lock OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 530 of 625

REFRIGERANT COMPONENTS ALL MODELSSE- 21

about heat instead of refrigeration. But in doing so,

we have learned how a simple ice-box works. It’s

because the magic of latent heat of fusion gives ice

the ability to soak up quantities of heat without get-

ting any warmer.

Therefore, since it stays cold, it can continue to draw

heat away from stored foods and make them cooler.

The latent heat of vaporization can be an even better

“magnet” because it will soak up even more heat.

Whenever we think of anything boiling, we instinc-

tively think of it being very hot. However, that’s not

true in every case. Just because water

boi1.s at 212

degrees doesn’t mean that all other substances will

boil at the same temperature. Some would have to be

put into a blast furnace to make them bubble and

give off vapor. On the other hand, others will boil

violently while sitting on a block of ice.

And so each substance has its own particular boiling

point temperature. But regardless of whether it is

high or low, they all absorb unusually large quanti-

ties of heat without getting any warmer when they

change from a liquid into a vapor.

Consequently, any liquid that will boil at a tempera-

ture below the freezing point of water, will make ice

cubes and keep vegetables cool in a mechanical re-

frigerator.

Figure

9B-10 Simple R-12 Refrigerator

Refrigerant - 12Refrigerant-12 is used in the air conditioning system

and boils at 21.7 degrees below zero. Maybe that

doesn’t mean very much until we picture a flask of

R-12 sitting at the North Pole boiling away just like

a tea-kettle on a stove. No one would dare pick up

the flask with his bare hands because, even though

boiling, it would be so cold and it would be drawing

heat away from nearby objects so fast that human

flesh would freeze in a very short time. If we were toput a flask of R-12 inside a refrigerator cabinet, it

would boil and draw heat away from everything sur-

rounding it (Fig.

9B-10). So long as any refrigerant

remained in the flask, it would keep on soaking up

heat until the temperature got down to 21.7 degrees

below zero.

Now we can begin to see the similarity between a

boiling tea-kettle and a refrigerator. Ordinarily we

think of the flame pushing heat into the tea-kettle.

Yet, it is just as logical to turn our thinking around

and picture the tea-kettle pulling heat out of the

flame. Both the tea-kettle and the flask of refrigerant

do the same thing they draw in heat to boil

although they do so at different temperature levels.

There also is another similarity between the ice-box

and the mechanical refrigerator. In the ice-box, wa-

ter from melting ice literally carried heat out of the

cabinet. In our simple refrigerator, rising vapors do

the same job.Rdsing

Our R-l 2Water is so cheap that we could afford to throw it

away. But R-12, or any other refrigerant, is too ex-

pensive just to let float away into the atmosphere. If

there was some way to remove the heat from the

vapor and change it back into a liquid, it could be

returned to the flask and used over again (Fig. 9B-

11).There is a way, and that is where we find the biggest

difference between the old ice-box and the modern

refrigerator. We used to put in new ice to replace that

lost by melting. Now we use the same refrigerantover and over again.

