lock OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 453 of 625

7C- 92

1973 OPEL SERVICE MANUAL

Figure 7C-84Figure

7C-855. Unhook detent cable from detent valve. See Figure7c-87.

6. Pry detent cable pipe out of retainers.

7. Unscrew upper and lower adjuster nuts and

remove detent cable (on Manta models, loosen lock

nut and screw adjuster out of bulkhead).

Installation

1. Route cable and place in retainers,

2. Place cable in upper bracket and install upper and

lower adjuster nuts and retainer (on Manta models,

screw adjuster into bulkhead).

3. Hook detent cable to valve and install retainer.Figure

7C-86Figure

7C.87

AdjustmentBefore carrying out any adjustment to the detent

cable, it is essential that the throttle control linkage

is correctly adjusted so that full throttle opening is

obtained at the carburetor.

After the throttle control linkage has been set, the

adjustment for the detent cable may be checked as

FOllOWS:1. Position accelerator to full throttle (pedal is nol

fully depressed at full throttle) and loosen and

tighten upper and lower adjuster nuts of detent cable

Page 455 of 625

7C. 941973 OPEL SERVICE MANUAL

7. Drive out retaining pin and shaft and remove se-

lector detent. See Figure 7C-93.Figure

7C-93Figure

7C-94 - Exploded View of Selector Lever

8. To replace bowden cable in selector lever, knock

off selector handle, remove screws from clamping

piece and pull knob.

9. Remove pull knob and bowden cable, taking care

not to lose lock bolt bushing, thrust springs, ‘and

washer.

10. Place thrust spring, bushing, washer, and thrust

spring onto new bowden cable, in that order, and

insert cable into selector lever.

1 I. Slide pull onto selector lever and clamping piece

onto cable.

12. Heat up new selector lever handle in water to 176

degrees F. and push onto selector lever.

13. Set dimension between pull knob and selector

lever handle at

.4 inch and tighten set screws.

14. Lubricate selector lever detent and shaft. Install

detent, align selector lever with support, install shaft,

and drive in new retaining pin.

15. Install assembly to support housing and install

intermediate selector lever.

16. Install assembly to vehicle and install neutral

start switch.

17. Install console lights and cigar lighter connec-

tions to console and install console to vehicle.

18. Lubricate and connect selector rod to intermedi-

ate selector lever and adjust according to Figure 7C-

198.

MAJOR REPAIRREMOVAL AND INSTALLATION OF AUTOMATIC

TRANSMISSION

Removal

- Opel 1900 and Manta

I. Disconnect battery.

2. Remove dipstick.

3. Remove screws from fan shroud.

4. Remove 2 upper starter bolts.

5. Raise car and provide support for front and rear

and drain oil.

6. Remove bolts from engine support brackets, both

sides. Let brackets hang by front bolts. See Figure7c-105.

7. Remove flywheel cover pan.

8. Remove exhaust pipe from manifold and unhook

rubber tailpipe suspension.

9. Remove drive shaft. Do not misplace thrust spring

in spline.

10. Disconnect cooler lines at flexible hoses.

II. Detach both stabilizer supports from

crossmem-ber to body supports and loosen stabilizer bolts in

lower control arms. See Figure X-84, Callout “B”,

Page 456 of 625

AUTOMATIC TRANSMISSION 7C- 95

12. Place suitable jack under transmission and

remove transmission support bolts.

13. Lower transmission enough to remove detent

cable and modulator vacuum line.

14. Remove speedometer cable.

15. Remove selector lever.

16. Mark flywheel and converter for reassembly in

same position, and remove converter to flywheel

bolts. See Figure 7C-106.17. Remove converter housing to engine bolts and

tiller tube.

18. Pry transmission loose from engine.

19. Keep rear of transmission lower than front to

prevent converter from falling and install converter

holding fixture J-21366. Lower transmission and

move to bench.

Installation. Opel 1900 and Manta1. Assemble transmission to suitable jack and raise

transmission into position. Rotate converter to per-

mit coupling of fly wheel and converter with original

relationship. Remove J-21366.

2. Install tiller tube and converter housing to engine

block bolts. Torque to 35 lb. ft. DO NOT over

torque.

