transmission OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 60 of 625

WINDSHIELD WIPERSlE- 39

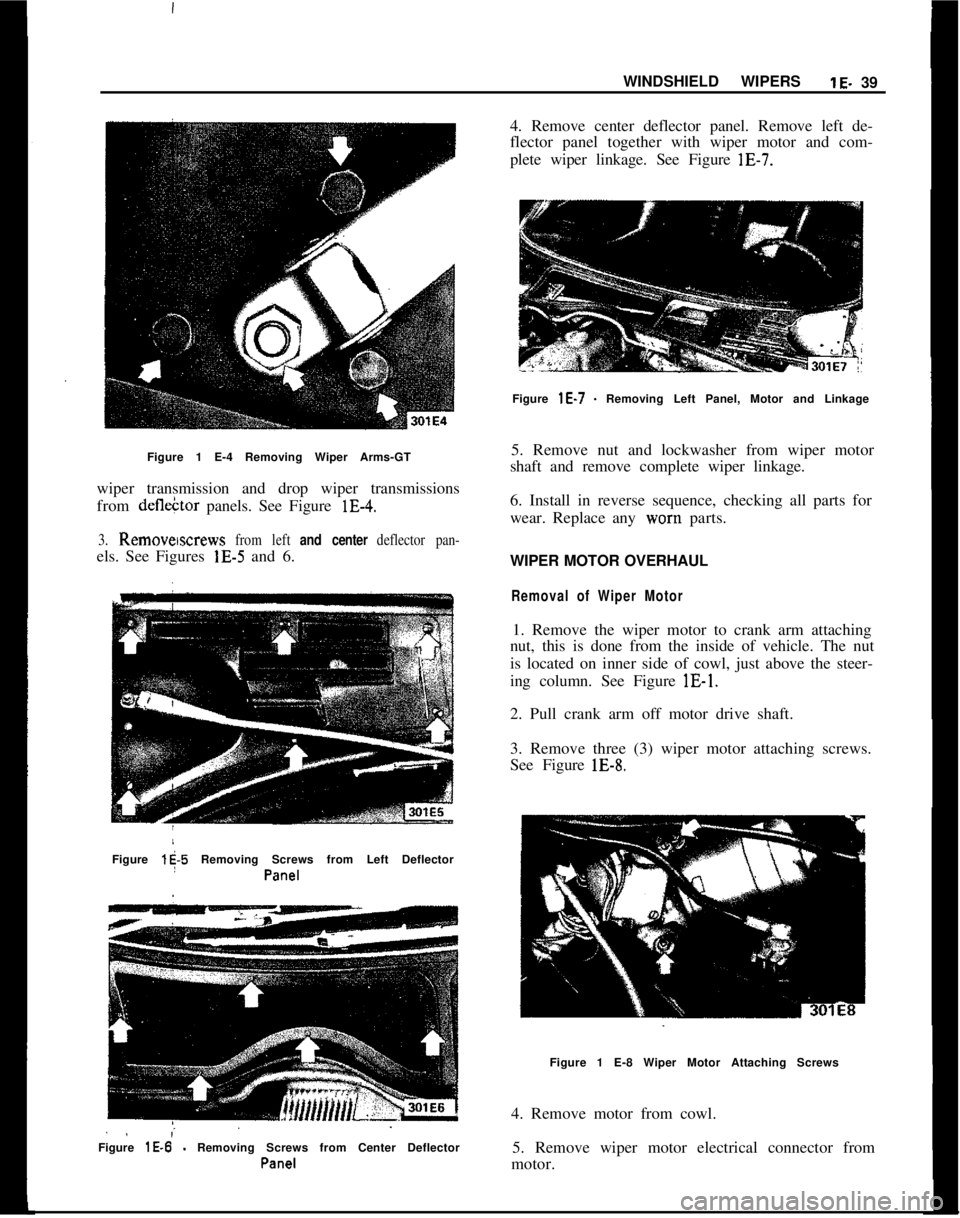

Figure 1 E-4 Removing Wiper Arms-GT

wiper transmission and drop wiper transmissions

from defleCtor panels. See Figure lE-4.3. Remowscrews from left and center deflector pan-els. See Figures lE-5 and 6.