Figure 9B-1 1 Re-Using Refrigerant

Page 533 of 625

9B-24 1973 OPEL SERVICE MANUAL

Figure 9B-15 Compressor Assembly - GT Shown

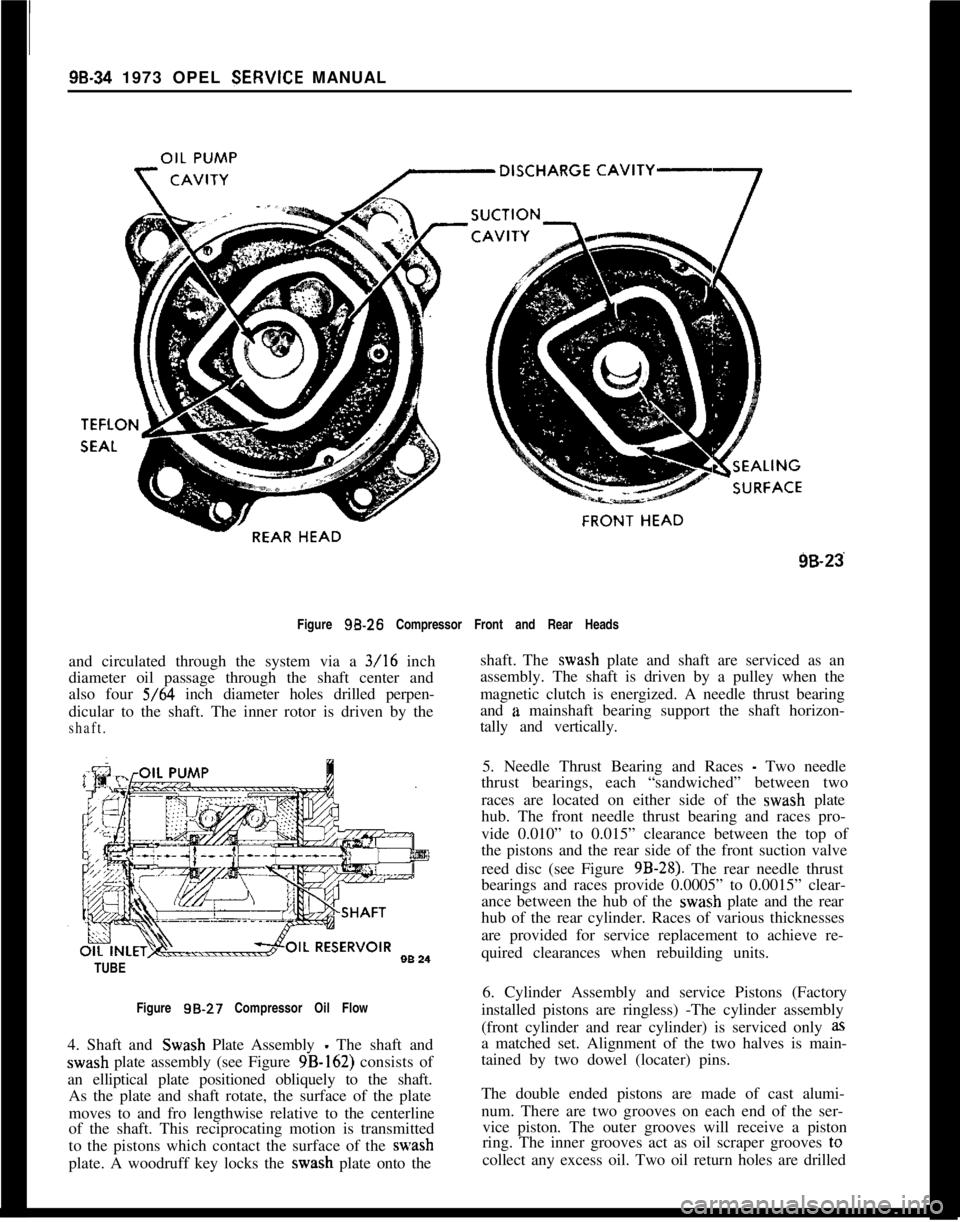

Figure 3B-16 Condenser Assembly

condenser. The refrigerant vapor gives up its heat,

which is quickly and easily radiated into the sur-

rounding air through the large finned surfaces of the

condenser. In giving up its heat, the refrigerant vapor

condenses back into liquid which collects in a pool

at the bottom of the condenser.

As we have said before, when the refrigerant con-

denses into a liquid, it again is ready for boiling in the

evaporator. So, we can run a pipe from the condenser

back to the evaporator.

Main Units of the SystemThese three units then; the evaporator, the compres-

sor, and the condenser are the main working

parts of any typical air conditioning system. We have

the evaporator where the refrigerant boils andchanges into a vapor, absorbing heat as it does so. We

have the pump or compressor to put pressure on the

refrigerant so it can get rid of its heat. And we have

a condenser outside the car body to help discharge

the heat into the surrounding air.

Pressure and FlowThere is one more unit that co-operates with thesethree. It doesn’t do any real work, but it does act as

sort of a traffic officer in controlling the flow of the

refrigerant through the system. To get a better idea

of what this does. let’s first do a li,ttle exoerimentine

with an ordinary’ tire pump.

When we use a

t,ire pump to Sate an automobile

tire, we are creating pressure only because we are

“pushing” against the air already entrapped inside

the tire. If you question this, just try pumping up a

tire that has a large puncture in it. You could pump

all day, and still not be able to build up any pressure.

As fast as you would pump the air in, it would leak

out through the puncture.

Abou~t all you would be

doing would be circulating nice fresh air through the

tire.

1Jnless you have something lo push against - to

block the tlow of air

- you can’t create more than a

mere semblance of pressure.

The same situation holds true in an air conditioning

system. The compressor can pump refrigerant vapor

through the system, but unless it has something to

push against, it cannot build up pressure. All the

compressor would be doing would be to circulate the

vapor without increasing its

pres,sure.Yet we can’t just block the flow through the system

entirely. All we want to do is put pressure on the

refrigerant vapor so it will condense at normal tem-

peratures. What’s more, this

musi: be done some time

after the vapor leaves the evaporator and before it

returns again as a liquid. We can’t have high pressure

in the evaporator because that would slow down the

boiling of the refrigerant and thus penalize the re-

frigerating effect.

Controlling Pressure and FlowPressure and flow can be controlled with a float

valve, or with a pressure-regulating valve. They do

the same job, but in a different way.

Since the float valve type will give us a better idea of

pressure and flow control, let’s look at it first (Fig.

9B-17).It consists simply of a float that rides on the surface

of the liquid refrigerant. As the refrigerant liquid

boils and passes off as a vapor, naturally the liquid

level drops lower and lower. Correspondingly, the

float, because it rides on the surface of the refriger-

ant, also drops lower and lower as the liquid goes

down.By means of a simple system of mechanical linkage,

the downward movement of the float opens a valve

to let refrigerant in. The incoming liquid raises the

fluid level and, of course, the float rides up with it.