3. Install flywheel to converter bolts. Torque to 30 lb.

ft.4. Install detent cable to transmission.

5. Connect oil cooler lines.

6. Install lower bolt on starter. Torque to 40 lb. ft.

7. Connect shift linkage to transmission.

8. Connect modulator line.

9. Connect speedometer cable.

10. Install transmission support.

11. Install drive shaft. Torque U-Bolts to 18 lb. ft.

12. Install flywheel cover pan. Torque to 15 lb. ft.

13. Install engine support brackets.

14. Reconnect exhaust system.15. Attach stabilizer supports and tighten stabilizer

bolts in lower control arms.

16. Lower car.

17. Install starter bolts. Torque to 40 lb. ft.

18. Reconnect battery.

19. Fill transmission with fluid as described in

Specifications. Check selector lever and detent cable

adjustment.

Removal GT1. Disconnect battery.

2. Remove dipstick.

3. Pull throttle control rod off ball pin.

4. Remove screws from fan shroud.

5. Raise car and provide support for front and rear.

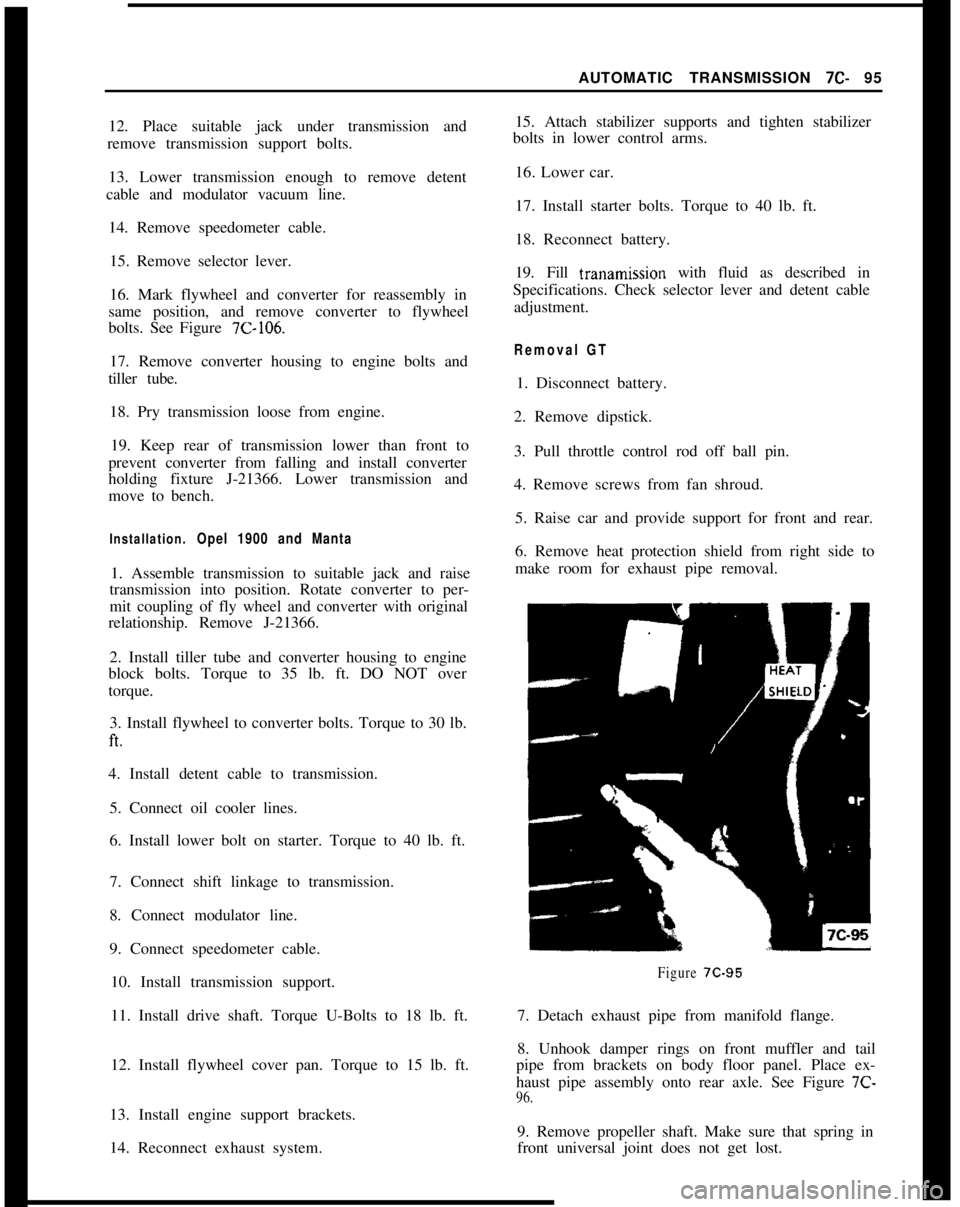

6. Remove heat protection shield from right side to

make room for exhaust pipe removal.

Figure 7C-957. Detach exhaust pipe from manifold flange.

8. Unhook damper rings on front muffler and tail

pipe from brackets on body floor panel. Place ex-

haust pipe assembly onto rear axle. See Figure 7C-

96.9. Remove propeller shaft. Make sure that spring in

front universal joint does not get lost.

Page 462 of 625

AUTOMATIC TRANSMISSION 7C-101

Figure 7C-1 16

-117Figure

7C-118 GT Models

Figure 7C-1 17 GT Modelsthat one case services both models and is machined

to accept selector lever on either side with the unused

hole being plugged.

1. Remove retaining ring From parking actuator rod

to selector inner lever. See Figure 7C-119.

2. Remove selector inner lever locking nut from se-

lector lever shaft.

3. Remove selector inner lever from selector lever

