maintenance OPEL GT-R 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 125 of 625

I2A- 21973 OPEL SERVICE MANUAL

GENERAL INFORlVlATION

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

PaintMaintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-2

ChromeMaintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-2

StainRemoval

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-2

MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:

Bolt

TorqueSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-4

Special Body Tools

. . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A-5

MAINTENANCE AND ADJUSTMENTSPAINT MAINTENANCE

To remove heavy concentrations of road dirt and

grime, it is recommended that the car be washed

using an automotive shampoo or mild soap, and cold

to lukewarm water. Use of harsh soaps or detergents

is not advised. In areas where salt is used on the

roads during the winter months, more frequentwashing is recommended.

Use of cleaners and polishes are required if no high

luster is obtainable by waxing. To protect the paint

finish, sparingly apply several coats of wax. Each

coat should be thoroughly rubbed to remove any

surplus wax.

Once the car is properly waxed, road dirt may easily

be removed by use of cold to lukewarm water and a

sponge. Dry by use of a chamois.

CHROME MAINTENANCE

Chrome parts should be washed with water and a

mild detergent. If rust or salt corrosion should ap-

pear, they may be removed with Buick Rust Eraser

or equivalent. Do not use scouring powders or stiff

brushes.STAIN REMOVAL

Before attempting to remove spots or stains from

upholstery fabrics, determine as accurately as possi-

ble: (1) Nature and age of the spot or stain. (2) The

affect of stain removing agents on the color, struc-

ture and general appearance of the fabric.

For best results, stains should be removed from

upholstery as soon as possible after they have been

made. If they are allowed to stand for some time,

they often become set, and removal becomes more

diffxult and frequently impossible.

There are three basic types of acceptable’ cleaners

available to car owners: (1) Volatile cleaners, (2) Syn-

thetic detergents, (3) Neutral soap (non-alkaline).

The volatile cleaners are recommended since they

have great solvent powers for grease, oils and general

road grime. Synthetic detergents generally loosen

stains satisfactorily, however, the use of improper

type detergents (containing bleach) involves risk of

damage to the color or finish of fabrics.

Precautions For Cleaning FabricsDo not use laundry soap or detergents containing

bleaches. The use of these agents tends to weaken

fabric and to change its color. Do

not use too much

cleaning fluid. Some interior trim assemblies are pad-

Page 129 of 625

2B- 61973 OPEL SERVICE MANUAL

OPEL 1900, MANTA AND GT FRAME ANDBODY

MOUNTINGS

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:

FrameandBodyMountingSpecifications. . . . . . . . . . . . . . . .Page No.28-6LOWER

I.

1.Ii

NOTE: TOLERANCES

NOTTOEXCEED*1,16I IDATUM LINEZB2

Figure

ZB-2 GT Frame Details

Page 132 of 625

WINDOWS AND WINDOW MOLDINGS2c-9WINDOWS AND WINDOW MOLDINGS

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

Removal and Installation

Windshield

RevealMolding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Windshield

andBackWindow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DoorWindow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear Quarter Window Molding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear Quarter Window

-1900 -Manta. . . . . . . . . . . . . . . . . .RearQuarterWindow

-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RearQuarterWindowLock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)Page No.

2c- 9

2c-10

2c-11

2c-11

2c-12

2c-12

2c-12

MAJOR REPAIR

REMOVAL AND INSTALLATION OF WINDSHIELD3. With Tools J-2 1828 and J-2 1549, insert new reveal

REVEAL MOLDINGmolding and install escutcheon.

1. Remove reveal molding escutcheon. Starting at

one end, pull molding out of rubber channel. See

Figure

2C-2.Figure ZC-2 Removing Reveal Molding

Figure ZC-3 Pushing Windshield Out 2. Prior to installation, place molding in water and

heat up to approximately 113

- 122 degrees F.

Page 136 of 625

DOORS

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

Front Door - Removal and Installation

DoorLockStriker..........................................................

WindowRegulator

Handle..........................................

Trim

Pad............................................................................

DoorHandle.Inside......................................................

RevealMolding................................................................

WindowLifter..................................................................

DoorLockCylinder........................................................

Weatherstrip....................................................................

Door....................................................................................

Rear Door

- Removal and Installation

SashWindow..................................................................

Window Regulator........................................................

TailGate............................................................................

Door....................................................................................

SPECIFICATIONS:Page No.

2D-13

2D-13

2D-13

2D-15

2D-1520-l

5

2D-17

2D-10

20-18

2D-19

2D-20

2D-21

2D-21

MAJOR REPAIRREMOVAL AND INSTALLATION OF DOOR LOCK

STRIKER1. Mark position of old striker on lock pillar and

unscrew striker, using Tool J-23659. See Figure

2D-2.2. Place new striker in installation position and tem-

porarily tighten striker, observing marking on lock

pillar. Close door and check whether this can be

done without exerting any force. If this is not the

case, adjust striker accordingly.