When the surface level of the refrigerant liquid re-

aches a desired height, the float: will have risen far

Page 543 of 625

98-34 1973 OPEL 3ERVlCE MANUAL

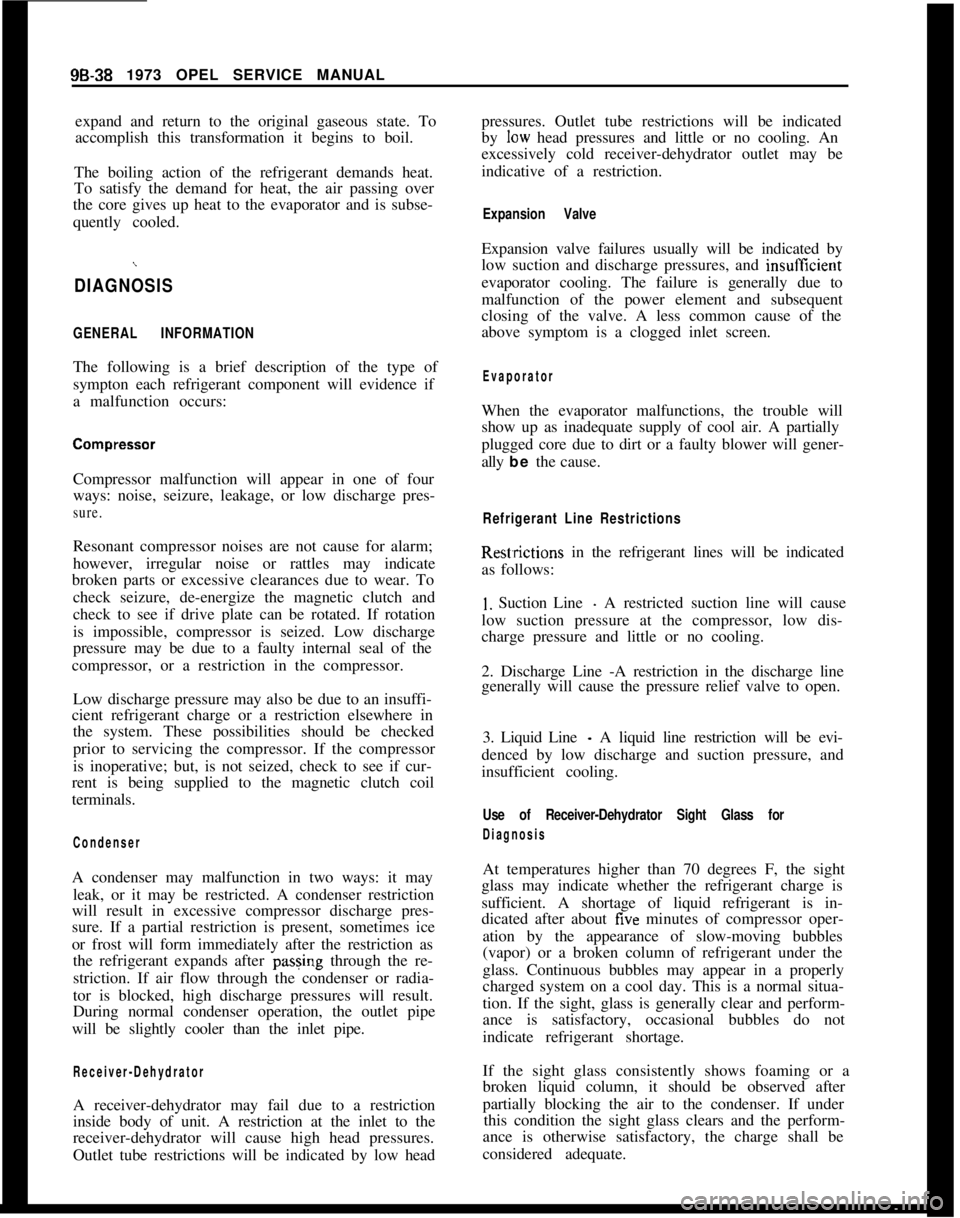

9B-23Figure

98.26 Compressor Front and Rear Heads

and circulated through the system via a 3/16 inch

diameter oil passage through the shaft center and

also four 5/64 inch diameter holes drilled perpen-

dicular to the shaft. The inner rotor is driven by the

shaft.TUBE

Figure

98-27 Compressor Oil Flow

4. Shaft and

Gash Plate Assembly - The shaft andwash plate assembly (see Figure 9B-162) consists of

an elliptical plate positioned obliquely to the shaft.

As the plate and shaft rotate, the surface of the plate

moves to and fro lengthwise relative to the centerline

of the shaft. This reciprocating motion is transmitted

to the pistons which contact the surface of the wash

plate. A woodruff key locks the wash plate onto theshaft. The wash plate and shaft are serviced as an

assembly. The shaft is driven by a pulley when the

magnetic clutch is energized. A needle thrust bearing

and

L mainshaft bearing support the shaft horizon-

tally and vertically.

5. Needle Thrust Bearing and Races

- Two needle

thrust bearings, each“sandwiched” between two

races are located on either side of the wash plate

hub. The front needle thrust bearing and races pro-

vide 0.010” to 0.015” clearance between the top of

the pistons and the rear side of the front suction valve

reed disc (see Figure

9B-28). The rear needle thrust

bearings and races provide 0.0005” to 0.0015” clear-

ance between the hub of the wash plate and the rear

hub of the rear cylinder. Races of various thicknesses

are provided for service replacement to achieve re-

quired clearances when rebuilding units.

6. Cylinder Assembly and service Pistons (Factory

installed pistons are ringless) -The cylinder assembly

(front cylinder and rear cylinder) is serviced only as

a matched set. Alignment of the two halves is main-

tained by two dowel (locater) pins.

The double ended pistons are made of cast alumi-

num. There are two grooves on each end of the ser-

vice piston. The outer grooves will receive a piston

ring. The inner grooves act as oil scraper grooves to

collect any excess oil. Two oil return holes are drilled

Page 547 of 625

9B-38 1973 OPEL SERVICE MANUAL

expand and return to the original gaseous state. To

accomplish this transformation it begins to boil.

The boiling action of the refrigerant demands heat.

To satisfy the demand for heat, the air passing over

the core gives up heat to the evaporator and is subse-

quently cooled.\

DIAGNOSIS

GENERAL INFORMATIONThe following is a brief description of the type of

sympton each refrigerant component will evidence if

a malfunction occurs:

Compressor malfunction will appear in one of four

ways: noise, seizure, leakage, or low discharge pres-

sure.Resonant compressor noises are not cause for alarm;

however, irregular noise or rattles may indicate

broken parts or excessive clearances due to wear. To

check seizure, de-energize the magnetic clutch and

check to see if drive plate can be rotated. If rotation

is impossible, compressor is seized. Low discharge

pressure may be due to a faulty internal seal of the

compressor, or a restriction in the compressor.

Low discharge pressure may also be due to an insuffi-

cient refrigerant charge or a restriction elsewhere in

the system. These possibilities should be checked

prior to servicing the compressor. If the compressor

is inoperative; but, is not seized, check to see if cur-

rent is being supplied to the magnetic clutch coil

terminals.

CondenserA condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge pres-

sure. If a partial restriction is present, sometimes ice

or frost will form immediately after the restriction as

the refrigerant expands after pas?ing through the re-

striction. If air flow through the condenser or radia-

tor is blocked, high discharge pressures will result.

During normal condenser operation, the outlet pipe

will be slightly cooler than the inlet pipe.

Receiver-DehydratorA receiver-dehydrator may fail due to a restriction

inside body of unit. A restriction at the inlet to the

receiver-dehydrator will cause high head pressures.

Outlet tube restrictions will be indicated by low headpressures. Outlet tube restrictions will be indicated

by

low head pressures and little or no cooling. An

excessively cold receiver-dehydrator outlet may be

indicative of a restriction.

Expansion ValveExpansion valve failures usually will be indicated by

low suction and discharge pressures, and insuff%ient

evaporator cooling. The failure is generally due to

malfunction of the power element and subsequent

closing of the valve. A less common cause of the

above symptom is a clogged inlet screen.

