ignition OPEL GT-R 1973 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 215 of 625

3E- 481973 OPEL SERVICE MANUAL

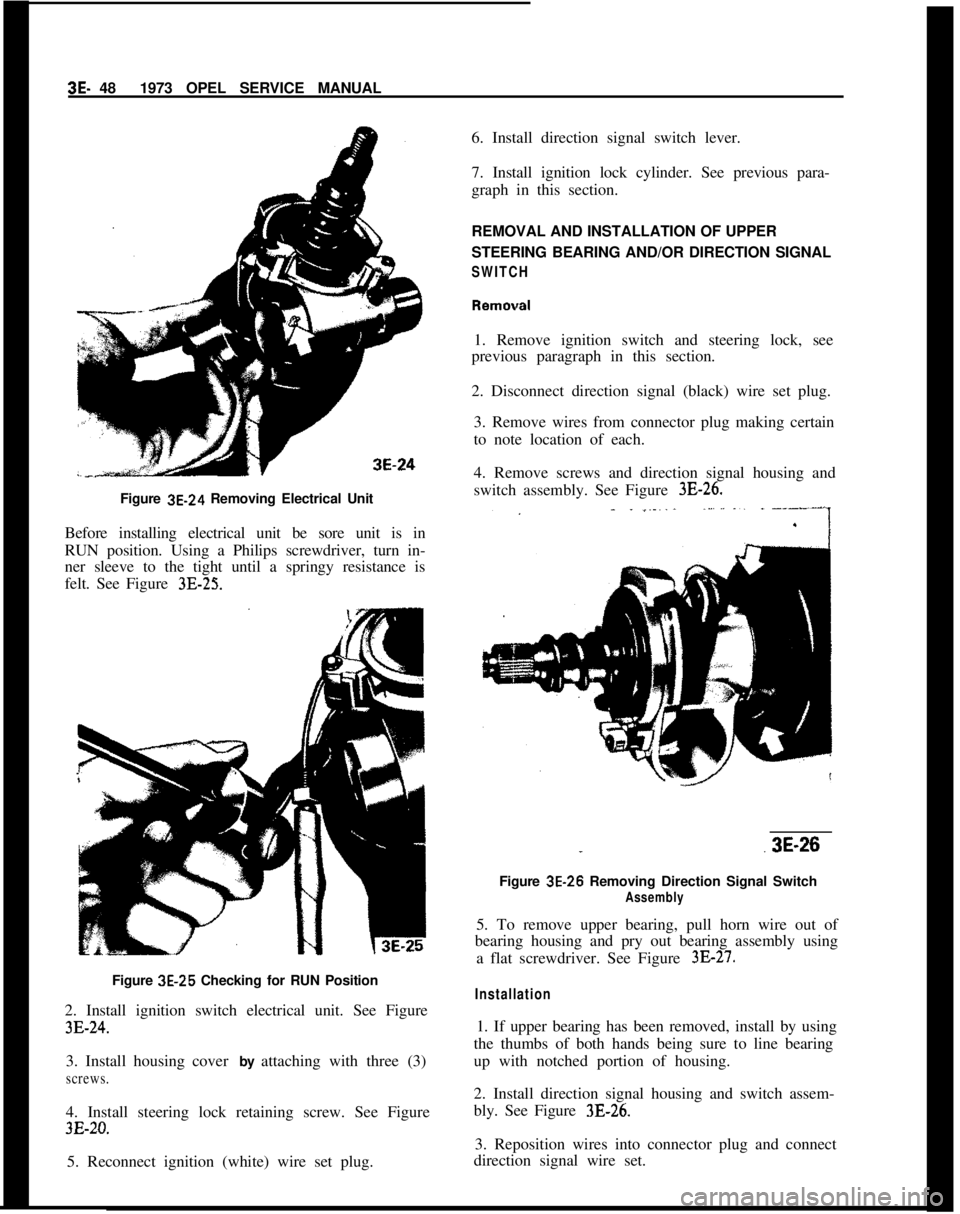

Figure 3E-24 Removing Electrical Unit

Before installing electrical unit be sore unit is in

RUN position. Using a Philips screwdriver, turn in-

ner sleeve to the tight until a springy resistance is

felt. See Figure 3E-25.Figure 3E-25 Checking for RUN Position

2. Install ignition switch electrical unit. See Figure

3E-24.3. Install housing cover by attaching with three (3)

screws.4. Install steering lock retaining screw. See Figure

3E-20.5. Reconnect ignition (white) wire set plug.6. Install direction signal switch lever.

7. Install ignition lock cylinder. See previous para-

graph in this section.

REMOVAL AND INSTALLATION OF UPPER

STEERING BEARING AND/OR DIRECTION SIGNAL

SWITCH1. Remove ignition switch and steering lock, see

previous paragraph in this section.

2. Disconnect direction signal (black) wire set plug.

3. Remove wires from connector plug making certain

to note location of each.

4. Remove screws and direction signal housing and

switch assembly. See Figure

3E-26.

..3E-26

Figure 3E-26 Removing Direction Signal Switch

Assembly5. To remove upper bearing, pull horn wire out of

bearing housing and pry out bearing assembly using

a flat screwdriver. See Figure

3E-27.

Installation1. If upper bearing has been removed, install by using

the thumbs of both hands being sure to line bearing

up with notched portion of housing.

2. Install direction signal housing and switch assem-

bly. See Figure 3B26.

3. Reposition wires into connector plug and connect

direction signal wire set.

