete?

—Verify repair—

121. Run the fuel pump with Tech 2.

2. After pressure has built up, turn off the pump and

clamp the supply hose shut with suitable locking

pliers.

Does the fuel pressure indicated by the fuel pressure

gauge remain constant?

—Go to Step 13Go to Step 15

13Visually inspect the fuel supply line and repair any

leaks.

Was a problem found?

—Verify repairGo to Step 14

14Remove the fuel tank and inspect for leaky hose or

in-tank fuel line.

Was a problem found?

—Verify repairGo to Step 8

151. If the pliers are still clamped to the fuel supply hose,

remove the locking pliers.

2. With suitable locking pliers, clamp the fuel return

line to prevent fuel from returning to the fuel tank.

3. Run the fuel pump with Tech 2.

4. After pressure has built up, remove power to the

pump.

Does the fuel pressure indicated by the fuel pressure

gauge remain constant?

—Go to Step 11Go to Step 16

16Locate and replace any leaking fuel injector(s).

Is the action complete?

—Verify repair—

17Is the fuel pressure indicated by the fuel pressure

gauge above the specified limit?376 kPa

(55 psi)

Go to Step 18Go to Step 21

181. Relieve the fuel pressure. Refer to the Fuel

Pressure Relief.

2. Disconnect the fuel return line from the fuel rail.

3. Attach a length of flexible hose to the fuel rail return

outlet passage.

4. Place the open end of the flexible hose into an

approved gasoline container.

5. Run the fuel pump with Tech 2.

6. Observe the fuel pressure indicated by the fuel

pressure gauge with the fuel pump running.

Is the fuel pressure within the specified limits?

290-376 kPa

(42-55 psi)

Go to Step 19Go to Step 20

19Locate and correct the restriction in the fuel return line.

Is the action complete?

—Verify repair—

20Visually and physically inspect the fuel rail outlet

passages for a restriction.

Was a restriction found?

—Verify repairGo to Step 11

21Is the fuel pressure indicated by the fuel pressure

gauge above the specified value?

0kPa (0psi)Go to Step 22Go to Step 23

Page 1214 of 6000

6E–97 ENGINE DRIVEABILITY AND EMISSIONS

Exhaust Gas Recirculation (EGR) System Check

D06RW106

Circuit Description

A properly operation exhaust gas recirculation (EGR)

system will directly affect the air/fuel requirements of the

engine. Since the exhaust gas introduced into the air/fuel

mixture is an inert gas (contains very little or no oxygen),

less fuel is required to maintain a correct air/fuel ratio.

Introducing exhaust gas into the combustion chamber

lowers combustion temperatures and reduces the

formation of oxides of nitrogen (NOx) in the exhaust gas.

Lower combustion temperatures also prevent detonation.

If the EGR pintle were to stay closed, the inert exhaust

gas would be replaced with air and the air/fuel mixture

would be leaner. The powertrain control module (PCM)

would compensate for the lean condition by adding fuel,

resulting in higher long term fuel trim values.

Diagnostic Aids

The EGR valve chart is a check of the EGR system. An

EGR pintle constantly in the closed position could cause

detonation and high emissions of NOx. It could also result

in high long term fuel trim values in the open throttle cell,

but not in the closed throttle cell. An EGR pintle

constantly in the open position would cause a rough idle.

Also, an EGR mounted incorrectly (rotated 180

) could

cause rough idle. Check for the following items:

EGR passages – Check for restricted or blocked EGR

passages.

Manifold absolute pressure sensor – A manifold

absolute pressure sensor may shift in calibration

enough to affect fuel delivery. Refer to

Manifold

Absolute Pressure Output Check.

Page 1215 of 6000

6E–98

ENGINE DRIVEABILITY AND EMISSIONS

Exhaust Gas Recirculation (EGR) System Check

StepActionVa l u e ( s )Ye sNo

1Check the EGR valve for looseness.

Is the EGR valve Loose?

—Go to Step 2Go to Step 3

2Tighten the EGR valve.

Is the action complete?

—Verify repair—

31. Place the transmission selector in Park or Neutral.

2. Start the engine and idle until warm.

3. Using Tech 2, command EGR “50% ON.”

Does the engine idle rough and lose RPMs?

—

EGR system

working

properly. No

problem

found.

Go to Step 4

41. Engine “OFF.”

2. Ignition “ON.”

3. Using a test light to ground, check the EGR harness

between the EGR valve and the ignition feed.

Does the test light illuminate?

—Go to Step 6Go to Step 5

5Repair the EGR harness ignition feed.

Was the problem corrected?

—Verify repairGo to Step 6

61. Remove the EGR valve.

2. Visually and physically inspect the EGR valve

pintle, valve passages and adapter for excessive

deposits, obstructions or any restrictions.

Does the EGR valve have excessive deposits,

obstructions or any restrictions?

—Go to Step 7Go to Step 8

7Clean or replace EGR system components as

necessary.

Was the problem corrected?

—Verify repairGo to Step 8

81. Ground the EGR valve metal case to battery (–).

2. Using Tech 2, command EGR “ON” and observe the

EGR valve pintle for movement.