EvaporatorWhen the evaporator malfunctions, the trouble will

show up as inadequate supply of cool air. A partially

plugged core due to dirt or a faulty blower will gener-

ally be the cause.

Refrigerant Line Restrictions

Rest~rictions in the refrigerant lines will be indicated

as follows:

I. Suction Line - A restricted suction line will cause

low suction pressure at the compressor, low dis-

charge pressure and little or no cooling.

2. Discharge Line -A restriction in the discharge line

generally will cause the pressure relief valve to open.

3. Liquid Line

- A liquid line restriction will be evi-

denced by low discharge and suction pressure, and

insufficient cooling.

Use of Receiver-Dehydrator Sight Glass for

DiagnosisAt temperatures higher than 70 degrees F, the sight

glass may indicate whether the refrigerant charge is

sufficient. A shortage of liquid refrigerant is in-

dicated after about

five minutes of compressor oper-

ation by the appearance of slow-moving bubbles

(vapor) or a broken column of refrigerant under the

glass. Continuous bubbles may appear in a properly

charged system on a cool day. This is a normal situa-

tion. If the sight, glass is generally clear and perform-

ance is satisfactory, occasional bubbles do not

indicate refrigerant shortage.

If the sight glass consistently shows foaming or a

broken liquid column, it should be observed after

partially blocking the air to the condenser. If under

this condition the sight glass clears and the perform-

ance is otherwise satisfactory, the charge shall be

considered adequate.

Page 550 of 625

REFRIGERANT COMPONENTS ALL MODELS9s. 41

BIower Operating Normal Check for the following:Restriction or leakage in air ducts, A/C outlets not

opening.2. Do not carry cylinder in passenger compartment

of car.3. Do not subject cylinder to high temperatures.

MAINTENANCE AND ADJUSTMENTS4. Do not weld or steam clean on or near cylinder.

5. Do not fill cylinder completely.

GENERAL SERVICE INFORMATION AND SAFETY

PRECAUTIONS6. Do not discharge vapor into area where flame is

exposed or directly into engine air intake.

General InformationAll subassemblies are shipped sealed and dehy-

drated. They are to remain sealed until just prior to

making connections, and should be at room tempera-

ture before uncapping. This prevents condensation of

moisture from air that enters the system.

All precautions should be taken to prevent damage

to fittings or connections. Even minute damage to a

connection could cause it to leak. Any fittings with

grease or dirt on them should be wiped clean with a

cloth dipped in alcohol.

Do not clean fitting or hoses with solvents because

they are contaminants. If dirt, grease or moisture

gets inside the pipes or hoses and cannot be removed,the pipe or hose is to be replaced. Use a small amount

of clean refrigeration oil on all tube and hose con-

necting joints, and lubricate the

“0” ring gasket with

this oil before assembling the joint. The oil will help

in effectitig a leak-proofjoint and assist the

“0” ring

to slip into the proper location without being cut or

damaged. Always use new

“0” rings.

When tightening joints, use a second wrench to hold

the stationary part of the connection to prevent

twisting and to prevent hose kinking. Kinked hoses

are apt to transmit noise and vibration. Tighten all

connections in accordance with recommended

torques (see Division VI, Specifications).7. Do not expose eyes to liquid

- WEAR SAFETY

GOGGLES whenever discharging, charging or leak

testing system.

CHARGING AND DISCHARGING SYSTEMRemoval of any part in the refrigerant circuit will

require discharging of the entire system.