Page 216 of 625

GT STEERING COLUMN ASSEMBLY3E- 49

4. Install ignition switch and steering lock

REMOVAL AND INSTALLATION OF STEERING

COLUMN LOWER BEARING

The following is with steering column assembly

removed.

1. Remove steering wheel.

2. Remove screws securing lower bearing housing to

mast jacket.

3. Remove steering shaft together with universal

joint and bearing and housing.

4. Remove universal joint from shaft. See Figure 3E-28.Figure 3627 Removing Upper Bearing

SERRATED SOCKET

“‘*E.Z<~lh I’

I//

11 uBEARING HOUSINGy

SE-28Figure 3E.28 Removing Lower Bearing

5. Remove bearing retainer snap ring and remove

bearing.

Installation3. Install steering shaft, together with universal joint

bearing and housing to mast jacket. Serrated socket

head screw must be installed on

tm side of steering

column assembly. See Figure 3E-2\.

1. Install bearing and bearing retainer snap ring.

2. Install universal joint and torque to 22

Ib.ft.4. Install steering wheel. On installation of steering

wheel, make sure that with flats of lower portion of

universal joint horizontal, the center steering wheel

spoke must be vertical.

Page 314 of 625

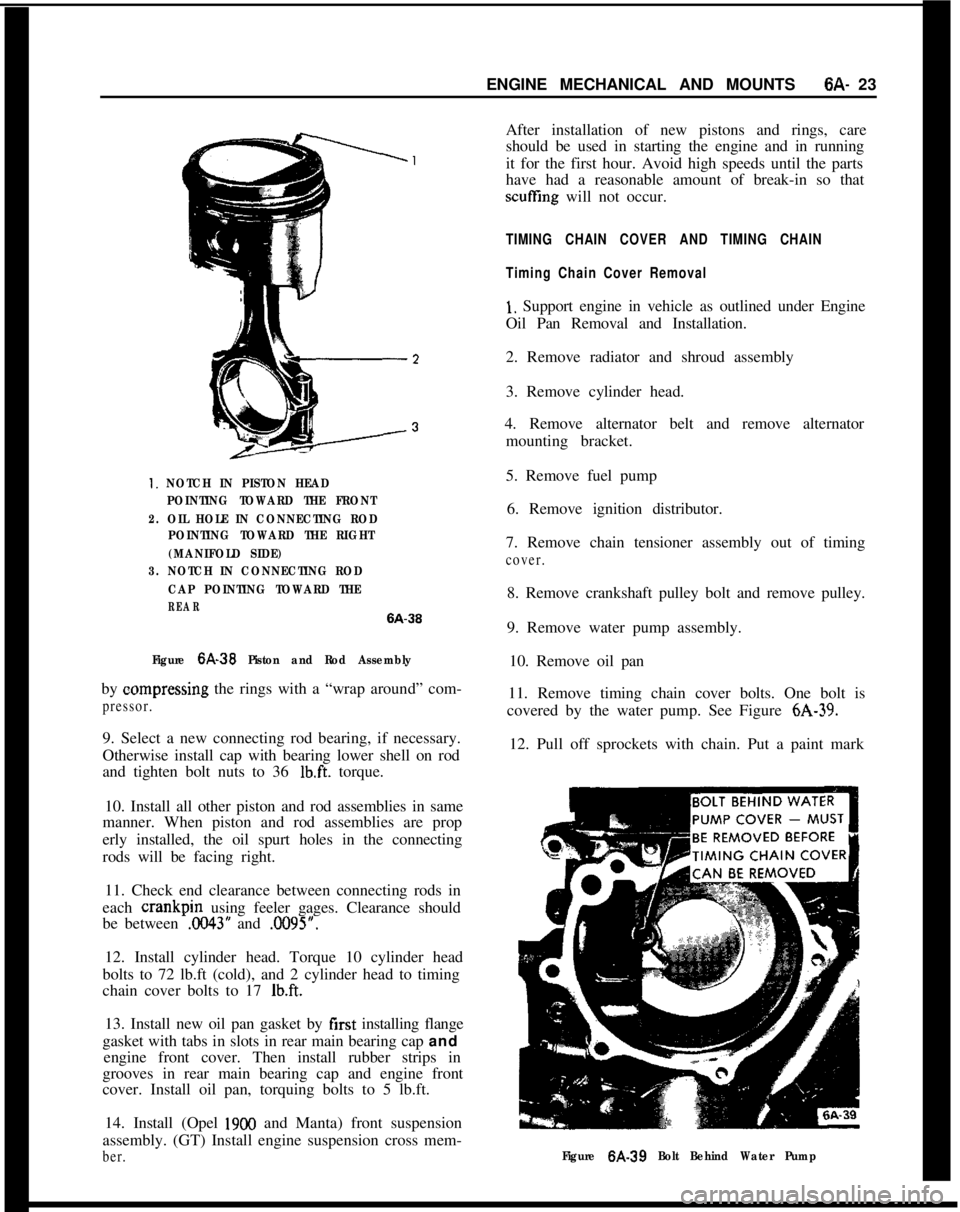

ENGINE MECHANICAL AND MOUNTS6A- 231. NOTCH IN PISTON HEAD

POINTING TOWARD THE FRONT

2. OIL HOLE IN CONNECTING ROD

POINTING TOWARD THE RIGHT

(MANIFOLD SIDE)

3. NOTCH IN CONNECTING ROD

CAP POINTING TOWARD THE

REAR6A-36

Figure

6A-39 Piston and Rod Assemblyby oompressing the rings with a “wrap around” com-

pressor.9. Select a new connecting rod bearing, if necessary.

