engine OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 555 of 625

98-46 1973 OPEL SERVICE MANUAL

shut off vacuum pump. Open refrigerant control

valve and allow some refrigerant to enter system.

Locate and repair all leaks.

7. After evacuating for 15 minutes, add l/2 lb. of

refrigerant to system. Purge this

l/2 lb. and reevacu-

ate for 15 minutes. This second evacuation is to be

certain that as much contamination is removed from

the system as possible.

8. Only after evacuating as above, system is ready

for charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, till to proper level.

9. Close low pressure valve on charging station.

Fully open station refrigerant control valve and al-

low all liquid refrigerant to enter system. When full

charge of refrigerant has entered system, turn off

refrigerant control valve and close both hand shut-

off valves.

10. If full charge of refrigerant will not enter system,

close high pressure control and refrigerant control

valves. Start engine and run at low idle with com-

pressor operating. Crack refrigerant control valve

and low pressure control on station. Watch low side

gauge and keep gauge below 50 psi by regulating

refrigerant control valve. Closing valve will lower

pressure. This is to prevent liquid refrigerant from

reaching the compressor while the compressor is op-

erating. When required charge has entered system,

close refrigerant control valve and close low pressure

control.

11. System is now charged and should be perform-

ance- tested before removing gauges.

Adding Refrigerant

The following procedure should be used in adding

small amounts of refrigerant that may have been lost

by leaks or while opening system for servicing the

compressor. Before adding refrigerent to replace that

lost by leaks, check for evidence of oil loss and add

oil if necessary.

This procedure will only apply if the air inlet temper-

ature is above 70 degrees F. at the condenser.

1. Remove caps from compressor gauge fittings.

Attach gauge set to gauge fittings, making sure

adapter (J- 5420) is between low pressure gauge hose

and suction gauge fitting, and J-9459 is between high

pressure gauge hose and discharge gauge fitting.

2. Start engine, turn air conditioning temperature

control knob to full cold position, blower switch to

Max Hi. Operate for ten

(IO) minutes at 2000 RPM

to stabilize system.

3. Observe the refrigerant through the sight glasscover of receiver-dehydrator with the system operat-

ing,

IO see if there are any bubbles evident.

a. If no bubbles are evident, then bleed system slowly

through the discharge valve until bubbles appear in

the receiver-dehydrator. Add 1 lb. of refrigerant as

explained under “Charging the

ISystem”.b. If bubbles are visible in the receiver-dehydrator

with the temperature control krlob in the full cold

position and the blower at MAX speed, it indicates

a partial or complete plug in a line, a shortage of

refrigerant, or both. Correct condition. Add refriger-

ant

u~ntil the sight glass clears, then add another 1 lb.

of refrigerant.

4. Attach flexible hose from center fitting of gauge

set loosely to refrigerant drum or on disposable can

valvxs. Open high and low pressure valves on the

gauge set slightly to purge pressure gauge lines of air.

Tighten fitting of refrigerant drum or can when satis-

fied ihat all air has been removed from gauge lines.

Close (clockwise) both hand shut-off valves or gauge

set.5. Partially charge system.

REFRIGERANT DRUM METHOD:

A. Place pail containing hot water that does not have

a temperature exceeding 125 degrees F. on scales,

place refrigerant drum in pa” containing water, note

weig,ht and only open low pressure valve on gauge

set.B. Start engine, turn temperature control knob to full

cold position and place blower switch in Max Hi.

Operate engine for 10 minutes at 2000 RPM to sta-

bilize system.

C. With compressor operating, slowly open valve on

refrigerant drum and allow refrigerant to flow into

system (through manifold gauge set) until liquid in-

dicator clears up and immediately shut off valve ai

gauge set or on refrigerant drum. Check weight of

refrigerant drum and pail of water. Then slowly open

valve on gauge set (or refrigerant drum) and add one

more lb. of refrigerant. Note total amount of refriger-

ant added.

DISPOSABLE CAN METHOD:

A. Make sure the outlet valve on the J-6271 valve is

fully clockwise and attach the J-6271 to a 1 lb. can

of refrigerant by backing off the valve from the top

of the retainer, slipping the valve onto the can and

turning the valve into the retainer until tight. DO

NOT accidentally open outlet valve during this oper-

ation, as turning the valve into the retainer punctures

the top of the can to make it ready for charging.

.

Page 556 of 625

REFRIGERANT COMPONENTS ALL MODELS9a- 47

B. Connect center flexible line of gauge set to the

fitting on the valve.

C. Start engine, turn temperature control knob to full

cold position, set blower switch to Max Hi. Operate

engine for 10 minutes at 2000 RPM to stabilize sys-tem.D. With compressor operating, slowly open valve on

refrigerant can and allow refrigerant to flow into

system (through manifold gauge set) until liquid in-

dicator clears up and immediately shut off valve at

gauge set and on refrigerant can. Check weight of

can and valve assembly and record.

E. Add an additional 1 lb. of refrigerant by adding

refrigerant from the can just weighed until can is

empty. Attach another can and add refrigerant until

can and valve assembly weigh the same as recorded.

6. Close valves at refrigerant drum or

can,7. Test for leaks and make operational check of

system.