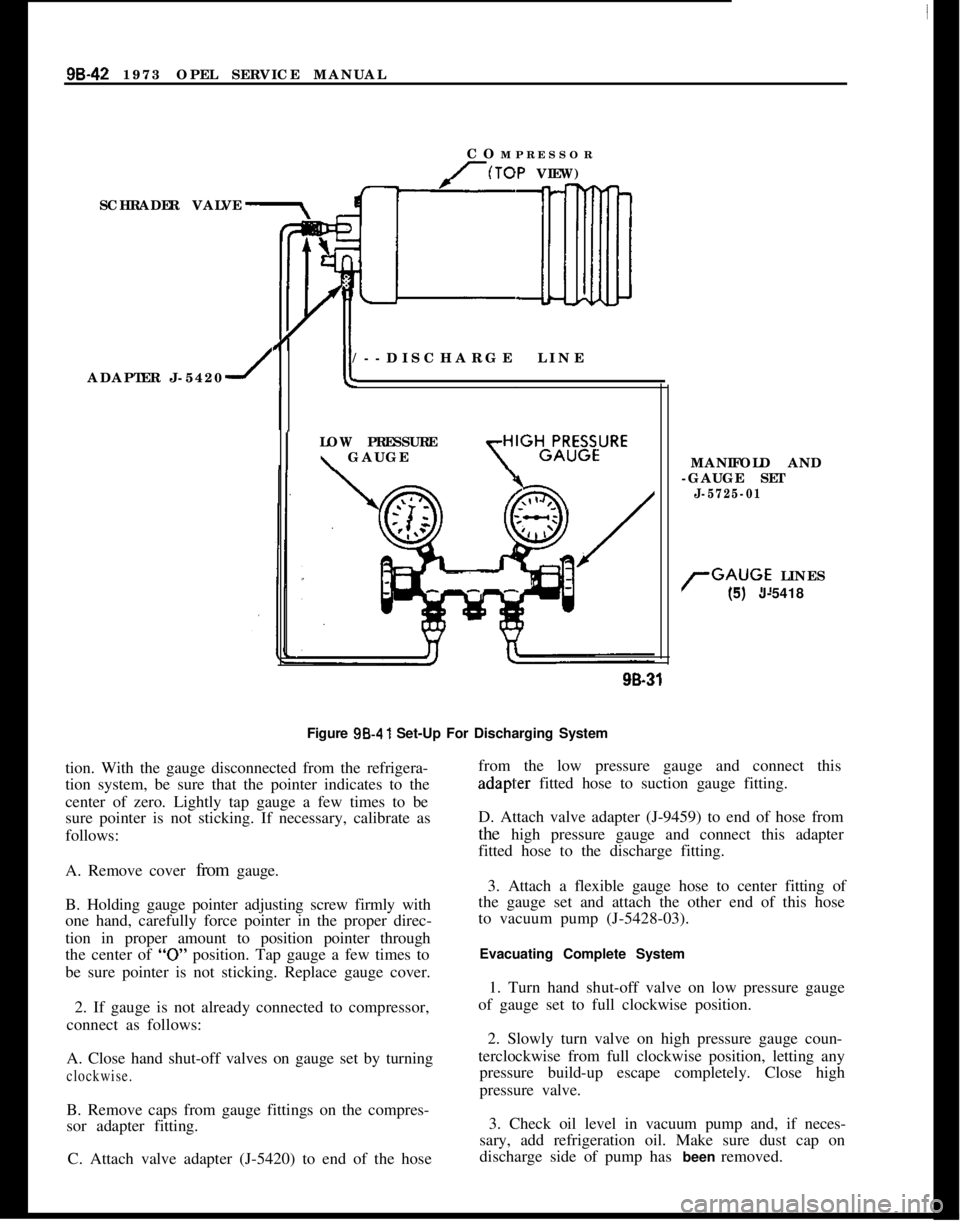

Discharging the System1. Remove caps from gauge fittings on the compres-

sor adapter fitting on the compressor.

2. With both valves on manifold gauge set (J-5725-

04) closed (clockwise), attach manifold to the com-

pressor adapter fitting on the compressor, using

J-5420 valve adapter at suction gauge fitting and

J-9459 valve adapter at discharge gauge fitting. See

Figure

9B-41.3. Fully open high pressure valve on manifold gauge

set to allow escape of refrigerant from system

through the manifold gauge set and out the center

fitting and hose. (Place end of hose in clean container

to collect oil loss due to rapid discharge of system).

4. When hissing ceases, indicating all refrigerant

has escaped, close high pressure valve on manifold

gauge set by turning valve clockwise.

Do not connect receiver-dehydrator assembly until

all other connections have been made. This is neces-

sary to itisure maximum moisture removal from sys-

tem.It is important that air conditioning hoses do not rest

on or contact body sheet metal except where neces-

sary. Because of the high frequency at which the

compressor operates, the passenger compartment is

susceptible to transfer of noise.

Evacuating the SystemWhen the refrigeration system is depressurized and

opened for service, some air will enter the lines, re-

gardless of how quickly openings are capped. In

or-der to remove this air and as much as possible of the

moisture it contains, the complete system must be

evacuated. Evacuating is merely the process of

removing all air from the system, thereby creating a

vacuum in the system.

Safety PiecautionsThe following safety precautions should always be

followed~,when servicing refrigerant charged compo-nents:Under no circumstances should alcohol be used in

the system in an attempt to remove moisture,

regard-less of the successful use of alcohol in other refrigera-

tion systems.

Preparations for Evacuating Complete System

1. Do not leave Refrigerant-12 cylinder uncapped.

1. Check the low pressure gauge for proper calibra-

Page 551 of 625

98-42 1973 OPEL SERVICE MANUAL

SCHRADER VALVE

ADAPTER J-54201COMPRESSOR(TOP VIEW)[/--DISCHARGE LINE

ILOW PRESSURE\ GAUGE

MANIFOLD AND

-GAUGE SET

J-5725-01

rGAUGE LINES

(5) J-541899-31

Figure 98.41 Set-Up For Discharging System

tion. With the gauge disconnected from the refrigera-

tion system, be sure that the pointer indicates to the

center of zero. Lightly tap gauge a few times to be

sure pointer is not sticking. If necessary, calibrate as

follows:

A. Remove cover from gauge.

B. Holding gauge pointer adjusting screw firmly with

one hand, carefully force pointer in the proper direc-

tion in proper amount to position pointer through

the center of

“0” position. Tap gauge a few times to

be sure pointer is not sticking. Replace gauge cover.

2. If gauge is not already connected to compressor,

connect as follows:

A. Close hand shut-off valves on gauge set by turning

clockwise.B. Remove caps from gauge fittings on the compres-

sor adapter fitting.

C. Attach valve adapter (J-5420) to end of the hosefrom the low pressure gauge and connect thisadapl:er fitted hose to suction gauge fitting.

D. Attach valve adapter (J-9459) to end of hose from

the high pressure gauge and connect this adapter

fitted hose to the discharge fitting.

3. Attach a flexible gauge hose to center fitting of

the gauge set and attach the other end of this hose

to vacuum pump (J-5428-03).

Evacuating Complete System

1. Turn hand shut-off valve on low pressure gauge

of gauge set to full clockwise position.

2. Slowly turn valve on high pressure gauge coun-

terclockwise from full clockwise position, letting any

pressure build-up escape completely. Close high

pressure valve.

3. Check oil level in vacuum pump and, if neces-

sary, add refrigeration oil. Make sure dust cap on

discharge side of pump has been removed.

Page 552 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 43

4. Start the vacuum pump and slowly open low and

high pressure sides of manifold gauge set to avoid

forcing oil out of refrigeration system and pump,

Pressure is now being reduced on both sides of the

refrigeration system. If oil is blown from the vacuum

pump, it should be refilled to the proper level.

5. Observe low pressure gauge and operate vacuum

pump until gauge shows 28-29 inches vacuum. In all

evacuating procedures, specifications of 28-29 inchesof vacuum is used. This evacuation can only be at-

tained at or near sea level.

For each 1000 feet above sea level where this operat-ion is being-performed, the specification should be

lowered by one inch of mercury vacuum. At 5000

feet elevation, only 23 inches to 24 inches of vacuum

can normally be obtained.

If vacuum cannot be pulled to the minimum specifi-

cation for the respective altitude, it indicates a leak

in the system or gauge connections or a defective

vacuum pump. In this case, it will be necessary to

check for leaks as described under “Leak Testing

Refrigerant System”.