Otherwise install cap with bearing lower shell on rod

and tighten bolt nuts to 36

lb.ft. torque.

10. Install all other piston and rod assemblies in same

manner. When piston and rod assemblies are prop

erly installed, the oil spurt holes in the connecting

rods will be facing right.

11. Check end clearance between connecting rods in

each crankpin using feeler gages. Clearance should

be between

.0043” and .0095”.

12. Install cylinder head. Torque 10 cylinder head

bolts to 72 lb.ft (cold), and 2 cylinder head to timing

chain cover bolts to 17

lb.ft.13. Install new oil pan gasket by first installing flange

gasket with tabs in slots in rear main bearing cap and

engine front cover. Then install rubber strips in

grooves in rear main bearing cap and engine front

cover. Install oil pan, torquing bolts to 5 lb.ft.

14. Install (Opel

1900 and Manta) front suspension

assembly. (GT) Install engine suspension cross mem-

ber.After installation of new pistons and rings, care

should be used in starting the engine and in running

it for the first hour. Avoid high speeds until the parts

have had a reasonable amount of break-in so that

scuffling will not occur.

TIMING CHAIN COVER AND TIMING CHAIN

Timing Chain Cover Removal

1, Support engine in vehicle as outlined under Engine

Oil Pan Removal and Installation.

2. Remove radiator and shroud assembly

3. Remove cylinder head.

4. Remove alternator belt and remove alternator

mounting bracket.

5. Remove fuel pump

6. Remove ignition distributor.

7. Remove chain tensioner assembly out of timing

cover.8. Remove crankshaft pulley bolt and remove pulley.

9. Remove water pump assembly.

10. Remove oil pan

11. Remove timing chain cover bolts. One bolt is

covered by the water pump. See Figure 6A-39.

12. Pull off sprockets with chain. Put a paint mark

Figure 6A-39 Bolt Behind Water Pump

Page 340 of 625

CARBURETOR AND THROTTLE LINKAGE6E- 49DIAGNOSIS

CARBURETORCondition I

Hesitation or Stall Upon Light AccelerationCorrection

1. Check spark plugs and plug gap. Plug gap should

be

,030 in.

2. Check dwell and timing.

3. Adjust carburetor.

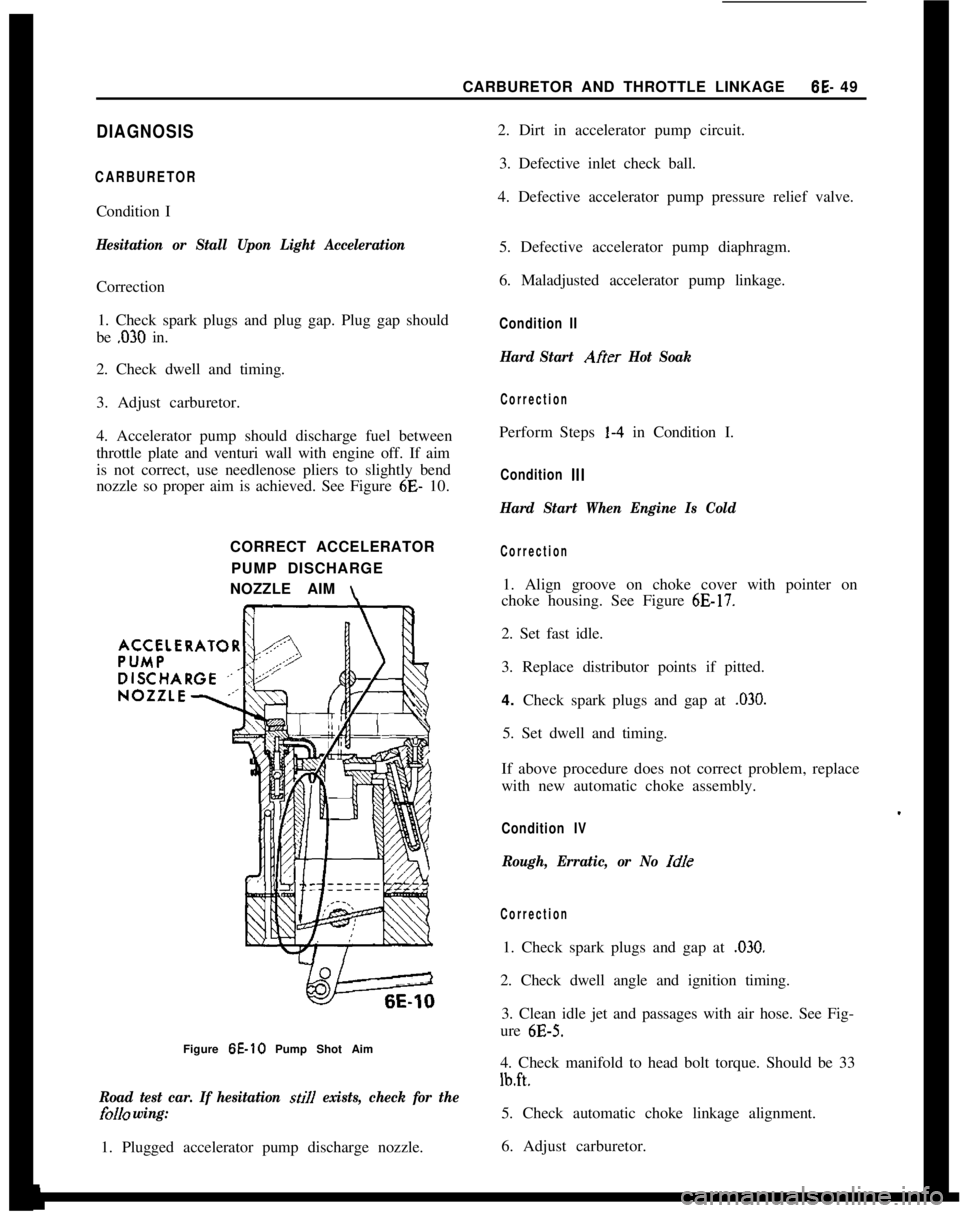

4. Accelerator pump should discharge fuel between

throttle plate and venturi wall with engine off. If aim

is not correct, use needlenose pliers to slightly bend

nozzle so proper aim is achieved. See Figure 6E- 10.