ADDING OIL TO THE SYSTEM (MAJOR

OVERHAUL)The oil in the refrigeration system does not remain

in the compressor during system operation, but cir-culates throughout the system. The compressor is

initially charged with 10 oz. of 525 viscosity oil.

After system has been in operation the oil content in

the compressor will vary depending on the engine

RPM and air conditioning load. At higher engine

RPM’s a lesser amount of oil will be retained in the

compressor reservoir. It is important that the total

system oil content does not vary from a total of10-l/2 oz. Excessive oil content will reduce cooling

capacity. Inadequate oil content may result in dam-

age to compressor moving parts.

The refrigeration system will not require adding of

oil unless there is an oil loss because of a ruptured

line, badly leaking compressor seal, replacement of

evaporator, compressor, receiver-dehydrator, or loss

due to a collision. Oil is generally added to the sys-

tem via the oil drain hole in the lower side of the

compressor for this condition. To add oil to the sys-

tem via the compressor, the compressor must be

removed. If no major loss of oil has occurred and a

component (condenser,receiver-dehydrator or

evaporator) is removed for servicing, the oil may be

added directly to the component. To add oil to a

component removed for servicing and when no ma-

jor loss has occurred, drain and measure oil in com-

ponent, then replace with a like amount. To add oil

to the system when a major loss of oil is evidenced,

or when the compressor is being serviced, remove

compressor, drain and measure oil, and replace oil

amount specified in the Oil Replacement Table.

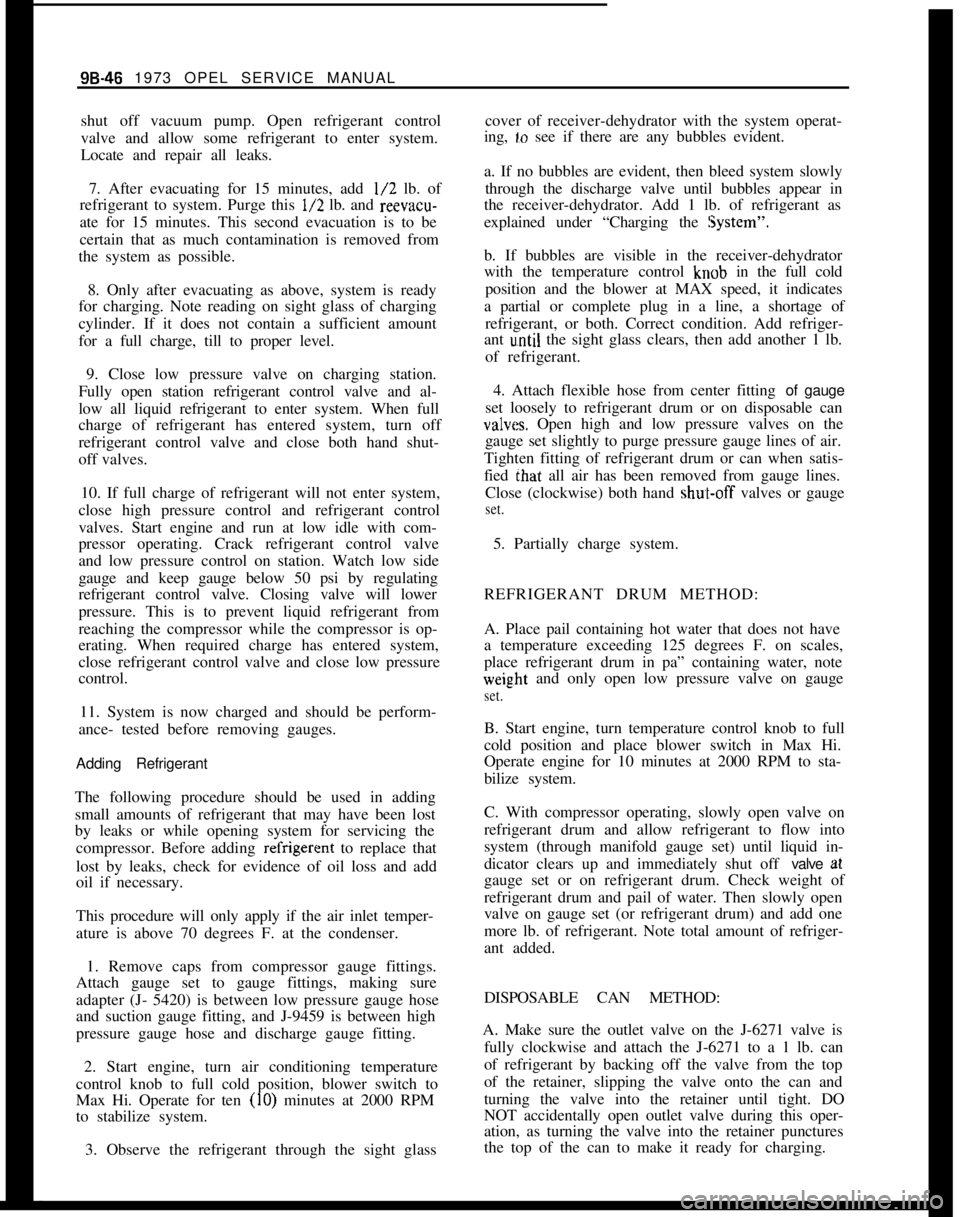

OIL REP,‘LACEMENT TABLE

Condition

1. Major loss of oil and

a component (conden-

ser, receiver-dehydra-

tor, or evaporator)

has to be replaced.