shaft.4. Remove selector lever shaft spring pin by pulling

upwards with small pliers.Figure

7C-1195. Remove selector lever shaft. See Figure 7C-120.

6. Remove selector lever shaft oil seal and discard.

Removal of Modulator Assembly

This operation can be performed with transmission

in vehicle using tool J-23

100.1. Remove vacuum modulator From transmission

case. See Figure

7C-94. Care should be taken not to

lose the modulator plunger.

Page 478 of 625

AUTOMATIC TRANSMISSION 7C-117WIRE CRIMPED

INTO COPPERTUBING

Figure 7C-178

19. Inspect condition of the third clutch composition

and steel plates. Do not diagnose a composition

drive plate by color,A. Dry composition plates with compressed air and

inspect the composition surface for:

1. Pitting and flaking

2. Wear

3. Glazing

4. Cracking

5. Charring

6. Chips or metal particles imbedded in lining

If a composition drive plate exhibits any of the above

conditions, replacement is required.

B. Wipe steel plates dry and check for heat discolora-

tion. If the surface is smooth and an even color smear

is indicated, the plates should be reused. If severe

heat spot discoloration or surface

scutXng is in-

dicated, the plates must be replaced.

20. Install third clutch plates into third clutch drum

beginning with a steel plate, composition plate, steel

plate, composition plate, etc. Use a liberal amount of

transmission fluid.

21. Inspect thrust washer and needle thrust bearing

for damage. Replace if necessary.

22. Install thrust washer and bearing onto input

shaft. Secure with petroleum jelly (unmedicated).23. Inspect sprag assembly for wear, damage orsprags that freely fall out of cage. Inspect input sun

gear for chipped or nicked teeth or abnormal wear.

Replace part if necessary.

24. Install sprag onto third clutch hub with groove

on sprag cage outer diameter toward input sun gear.