CORRECT ACCELERATOR

PUMP DISCHARGE

NOZZLE AIM

\Figure 6E-10 Pump Shot Aim

Road test car. If hesitation still exists, check for the

folI0 wing:1. Plugged accelerator pump discharge nozzle.2. Dirt in accelerator pump circuit.

3. Defective inlet check ball.

4. Defective accelerator pump pressure relief valve.

5. Defective accelerator pump diaphragm.

6. Maladjusted accelerator pump linkage.

Condition II

Hard Start Afier Hot Soak

CorrectionPerform Steps l-4 in Condition I.

Condition Ill

Hard Start When Engine Is Cold

Correction1. Align groove on choke cover with pointer on

choke housing. See Figure

6E-17.2. Set fast idle.

3. Replace distributor points if pitted.

4. Check spark plugs and gap at

,030.5. Set dwell and timing.

If above procedure does not correct problem, replace

with new automatic choke assembly.

Condition IV

Rough, Erratic, or No Idle

Correction1. Check spark plugs and gap at

,030.2. Check dwell angle and ignition timing.

3. Clean idle jet and passages with air hose. See Fig-

ure

6E-5.4. Check manifold to head bolt torque. Should be 33

lb.ft.5. Check automatic choke linkage alignment.

6. Adjust carburetor.

Page 341 of 625

6E- 501973 OPEL SERVICE MANUALMAINTENANCE AND ADJUSTMENTS

IDLE SPEED ADJUSTMENT

Note:

Idle speeds of 600 to 800 R.P.M. are normal

for engines with less than

3,ooO miles.Prior to making any adjustment to the carburetor,

the following items must be checked for proper oper-

ation and/or setting:

1. Valve Adjustment (Hydraulic lifters can be im-

properly adjusted.)

2. Dwell Angle.

3. Ignition Timing.

4. Spark Plug Gap.

5. Exhaust Gas Recirculation Valve (See “Check-

ing” under EXHAUST GAS RECIRCULATION

SYSTEM.)

After it has been ascertained that the above items are

properly adjusted and operating correctly and idle

R.P.M. is still not within specifications, proceed as

follows:

1. With air cleaner installed, run engine until normal

operating temperature is reached.