3. Tighten attaching screws, using Tool J-23659, and

check for proper operation.REMOVAL AND INSTALLATION OF WINDOW

REGULATOR HANDLE1. Insert Tool J-7797 between handle and nylon disc.

See Figure

2D-3.2. With the two fork-shaped ends of the tool, slide

lock spring outwards. See Figure

2D-4.3. Place lock spring of new handle in installation

position and install it onto window regulator shaft.

4. With the window in closed position, the window

regulator handle should point upwards towards the

front at an angle of approximately 45 degrees.

REMOVAL AND INSTALLATION OF FRONT

DOORTRIM PAD

1. Remove window regulator handle.

Page 145 of 625

ZE-221973 OPEL SERVICE MANUAL’REAR COMPARTMENT LID

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

Removal and Installation

Weatherstrip

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lock Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LuggageCompartmentLid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)Page No.

2E-22

2E-22

2E-23

MAJOR REPAIRREMOVAL AND INSTALLATION OF LUGGAGE

COMPARTMENT LID WEATHERSTRIP

1. Detach old weatherstrip and clean sealing surface.2. Coat new weatherstrip and contacting surface

with rubber cement, and allow cement to dry for a

few minutes.3. Install new weatherstrip with rubber cement. See

Figure

2E-2.REMOVAL AND INSTALLATION OF LUGGAGE

COMPARTMENT LID LOCK CYLINDER

Removal

1. Remove luggage compartment lid lock. See Figure

2E-3.Figure

ZE-2 installing Luggage Compartment Lid2. With luggage compartment lid in almost horizon-Weatherstriptal position, unscrew lock cylinder nut, using a 13/16Figure

2E-3 Lid Lock Attaching Screws

Page 147 of 625

2F-241973 OPEL SERVICE MANUAL

ROOF AND SUN ROOF

CONTENTS

,.,Subject

DESC,RIF?TION AND OPERATION: (Not Applicable)

DIAGNOSIS: Sun Roof Diagnosis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND ADJUSTMENTS:Sun Roof Height Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .

MAJOR REPAIR:

Removal and Installation

Sun Roof Panel andFrame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .

Velvet Strip and Weather Strip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RearGuides andCables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . .

Drive Pinion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water DrainHoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . .

Luggage Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS: (Not Applicable) Page No.

2F-24

2F-26

iF-27

2F-29

2F-29

2F-30

2F-31

2F-3i

DIAGNOSIS

SUN ROOF DIAGNOSIS

_ -

CONhTlONPAUSEI~C~RRECTI~X~

Sun roof does not operate

Transporter cable lengths

parallel. equal.Close sun roof, slide sun roof

frame to rear, remove.crank

handle

and cable crank. Check

that sun roof bears against sun

roof opening velvet strip and

that lifter’ portion of rear lifter

guides is positioned approximately

90 degrees to guide rails.

Turn

cable crank fully clockwise and

reinstall into cable box.

Transporter cables damaged

or worn. Replace cables. Both cables

must be replaced if either one

is damaged or worn.