See Figure

7C-179.Figure 7C-179

25. Install sprag race and retainer assembly over

sprag assembly. Holding input sun gear with left

hand, sprag race and retainer assembly should “lock

up” when turned with right hand in a clockwise

direction and should rotate freely when turned coun-

terclockwise. See Figure

7C-180.Figure 7C-180

Page 479 of 625

712.1191973 OPEL SERVICE MANUAL

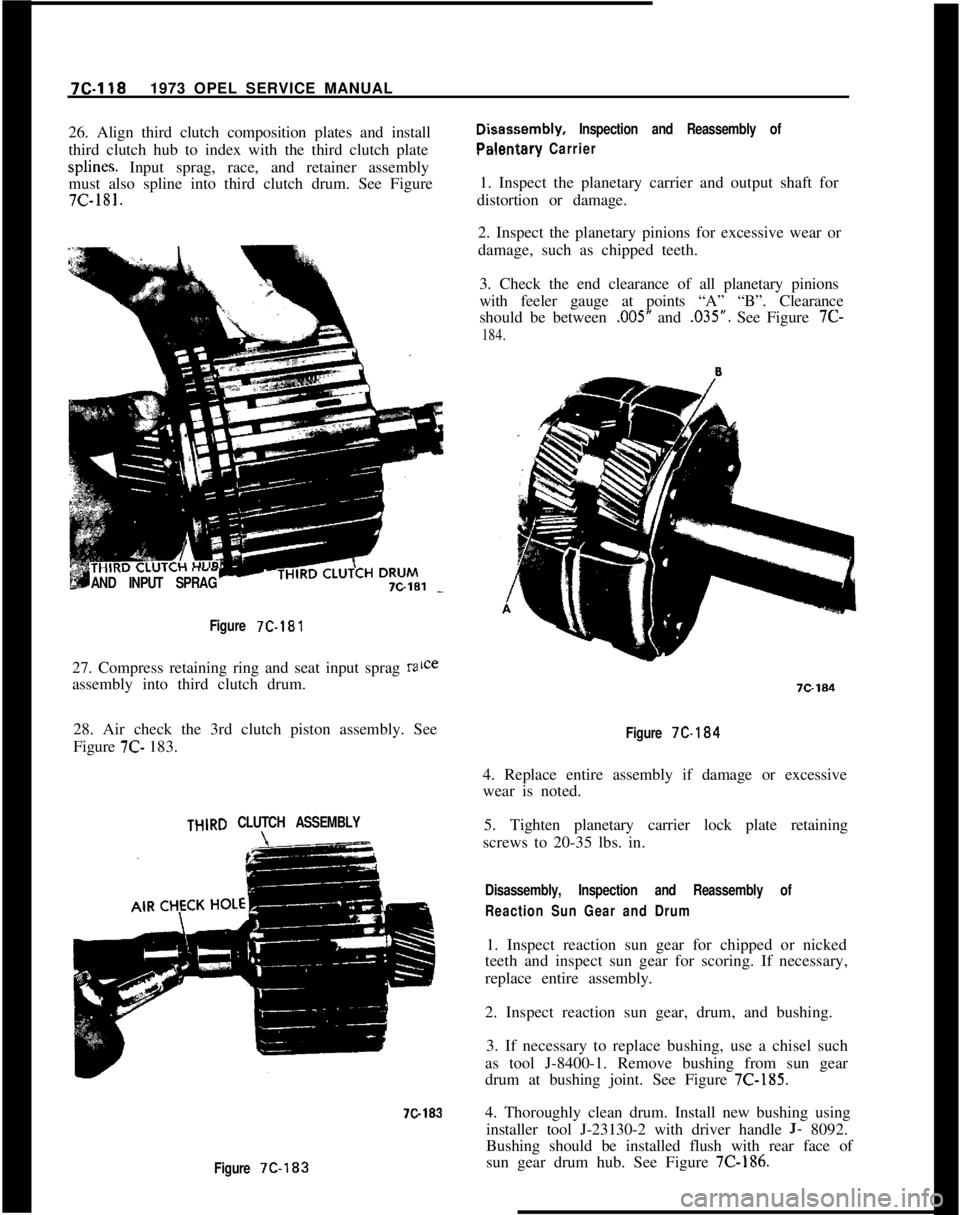

26. Align third clutch composition plates and install

third clutch hub to index with the third clutch platesplines. Input sprag, race, and retainer assembly

must also spline into third clutch drum. See Figure7c-181...-I-AND INPUT SPRAG

Disaseembly, Inspection and Reassembly of

Palentary Carrier1. Inspect the planetary carrier and output shaft for

distortion or damage.

2. Inspect the planetary pinions for excessive wear or

damage, such as chipped teeth.

3. Check the end clearance of all planetary pinions

with feeler gauge at points “A” “B”. Clearance

should be between

,005” and .035”. See Figure 7C-

184.