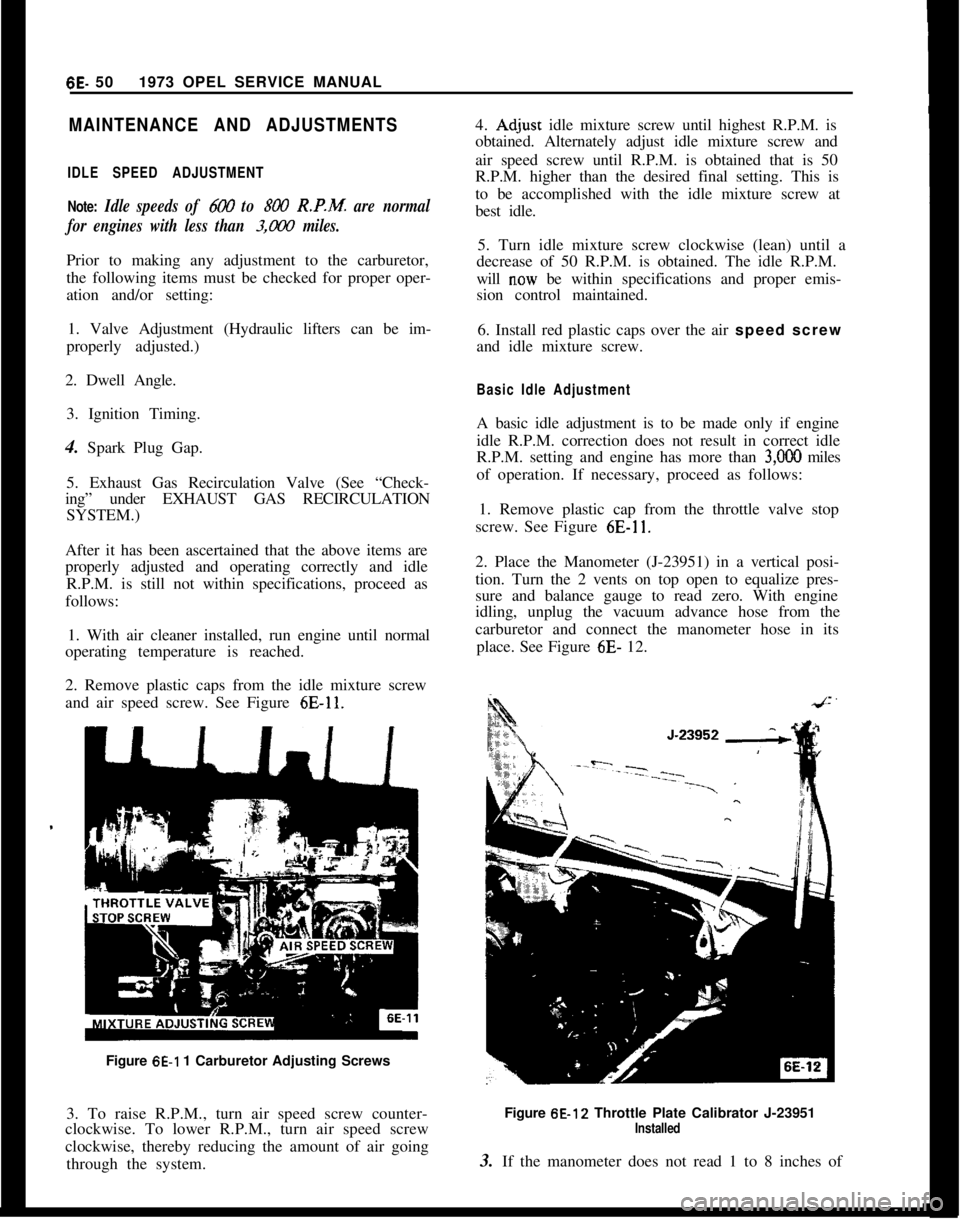

2. Remove plastic caps from the idle mixture screw

and air speed screw. See Figure

6E-11.Figure

6E-1 1 Carburetor Adjusting Screws

3. To raise R.P.M., turn air speed screw counter-

clockwise. To lower R.P.M., turn air speed screw

clockwise, thereby reducing the amount of air going

through the system.4.

Ad,just idle mixture screw until highest R.P.M. is

obtained. Alternately adjust idle mixture screw and

air speed screw until R.P.M. is obtained that is 50

R.P.M. higher than the desired final setting. This is

to be accomplished with the idle mixture screw at

best idle.

5. Turn idle mixture screw clockwise (lean) until a

decrease of 50 R.P.M. is obtained. The idle R.P.M.

will

n.ow be within specifications and proper emis-

sion control maintained.

6. Install red plastic caps over the air speed screw

and idle mixture screw.

Basic Idle AdjustmentA basic idle adjustment is to be made only if engine

idle R.P.M. correction does not result in correct idle

R.P.M. setting and engine has more than

3,OOO miles

of operation. If necessary, proceed as follows:

1. Remove plastic cap from the throttle valve stop

screw. See Figure

6E-11.2. Place the Manometer (J-23951) in a vertical posi-

tion. Turn the 2 vents on top open to equalize pres-

sure and balance gauge to read zero. With engine

idling, unplug the vacuum advance hose from the

carburetor and connect the manometer hose in its

place. See Figure 6E- 12.

Figure 6E-12 Throttle Plate Calibrator J-23951

Installed3. If the manometer does not read 1 to 8 inches of

Page 356 of 625

TUNE-UP

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Purpose of a Tune-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

EngineTune-UpMechanicalOperations. . . . . . . . . . . . . . . . . . . .

EngineTune-UpInstrumentChecks. . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:

Tune-Uo Soecifications and Adjustments

. . . . . . . . . . . . . . . .Page No.6G-65

6G-6566-6766-68

DESCRIPTION AND OPERATION

PURPOSE OF TUNE-UP

The purpose of an engine tune-up is to restore powerand performance that may have been lost through,

loss of adjustment, wear, corrosion, or deterioration

of one or more parts or units. In the normal operat-

ion of an engine, these changes take place gradually

at quite a number of points so that it is seldom advis-able to attempt an improvement in performance by

correcting one or two items only. Time will be savedand more lasting results will be assured by following

a definite and thorough procedure of analysis and

correction of all items affecting power and perform-

ance. Because of Federal laws, limiting exhaust emis-sions, it is even more important that the engines

tune-up is done accurately, using the specifications

listed and the tune-up sticker found in each engine

compartment.

Economical, trouble free operation can better be as-sured if a complete tune-up is performed at first 4

months or

6,ooO miles of operation - then at 12

month or 12,000 mile intervals.

The parts or units which affect power and perform-

ance may be divided, into three groups (1) compres-sion, (2) ignition and (3) carburetion. The tune-up

procedure should cover these groups in the order

given. While the items affecting compression and

ignition may be handled according to individual

preference, correction of items in the carburetiongroup should not be attemplcu

ulllll all items in

compression and ignition have been satisfactorily

corrected.

MAINTENANCE AND ADJUSTMENTS

ENGINE TUNE-UP OPERATIONS

CompressionTo make sure hydrocarbon and carbon monoxide

emissions will be within limits, it is very important

that the adjustments be followed exactly.

The suggested procedure for engine tune-up is as

follows:1. Remove all spark plugs.

2. Position throttle and choke valve in full open posi-tion.

3. Connect jumper wire between distributor terminalof coil and ground on engine to avoid high tension

sparking while cranking engine.

4. Hook up starter remote control cable and turn

ignition switch to “on” position.