Page 149 of 625

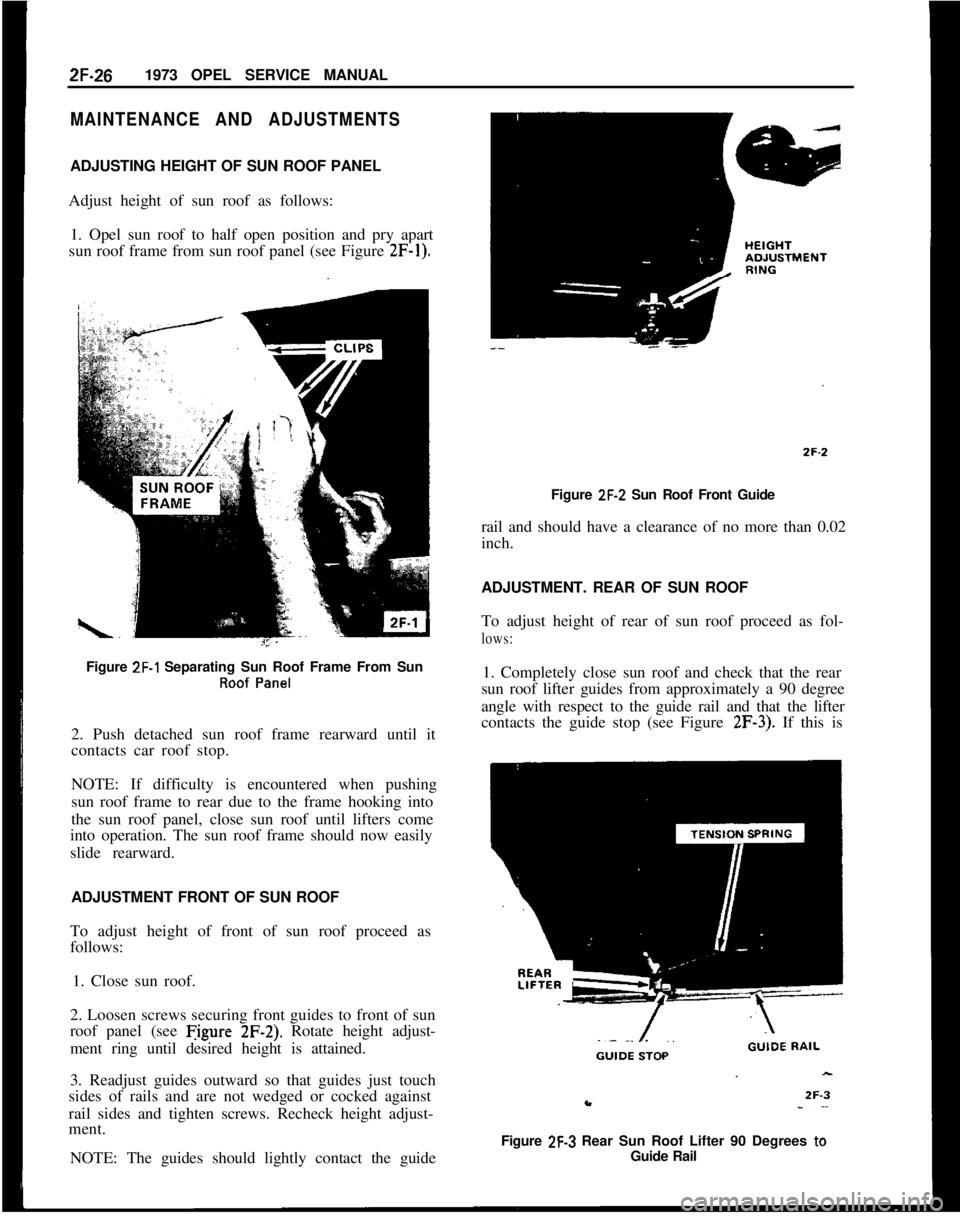

2F-261973 OPEL SERVICE MANUALMAINTENANCE AND ADJUSTMENTSADJUSTING HEIGHT OF SUN ROOF PANEL

Adjust height of sun roof as follows:

1. Opel sun roof to half open position and pry apart

sun roof frame from sun roof panel (see Figure

2F-1).Figure

ZF-1 Separating Sun Roof Frame From SunRoof Panel2. Push detached sun roof frame rearward until it

contacts car roof stop.

NOTE: If difficulty is encountered when pushing

sun roof frame to rear due to the frame hooking into

the sun roof panel, close sun roof until lifters come

into operation. The sun roof frame should now easily

slide rearward.

ADJUSTMENT FRONT OF SUN ROOF

To adjust height of front of sun roof proceed as

follows:

1. Close sun roof.

2. Loosen screws securing front guides to front of sun

roof panel (see Figure

2F-2). Rotate height adjust-

ment ring until desired height is attained.

3. Readjust guides outward so that guides just touch

sides of rails and are not wedged or cocked against

rail sides and tighten screws. Recheck height adjust-

ment.

NOTE: The guides should lightly contact the guideFigure

ZF-2 Sun Roof Front Guide

rail and should have a clearance of no more than 0.02

inch.

ADJUSTMENT. REAR OF SUN ROOF

To adjust height of rear of sun roof proceed as fol-

lows:1. Completely close sun roof and check that the rear

sun roof lifter guides from approximately a 90 degree

angle with respect to the guide rail and that the lifter

contacts the guide stop (see Figure

2F-3). If this is

Figure

2F-3 Rear Sun Roof Lifter 90 Degrees toGuide Rail

Page 156 of 625

SEATS, INTERIOR TRIM AND HEADLINING26-33SEATS, INTERIOR TRIM AND HEADLINING

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

Removal and Installation

FrontSeat

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RearSeat

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glove Compartment Lock ..,.........................................

Front

SidePanelTrimPad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlining

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RearSidePanelTrimPad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)26-33

26-33

26-3426-34

26-3526-37

MAJOR REPAIRREMOVAL AND INSTALLATION OF FRONT SEAT

1. Pull hook out of seat lock. See Figure 2G-2.

2.TZ.Gy3at towards the front and unscrew. See Fig

Figure

2G-2 Pulling Hook Out of Seat LockFigure

2G-3 Seat To Underbody Attachment

REMOVAL AND INSTALLATION OF REAR SEAT

BACK1. Push seat towards seat back and unhook it to-

wards the top. See Figure

2G-4.