Figure

7C-18127. Compress retaining ring and seat input sprag

raassembly into third clutch drum.

28. Air check the 3rd clutch piston assembly. See

Figure 7C- 183.

THlRD CLUTCH ASSEMBLY

7C183

Figure 7C-183

Figure 7C-184

4. Replace entire assembly if damage or excessive

wear is noted.

5. Tighten planetary carrier lock plate retaining

screws to 20-35 lbs. in.

Disassembly, Inspection and Reassembly of

Reaction Sun Gear and Drum1. Inspect reaction sun gear for chipped or nicked

teeth and inspect sun gear for scoring. If necessary,

replace entire assembly.

2. Inspect reaction sun gear, drum, and bushing.

3. If necessary to replace bushing, use a chisel such

as tool J-8400-1. Remove bushing from sun gear

drum at bushing joint. See Figure

7C-185.4. Thoroughly clean drum. Install new bushing using

installer tool J-23130-2 with driver handle

J- 8092.

Bushing should be installed flush with rear face of

sun gear drum hub. See Figure

7C-186.

Page 481 of 625

7C-1201973 OPEL SERVICE MANUAL

4. Inspect the secondary valve spring for distortion

or breakage.

5. Clean in solvent, air clean, and blow out all oil

passages. Inspect all oil passages, valve bores for

nicks, burrs or varnish in governor body. Replace if

necessary.6. Install roll pin flush to

,010” below the front face.

7. Install primary valve in governor placing the small

portion of the valve in

first. Use liberal amount of

transmission fluid. There is no spring for the primary

valve.

8. Install secondary valve with small spool portion of

valve in

first.9. Install secondary valve spring.

10. Depress secondary valve spring with small screw

driver and install retainer.

Disassembly, Inspection and Reassembly of

Governor Hub1. Inspect the three oil seal rings. See Figure

7C-189.Figure 7C.189

2. Remove governor hub oil screen. Inspect screen

and clean with solvent and air dry. Replace if neces-

sary. See Figure 7C-191.

3. Install oil screen flush to governor hub.

4. Inspect governor hub splines for cracks or chipped

teeth in splines. Replace governor hub if required.Figure 7C-191

Disassembly, Inspection end Reassembly of

Extension Housing1. Inspect extension housing for damage. Replace

housing if necessary.

2. Inspect parking

paw1 and spring for damage. Re-

place if necessary.

3. If lubricant leakage was noted prior to removal ofU-Joint from extension housing, extension housing

rear seal should be replaced.

4. Use screw driver to pry out extension housing seal.

5. Inspect extension housing bushing. If worn, scored

or damaged, bushing can be removed with remover

and installer tool J-21424-9 used with driver handle

J- 8092. See Figure

7C-192.6. Clean extension housing of dirt and foreign mat-

ter. Install new extension housing bushing using

remover/installer tool J-21424-9 with driver handle

J- 8092. Bushing must be installed flush to shoulder

of exi:ension housing. See Figure 7C-192.

7. Install new extension housing seal using installer

tool

Jo-21426. See Figure 7C-193.

Disassembly, Inspection and Reassembly of Servo

Piston1. Remove servo piston apply rod

2. Holding servo piston sleeve at flat portion of sleeve

with wrench, loosen the adjusting bolt lock nut and

remove. See Figure

7C-194.

Page 486 of 625

AUTOMATIC TRANSMISSION 7C-1251. CASE VENT4.3RD CLUTCH7.SUCTION

2. CONVERTER OUT5MODULATOR8.LINE/3.2ND CLUTCH

6. BOOST9.REVERSEFigure 7C-202 Case Front View Oil Passage

Identification

7.

!nspect reaction sun gear drum bushing sleeve

inside case at rear for scoring. If necessary, replace

sleeve before installing rear case bushing.

8. Remove sleeve by grinding. Care must be used in

order that aluminum case is not damaged when

grinding sleeve.

9. Install new sleeve using installer tool J-23130-7

and driver handle J-8092.

10. Install new case bushing using remover and in-

staller tool J-23130-3 and driver handle J-8092.

Bushing should be installed flush with case at rear.

