ignition OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 43 of 625

lC- 22 1973 OPEL SERVICE MANUAL j

3. Start engine and disconnect a wire from a spark

plug. Read output voltage of disconnected spark

plug circuit. Reading should exceed 20 KV

(20,poO

volts).I

CHECK DISTRIBUTOR

!1. Clean distributor cap and inspect it for cracks or

tracking. Inspect inner segments for erosion and

outer sockets for corrosion.

2. Clean and inspect ignition wires. Make sure resist-

ance of each wire is less than 10,000 ohms. Replace

any defective spark plug boots or distributor

capnipples. See paragraph lC-12.

3. Inspect breaker points and replace if necessary.

Adjust breaker point gap to

,016 inch with rubbing

block on peak of cam lobe or check dwell and adjust

if not 50 degrees plus or minus 3 degrees. 4. Check

dwell variation by reading dwell at idle and at 3000

RPM. Dwell must not vary more than 3 degrees.

Excessive variation means distributor shaft, cam or

breaker plate are worn or damaged--overhaul dis-

tributor and replace defective parts.

5. Check distributor condenser for a minimum series

resistance and insulation leakage. Check for a

capacity between

.15 and .20 microfarads.

6. Check total advance (centrifugal and vacuum) at

2500 engine RPM using a timing light having a dial

for reading advance.

(a) The timing marks are aligned with both the

vacuum advance and the vacuum retard hoses dis-

connected and plugged.

Engine idle should be 900 RPM.

(b) Reconnect vacuum hoses. Run engine at

3600RPM and adjust knob until timing marks are

aligned. Read advance on dial. Maximum centrifugal

advance should be between 28-32 degrees.

7. If total advance is out of specifications, check

centrifugal advance only, at

2500 RPM. Discon+ectand plug all vacuum hoses. Maximum vacuum ad-

vance should be l-5 degrees at 4.5-5.0 in. hg.

8. Replace centrifugal or vacuum advance parts as

required to bring distributor total advance within

specifications.

9. Check operation of vacuum retard unit (rear unit)

by first making sure timing marks are aligned with

vacuum hoses disconnected and at slow idle (700

RPM). Then connect vacuum hose to vacuum retard

unit (rear unit). Timing ball should move in a retard

direction (upward).

CHEICK SPARK PLUGS1. Remove spark plugs. If electrodes are badly worn,

discard plugs. If inner or outer porcelain is cracked

or broken, discard plugs.

2. Note color and general appearance of inner end of

spark plug. Brown to grayish

- tan deposits and slight

electrode wear indicate correct spark plug heat

range. Plugs having this appearance may be cleaned,

regapped, tested and reinstalled.

3. Clean spark plugs in a sand blast type cleaner.

Clean only enough to remove deposits, not enough to

wear away porcelain. If deposits are too hard to

remove or if porcelain is glazed, discard plugs.

4. After cleaning spark plugs, clean tiring surfaces of

electrodes with a line file.

5. Test cleaned spark plugs on a pressure tester by

comparing spark of the used plugs with that of a new

plug. Install tested plugs, using new gaskets.

6. If removed spark plugs have excessive carbon foul-

ing and if the car will be driven mostly at low speeds

in city driving, it is advisable to replace plugs with

a hotter plug, AC43FS.

7. If removed plugs show rapid electrode wear or

inner porcelain breakage at low mileage. Check for

a vacuum leak such as a poor manifold to head fit.

8.