Amount of Oil Drained

From Compressora. More than 4 oz.Amount of 525 Oil to Install

In Compressora. Amount drained from compressor,

plus amount for component

being replaced.

Evaporator

- Add 2 oz.

Condenser

- Add I oz.

Receiver-Dehydrator

- Add 1 oz.

b. Less than 4 oz.b. Install 6 oz., plus amount for

component being replaced as

shown above.

2. Compressor being

replaced with a

ser-vice replacement

compressor

- no major

oil loss.a. More than 1

l/2 oz.a. Same amount as drained from

compressor being replaced.

b. Less than 1

l/2 oz.b. Install 6 oz

Page 557 of 625

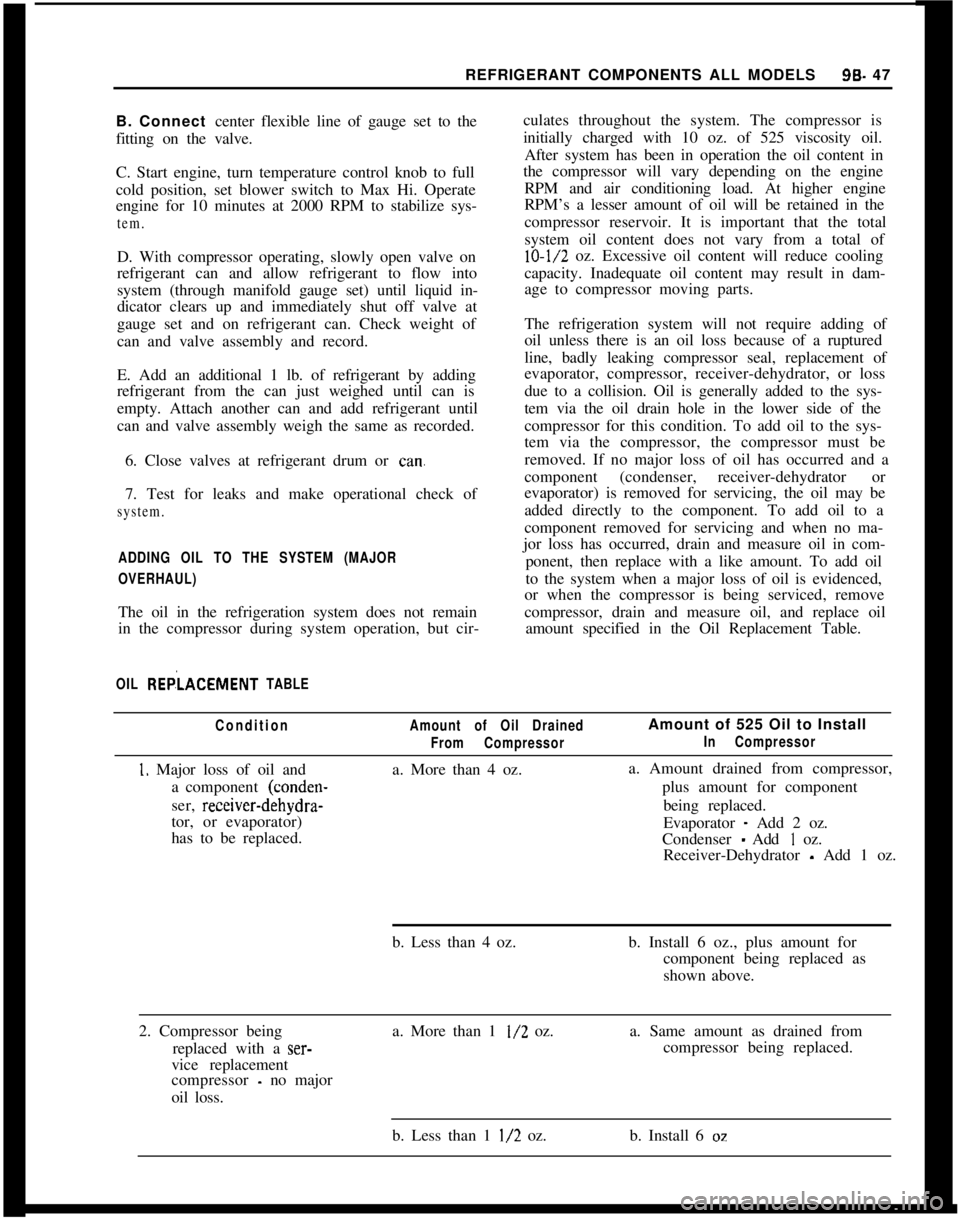

98-48 1973 OPEL SERVICE MANUALCondition3. Compressor being

replaced with a ser-vice replacement

compressor major

oil loss evident.

Amount of Oil Drained

From Compressora. More than 4 oz.Amount of 525 Oil to Install

In Compressor

a.

Same amount as drained from

compressor being replaced.4. Compressor being

rebuilt or repaired

-no major oil loss

evident.b. Less than 4 oz.

a. More than 1

l/2 oz.b. Install 6 oz.

a. Same amount a.s drained from

compressor, plus

1 oz. additional.