See Figure

7C-203.Figure 7C-2031. Drain Converter. If clutch disc material or

foreign matter has been found while draining con-

verter,

replace entire converter assembly as it can not be

cleaned properly.

2. Air check converter for leaks using converter

checking tool J-21369. Install tool and tighten. Ap-

ply 80 psi air pressure to tool. See Figure

7C-204.Figure 7C-204

3. Submerge in water and check for leaks.

4. Check converter hub surfaces for scoring or wear.

Installation of Selector Lever and Shaft1. Install new selector lever shaft oil seal in case.

Insert selector lever shaft through case from outside.

Care should be exercised so that oil seal is not da-

maged. See Figure

7C-206.2. Insert spring pin in case to secure selector lever

shaft.3. Guide selector lever over shaft and secure with

lock nut.

4. Insert parking

paw1 actuator rod from front of the

case and through hole in case at rear. See Figure 7C-

207.5. Install parking

paw1 actuator rod retaining ring.

Installation of Low Band1. Turn transmission case so that front of case is

upward.

Page 493 of 625

7C-1321973 OPEL SERVICE MANUAL

Figure 7C-226

Figure 7C.224

Figure 7C-225

4. Using 3/16” hex head wrench on servo adjusting

bolt, adjust servo apply rod by tightening adjusting

bolt to 40 lbs. in. Back off bolt five (5) turns. exact/u.See Figure

7C-226.5. Tighten lock nut holding adjusting bolt and sleeve

firm with hex head wrench. See Figure

7C-227.

installation of Valve Body

1. I&all steel balls in oil passages in case. See Figure

7C-228.Figure 7C-227

2. Install new case to transfer plate gasket.

3. Locate guide pins in transmission case for correct

alignment of valve body and transfer plate. See Fig-

ure

7C-229.4. Install manual valve into valve body bore using

liberal amount of transmission fluid.

5. Install long side of manual valve link pin into

manual valve. See Figure

7C-230.

Page 497 of 625

7C-1361973 OPEL SERVICE MANUALshould be secured to keep the front wheels in a

straight-ahead position.sand,. mud, or snow, move the selector lever from

“D” to “R” in a repeat pattern while simultaneously

applying moderate pressure to the accelerator. DoRocking Carnot race engine. Avoid spinning wheels when trying

If it becomes necessary to rock the car to free it fromto free the car.

