maintenance OPEL GT-R 1973 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 171 of 625

3A- 41973 OPEL SERVICE MANUAL

The two cross-members to body supports are at-

tached to the horizontal part of the cross-member

with two bolts. The oufererbolt serves simultaneously

as support for the lower control arm. As the bolt is

inserted from the front, the cross-member to body

support can be removed without the lower control

arm. The inner bolt attaches simultaneously to the

steering.

The stabilizer is U-shaped and supported in rubber

bushings in the two cross-members to body supports.

The complete front suspension is attached to the

underbody in four places.

The engine damper blocks are bolted to the inside of

the inclined parts of the cross-member.

The front wheel bearings are roller bearings.

All front suspension joints are maintenance-free.

MAINTENANCE AND ADJUSTMENTSFRONT WHEEL BEARING ADJUSTMENT

1. If wheel has not previously been removed from the

car, remove grease cap, cotter pin, and spindle nut.

Discard cotter pin.

2. Torque spindle nut to 18

lb.ft. while rotating

wheel. This will allow the bearings to settle.

3. Back offspindle nut

l/4 turn. If slot and cotter pin

hole are staggered, further back off nut

l/l2 turn,

but do not tighten, until next slot in nut is in align-

ment with hole in spindle. Install new cotter pin. A

properly adjusted wheel bearing has a small amount

of end play and a loose nut when adjusted in the

above manner.

MAJOR REPAIRREMOVAL AND INSTALLATION OF FRONT

SUSPENSION

(COMPLETE ASSEMBLY)

Removal GT1. Prior to raising front end of car, apply parking

brake and block rear wheels.

2. Raise front end of car with a jack. It is recom-

mended that a wood block be placed between thejack and the front cross member to prevent damage

to the cross member.

3. Support front end of car by placing floor standsunde:r jacking brackets.

4. Support engine-transmission assembly in upper-

most position with jack stand at rear of engine, or an

alternate method would be to use Engine Holding

Fixture, Tool J-23375. See Figure 3A-5.

Install tool by removing upper kngine mount nut and

installing fixture. Replace nut and tighten. The en-

gine will now be supported by the tool between the

frame rails.

Figure

3A-5 Engine Holding Fixture Installed

5. Loosen steering mast at the lower universal joint

and take out clamp bolt. Loosen clamp at the upper

universal joint and lift steering mast upwards until it

is free at the lower universal joint. See Figure

3A-6.6. Disconnect brake lines at brake hose.

7. Disconnect shock absorber at upper mounting. It

is necessary to remove air cleaner. See Figure

3A-24.8. Disconnect engine mounts at cross member.

9. Remove front suspension cross member attaching

nuts and lower the cross member.

Removal Opel 1900 - Manta1. Prior to raising front end of car, apply parking

brake and block rear wheels.

Page 176 of 625

FRONT SUSPENSION3A- 9

8. Press ball stud out of lower control arm.Removal Opel 1900 - MantaBefore raising vehicle, install Hooks J-23697 on re-

spective vehicle side to cross member and upper con-

trol arm. See Figure 3A-7.

1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. At the lower control arm ball joint, remove castle

nut cotter pin and slacken back nut so that the thread

can no longer be damaged.

4. With a suitable drift, detach ball joint from steer-

ing knuckle. With jack, lift up lower control arm,

unscrew castle nut and remove Hooks J-23697.

5. Unscrew upper control arm ball joint and suspend

front wheel hub and brake caliper in wheel house. Do

not turn upper control arm ball joint flange, as this

would result in a change of camber.

6. Remove defective lower control arm ball joint

using Tools J-9519 and Receiver J-23754.

Installation GT

CAUTION:

Fasteners are important attachingparts in

that they could affect the performance of

vitaI com-

ponents and systems, and/or could result in

ma&r

repair expense. They must be replaced with one of

the same part

numer or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.1. When pressing the ball joint in place, make certain

the locating notch in the lower rim of the ball joint

matches the alignment reference mark placed on the

lower control arm prior to removal. The notch in the

ball joint bottom plate, identifying the direction of

the elongated slot, must point towards the brake

drum backing plate. See Figure

3A-17. Alignment

must be within 2 degrees of lower control arm center-

line. If proper positioning of the ball joint is not

accomplished, the result is a limitation of the neces-

sary ball stud movement. If ball stud movement is

limited, an interference between the ball stud and

housing is created, and binding or even fracture may

occur. Replacement ball joints may or may not have

marking notch as shown in Figure

3A-20. If it does

not have a marking notch, the joint is completelysymetrical and may be installed in any position.