Clap spark plugs carefully (new or cleaned) using

a

,030 round wire feeler gage.IC6

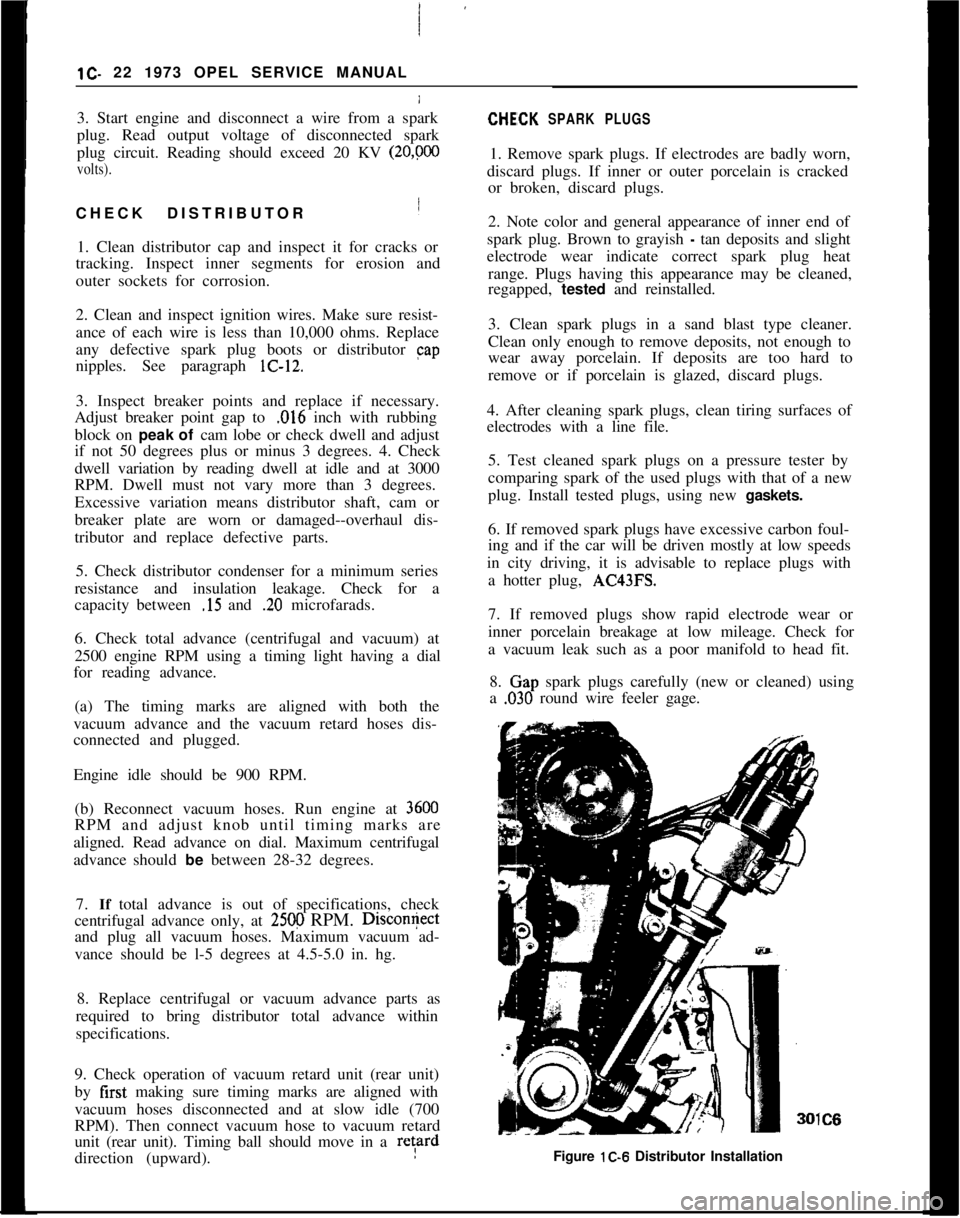

Figure lC-6 Distributor Installation

Page 44 of 625

IGNITION SYSTEMlC- 23

9. Install:spark plugs using a 13/16 deep socket, an

extension and a torque wrench. Tighten to 22-29Ib.ft. 1

MAJOR REPAIRDlSTRlBtiTOR OVERHAULDistributbr Removal

1. Remove fuel pump. This is necessary because the

fuel

punp will block the distributor drive gear,

thereby preventing removal of the distributor. See

Figure lC-6.

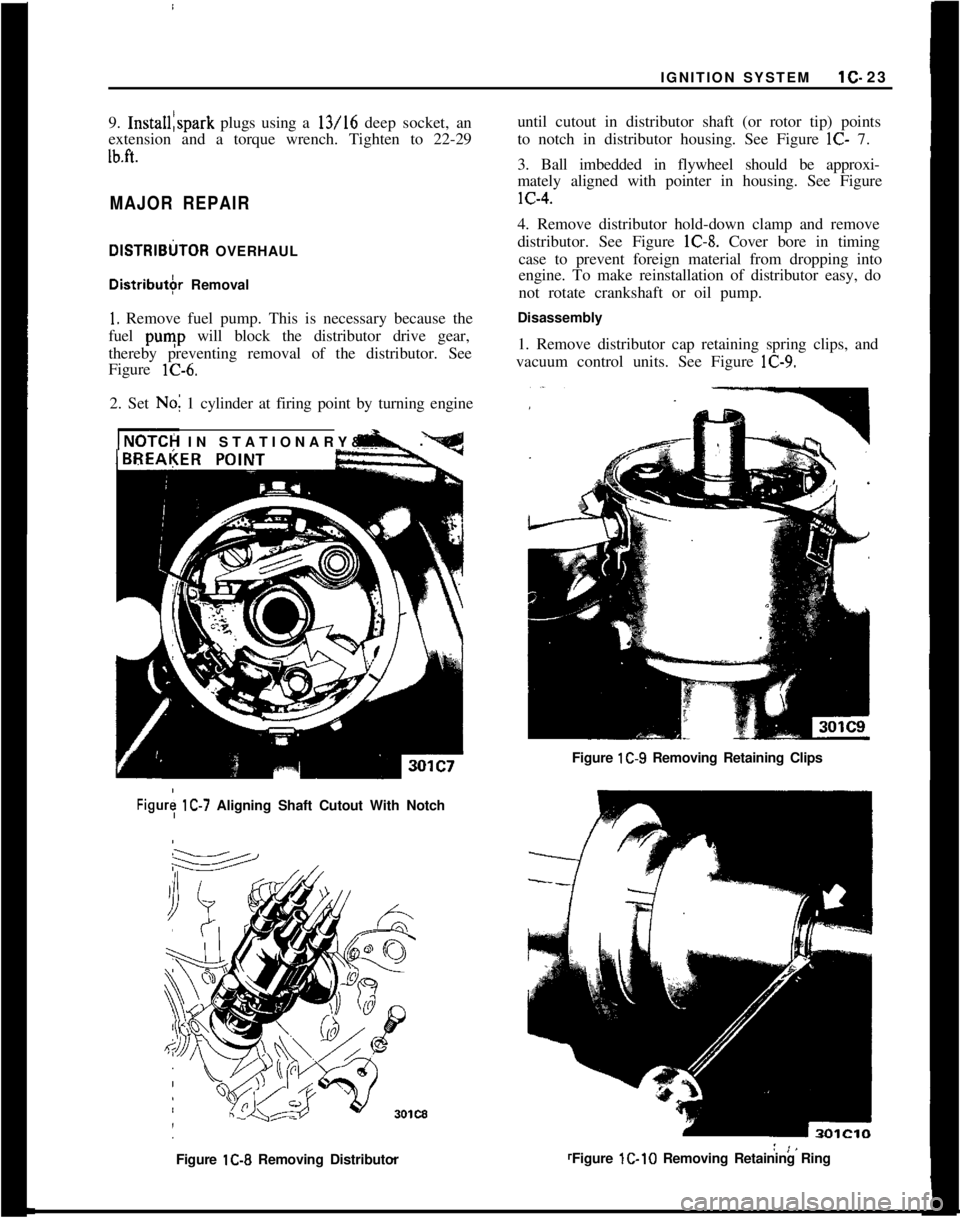

2. Set No; 1 cylinder at firing point by turning engine

INOTCH IN STATIONARY& -.until cutout in distributor shaft (or rotor tip) points

to notch in distributor housing. See Figure

lC- 7.