Figure

l$-5 Removing Screws from Left Deflector

I

Pa%?1

. .;Figure

lE-6 - Removing Screws from Center Deflector

Pall-Z!14. Remove center deflector panel. Remove left de-

flector panel together with wiper motor and com-

plete wiper linkage. See Figure lE-7.

Figure

lE-7 - Removing Left Panel, Motor and Linkage

5. Remove nut and lockwasher from wiper motor

shaft and remove complete wiper linkage.

6. Install in reverse sequence, checking all parts for

wear. Replace any worn parts.

WIPER MOTOR OVERHAUL

Removal of Wiper Motor1. Remove the wiper motor to crank arm attaching

nut, this is done from the inside of vehicle. The nut

is located on inner side of cowl, just above the steer-

ing column. See Figure lE-1.

2. Pull crank arm off motor drive shaft.

3. Remove three (3) wiper motor attaching screws.

See Figure lE-8.

Figure 1 E-8 Wiper Motor Attaching Screws

4. Remove motor from cowl.

5. Remove wiper motor electrical connector from

motor.

Page 61 of 625

1 E- 40 1973 OPEL SERVICE MANUALDisassemblyI

1. Remove two (2) motor housing attaching

screw$(Item No. 4) and two (2) angle brackets (Item No.

3). See Figure lE-9.

Figure 1 E-S Removing Motor Housing Attaching

SCFS”JSFigure

1 E-l 0 Transmission and Armature Removed

from Motor Housing2. Remoyz transmission housing together with arma-

ture from motor housing. See Figure lE-10. It may

be necessary to hold armature in transmission hous-

ing with a screw driver.

3.

Rem~ove armature from transmission housing.

4. Remove five (5) transmission housing cover

screws. See Figure lE-11.Figure 1 E-l 1 Remove Transmission Housing CoverSCEWS

5. Remove cover, gasket and driven gear from trans-

mission housing. See Figure IE-12. Remove pivot

ball from driven gear. See Figure lE-15.

Figure 1 E-l 2 Remove Driven Gear

6. If required, remove brushes.

a. To remove positive brushes, cut brush leads off at

brush holder. See Figure lE-13.

b. To remove negative brush, remove brush retaining

screw from commutator end frame. See Figure

lE-

14.

Page 62 of 625

WINDSHIELD WIPERSlE-41

Figurk 1 E-l 3 Cut Off Positive Brush Leads

i

Figure iE-14 Remove Negative Brush Retaining

S.X?WI

Cleaning apd Inspection of PartsWith the ekception of electrical parts and bushings,

clean all components in a cleaning solvent.

1. Check irmatare windings for ground, or open

circuit. If

b ground or open circuit is evident, the

armature must be replaced. If the armature checks

out, the c

brushes should be 6.35 to 8.47 ounces. Spring pres-

sure of worn brushes should be at least 3.5 ounces.

In case of /ower spring pressure, replace springs.

3. Check blushes for wear and replace if necessary.

Minimum brush length should be

.24’inch.4. Check d$ven gear for wear and replace if neces-

sary.

Assembly

02383. I

2. Install

d&en gear into housing3. Apply a small amount of grease to ball cavity of

driven gear and insert ball. See Figure lE-15.

Figure lE-15 Insert Ball into Driven Gear

4. Install transmission housing cover. See Figure

lE-

16.2. DRIVEN GEAR

3. CONTACT SPRINGS

4. TRANSMISSION

HOUSING COVER

Figure 1 E-l 6 Install Transmission Housing

Cover5. Solder positive brush lead(s) to brush holder(s).

Hold brush lead with needle nose pliers to prevent

solder from running up wire strands. See Figure

lE-

17.6. Install negative brush

7. Apply a small amount of grease to end of armature

shaft. Lightly oil armature shaft.

8. Insert brush springs and brushes into brush hold-

ers. Slide armature into housing, taking care not to

damage brushes.

Page 65 of 625

1 E- 44 1973 OPEL SERVICE MANUAL)

‘30

1.2.