5. Compressor being

rebuilt or repaired

major loss of oil

evident.b. Less than 1

l/2 oz.

a. More than 4 oz.b. Install 7 oz.

a. Same amount as drained from

compressor, plus 1

ozadditional.If foreign material is noted in oil drained from sys-

tem or evidence of moisture is obvious in the compo-

nents removed, it is recommended that the entire

system be flushed and the receiver-dehydrator be

replaced. A full oil charge of 10 oz. of 525 viscosity

refrigeration oil should be replaced in the system. It

should be noted that all service replacement com-

pressors will be supplied with 10 pz. of oil. In most

cases it will be necessary to drain oil from service

replacement compressor and refill it with amount as

specified in the Oil Replacement Table.filter screen on the expansion valve should be re-

placed. If the evaporator assembly is flushed while

installed in the car, the temperature bulb on the

evaporator outlet pipe must be disconnected to keep

the expansion valve from closing at the inlet source.

FLUSHING THE SYSTEMIt is recommended that dry nitrogen be used as a

flushing agent due to the low cost involved. In addi-

tion, dry nitrogen will not cause a temperature drop,

as in the case of refrigerant-12, which results in

thickening of refrigerant oil. Dry nitrogen has the

additional advantage of removing moisture from thesystem.Flushing of the system may involve all the compo-

nents of the system or individual components in the

system. The components may be flushed while

mounted in the engine compartment or may be

removed for flushing. When a component is not

removed, disconnect all refrigerant lines or hoses

attached to component. To perform flushing operat-

ion, connect a cylinder of refrigerant-12 to the com-

ponent to be flushed, ,then invert the cylinder and

open the cylinder valve so that the liquid refrigerant

pours out and through the component. When liquid

Refrigerant-12 reaches atmospheric pressure, it im-

mediately drops to minus 21.7 degrees F. Insure that

area immediately surrounding outlet of component is

clear of anything that may be damaged by contact

because of the sudden drop in temperature.MAJOR REPAIR

REMOVAL AND INSTALLATION OF

COMPRESSOR

- OPEL 1900 - MANTA

Removal

I. Remove negative battery cable from battery.

2. Remove air cleaner and heat pipe. Cover the

carburetor to keep out dirt etc.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

In all cases where a complete system flushing operat-4. While system is discharging remove sheet metal

ion is performed, the receiver-dehydrator and thecover. See Figure

9B-50.

Page 563 of 625

96-54 1973 OPEL SERVICE MANUAL

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw into old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws. See Figure 9B-70.3. Install blower motor assembly into case and se-

cure with attaching screws. See Figure

9B-69.4. Install finger guard shields and fan housing case.

See Figure

9B-69.5. Install resistor assembly and electrical connector.

Install blower motor connector. See Figure

9B-69.6. Install assembly into car carefully guiding

evaporator pipes up through cowl opening. See Fig-

ure

9B-71.Figure 93-7 1 Inlet and Outlet Pipes and O-Rings

-Opel 1900 Manta

7. Install two (2) upper attaching evaporator at-

taching nuts. See Figures 9B-66 and

9B-67.8. Install two (2) attaching case mounting bracket

to instrument panel screws. See Figure

9B-67.9. Connect two (2) drain hoses underneath evapora-

tor.10. Install evaporator inlet and outlet pipes retainer

and rubber grommet. See Figure

9B-65.11. Connect vacuum cut-off switch and electrical

wiring, making sure the delay restrictor and checkvalve hoses are installed correctly. See Figures

9B-63and 64.

.gB-72 Delay Restrictor and Check Valve Hose.Assembly

12. Install refrigerant hoses and pipes using new

o-rings on line fittings and evacuate system. Refer to

EVACUATING SYSTEM.

13. While system is being evacuated, install in-line

fuse and left side of distributor duct. See Figure 9B-

61.14. Install glove box.

15. Install negative battery cable and charge system.

Refer to CHARGING SYSTEM.

REMOVAL AND INSTALLATION OF CONDENSER

ASSEMBLY -OPEL 1900. MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove air cleaner.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

4. While system is discharging, remove lower radia-

tor hose from radiator and drain coolant into a suita-

ble container.

5. Remove fan shroud.

6. On vehicles with automatic transmission, un-

screw oil lines from connectors on lower radiator

tank and plug lines. It is essential that no dirt enters

the oil lines. When unscrewing oil lines, hold connec-

tors on lower radiator tank with pliers to avoid leak-

ages. Ensure that no dirt enters oil cooler.

7. Remove upper radiator hose from radiator.

8. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

9. Remove inlet and outlet hoses from condenser

Page 564 of 625

REFRIGERANT COMPONENTS ALL MODELS99.55pipes and tape closed the open ends of refrigerant

lines, and also the open ends of the inlet and outlet

pipes of the condenser.

10. Remove two (2) top retaining screws.

Figure

9,S-73 Condenser Retaining Screws - Opel

1900

- Manta

11. Remove radiator grille and two (2) condenser to

body mounting screws. See Figure 98.74.

Figure 98-74 Condenser Assembly and Attachments.

Opel 1900

- Manta

12. Remove condenser.

Installation

If refrigerarit circuit or condenser has been exposed

to the atmosphere and moisture may be present in

the circuit, the system and/or component must beFigure 98-75 Condenser Assembly Mounting Brackets

Opel 1900 Manta

flushed prior to installation. Refer to FLUSHING

THE SYSTEM.