3. Ball imbedded in flywheel should be approxi-

mately aligned with pointer in housing. See FigurelC-4.

4. Remove distributor hold-down clamp and remove

distributor. See Figure lC-8. Cover bore in timing

case to prevent foreign material from dropping into

engine. To make reinstallation of distributor easy, do

not rotate crankshaft or oil pump.

Disassembly

1. Remove distributor cap retaining spring clips, and

vacuum control units. See Figure lC-9.

Figure lC-9 Removing Retaining Clips

Figury lC-7 Aligning Shaft Cutout With Notch

Figure lC-8 Removing DistributorFigure lC-10 Removing Retaining Ring

Page 45 of 625

1 C- 241973 OPEL SERVliTE MANUAL

2. Push retaining ring out of groove in

distribitorshaft. See Figure lC-10.I

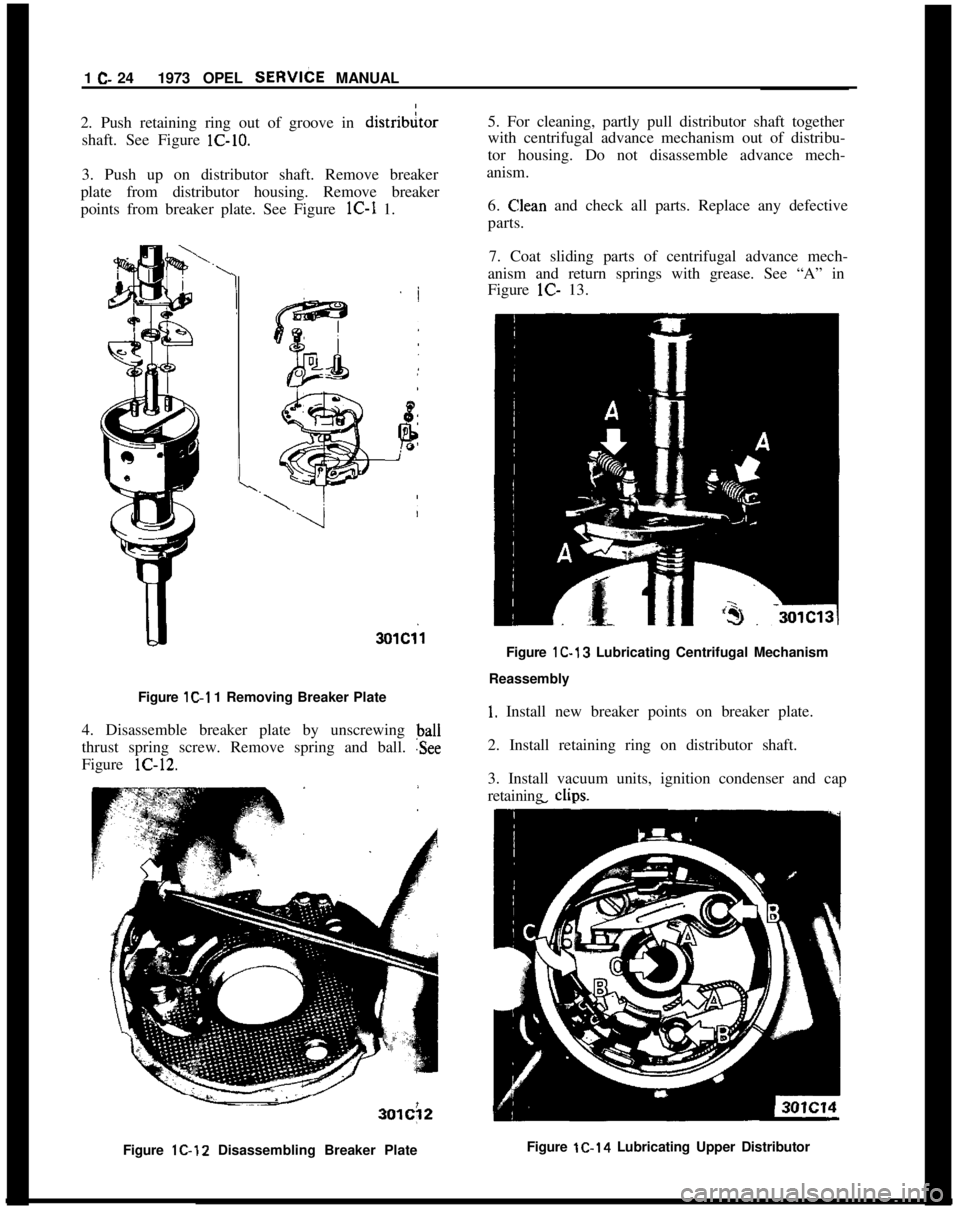

3. Push up on distributor shaft. Remove breaker

plate from distributor housing. Remove breaker

points from breaker plate. See Figure lC-I 1.’

I

1

I3OlCl’l

Figure lC-1 1 Removing Breaker Plate:

4. Disassemble breaker plate by unscrewing Pall

thrust spring screw. Remove spring and ball.