3.4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.ATTACHING SCREWS16. NEGATIVE BRUSH

TRANSMISSION COVER 17. ATTACHING SCREW

HEX. NUT

THREADED END ~18. RETAiNING PLATE

19. POSlilVE BRUSH

PLAY PIN20. WIRE’

GASKET21. THRUST SPRING

BALL22. RUBBFR MOUNTS

DRIVEN GEAR23. ARMATURE

WASHER24. ATTACHING SCREWS

THREADED END25. LOCKWASHER

PLAY PIN26. ANGLE BRACKE’TS

SLEEVE27. MOTOR HOUSING

MOUNTING PLATE28. MAGNET RING

GASKET29. MAGNET THREADED

TOOTHED WASHERSPi N

LOCATORSATTACHING SCREWS30. NORTH POLE PAINT

TRANSMISSIONMARKING ON

HOUSING

THISfSIDENOTE: MOTOR HOUSING

WITH MAGNET RING HAS

TO BE INSTALLED SO THAT

THE NORTH POLE MARKING

(PAINT DOT ON MAGNET

RING) FACES TOWARDS

‘IRANSMISSION.

301 E20Figure 1620 Wi$er Motor

- Exploded View

Page 76 of 625

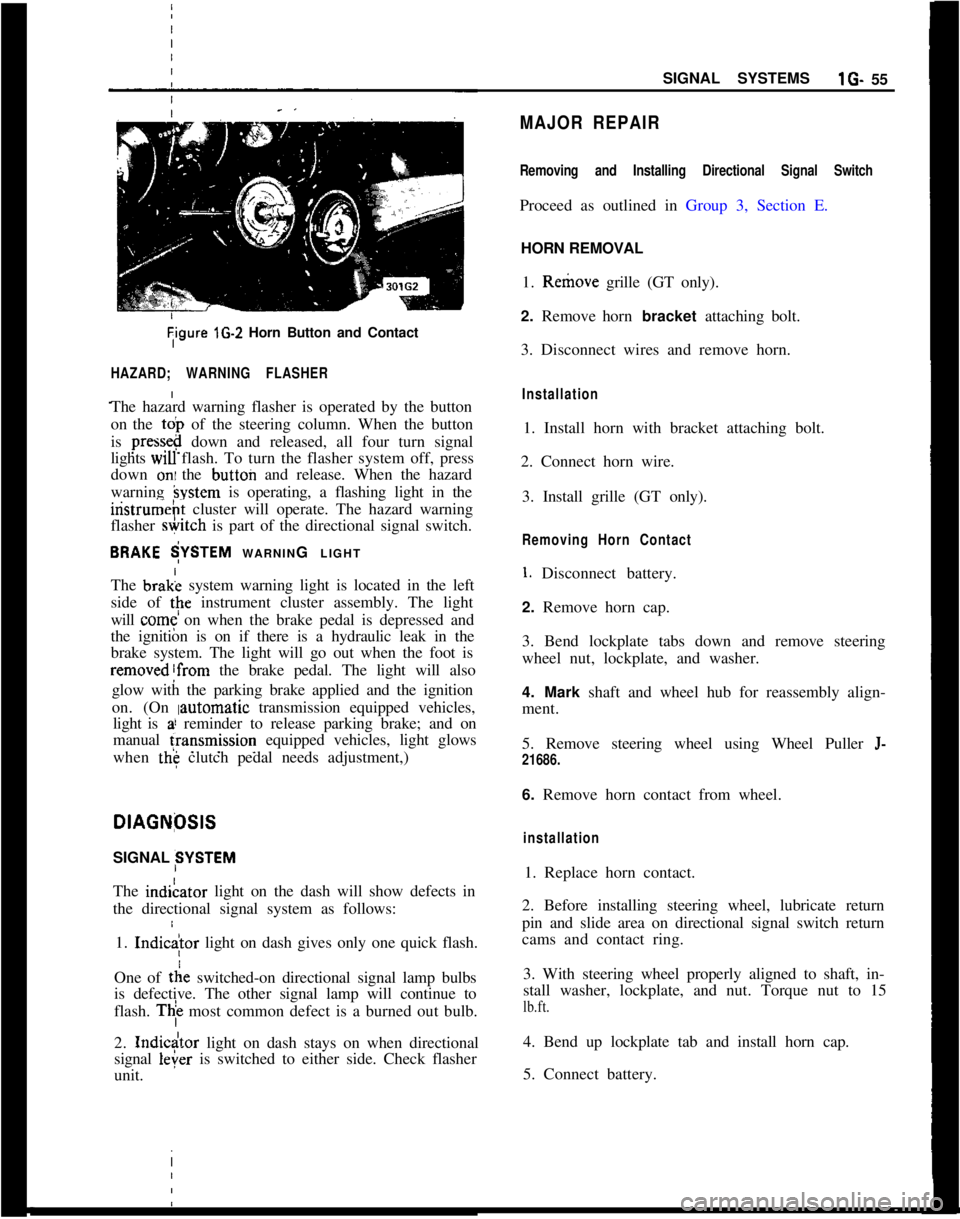

Tigure lG-2 Horn Button and Contact

HAZARD; WARNING FLASHER

The hazard warning flasher is operated by the button

on the

toi, of the steering column. When the button

is

press&@ down and released, all four turn signal

lights

WIU flash. To turn the flasher system off, press

down

oni the button and release. When the hazard

warning

hystem is operating, a flashing light in the

iristrumeht cluster will operate. The hazard warning

flasher

&itch is part of the directional signal switch.

BRAKE $YSTEM WARNING LIGHT

The brak; system warning light is located in the left

side of

tpe instrument cluster assembly. The light

will

come on when the brake pedal is depressed and

the ignition is on if there is a hydraulic leak in the

brake system. The light will go out when the foot is

removed!from the brake pedal. The light will also