1. Install comjenser into car and install 2 condenser

to body mounting screws. See Figure 98-74. Install

radiator grill.

2. Install 2 top retaining screws.

3. Remove tape from the condenser pipes and re-

frigerant hoses and install hoses using new o-rings on

lines lubricated with No.

525 viscosity oil.

4. Evacuate system. Refer to EVACUATING SYS-

TEM.

5. While system is being evacuated, install radiator

into engine compartment and secure lower attaching

nut.

Figure 98.76 Clearance Between Lower Radiator

Tank and Fan Blades

- Opel 1900 Manta

6. On vehicles with automatic transmissions, fasten

Page 565 of 625

98-56 1973 OPEL SERVICE MANUAL

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 11-15 Ibs. ft.

7. Install fan shroud.

8. Install upper radiator hose.

9. Install lower radiator hose and add collected coo-

lant.

All Opel

1900’s and Manta’s are provided with a

radiator initial fill of an anti-freeze solution contain-

ing corrosion inhibitor. The anti-freeze has either a

glycol or glycerin base and protects the engine

against freezing, down to minus 22 degrees F. (minus

30 degrees C.). Before the start of the cold season,

coolant must be checked with a hydrometer and if

necessary, brought to the necessary specific gravity

by adding anti-freeze. Anti-freeze added, must have

a glycol or glycerin base. As the specific gravities of

all anti-freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.).

IO. Install negative battery cable and air cleaner.

11. Charge system. Refer to CHARGING SYS-

TEM.