.SeeFigure lC-12.3OlCi25. For cleaning, partly pull distributor shaft together

with centrifugal advance mechanism out of distribu-

tor housing. Do not disassemble advance mech-

anism.

6.

C!lean and check all parts. Replace any defective

parts.

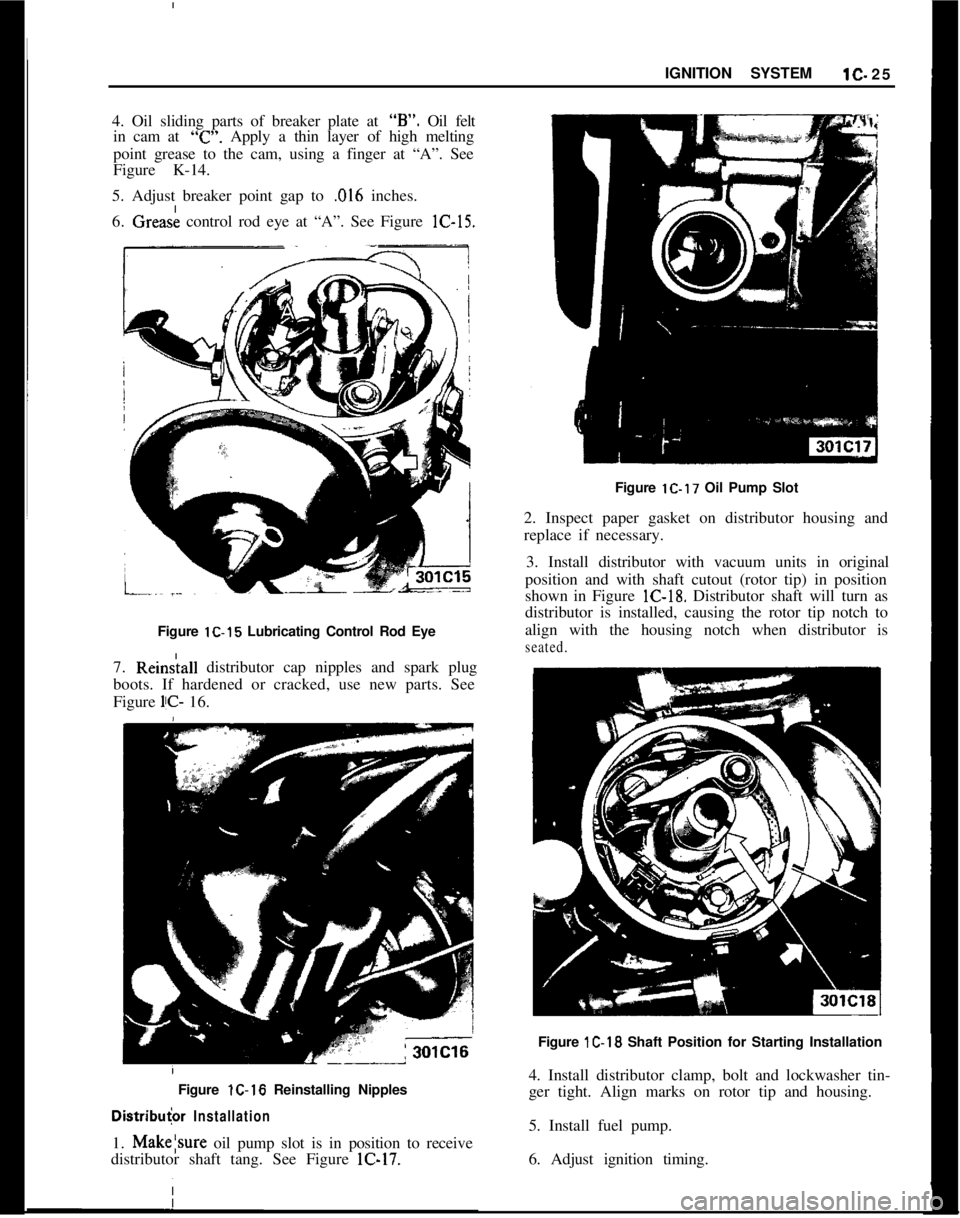

7. Coat sliding parts of centrifugal advance mech-

anism and return springs with grease. See “A” in

Figure

lC- 13.

Figure lC-13 Lubricating Centrifugal Mechanism

Reassembly

1. Install new breaker points on breaker plate.

2. Install retaining ring on distributor shaft.

3. Install vacuum units, ignition condenser and cap

retaining

clios.Figure lC-12 Disassembling Breaker PlateFigure lC-14 Lubricating Upper Distributor

Page 46 of 625

IGNITION SYSTEM1C. 25

4. Oil sliding parts of breaker plate at “B”. Oil felt

in cam at

“c”. Apply a thin layer of high melting

point grease to the cam, using a finger at “A”. See

Figure K-14.

/

5. Adjust breaker point gap to

,016 inches.

6. Grease control rod eye at “A”. See Figure lC-15.

Figure lC-15 Lubricating Control Rod Eye

7. Rein&all distributor cap nipples and spark plug

boots. If hardened or cracked, use new parts. See

Figure

l!C- 16.

/ Figure lC-16 Reinstalling Nipples

Distribu

2. Inspect paper gasket on distributor housing and

replace if necessary.

3. Install distributor with vacuum units in original

position and with shaft cutout (rotor tip) in position

shown in Figure lC-18. Distributor shaft will turn as

distributor is installed, causing the rotor tip notch to

align with the housing notch when distributor is

seated.Figure

1C-18 Shaft Position for Starting Installation

4. Install distributor clamp, bolt and lockwasher tin-

ger tight. Align marks on rotor tip and housing.