When specified vacuum level (28-29 inches at sea

level) is obtained, continue to run vacuum pump for

ten (10) ‘additional minutes. During these ten (10)

minutes:

A. Prepare for charging the system. If using a charg-

ing station, till charging cylinder. If using manifold

gauge set, make all preparations for charging system

as described under “Disposable Can Method” or

“Refrigerant Drum Method”.

B. Measure oil loss collected as a result of rapid

discharge.

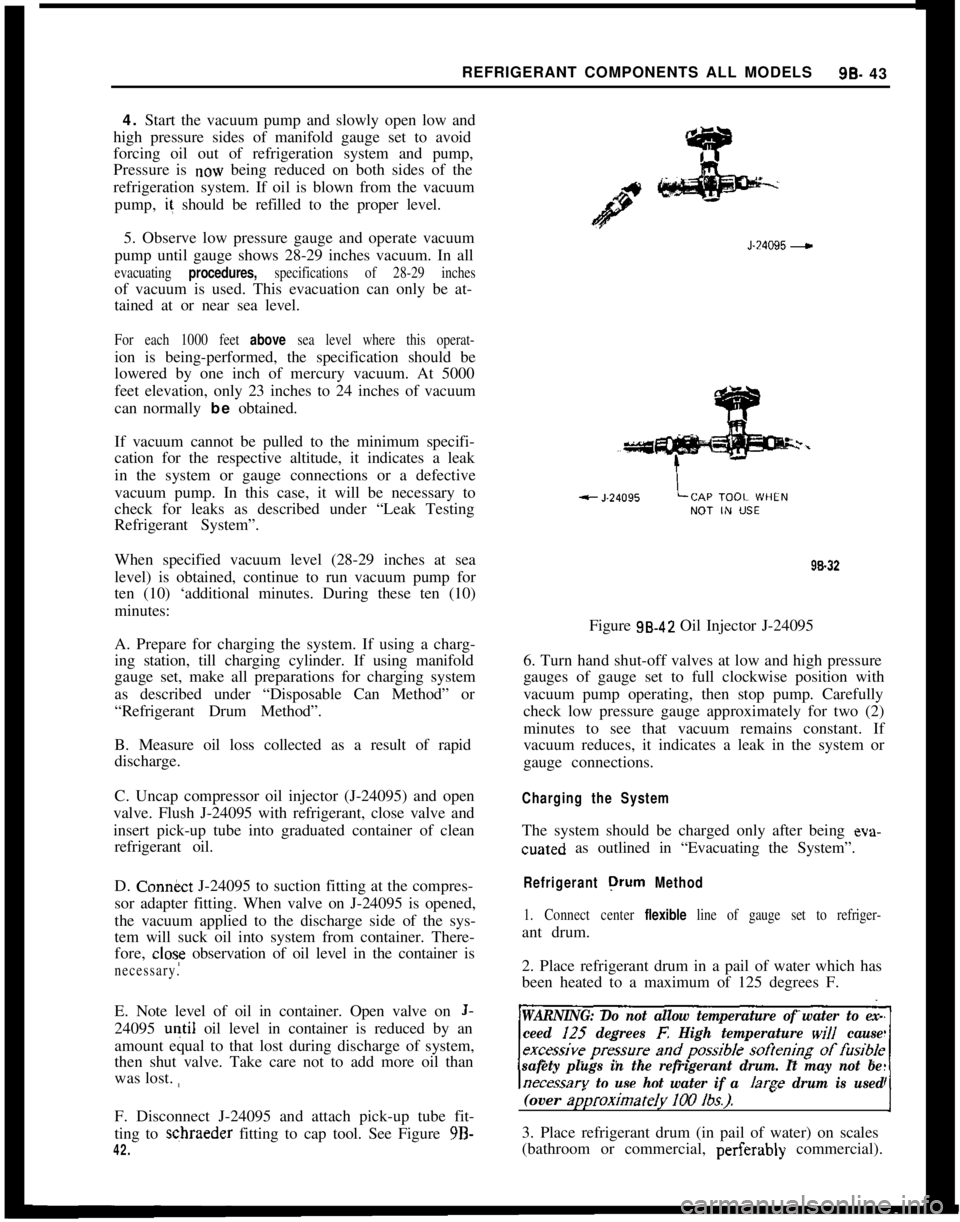

C. Uncap compressor oil injector (J-24095) and open

valve. Flush J-24095 with refrigerant, close valve and

insert pick-up tube into graduated container of clean

refrigerant oil.

D. Con&ct J-24095 to suction fitting at the compres-

sor adapter fitting. When valve on J-24095 is opened,

the vacuum applied to the discharge side of the sys-

tem will suck oil into system from container. There-

fore,

close observation of oil level in the container is

necessary.E. Note level of oil in container. Open valve on

J-24095

u+il oil level in container is reduced by an

amount equal to that lost during discharge of system,

then shut valve. Take care not to add more oil than

was lost. ,,

F. Disconnect J-24095 and attach pick-up tube fit-

ting to schraeder fitting to cap tool. See Figure 9B-

42.J-24095

-98.32

Figure 98.42 Oil Injector J-24095

6. Turn hand shut-off valves at low and high pressure

gauges of gauge set to full clockwise position with

vacuum pump operating, then stop pump. Carefully

check low pressure gauge approximately for two (2)

minutes to see that vacuum remains constant. If

vacuum reduces, it indicates a leak in the system or

gauge connections.

Charging the SystemThe system should be charged only after being eva-cuated as outlined in “Evacuating the System”.

Refrigerant orurn Method

1. Connect center flexible line of gauge set to refriger-ant drum.

2. Place refrigerant drum in a pail of water which has

been heated to a maximum of 125 degrees F.

WARNING: Do not allow temperature of water to ex-

ceed I25

degrees E High temperature will cause

safety plugs in the refrigerant drum. It may not be

necessarv to use hot water if a /arae drum is used(over

ap)roximateIy 100 lbs.).-I3. Place refrigerant drum (in pail of water) on scales

(bathroom or commercial, perferably commercial).

Page 553 of 625

9B-44 1973 OPEL SERVICE MANUAL

Do not turn refrigerant drum upside down, as this

would allow liquid refrigerant to enter compressor

which may cause damage.