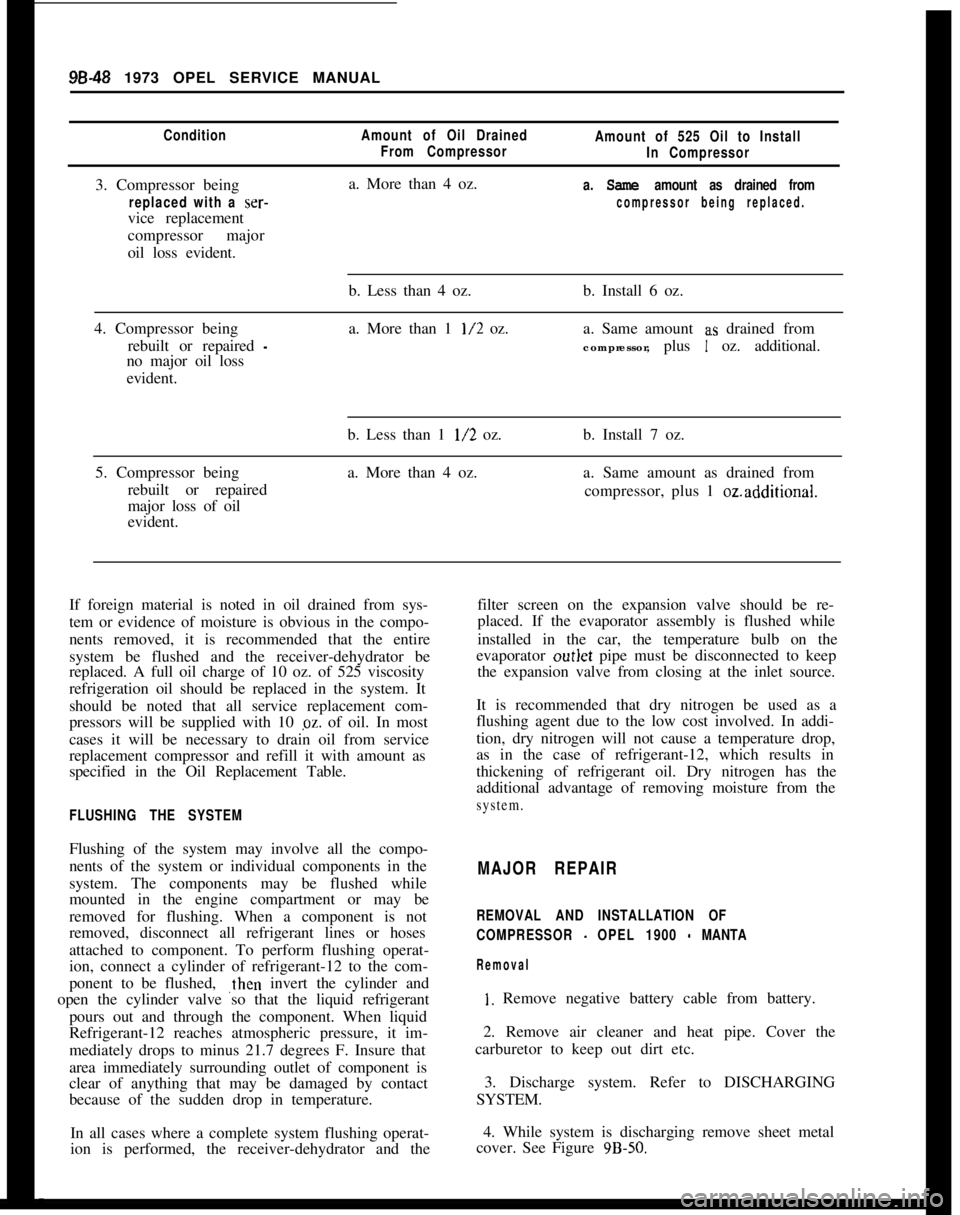

Figure 99.80 Location of Idler Pulley and Bracket

Assembly

- GTFigure 99.81 Idler Pulley and Bracket Assembly and

Support Bracket GT

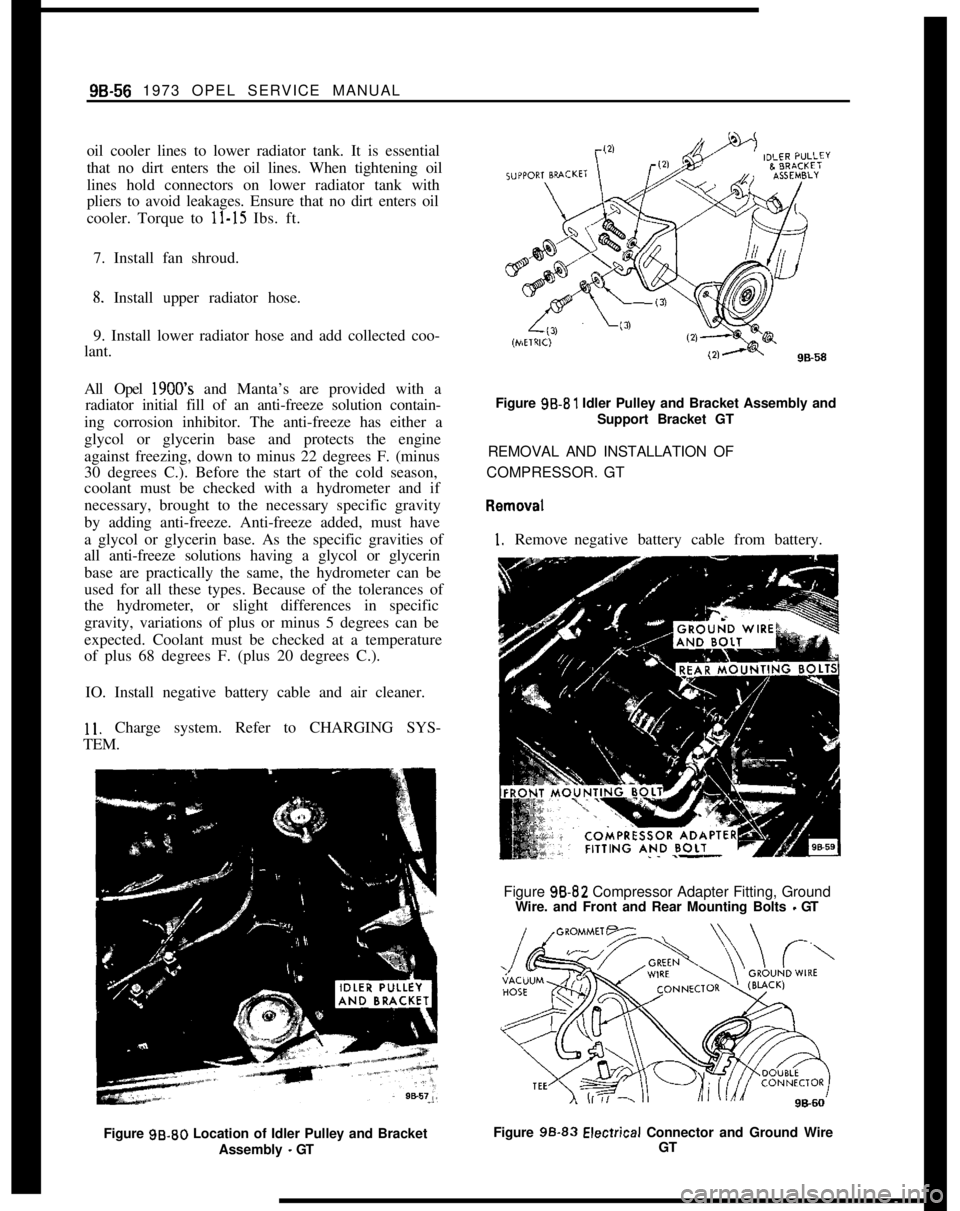

REMOVAL AND INSTALLATION OF

COMPRESSOR. GT

I. Removenegative battery cable from battery.

Figure 98-82 Compressor Adapter Fitting, Ground

Wire. and Front and Rear Mounting Bolts

- GT

Figure 99.83

Elecirical Connector and Ground Wire

GT

Page 591 of 625

r98-82 1973 OPEL SERVICE MANUAL

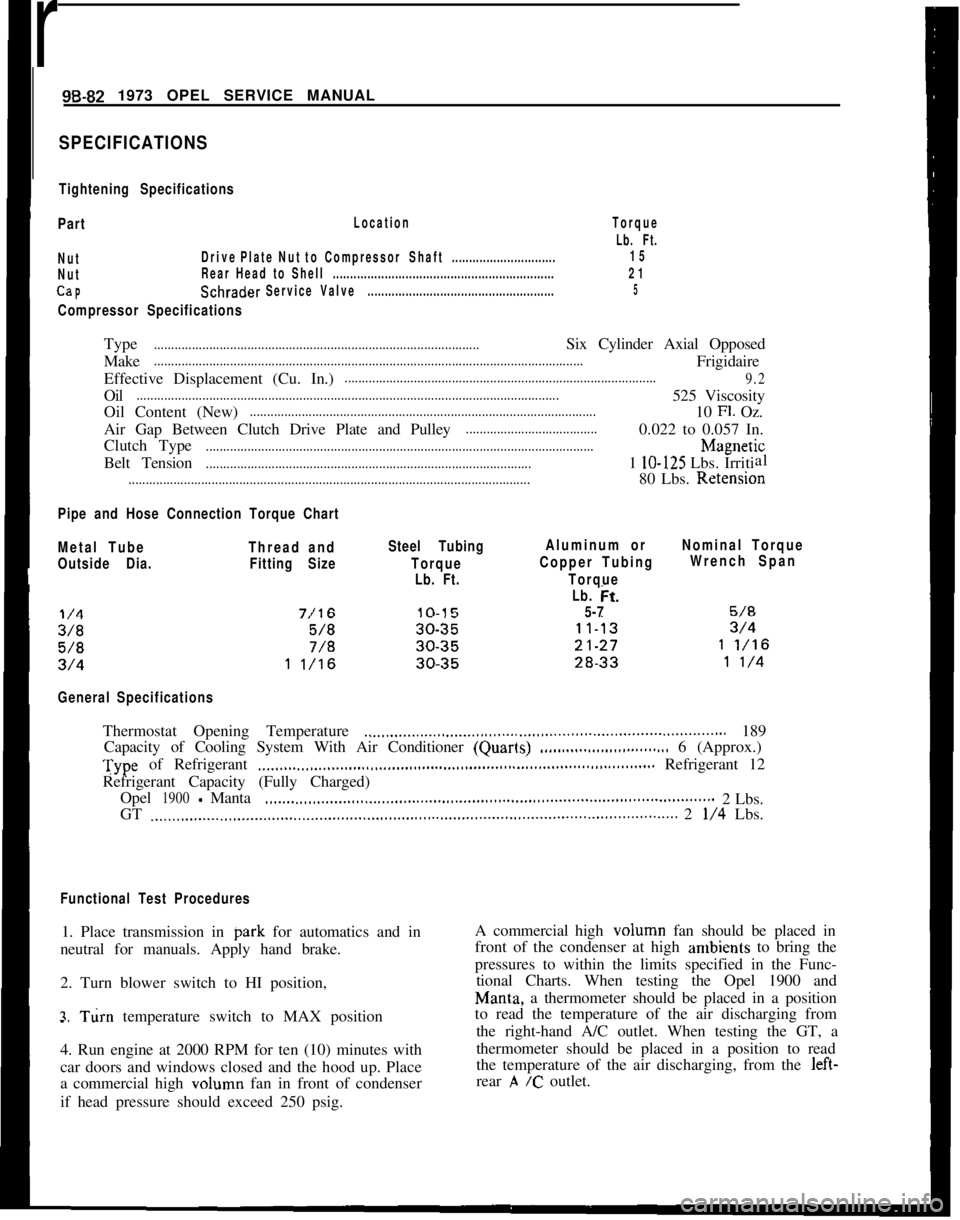

SPECIFICATIONS

Tightening Specifications

Part

Location

NutDrivePlateNut toCompressorShaft..............................

NutRear Head to Shell................................................................

CaPSchraderServiceValve......................................................

Compressor Specifications

Torque

Lb. Ft.

15

21

5Type

..............................................................................................Six Cylinder Axial Opposed

Make

............................................................................................................................Frigidaire

Effective Displacement (Cu. In.)

..........................................................................................

9.2Oil

..........................................................................................................................525 Viscosity

Oil Content (New)

....................................................................................................10 Fl. Oz.