5. Install fuel pump.

6. Adjust ignition timing.

Page 47 of 625

lC- 261973 OPEL SERVICE MANUAL /

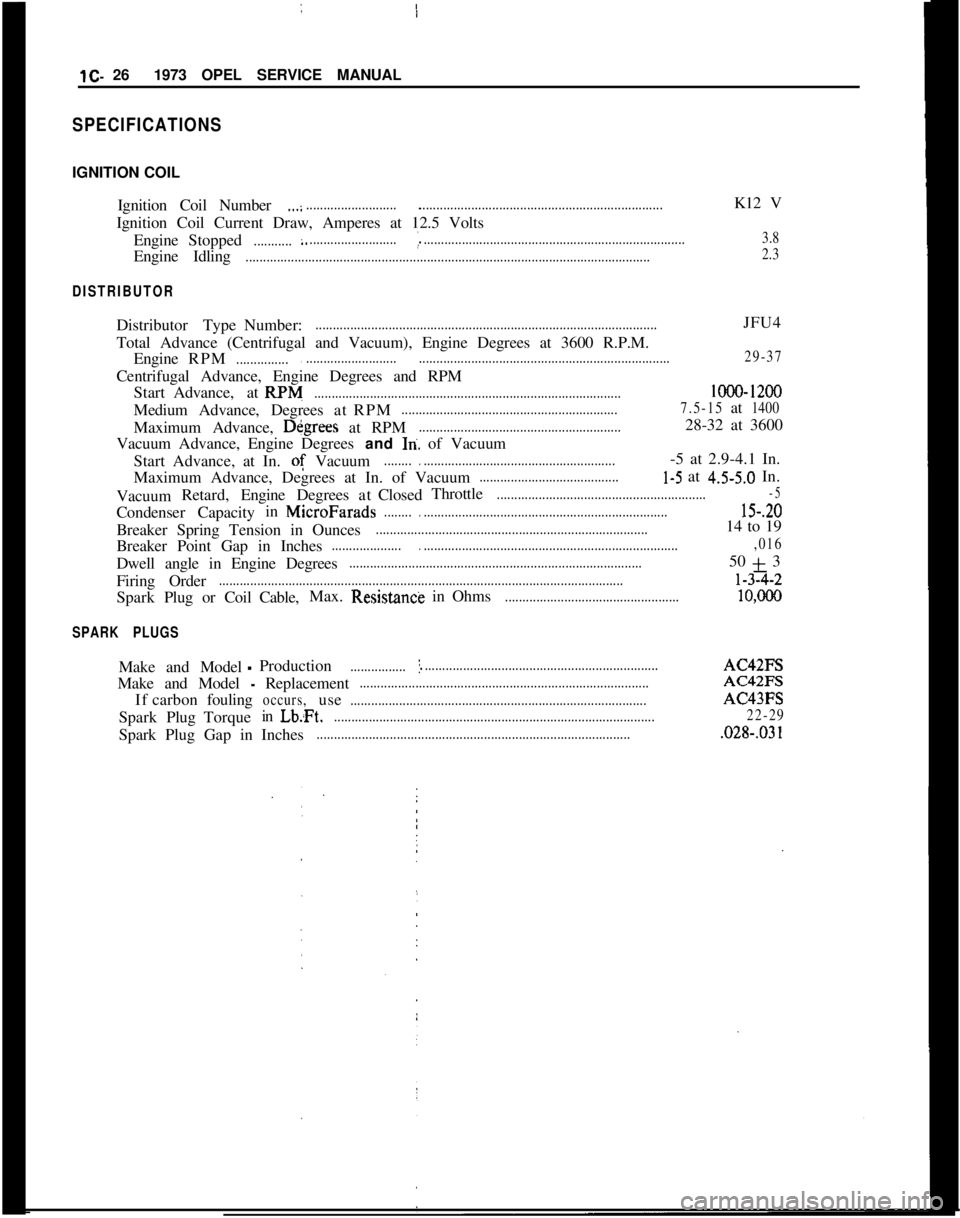

SPECIFICATIONSIGNITION COIL

Ignition Coil Number

.,.:.................................................................................................K12 V

Ignition Coil Current Draw, Amperes at 12.5 Volts

EngineStopped

...........:.........................._............................................................................3.8Engine Idling

....................................................................................................................2.3

DISTRIBUTORDistributor TypeNumber:

..................................................................................................JFU4

Total Advance (Centrifugal and Vacuum), Engine Degrees at 3600 R.P.M.

EngineRPM

..................................................................................................................29-37Centrifugal Advance, Engine Degrees and RPM

StartAdvance,atRPM

........................................................................................lOOO-1200MediumAdvance,DegreesatRPM

..............................................................7.5-15at1400Maximum Advance, Dkgrees at RPM

..........................................................28-32 at 3600

Vacuum Advance, Engine Degrees and

In. of Vacuum

Start Advance, at In. of Vacuum

................................................................-5 at 2.9-4.1 In.

Maximum Advance, Degrees at In. of Vacuum

........................................l-5 at 4.5-5.0 In.

VacuumRetard,EngineDegreesatClosedThrottle

............................................................-5CondenserCapacityinMicroFarads

...............................................................................15-.20Breaker Spring Tension in Ounces

..............................................................................14 to 19

Breaker Point Gap in Inches

..............................................................................................,016Dwell angle in Engine Degrees

....................................................................................50 + 3

Firing Order

....................................................................................................................l-32-2

SparkPlug or CoilCable,Max.Resistancti in Ohms

..................................................10,ooO

SPARK PLUGSMake and Model

-Production................I....................................................................AC42FS

Make and Model

- Replacement...................................................................................AC42FS

Ifcarbonfouling

occurs,use.....................................................................................AC43FS

SparkPlugTorqueinLb:Ft.