5. Firmly insert compression gage in spark plug port.Crank engine to obtain highest possible reading.

Page 357 of 625

6G- 661973 OPEL SERVICE MANUAL

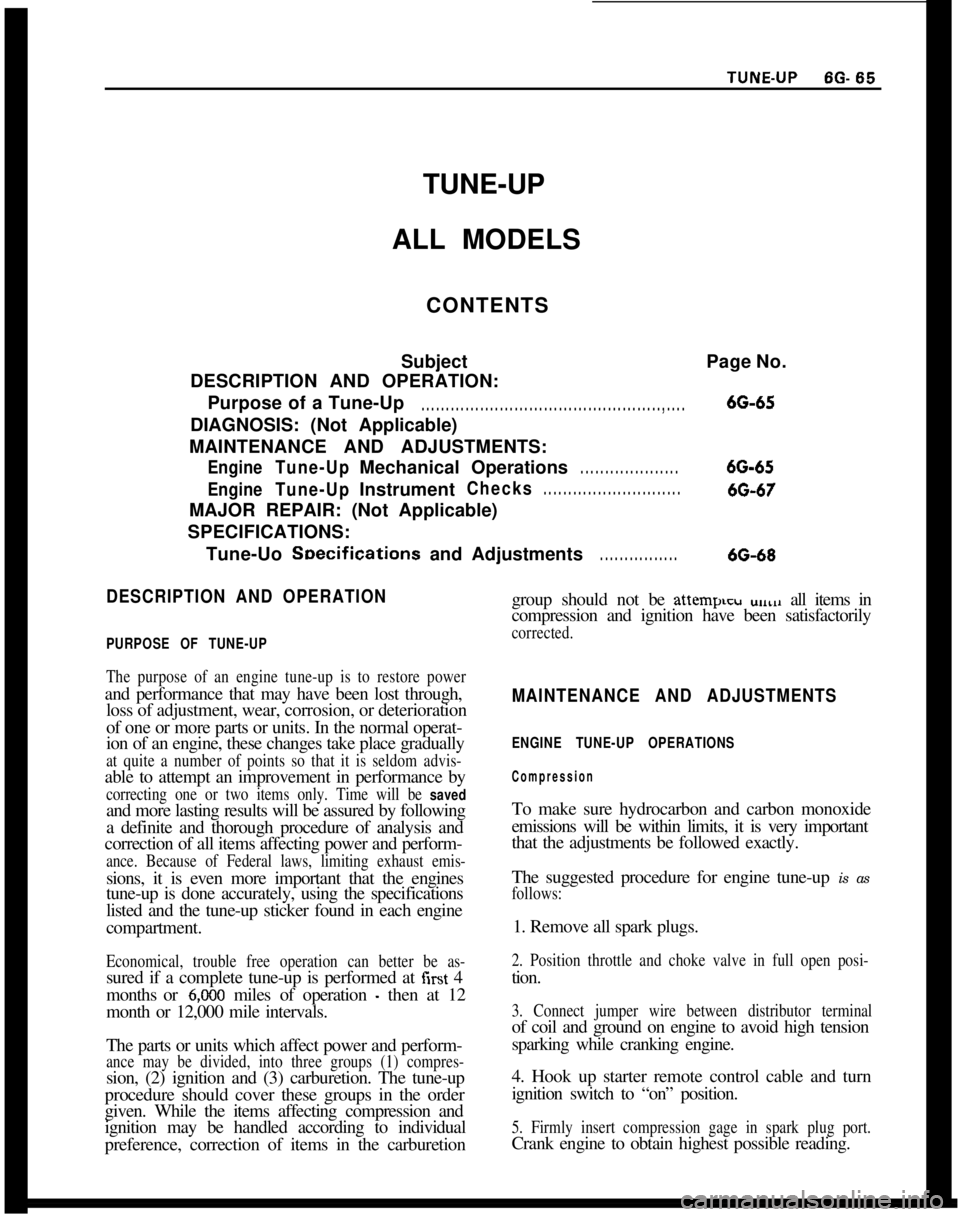

6. Check compression of each cylinder. Repeat

compression check and record highest reading ob-

tained on each cylinder during the two pressurechecks.The recorded compression pressures are to be con-

sidered normal if the lowest reading cylinder is more

than 75 percent of the highest reading cylinder. See

the following example and the “Compression Pres-

sure Limit Chart.” See Figure

6G-2.Seventy-five percent of 140 (highest) is 105. Thus,

cylinder No. 4 is less than 75 percent of No. 3. This

condition, accompanied by low speed missing, indi-

cates an improperly seated valve or worn or broken

piston ring. See Figure 6G-1.

23

I

SO-1Figure 6G-1 Example of Compression Check

7. If one or more cylinders read low, inject about a

tablespoon of engine oil on top of pistons in low

reading cylinders through spark plug port. Repeat

compression check on these cylinders.

a: If compression improves considerably, rings are

lV0*tl.b. If compression does not improve, valves are stick-

ing or seating poorly.

c. If two adjacent cylinders indicate low compression

and injecting oil does not increase compression, the

cause may be the head gasket leaking between the

cylinders. Engine coolant and/or oil in cylinders

could result from this defect.