glow with the parking brake applied and the ignition

on. (On

Iautomatic transmission equipped vehicles,

light is

a! reminder to release parking brake; and on

manual

fransmission equipped vehicles, light glows

when

the clutch pedal needs adjustment,)

I

DlAGNfXlS

SIGNAL SYSTEM

The indiLator light on the dash will show defects in

the directional signal system as follows:

1.

Indic

tie switched-on directional signal lamp bulbs

is defective. The other signal lamp will continue to

flash.

Thi most common defect is a burned out bulb.

2.

Indicdtor light on dash stays on when directional

signal

leier is switched to either side. Check flasher

unit. I

SIGNAL SYSTEMSlG- 55

MAJOR REPAIR

Removing and Installing Directional Signal Switch

Proceed as outlined in Group 3, Section E.

HORN REMOVAL

1. Remove grille (GT only).

2. Remove horn bracket attaching bolt.

3. Disconnect wires and remove horn.

Installation

1. Install horn with bracket attaching bolt.

2. Connect horn wire.

3. Install grille (GT only).

Removing Horn Contact

1. Disconnect battery.

2. Remove horn cap.

3. Bend lockplate tabs down and remove steering

wheel nut, lockplate, and washer.

4. Mark shaft and wheel hub for reassembly align-

ment.

5. Remove steering wheel using Wheel Puller

J-

21686.

6. Remove horn contact from wheel.

installation

1. Replace horn contact.

2. Before installing steering wheel, lubricate return

pin and slide area on directional signal switch return

cams and contact ring.

3. With steering wheel properly aligned to shaft, in-

stall washer, lockplate, and nut. Torque nut to 15

lb.ft.