............................................................................................22-29Spark Plug Gap in Inches

...........................................................................................028-.03 1

Page 48 of 625

IGNITION SYSTEMlC- 27

93OlC19

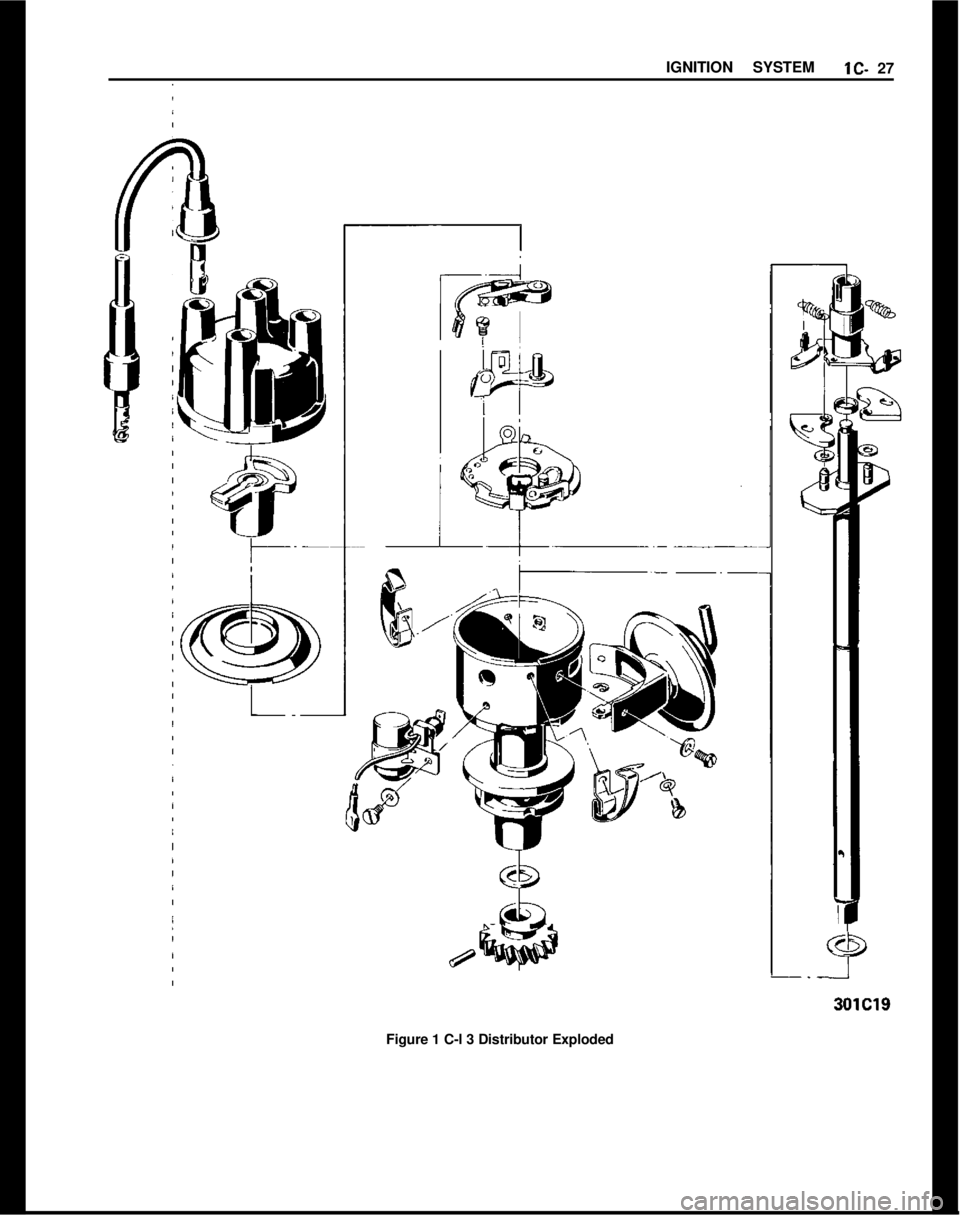

Figure 1 C-l 3 Distributor Exploded

Page 50 of 625

CHARGING SYSTEMlD- 29

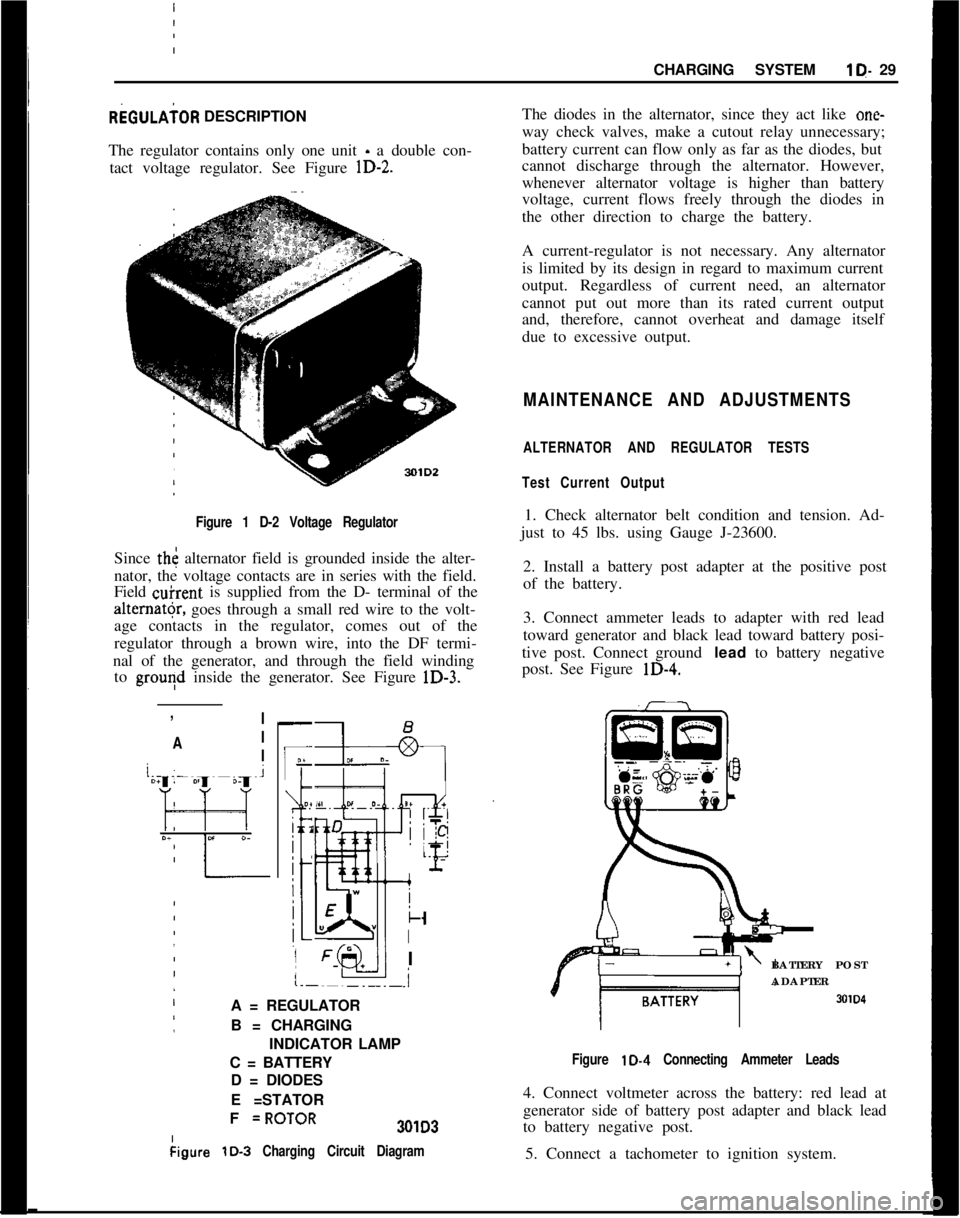

REGULAiOR DESCRIPTION

The regulator contains only one unit - a double con-

tact voltage regulator. See Figure

lD-2.

I Figure 1 D-2 Voltage Regulator

Since th< alternator field is grounded inside the alter-

nator, the voltage contacts are in series with the field.

Field

&rent is supplied from the D- terminal of the

alter”@, goes through a small red wire to the volt-

age contacts in the regulator, comes out of the

regulator through a brown wire, into the DF termi-

nal of the generator, and through the field winding to

grouqd inside the generator. See Figure lD-3.

:

,

!

/ I

’ A I

j

/ I

-

IF

O?

i 2

j

:

:

k

I

I

.i

A = REGULATOR

B = CHARGING

INDICATOR LAMP

C = BATTERY D = DIODES

E =STATOR

I

I F

=ROTOR301D3

kigure

lD-3 Charging Circuit Diagram

The diodes in the alternator, since they act like one-

way check valves, make a cutout relay unnecessary;

battery current can flow only as far as the diodes, but

cannot discharge through the alternator. However,

whenever alternator voltage is higher than battery

voltage, current flows freely through the diodes in

the other direction to charge the battery.

A current-regulator is not necessary. Any alternator

is limited by its design in regard to maximum current

output. Regardless of current need, an alternator

cannot put out more than its rated current output

and, therefore, cannot overheat and damage itself

due to excessive output.

MAINTENANCE AND ADJUSTMENTS

ALTERNATOR AND REGULATOR TESTS