Air Gap Between Clutch Drive Plate and Pulley

......................................0.022 to 0.057 In.

Clutch Type

................................................................................................................h4agnetic

Belt Tension

..............................................................................................1 lo-125 Lbs. Irritial

....................................................................................................................80 Lbs. Retension

Pipe and Hose Connection Torque Chart

Metal TubeThread andSteel TubingAluminum orNominal Torque

I

Outside Dia.Fitting SizeTorqueCopper TubingWrench Span

Lb. Ft.Torque

Lb. tit.

5-7

General SpecificationsThermostat Opening Temperature

.._.....,,,...__....,,.............................................................. 189

Capacity of Cooling System With Air Conditioner (Quarls)

.,,..___....___............... 6 (Approx.)Type of Refrigerant

.___,,,._...,.,,,.__.....,,,.......,,,,.......,,,...................,,,......,,,............ Refrigerant 12

Refrigerant Capacity (Fully Charged)

Opel

1900-Manta,,._....,,,,._...._.,,,,.......,,,........,,............................................................2 Lbs.

GT

,..__..,..,..__..,,,.......,,,,.......,,,........,,,.,......,,,,,......,,.,,........,,.......,,..........,,............... 2 l/4 Lbs.

Functional Test Procedures1. Place transmission in park for automatics and in

neutral for manuals. Apply hand brake.