4. If line at center gauge fitting has not been purged

of air, loosen line at center fitting on gauge set and

crack valve on refrigerant drum to blow air from

line. Retighten line at center fitting and record exact

weight of refrigerant tank in water on the scales.

5. Open valve on refrigerant drum and both valves

on gauge set to allow refrigerant to flow into system.

Continue charging until the scales show that 2

Ibs.Opel 1900

- Manta and 2 l/4 lbs. GT, of refrigerant

have been transferred from refrigerant drum to sys-

tem.If full charge cannot be obtained, close both valves

on gauge set, start engine, and set temperature con-

trol knob to full cold position with blower in Max Hi.

Open low pressure valve on gauge set slowly and

leave open until full charge is added.

WARNING: Observe high pressure gauge while charg-

ing with compressor running. Shut

offengine ifpres-

sure exceeds 250 psi. A large fan placed in front

ol

the car wi// help reduce excessively high head pres-6. Close both valves on gauge set (high pressure valve

will already be closed if charging was completed by

running compressor) and close valve on refrigerant

drum.

If the engine was used to complete the charge into

the system, close valve on refrigerant drum to permit

compressor to draw any refrigerant left in the line

from the drum to the center fitting of the gauge set,

then close the low pressure valve on the gauge set.

7. Operate engine at 2000 RPM with temperature

control knob at full cold, blower speed in Max Hi.

After ten minutes of operation, observe appearance

of refrigerant in receiver-dehydrator. If bubbles are

observed, open low pressure gauge valve and valve

on refrigerant drum to allow more refrigerant to en-

ter system. Close valve when receiver-dehydrator

clears

up.If an air inlet temperature is below 70 degrees F.

when this check is made, bubbles may appear, even

though the proper amount of refrigerant is in the

system. Air inlet temperature must be 70 degrees F.

or above to make an accurate check.

8. When refrigerant has been installed, continue to

operate system and test for proper operation as ou-

tlined under “Operational Test”.

9. When satisfied that air conditioning system is op-

erating properly, stop engine, remove gauge set and

replace protective caps on compressor fittings.10. Using leak detector, check complete system for

leaks.Disposable Can Method

After having

depress&ed, repaired (if necessary)

and evacuated the refrigerant system, the system

may be charged as follows using refrigerant in dis-

posable cans:

1. Obtain three (3) 1

lb. cans or one 12 lb. can of

refrigerant.

2. If using 1 lb. cans, mount two (2) cans in J-6272-

02 (Multi-opener) or attach J-6271 (single-can

opener valve) on one can. If using the 12

lb. disposa-

ble can, attach J-23390 (disposable can control valve)

on can.WARNING: Make sure outlet valve on opener is

closed (clockwise) before installing opener.A. If the J-6272-02 multi-opener is used, raise lock-

ing lever, position three (3) cans of refrigerant and

force locking lever down to secure cans and at same

time puncture top of can to make it ready for charg-

ing.

B. If the J-6271 valve is used, back off the valve from

the can top retainer, slip the valve onto the can and

turn the valve into retainer until tight. DO NOT

open outlet valve during this operation, as turning

the valve into the retainer punctures top of can to

make it ready for charging.

3. Connect center flexible line of gauge set to fitting

on a can opener valve. If the line at center gauge

fitting has not been purged of air, loosen line at

center fitting on gauge set and “crack” valve at can

opener (for a second or two) to force air from the

line. Retighten line at center fitting.

4. Open valve at refrigerant source and at low and

high pressure valves on manifold gauge set. Leave

valve open at refrigerant source until all refrigerant

(when using 1 lb. can) has ‘entered the refrigeration

system or system is fully charged. Close valve on can.

A. If the system is charged using

1 lb. cans and the

J- 627 1 valve, disconnect valve from can. Leave valve

closed to flexible line to the center fitting of the

manifold gauge set. Install valve on a new and full

disposable can of refrigerant.

Page 554 of 625

REFRIGERANT COMPONENTS ALL MODELS9t3- 45

B. If system is charged using J-6272-02, close the

valve of opener after all cans are empty. Release the locking lever and discard the three (3) empty cans.

If this tool will be used to complete the charge with

additional cans to provide the required refrigerant

charge, leave the empty cans in position, locate one

full can and lock the lever into place. These empty

cans balance the assembly and prevent the loss of

refrigerant through the open “series” passage. Align

the pierced hole in the empty can with the punch in

the cover of the tool.

If the J-6271 valve for single cans is available, com-

plete charging as explained in 4a above.

5. Close high side valve on manifold gauge set,

WARNING: Prior to starting up engine, the high side

valve on the charging manifold must be closed due

to excessive pressure

bui/d-up which can result in

bursting of the container(s) causing serious injury. If

you are inexperienced in the use of this procedure, seek professional assistance.

6. Operate engine at 2000 RPM with temperature

control knob at full cold position and blower speed

on Max Hi. If air inlet temperature at the condenser

is below 70 degrees F. when this check is made,

bubbles may appear, even though the proper amount

of refrigerant is in the system. Air inlet temperature

must be 70 degrees F. or above to make an accurate

check.

7. When refrigerant has been installed, continue to

operate system and test for proper operation as ou-

tlined

under “Operational Test”.

8. When satisfied that the air conditioning system

is operating properly, stop engine, remove gauge set

and replace protective caps on suction and discharge

fittings.

from thegauge fitting to prevent damage-or injury to

personnel.

9. Using a leak detector, check complete system for

leaks.

Charging Station Method

INSTALLING J-8393-02

-

1. Be ceitain compressor hand shut-off valves to

gauge fittings are closed (counterclockwise).

2. Be certain all valves on charging station are

closed.

3. Connect high pressure gauge line to compressor

high pressure gauge fitting.

4. Turn high pressure hand shut-off valve one turn

clockwise, and high pressure control one turn coun-

terclockwise (open). Crack open low pressure con-

trol and allow refrigerant gas to hiss from low

pressure gauge line for three seconds, then connect

low pressure gauge line to low pressure gauge fitting

on compressor adapter fitting. (Place J-9459 adapter

on hose, then attach adapter to gauge fitting.)