Test Current Output

1. Check alternator belt condition and tension. Ad-

just to 45 lbs. using Gauge J-23600.

2. Install a battery post adapter at the positive post

of the battery.

3. Connect ammeter leads to adapter with red lead

toward generator and black lead toward battery posi-

tive post. Connect ground

lead to battery negative

post. See Figure

lD-4.

BATTERY POST

ADAPTER

SOID

Figure lD-4 Connecting Ammeter Leads

4. Connect voltmeter across the battery: red lead at

generator side of battery post adapter and black lead

to battery negative post.

5. Connect a tachometer to ignition system.

Page 58 of 625

WINDSHIELD WIPERSlE- 37WINDSHEILD WIPERS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Windshield Wiper Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Windshield Wiper

. . . . . . . . . . . . . . . . . . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Wiper Transmission

- 1900 and Manta. . . . . . . . . . . . . . . . . . . .W/per Transmission

- GT. . . . . a.* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and Inspection of Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Assembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

GeneralSpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Torque Specifications

. . . . . . . a.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTIOfV AND OPERATION

GENERAL;DESCRlPTlDNThe two-sbeed wiper consists of a round shaped per-

manent magnet type motor and speed reduction gear

box. IOPERATldN

=The wipei motor is controlled through a dash

mounted &itch on all cars. The Rallye and GT, in

addition tb the dash mounted switch, also have a

switch moimted in conjunction with the windshield

washer fodt pump. Depressing the washer pump will

allow the bipers to operate while the pump is de-

pressed. i

DIAGNO;SIS

PRELIMINj9RY INSPECTION

1. Make

c&in of firm wire connections at wiper

motor fuse block and wiper switch.

Page No.