4. Bend up lockplate tab and install horn cap.

5. Connect battery.

Page 93 of 625

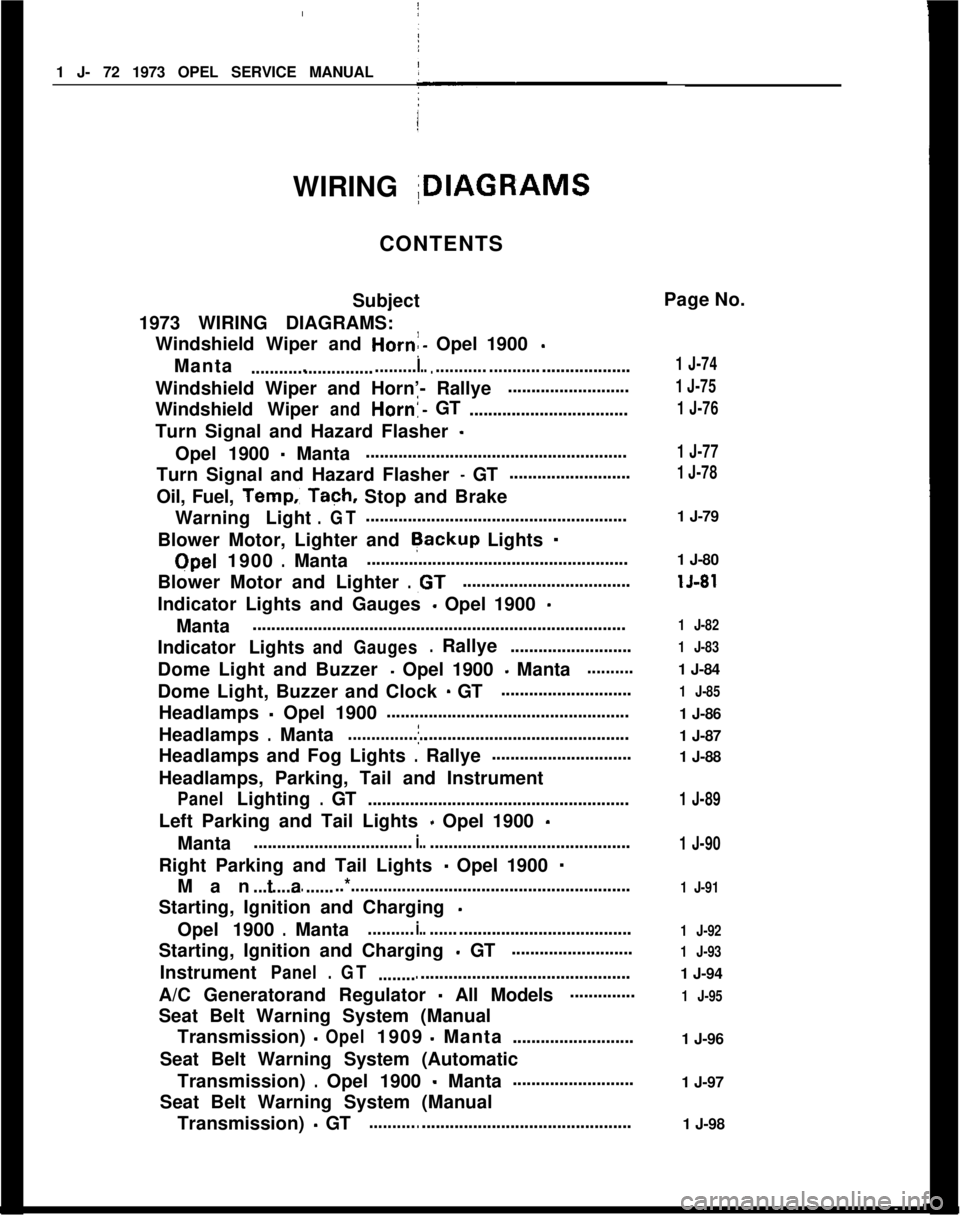

1 J- 72 1973 OPEL SERVICE MANUAL

I

WIRING IDIAGRAMS

CONTENTS

Subject

1973 WIRING DIAGRAMS: Windshield Wiper and

Horn:- Opel 1900 -

Manta....................................I.............. ..............................

Windshield Wiper and Horn’- Rallye ..........................

Windshield Wiper

andHorn!-GT

..................................

Turn Signal and Hazard Flasher

-

Opel 1900 - Manta !

........................................................

Turn Signal and Hazard Flasher

- GT ..........................

Oil, Fuel,

Temp.: Tach, Stop and Brake

Warning Light

.GT........................................................

Blower Motor, Lighter and

Rackup Lights -

Qpel 1900.Manta ........................................................

Blower Motor and Lighter

.,GT....................................

Indicator Lights and Gauges

- Opel 1900 -

Manta ........................................................................\

........

Indicator Lights

andGauges.Rallye ..........................

Dome Light and Buzzer

- Opel 1900 - Manta..........

Dome Light, Buzzer and Clock - GT ............................

Headlamps

- Opel 1900 ’

....................................................

Headlamps

.Mantaj............................................................

Headlamps and Fog Lights

.Rallye ..............................

Headlamps, Parking, Tail and Instrument

PanelLighting.GT ........................................................

Left Parking and Tail Lights

- Opel 1900 -

Manta ..................................i.............................................

Right Parking and Tail Lights

- Opel 1900 -

Manta................. ..*............................................................

Starting, Ignition and Charging

-

Opel 1900.Manta..........i.............................................

Starting, Ignition and Charging

- GT ..........................