FILLING CHARGING CYLINDER

1. Open Control valve on refrigerant container.

2. Open valve on bottom of charging cylinder, al-

lowing refrigerant to enter cylinder.

3. Bleed charging cylinder to valve (behind control

panel) only as required to allow refrigerant to enter

cylinder. When refrigerant reaches desired charge

level, close valve at bottom of charging cylinder and

be certain cylinder bleed valve is closed securely.

While filling the cylinder, it will be necessary to close

the bleed valve periodically to allow boiling to sub-

side so that refrigerant level in the charging cylinder

can be accurately read.

CHARGING THE SYSTEM USING J-8393-02

1. With charging station connected, as previously

described, remove low pressure gauge line at com-

pressor adapter fitting.

2. Crack open high and low pressure control valves

on station and allow refrigerant gas to purge from

system. Purge slowly enough so, that oil does not

escape from system along with refrigerant.

3. When refrigerant flow nearly stops, connect low

pressure gauge line to

compress& adapter fitting.

4. Turn on vacuum pump and open vacuum control

valve.

5. With system purged as

abovk, run pump until

26-28 inches of vacuum is obtained Continue to run

pump for 15 minutes after the system reaches 26-28

inches vacuum.

In all evacuating procedures, the specification of

26.

28 inches of mercury vacuum is used. These figures

are only attainable at or near sea level. For each 1000

feet above sea level where this operation is being

performed, the specifications should be lowered by 1

inch. For example, at 5000 feet elevation, only 21 to

23 inches vacuum can normally be obtained.

6. If 26-28 inches vacuum (corrected to sea level)

cannot be obtained, close vacuum: control valve and

Page 555 of 625

98-46 1973 OPEL SERVICE MANUAL

shut off vacuum pump. Open refrigerant control

valve and allow some refrigerant to enter system.

Locate and repair all leaks.

7. After evacuating for 15 minutes, add l/2 lb. of

refrigerant to system. Purge this

l/2 lb. and reevacu-

ate for 15 minutes. This second evacuation is to be

certain that as much contamination is removed from

the system as possible.

8. Only after evacuating as above, system is ready

for charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, till to proper level.

9. Close low pressure valve on charging station.

Fully open station refrigerant control valve and al-

low all liquid refrigerant to enter system. When full

charge of refrigerant has entered system, turn off

refrigerant control valve and close both hand shut-

off valves.

10. If full charge of refrigerant will not enter system,

close high pressure control and refrigerant control

valves. Start engine and run at low idle with com-

pressor operating. Crack refrigerant control valve

and low pressure control on station. Watch low side

gauge and keep gauge below 50 psi by regulating

refrigerant control valve. Closing valve will lower

pressure. This is to prevent liquid refrigerant from

reaching the compressor while the compressor is op-

erating. When required charge has entered system,

close refrigerant control valve and close low pressure

control.

11. System is now charged and should be perform-

ance- tested before removing gauges.

Adding Refrigerant

The following procedure should be used in adding

small amounts of refrigerant that may have been lost

by leaks or while opening system for servicing the

compressor. Before adding refrigerent to replace that

lost by leaks, check for evidence of oil loss and add

oil if necessary.

This procedure will only apply if the air inlet temper-

ature is above 70 degrees F. at the condenser.

1. Remove caps from compressor gauge fittings.

Attach gauge set to gauge fittings, making sure

adapter (J- 5420) is between low pressure gauge hose

and suction gauge fitting, and J-9459 is between high

pressure gauge hose and discharge gauge fitting.

2. Start engine, turn air conditioning temperature

control knob to full cold position, blower switch to

Max Hi. Operate for ten

(IO) minutes at 2000 RPM

to stabilize system.

3. Observe the refrigerant through the sight glasscover of receiver-dehydrator with the system operat-

ing,

IO see if there are any bubbles evident.

a. If no bubbles are evident, then bleed system slowly

through the discharge valve until bubbles appear in

the receiver-dehydrator. Add 1 lb. of refrigerant as

explained under “Charging the

ISystem”.b. If bubbles are visible in the receiver-dehydrator

with the temperature control krlob in the full cold

position and the blower at MAX speed, it indicates

a partial or complete plug in a line, a shortage of

refrigerant, or both. Correct condition. Add refriger-

ant

u~ntil the sight glass clears, then add another 1 lb.

of refrigerant.

4. Attach flexible hose from center fitting of gauge

set loosely to refrigerant drum or on disposable can

valvxs. Open high and low pressure valves on the

gauge set slightly to purge pressure gauge lines of air.

Tighten fitting of refrigerant drum or can when satis-

fied ihat all air has been removed from gauge lines.

Close (clockwise) both hand shut-off valves or gauge

set.5. Partially charge system.

REFRIGERANT DRUM METHOD:

A. Place pail containing hot water that does not have

a temperature exceeding 125 degrees F. on scales,

place refrigerant drum in pa” containing water, note

weig,ht and only open low pressure valve on gauge

set.B. Start engine, turn temperature control knob to full

cold position and place blower switch in Max Hi.

Operate engine for 10 minutes at 2000 RPM to sta-

bilize system.

C. With compressor operating, slowly open valve on

refrigerant drum and allow refrigerant to flow into

system (through manifold gauge set) until liquid in-

dicator clears up and immediately shut off valve ai

gauge set or on refrigerant drum. Check weight of

refrigerant drum and pail of water. Then slowly open

valve on gauge set (or refrigerant drum) and add one

more lb. of refrigerant. Note total amount of refriger-

ant added.

DISPOSABLE CAN METHOD:

A. Make sure the outlet valve on the J-6271 valve is

fully clockwise and attach the J-6271 to a 1 lb. can

of refrigerant by backing off the valve from the top

of the retainer, slipping the valve onto the can and

turning the valve into the retainer until tight. DO

NOT accidentally open outlet valve during this oper-

ation, as turning the valve into the retainer punctures

the top of the can to make it ready for charging.

.