1 E-37

1 E-37E-38

E-38

E-40

E-41

E-4 1E-42

1 E-43

1 E-432. Check to see that the fuse is not blown.

3. Be sure wiper motor is not loose on fire wall.

4. With the yellow wire disconnected from terminal

No. 53 on the

wi@er motor, turn the ignition switch

and wiper switch to the on position and check volt-

age available to the wiper motor. There should be 12

volts available at the durple wire with a properly

charged battery.

Checking Wiper Operation1. Turn ignition switch on and engage wiper switch

to see if wiper motor will operate.

2. If wiper action is slow or inoperative, turn swit-

ches off and detach wiper control

inn from crank

arm.3. Operate wiper manually checking for excessive

bind in linkage. Correct if necessary.

Page 67 of 625

1F. 46 1973 OPEL SERVICE MANUAL

’

/

Headlight High-Low Beam Control and Passing:

SignalI

When the headlights have been switched on, high

and low beam selection is made by raising the direc-

tional signal lever toward steering wheel. Each

ti&the lever is raised, beam position, will change.

When the headlights are not on, a flashing headlight

signal may be given by raising and lotiering the di-

rectional signal lever. With the headlights on and

inlow beam position, raising and lowering the direc-

tional signal lever will also cause the headlights to

flash.

Fog Light SwitchAll Rallye models are equipped with two white f?g

lights mounted below the front bumper.

The fog light toggle switch is located on the

insty-ment cluster to the left of the temperature and

fuelgauge cluster.

/

The fog lights can be turned off at any time by the

toggle switch, but can only be tyrned on when: :

1. The ignition switch on or the

?gine running.!

2. The fog light toggle switch lower half is pushed

in.3. The parking lights and/or low beam headlights

are

OKThe fog lights are automatically turned off if the

ignition switch is on and the headlights are switched

to high beam position.

Courtesy LightThe courtesy light illuminates the interior of the Car

when any door is opened. The courtesy light can also

be turned on with all doors closed by tilting the l&s.

GT Headlamp MechanismThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps and pulling lever closes headlamps. Two

(2) meshing gear segments convert the movement, of

the lever to a rotation of 180 degrees. The pivots of

the headlamps lie below the centerline so that with

headlamps in closed position, the headlamp housing

is flush with front sheet metal. Refer to Group 110,

Section “F”, for service procedures on the GT head-

lamp mechanism.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened lorclosed The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating,

mechanism.

MAINTENANCE AND ADJUSTMENTSHEADLAMP AIMING

The headlamps must be properly aimed in order to

obtain maximum road illumination and safety that

has been built into the headlighting equipment. With

the Guide T-3 type sealed beam units, proper aiming

is even more important because the increased range

and power of this lamp make even slight variations

from recommended aiming hazardous to approach-

ing motorists. The headlamps must be checked for

proper aim whenever a sealed beam unit is replaced

and after an adjustment or repairs of the front end

sheet metal assembly.

Regardless of method used for checking headlamp

aim, car must be at normal weight, that is, with gas,

oil, water, and spare tire. Tires must be uniformly

inflated to specified pressure. If car will regularly

carry an unusual load in rear compartment, or a

trailer, these loads should be on car when headlamps

are checked. Some States have special requirements

for headlamp aiming adjustment, and these require-

ments should be known and observed.

Horizontal and vertical aiming of each seal beam

unit is provided by two adjusting screws which move

the mounting ring in the body against the tension of

the coil spring. There is no adjustment for focus,

since the sealed beam unit is set for proper focus

during manufacturing assembly.

MAJOR REPAIRHEADLIGHT SWITCH

- OPEL 1900. MANTA

Removal1. Remove instrument cluster cover panel. See Sec-

tion H.

2. Compress retaining springs and pull switch out.

See Figure 1 F-

1.3. Pull multiple socket off switch.

Installation

1: Plug multiple socket in switch and push switch in

panel until clips lock in place.

2. Replace instrument cover and secure with two (2)

screws.

Page 75 of 625

lG- 54 1973 OPEL SERVICE’ MANtiAL/SIGNAL SYSTEMSCdNTENTS

9Subject

DESCRIPTION AND OPERAT!ON:

Directional Signal Lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HazardWarning

Flasher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BrakeSystemWarningLight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

SignalSystem,.......................

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUS,TMENTS:

MAJOR REPAIR:

Directional Signal Switch

:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HornRemoval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing Horn Contact

. . . . :.............................................

SPECIFICATIONS:

FuseChart. . . . . . I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 G-54

1 G-54

1 G-55

lG-55 _1 G-55

1 G-55

16-551 G-55

1 G-56

DESCRIPTION AND OPERATION

DIRECTIONAL SIGNAL LEVERThe direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal,

and high and low beams. See Figure

lG-1.301Gl

Figure lG-1 Directional Signal Position for Headlamp

OperationThe direction signal lever is provided with a

two-step mechanism for operation of headlight high and

low beams, and passing signal (not in New Jersey).

With headlights off, moving the lever repeatedly to-

wards steering wheel flashes headlights as a passing

signal. With headlights on, moving the lever repeat-

edly towards steering wheel up to first stop also

flashes passing signal regardless whether or not the

direcl:ion signals are switched on. When the lever is

moved up to the second stop, the headlights are

changed from high to low beam

dr vice versa. On all

Rallye cars, when switching from low to high beam

position, with the fog lamp instrument panel switch

“ON” and ignition switch in “RUN” position, the

fog lights are automatically

switChed off. Direction

signals work in the normal manner; pushing the lever

up for right turn signal and pulling the lever down

for left turn signal.

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing

down on the ends of both spokes on Opel 1900 andManta’s or on the center horn button on the Rallye.

The button is provided with a spring-loaded plunger.See Figure

lG-2.