When pressing in ball joint do not press on bottom

plate, but on ball joint housing only.2. Install dust cap on lower ball joint and fill with

chassis lubricant. Attach dust cap retainer.

3. Press ball joint into steering knuckle. Use

J-9519-3 as installer and J-21690 as a supporting

sleeve.4. Install castle nut on ball joint stud and torque to

40

Ib.ft. Install new cotter pin.

5. Reconnect shock absorber to lower control arm

and torque to 30 lb.ft.

6. Remove spring compressor.

7. Install front wheel, and lower the car.

8. Always check caster and camber after ball joint

replacement.

Installation Opel 1900 - Manta

CAUTION:

Fasteners are important attachingparts in

that they could

aff’ect the performance of vital com-

ponents and systems, and/or could result in

ma&r

repair expense. They must be

rep/aced with one of

the same part number or with equivalent parts, if

rep/acement becomes necessary. Do not use a re-

p/acement part of lesser quality or substitute design.

Torque valves must be used as

specitied during reas-

sembIy to assure proper retention of these parts.1. Drive new ball joint into lower control arm using

Tools J-9519 as installer and J-23755 as a supporting

sleeve. Do not strike onto ball joint bottom.

The ball joint is maintenance-free. It is supplied as an

assembly only and cannot be disassembled further.

2. On new lower control arm ball joint, make sure

that the marking groove in the housing bottom in

alignment with the axis of the lower control arm.

Permissible deviation: minus 2 degrees to plus 2 de-

grees.This is required, to obtain the maximum freedom of

movement of the ball stud in the housing. See Figure

3A-18.3. Attach steering knuckle together with front wheel

hub and brake caliper to lower control arm ball joint.

Torque castle nut to 54

ft.lbs.4. Attach ball joint to upper control arm and torque

to 29

ft.lbs. Always use new self-locking nuts.

5. Install wheel and tighten nuts to a torque of 65

ft.lbs.6. Lower car and check caster and camber.

Page 181 of 625

3A. 141973 OPEL SERVkE MANUAL

Figure 3A-22 Caliper Removed and Hung by Wire

steering knuckle. Swing steering arm and tie rod to

the side.7. Remove castle nut cotter pin, unscrew nut and

pull steering knuckle off lower control arm ball joint.

Installation GTCAUTION: Fasteners are important attachingparts in

that they could affect the performance of

viral com-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part of lesser quality or substitute

desig.Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Always replace paper gasket when installing dust

shield on steering knuckle. Lightly coat both surfaces

of paper gasket with chassis lubricant before installa-tion and torque attaching bolts to 47

lb.ft.2. Install lower ball joint in steering knuckle. Torque

castle nut to 54

Ib.ft. Install new cotter pin.

3. Attach shock absorber at lower end. Torque boltsto 30 lbs. ft.

4. Install upper ball joint. Torque castle nut to 29

lb.ft. Install new cotter pin.

5. Remove spring compressor.6. Install hub and disc on spindle and tighten spindle

nut as stated under MAINTENANCE AND AD-

JUSTMENTS in this section.

7. Install caliper on steering knuckle and torque boltsto 72

lb.ft. See Figure 3A-21.8. Install wheel and torque wheel nuts to 65

lb.ft.

Installation Opel 1900

- MantaCAUTION: Fasteners are important attachingparts in

that they could

affit the performance of vital com-

ponents and systems, and/or could result in

ma&repair expense. They must be replaced with one of

the same part number or with equivalent parts, ifrepfacement becomes necessary. Do not use a re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Attach steering knuckle to lower control arm ball

joint. Torque castle nut to 54

lb.ft.

2.

Atl,ach brake cover plate and steering arm to steer-ing knuckle. If required, install new paper gasket

between cover plate and steering knuckle. Care for

proper seat of T-head bolts. See Figure

3A-23.Figure 3A-23 Attaching Brake Cover Plate

3. Install front wheel hub and brake caliper.

4. Attach steering knuckle to upper control arm ball

joint. Torque castle nut to 40

lb.ft.5. Steering arm to steering knuckle

_ 58 lb.ft.6. Brake caliper to steering knuckle

- 72 lb.ft.7. Adjust front wheel bearing clearance.