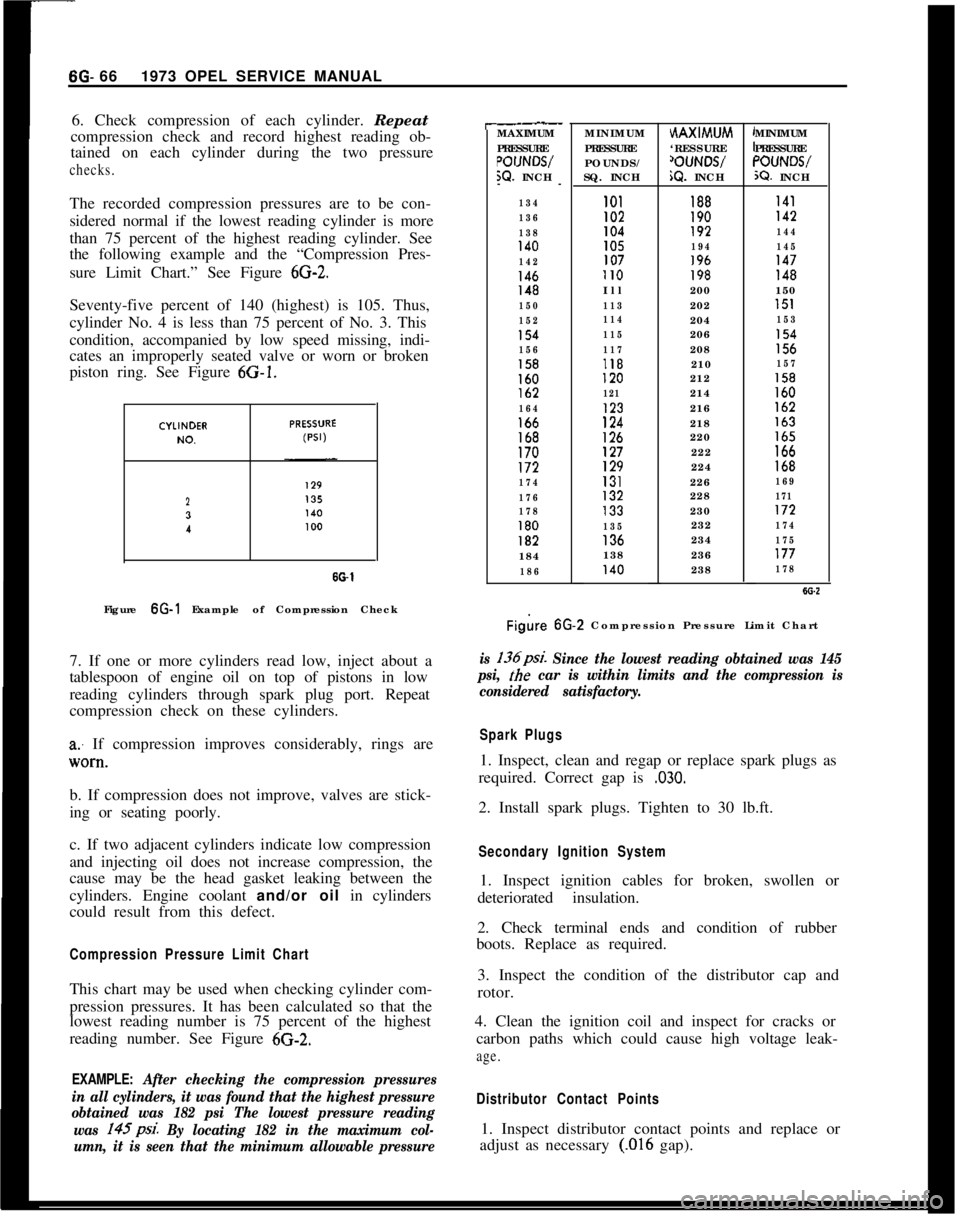

Compression Pressure Limit ChartThis chart may be used when checking cylinder com-

pression pressures. It has been calculated so that the

lowest reading number is 75 percent of the highest

reading number. See Figure 6G-2.

EXAMPLE: After checking the compression pressures

in all cylinders, it was found that the highest pressure

obtained was 182 psi The lowest pressure reading

was 145psi.

By locating 182 in the maximum col-

umn, it is seen that the minimum allowable pressure

r-.__MAXIMUM

PRESSURE

POIJNWW. INCH

--

134

136

138

140

142

146148

150

152

154

156

158160lb2

164166168170172

174

176

178

180182184

186MINIMUM

PRESSURE

POUNDS/

SQ. INCHHAXIMUM

‘RESSURE

‘OUNWiQ. INCHMINIMUM

PRESSURE“OUNWX?. INCH

101188I41I02190142104192144105194145107196147II0198148Ill200150

113202151

114204153

115206154

117208156118210157120212158

121214160123216162

124218163

126220165127222166129224168131226169132228171133230172

135232174136234175138236177140238178

Figire 6G.2 Compression Pressure Limit Chart

is 136psi. Since the lowest reading obtained was 145

psi,

the car is within limits and the compression is

considered satisfactory.

Spark Plugs1. Inspect, clean and regap or replace spark plugs as

required. Correct gap is

,030.2. Install spark plugs. Tighten to 30 lb.ft.

Secondary Ignition System1. Inspect ignition cables for broken, swollen or

deteriorated insulation.

2. Check terminal ends and condition of rubber

boots. Replace as required.

3. Inspect the condition of the distributor cap and

rotor.

4. Clean the ignition coil and inspect for cracks or

carbon paths which could cause high voltage leak-

age.

Distributor Contact Points1. Inspect distributor contact points and replace or

adjust as necessary

(.016 gap).

Page 358 of 625

2. If inspection of contact points indicates excessive

burning, pitting or wear, check condenser and re-

place if necessary.

3. Inspect all connections and wires in the primary

ignition circuit. Correct any abnormal conditions

found.Carburetor1. Clean fuel strainer in fuel pump. To prevent fuel

leakage in pump, disconnect “IN” line from pump

and raise end above fuel level. The in-line fuel filter

should be replaced every 12,000 miles or every 12

months.

2. Check for freedom of choke valve operation and

clean shaft if necessary, with suitable solvent.

3. Inspect throttle cable or linkage bracket and re-

turn spring for wear. With helper depressing acceler-

ator pedal to floor, check for wide open throttle.

Adjust accelerator pedal height so wide open throttle

is obtained when pedal is within

l/2 inch from floor.

Lubricate linkage pivot points with engine oil.