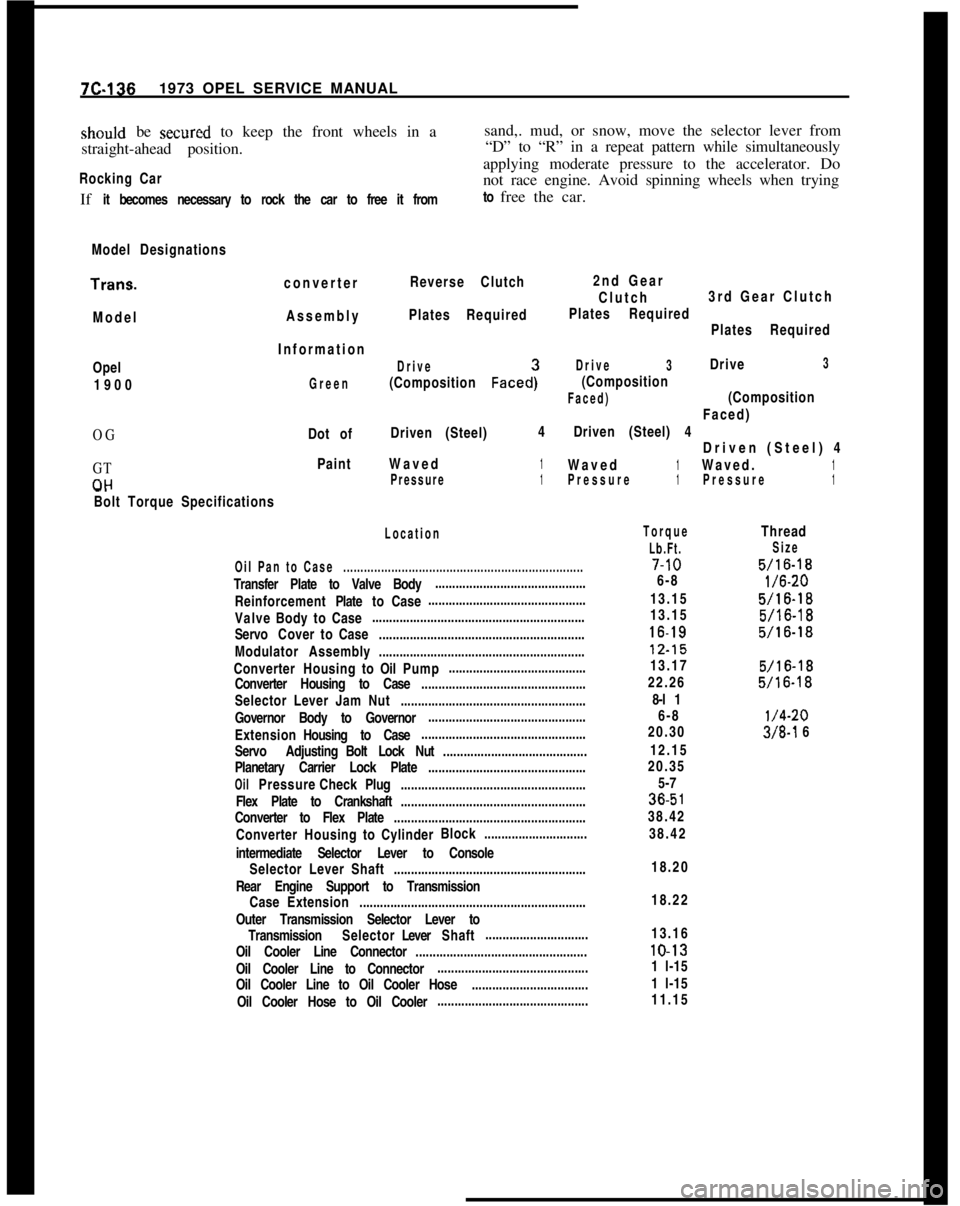

Model DesignationsTrans.

converterReverse Clutch

ModelAssemblyPlates Required2nd Gear

Clutch3rd Gear Clutch

Plates Required

Plates RequiredOpel

1900

OG

GT

CIHInformation

Drive

(Composition Faced:

Drive3Drive3

Green

(Composition

Faced)(CompositionFaced)

Dot ofDriven (Steel)4Driven (Steel) 4

Driven (Steel) 4

PaintWaved1Waved1Waved.1Pressure1Pressure1Pressure1-.

Bolt Torque Specifications

Location

Oil Pan to Case......................................................................Transfer Plate to Valve Body............................................

ReinforcementPlatetoCase..............................................

ValveBodytoCase..............................................................

ServoCovertoCase............................................................

Modulator Assembly............................................................

ConverterHousingtoOilPump........................................

Converter Housing to Case................................................

Selector Lever Jam Nut......................................................

Governor Body to Governor..............................................

ExtensionHousing to Case................................................

Servo AdjustingBolt Lock Nut..........................................

Planetary Carrier Lock Plate..............................................

OilPressureCheckPlug......................................................

Flex Plate to Crankshaft......................................................

Converter to Flex Plate........................................................

ConverterHousingtoCylinderBlock..............................

intermediate Selector Lever to Console

Selector Lever Shaft........................................................

Rear Engine Support to Transmission

CaseExtension..................................................................

Outer Transmission Selector Lever to

TransmissionSelectorLeverShaft..............................

Oil Cooler Line Connector..................................................

Oil Cooler Line to Connector............................................

Oil Cooler Line to Oil Cooler Hose..................................

Oil Cooler Hose to Oil Cooler............................................

Torque

Lb.Ft.7-10

6-8

13.15

13.1516-1812.15

13.17

22.26

8-l 1

6-8

20.30

12.15

20.35

5-736.5

138.42

38.42

Thread

Size

5/16-18

l/6-20

5/16-18

5/16-18

5/16-18

5/16-18

5/16-18

l/4-20

3/8-l 6

18.20

18.22

13.1610-13

1 l-15

1 l-15

11.15