2. Turn blower switch to HI position,

3. Turn temperature switch to MAX position-.

4. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a commercial high volumn fan in front of condenser

if head pressure should exceed 250 psig.A commercial high volumn fan should be placed in

front of the condenser at high ambients to bring the

pressures to within the limits specified in the Func-

tional Charts. When testing the Opel 1900 and

Man& a thermometer should be placed in a position

to read the temperature of the air discharging from

the right-hand A/C outlet. When testing the GT, a

thermometer should be placed in a position to read

the temperature of the air discharging, from the left-

rear

,A /c outlet.

Page 592 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 83

FUNCTIONAL TEST - OPEL 1900.

MANTA

Temp. of Air Entering

Cond.

Engine RPM

Camp. Head Pressure*

Suction Press.’

Discharge Air Temperature*

*When compressor clutch disengages,

FUNCTIIONAL TEST - GT

Temp. of Air Entering Cond.

Engine RPM

Camp. Head Pressure”

Suction Press.”

Discharge~Air Temperature*

“When compressor clutch disengages70

8090100110

20002000200020002000

155.165195.205200-210

250.260270.280

1922222729

38-4340.4542-47

45-5047-52

708090100110

2000

2000200020002000

125.135145.155180-190

210-220150.260

1720202224

37-42

38.4339-4440-4545-50

Page 613 of 625

RADIO. GT9c- 105

RADIO

GTCONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS:

RadioTroubleDiagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Antenna Trimmer Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

RemovingandInstallingRadio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

Page No.

9c-105

9C-106

9c-107

DIAGNOSIS

RADIO TROUBLE DIAGNOSISBecause radio problems are most often repaired at

United Delco authorized warranty repair stations,

the tendency for many dealer servicemen is to

remove the set when a problem is reported, without

any preliminary diagnosis. This results in a large

number of radios showing up as “NO TROUBLE

FOUND” units when received by the warranty re-

pair stations. This indicates that the trouble can

often be corrected without removal of the radio.

The inconvenience to an owner of driving without a

radio while his set is being serviced at a warranty

station can frequently be avoided if the following

quick checks are used to eliminate external radio

system :problems before removing the radio for re-

pair.

Always determine from the owner the exact nature

of the radio problem as an aid to diagnosis. Knowing

whether the condition is intermittent or constant,

whether it occurs with engine off or running, with

car stationary or moving, will help to pinpoint the

problem. Never turn on radio with speaker discon-

nected.

Radio Ii

Inoperative.1. Turn on the radio. The dial should light and a

thump should be heard from the speaker.a. If a thump is heard, go to Step No. 2 for antenna

check.b. If no thump is heard,

check the fuse.

(1) If fuse is bad, replace and try radio again. Race

engine and, if fuse blows again,‘remove the radio and

speaker assembly for repair by

4 trained radio techni-

cian.

(2) If fuse is good, check to

s&e that the speaker-to-

receiver interconnecting cable is connected securely.

If there is still no thump when the radio is turned on,

remove the receiver and speaker for repair.

2. Check the antenna by substituting with one held

out the car window.

a. If radio is still dead with substitute antenna,

remove the receiver and spea!er for repair.

b. If radio operates near normal with substitute an-

tenna, some part of the car antenna or lead-in is at

fault.

Radio Reception Is Weak1. Check to see if antenna trimmer is peaked.

a. Position antenna at a height of 31 inches.

b. Tune radio to weak station at or near 1400 KHz

on the dial, and turn volume control to maximum.

Page 614 of 625

9C-106 1973 OPEL SERVICE MANUAL

c. Adjust trimmer screw for maximum volume.

d. If antenna trimmer does not have a definite peak, check for defective antenna by substitution.

2. Check that the speaker connection is plugged in

SXUdY.

3. If the radio is still weak, remove the receiver and

speaker assembly for repair.

Radio Is Noisy

1. Radio is noisy all the time:

a. Check for defective antenna by striking antenna

with hand. If static is heard while tapping, replace

antenna.

b. If antenna is not defective, remove receiver and

speaker for repair.

2. Radio is noisy only when jarred:

a. Check antenna as in Step No. 1 above.

b. Check speaker connection. If speaker connection is not at fault, remove receiver and speaker for re-

pair.

3. Radio is noisy when engine is running:

a. Check noise suppressor by substituting on genera-

tor with known good one.

b. Check to see that antenna is mounted securely,

grounding the antenna base to the fender. The an-

tenna lead-in wire is shielded and the shield should

have good ground connection at the receiver and the

antenna base.

c. Check for other car wiring, passing too close to

radio receiver case.

d. If engine noise is still present, remove receiver and

speaker for repair.

4. Radio is noisy when car equipment is operated,

such as directional lights or brake lights:

Check for defective antenna lead-in wire or, loose

antenna mounting, as in Step No. 3b above.

MAINTENANCE AND ADJUSTMENTS

ANTENNA TRIMMER ADJUSTMENT

An antenna trimmer adjusment screw is provided for

matching of the antenna coil in the receiver to the car antenna. This adjustment must always be made after

installation of a receiver or an antenna, or after re-

pair to these units. This adjustment should also be

performed whenever radio reception is unsatisfac-

tory.

1. Position antenna to a height of 31 inches.

2. Tune receiver

tb a weak station at or near 1400

KHz that can barely be heard

with volume turned

fully up.

3. Insert a small-bladed screwdriver in antenna trim-

Figure 9C-1 Location of Access Trim Plug

Figure

9C-2 Removing Hex Head Screw