2. Unscrew safety belt on left and right side and bendup metal tabs below seat back. See Figure

2~3-5.

Page 161 of 625

2H-381973 OPEL SERVICE MANUAL

BUMPERS

CONTENTS

Subject

DESCRIPTION AND OPERATION: Protective Moldings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . *. . . . . . . . . . . . . . . . .

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable) MAJOR REPAIR: Removal and Installation

1900

- Manta. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GT. . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . .

Trailer Hitch Installation, . , . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . .

SPECIFICATIONS: (Not Applicable) Page No.

2H-38

2H-38

2H-39

2H-41

DESCRIPTION ‘AND OPERATION

PROTECTIVE MOLDINGS

All 1973 Opel bumpers are equipped with rubber

protective moldings as standard equipment. The

moldings are easily removed by removing the attach-

ing nuts located on the inboard side of the bumper.

MAJOR REPAIR

REMOVAL AND INSTALLATION OF FRONT

BUMPER AND BUMPER GUARDS

(OPEL 1900 -

MANTA)

Removal

1. Remove bumper attaching screws on inside

- left

and right

- and from left and right brackets. See

Figure

2H-2.

2. From the front, unscrew bumper guard attaching

screws. See Figure‘

2H-2.

Remove bumper and bumper guards.

Installation

1. Attach bumper guards to bumper.

Figure ZH-2 Bumper Attaching Screws

2. From the front, secure bumper guards with attach-

ing screws. See Figure

2H-2.

3. Install attaching bolts on left and right brackets,

and on left and right inside. See Figure

2H-2.

REMOVAL AND INSTALLATION OF FRONT

BUMPER BRACKETS (OPEL 1900

- MANTA)

The front bumper brackets are attached with three

screws. Removal of the three screws will allow re- moval and installation of the front bumper brackets.

See Figure

2H-3.

REMOVAL AND INSTALLATION OF REAR

BUMPER AND GUARDS (OPEL 1900

- MANTA)

1. Remove license plate lamp.

2. Remove bumper attaching screws and bumper

brackets. See Figure

2H-4.

Page 169 of 625

3A- 21973 OPEL SERVICE MANUAL

FRONT SUSPENSION

CONTENTS

Subject

DESCRIPTION AND OPERATION:SuspensionDescription. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

FrontWheel

BearingAdjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal and Installation of Front Suspension . . . . . . . .Upper Ball Joint Removal and Installation

. . . . . . . . . . . . . .Lower Ball Joint Removal and

Installation

. . . . . . . . . . . . . .Upper Control Arm

Removal andInstallation

. . . . . . . . . .Lower Control Arm Removal and Installation

. . . . . . . .Steering

Knuckle

RemovalandInstallation. . . . . . . . . . . . . .Shock Absorber

RemovalandInstallation. . . . . . . . . . . . . . . .Front Spring Removal and Installation

. . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:Page No.

3A- 2

3A- 4

3A- 4

3A- 7

3A- 73A-103A-113A-133A-153A-15

Bolt Torque and Front End Alignment Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3A-18

DESCRIPTION AND OPERATION

SUSPENSION DESCRIPTION

GTThe GT uses a maintenance-free independent front

wheel suspension and features unequal length con-

trol arms and a transverse three-leaf spring. The en-

tire front suspension is attached to the front cross

member and can be removed as a unit if so desired.

The engines installed in the GT are not supported by

mounting brackets but rest on a separate cross mem-

ber. The front suspension cross member is reinforced

in the area of the attachment to the frame. A one-

part damper plate is installed between cross member

and frame.

Ball joints are employed in the conventional manner

to provide pivoting joints between the control arms

and steering knuckles. Upward movement of the

control arms is limited by two large rubber bumpers

attached to the cross member.Road shock is dampened by the double direct acting

shock absorbers and a transverse double or triple

steel band spring. In addition, the shock absorber

limits downward travel of the control arms.

All moving parts, including ball joints, have no need

for lubrication as they have been pre-lubricated for

the life of the vehicle.

For distinguishing the individual front suspension

cross members,.a red label with black letters is stuck

onto the front side of the shock absorber support. See

Figure 3A-3.

Opel 1900. Manta

The front wheel suspension has coil springs and con-

trol arms of different length.

The stabilizer is designed to act as a tie strut. The end

is supported in a rubber bushing which is located in

a piece of tubing welded into the longer control arm.

To minimize brake torque, the horizontal shafts of