Instrument

Panel.GT ......................................................

A/C Generatorand Regulator

- All Models..............

Seat Belt Warning System (Manual Transmission)

-Opel1909-Manta ..........................

Seat Belt Warning System (Automatic Transmission)

.Opel 1900 - Manta..........................

Seat Belt Warning System (Manual Transmission)

- GT........................................................ Page No.

1 J-74

1 J-75

1 J-76

1 J-77

1 J-78

1 J-79

1 J-80

lJ-81

1 J-82

1 J-83

1 J-84

1 J-85

1 J-86

1 J-87

1 J-88

1 J-89

1 J-90

1 J-91

1 J-92

1 J-93

1 J-94

1 J-95

1 J-96

1 J-97

1 J-98

Page 94 of 625

I

/WIRING DIAGRAMS13-73ISeat Belt Warning System (Automatic

Page No.Transmission)

.GT.......................................................lJ-99HeatedRear Glass

.Opel1900.Manta...................15-100Heated Rear Glass

.GT..................................................*,lJ-101Opel 1900 Color Schematic.........................................

lJ-103Manta

ColorSchematic.................................................1 J-105GT

ColorSchematic

.........................................................1 J-107

Page 118 of 625

WIRING DIAGRAMSlJ- 97

cI

&N

/I

IFigure 1 J-24 Seat Belt Warning System (Automatic Transmission) Opel 1900 Manta

Page 120 of 625

WIRING DIAGRAMSlJ-99Figure

lJ-26 Seat Belt Warning System (Automatic Transmissionl - GT

Page 171 of 625

3A- 41973 OPEL SERVICE MANUAL

The two cross-members to body supports are at-

tached to the horizontal part of the cross-member

with two bolts. The oufererbolt serves simultaneously

as support for the lower control arm. As the bolt is

inserted from the front, the cross-member to body

support can be removed without the lower control

arm. The inner bolt attaches simultaneously to the

steering.

The stabilizer is U-shaped and supported in rubber

bushings in the two cross-members to body supports.

The complete front suspension is attached to the

underbody in four places.

The engine damper blocks are bolted to the inside of

the inclined parts of the cross-member.

The front wheel bearings are roller bearings.

All front suspension joints are maintenance-free.

MAINTENANCE AND ADJUSTMENTSFRONT WHEEL BEARING ADJUSTMENT

1. If wheel has not previously been removed from the

car, remove grease cap, cotter pin, and spindle nut.

Discard cotter pin.

2. Torque spindle nut to 18

lb.ft. while rotating

wheel. This will allow the bearings to settle.

3. Back offspindle nut

l/4 turn. If slot and cotter pin

hole are staggered, further back off nut

l/l2 turn,

but do not tighten, until next slot in nut is in align-

ment with hole in spindle. Install new cotter pin. A

properly adjusted wheel bearing has a small amount

of end play and a loose nut when adjusted in the

above manner.

MAJOR REPAIRREMOVAL AND INSTALLATION OF FRONT

SUSPENSION

(COMPLETE ASSEMBLY)

Removal GT1. Prior to raising front end of car, apply parking

brake and block rear wheels.

2. Raise front end of car with a jack. It is recom-

mended that a wood block be placed between thejack and the front cross member to prevent damage

to the cross member.

3. Support front end of car by placing floor standsunde:r jacking brackets.

4. Support engine-transmission assembly in upper-

most position with jack stand at rear of engine, or an

alternate method would be to use Engine Holding

Fixture, Tool J-23375. See Figure 3A-5.

Install tool by removing upper kngine mount nut and

installing fixture. Replace nut and tighten. The en-

gine will now be supported by the tool between the

frame rails.

Figure

3A-5 Engine Holding Fixture Installed

5. Loosen steering mast at the lower universal joint

and take out clamp bolt. Loosen clamp at the upper

universal joint and lift steering mast upwards until it

is free at the lower universal joint. See Figure

3A-6.6. Disconnect brake lines at brake hose.

7. Disconnect shock absorber at upper mounting. It

is necessary to remove air cleaner. See Figure

3A-24.8. Disconnect engine mounts at cross member.

9. Remove front suspension cross member attaching

nuts and lower the cross member.

Removal Opel 1900 - Manta1. Prior to raising front end of car, apply parking

brake and block rear wheels.