Does the EGR valve pintle move according to

command?

—Go to Step 9

Go to DTC

P1406 chart

91. Remove the EGR inlet and outlet pipes from the

intake and exhaust manifolds.

2. Visually and physically inspect manifold EGR ports

and EGR inlet and outlet pipes for blockage or

restriction caused by excessive deposits or other

damage.

Do the manifold EGR ports or inlet and outlet pipes

have excessive deposits, obstructions, or any

restrictions?

—Go to Step 10

EGR system

working

properly. No

problem

found.

10Clean or replace EGR system components as

necessary.

Is the action complete?

—Verify repair—

Page 1229 of 6000

6E–112

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0107 MAP Sensor Circuit Low Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the ignition “ON,” engine

not running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the exhaust gas recirculation (EGR) flow

test diagnostic is being run (refer to

DTC P0401), to

determine engine vacuum level for some other

diagnostics and to determine barometric pressure

(BARO). The PCM monitors the MAP signals for voltages

outside the normal range of the MAP sensor. If the PCM

detects a MAP signal voltage that is excessively low, DTC

P0107 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running.

Throttle angle is above 1% if engine speed is less than

1000 RPM.

Throttle angle is above 2% if engine speed is above

1000 RPM.

The MAP sensor indicates manifold absolute pressure

at or below 11 kPa for a total of approximately 10

seconds over a 16-second period.

Ignition voltage more than 11 volts.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0107 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check for intermittent codes.

The MAP sensor shares a 5 Volt reference with the

Rough Road Sensor. If these codes are also set, it

could indicate a problem with the 5 Volt reference

circuit .

The MAP sensor shares a ground with the Rough Road

Sensor, the ECT sensor, and the Transmission Fluid

Temperature sensor.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

Page 1256 of 6000

6E–139 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0131 HO2S Circuit Low Voltage Bank 1

Sensor 1

060RW236

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal high and signal low circuits. When

measured with a 10 megaohm digital voltmeter, this may

display as low as 350 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when exhaust

is lean. The PCM constantly monitors the HO2S signal

during “closed loop” operation and compensates for a rich

or lean condition by decreasing or increasing injector

pulse width as necessary. If the Bank 1 HO2S 1 voltage

remains excessively low for an extended period of time,

DTC P0131 will be set.

Conditions for Setting the DTC

No related DTCs.

Vehicle is operating in “closed loop.”

Engine coolant temperature is above 60C (140F).

“Closed loop” commanded air/fuel ratio is between

14.5 and 14.8.

Throttle angle is between 3% and 19%.

Bank 1 HO2S 1 signal voltage remains below 22 mV

during normal “closed loop” operation for a total of 77

seconds over a 90-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0131 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Heated oxygen sensor wiring – The sensor pigtail may

be routed incorrectly and contacting the exhaust

system.

Poor PCM to engine block grounds.

Fuel pressure – The system will go lean if pressure is

too low. The PCM can compensate for some

decrease. However, If fuel pressure is too low, a DTC

P0131 may be set. Refer to

Fuel System Diagnosis.

Lean injector(s) – Perform “Injector Balance Test.”

Vacuum leaks – Check for disconnected or damaged

vacuum hoses and for vacuum leaks at the intake

manifold, throttle body, EGR system, and PCV system.

Exhaust leaks – An exhaust leak may cause outside air

to be pulled into the exhaust gas stream past the

Page 1265 of 6000

6E–148

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0151 HO2S Circuit Low Voltage Bank 2

Sensor 1

060RW190

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal high and signal low circuits. When

measured with a 10 megaohm digital voltmeter, this may

display as low as 320 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when exhaust

is lean. The PCM constantly monitors the HO2S signal

during “closed loop” operation and compensates for a rich

or lean condition by decreasing or increasing injector

pulse width as necessary. If the Bank 2 HO2S 1 voltage

remains excessively low for an extended period of time,

DTC P0151 will be set.

Conditions for Setting the DTC

No related DTCs.

The engine is operating in “closed loop.”

Engine coolant temperature is above 60C (140F).

“Closed loop” commanded air/fuel ratio is between

14.5 and 14.8.

Throttle angle is between 3% and 19%.

Bank 2 HO2S 1 signal voltage remains below 22 mV

during normal “closed loop” operation for a total of 77

seconds over a 90-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

DTC P0151 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Heated oxygen sensor wiring – The sensor pigtail may

be mispositioned and contacting the exhaust system.

Poor PCM to engine block grounds.

Fuel pressure – The system will go lean if pressure is

too low. The PCM can compensate for some

decrease. However, if fuel pressure is too low, a DTC

P0151 may be set. Refer to

Fuel System Diagnosis.

Lean injector(s) – Perform “Injector Balance Test.”

Vacuum leaks – Check for disconnected or damaged

vacuum hoses and for vacuum leaks at the intake

manifold, throttle body, EGR system, and PCV system.

Exhaust leaks – An exhaust leak may cause outside air

to be pulled into the exhaust gas stream past the

HO2S, causing the system to appear lean. Check for