Air CleanerCheck paper element every 6,000 miles and replace

every

24,ooO miles. If a vehicle is operated in dusty

territory, check condition of air cleaner element

more frequently and replace if necessary.

Fan Belt1. Inspect belt for wear, cracks or frayed points.

Replace and/or adjust as necessary. Specified ten-

sion for belt using Gauge J-23600 is 45 lbs.

Cooling System1. Inspect the radiator, water pump, cylinder head

areas and all radiator and heater hose connections

for evidence of engine coolant leaks.

2. Inspect all hoses for deterioration from gas and oil

contact. Correct as required.

Inspection should be made with engine operating at

normal temperature, cooling system completely

filled, temperature control lever fully open and nor-

mal pressure in the system. Normal pressure should

be 13.2 to 15.2 psi.

Engine Lubrication SystemInspect engine for evidence of oil leakage. Correctany abnormal condition with sealastic or new seals

and gaskets.

Battery

1. Inspect battery, battery mount and cables and

check electrolyte level. Proper level should be just

above the cell plates.

CAUTION:Do not over fill.

2. Determine the serviceability of the battery by ap-

plying the 421 Battery Test.

Positive Crankcase VentilationClean crankcase ventilator metered orifice in the in-

take manifold fitting every 6,000 miles. Also all hoses

and fittings should be inspected, cleaned and re-

placed, if necessary.

To clean, remove rubber hose from metered orifice

and apply air pressure to orifice to remove any for-

eign particles that may be trapped.

Valve Lifter AdjustmentRefer to Engine Mechanical and Mounts section for

valve lifter adjustment procedure.

Engine Tune-Up Instrument ChecksThe following instrument checks and adjustments

serve as a final check on engine condition. These

checks may discover some new problems that may

not have been obvious before. The engine is also

given its final adjustments that will assure maximum

performance, reliability, and proper emission con-

trol.

Refer to Electrical Group for checking procedures of

the following:

Cranking Voltage Check

Ignition Timing

Distributor Advance

Ignition Output

Secondary Resistance

Current Output and Voltage Setting

Idle Speed and Mixture AdjustmentsRefer to carburetor section.

Page 359 of 625

6G- 68 1973 OPEL SERVICE MANUAL

SPECIFICATIONS

TUNE-UP SPECIFICATIONS AND ADJUSTMENTS

Voltage Regulator

Voltage Regulator Setting in Volts at2500 Engine RPM. . . . . . . . . . . . . . . . . . . . . .14+.5

Ignition Coil

Ignition Coil Current Draw, Amperes at 12.5 Volts

Engine Stopped

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . .3.8

EngineIdling. . . . . . . . . . . . . . . . . .._.....................................................................\

........................... 2.3

Total Advance (Centrifugal and Vacuum), Engine Degrees at 3600 Engine \

RPM......29-38

Centrifugal Advance, Engine Degrees and RPM

Start Advance, atRPM

........................................................................\

................ 1000-1200

Medium Advance, Degrees at RPM..............................................................7.5-15 at 1400

Maximum Advance, Degrees at RPM

..........................................................28-32 at 3600

Vacuum Advance, Engine Degrees and In. of Vacuum Start Advance..

........................................................................\

.................-5at2.9-4.1 In.

Maximum Advance..........................................................................\

........1-5at4.5-5.0In.

Vacuum Retard, Engine Degrees at Closed Throttle............................................................-5

Condenser Capacity in

MicroFarads........................................................................\

.......23-.32

Breaker Spring Tension in Ounces........................................................................\

......14 to 19

Breaker Point Gap in Inches

........................................................................\

......................,016

Dwell AngleinEngine Degrees........................................................................\

.......... 50+3

Firing

Order........................................................................\

............................................l-3-4-2

Spark Plug or Coil Cable,Max.Resistance in Ohms

..................................................

10,000

Spark Plugs

Make and Model Production........................................................................\

............AC42FS

Make andModel

-Replacement........................................................................\

..........AC42FS

If carbon fouling occurs, use

........................................................................\

............AC43FS

Spark Plug Torque in

Lb.Ft.........................................................................\

.........................30

Spark Plug Gap in Inches........................................................................\

..........................,030

Valve Lifter Adjustment

One full turn (clockwise) after zero clearance is obtained - refer to Valve Adjustment

Procedure

Ignition Timing

Align timing marks with distributor retard hose disconnected and plugged\

Page 615 of 625

RADIO - GT9c. 107mer screw and rotate screw until maximum volume

is achieved.

MAJOR REPAIR

REMOVING AND INSTALLING RADIORemoval

1.

Disc&ect battery.

2. Remove access trim plug from right side of con-

sole. See Figure

9C-1.Figure

9C-3 Location of Access Trim Cover3. Using a 8mm socket, remove hex head screw. See

Figure

9C-2.4. Remove access trim cover on left side of console.

See Figure

9C-3.5. Using a 4mm socket, remove

hex head screw. See

Figure

9C-4.6. Remove tear lock bolts by first,drilling a 3/16 inch

pilot hole and, using a

l/4 inch bolt extractor,

remove bolts. See Figure

9C-5.Figure

9C-5 Drilling Pilot HoleIn\, Tear Lock Bolts7. Disconnect ignition (white) and direction signal

(black) wire set plugs.

8. Support steering column assembly and remove

both hex head bolts.

9. Disconnect speedometer

cabI&10. Remove 6 instrument cluster retaining screws.

See Figure

9C-6.Figure SC-4 Location of Hex Head Screw and Flasher

UnitFigure SC-6 Removing Instrument Cluster Retaining

screws