8. Remove stands and lower car

Page 186 of 625

STEERING LINKAGE38.19STEERING LINKAGE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description

andOperationofTieRods. . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

RemovalandInstallationofTieRods. . . . . . . . . . . . . . . . . . . . . . . .Disassembly

andReassemblyofTieRods. . . . . . . . . . . . . . . .SPECIFICATIONS:

Tightening Specifications ..,.............................................Page No.

38-193B-1938-21jB-21

DESCRIPTION AND OPERATION2. Using remover J-21687, pull outer tie rod ball

studs out of steering arms. See Figure

3B-2.DESCRIPTION AND OPERATION OF TIE RODS

Tie rods on the GT are connected to both rack ends

by means of a ball joint. Two rubber bellows between

ball joint and steering gear housing protect rack and

ball joints against dirt, dust and mud. The ball joints

of the tie rods do not require service.

Tie rods on the Opel l&O and Manta are connected

to both rack ends by means of a axial joint. Two

rubber bellows between the axial joint and steering

gear housing protect the rack and axial joints against

dirt, dust, and mud. The ball joint of the tie rod ends

on the Opel 1900 and Manta are maintenance free

and must not be disassembled.

MAJOR REPAIRREMOVAL AND INSTALLATION OF TIE RODS

38-2

RemovalFigure

38-2 Removing Ball Stud

In order to avoid the possibility of dirt entering the

steering gear assembly via the rack, it is recom-

mended that rods and area immediately surrounding

the gear assembly be wiped free of loose dirt prior to

removal.3. Remove clamp securing one end of rubber bellows

to tie rods and slip bellows off tie rods to expose nut

or lock plates. See Figure

3B-3.1. Remove cotter pins securing nuts on tie rod ends

and remove nuts. Discard cotter pins.4. On the GT, bend up round edges of lock plate

from tie rod ball studs and unscrew ball studs From

rack. See Figure

3B-4.

Page 188 of 625

STEERING LINKAGE38-21

4. Attach rubber bellows to axial joint using hoseClamp.DISASSEMBLY AND REASSEMBLY OF TIE RODS

The ball joint of the tie rod end on the Opel 1900

_Manta is maintenance free and must not be disassem-

bled.

Disassembly - GT

?. Loosen tie rod clamp bolt and unscrew outer tie

rod ball stud from tie rod. See Figure

3B-6.2. Remove retainer ring from outer ball stud of tie

rod and take off rubber sealing cap.

Reassembly GT1. Install rubber sealing cap and retainer ring onto

outer ball stud.

2. Screw outer tie rod ball stud into tie rod and

tighten clamp bolt.

CAUTION: Fasteners for tie rods are important

attaching parts in that they could affect the per-

formance of vital components and systems, and-

TIE ROD rCLAMPOUTERy BALL STUD

RETAINER RING

SEALING RINGFigure

38-6 Tie Rod and Outer Ball Stud

/or could result in major repair expense.They must

be replaced with one of the same part number or with

an equivalent part if replacement becomes necessary.

Do not use a replacement part or lesser quality or

substitute design. Torque values must be used as

specified during reassembly to assure proper reten-

tion of these parts.

SPECIFICATIONSTIGHTENING SPECIFICATIONS

Location

Ball Stud to Rack (GT)Ball Stud to Steering Arm (GT)

Tie Rod End to Steering Arm (1900 . Manta)

Tie Rod Lock Nut (1900

- Manta)

Torque

Lb.Ft.

4329

29

47

Page 189 of 625

3C-22 1973 OPEL SERVICE MANUAL.

FRONT END ALIGNMENT

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

FrontWheelAlignment

. . . . . . . . . . . . . . . . . . . . . . ..“...........................DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Inspection Before Checking Front Wheel Alignment

AdjustingCaster

. . . . . . . . ...’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adjusting Camber

. . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adjusting Toe-In

. . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .King Pin Inclination

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR: (Not Applicable)

SPECIFICATIONS:3C-223C-223C-233C-253C-253C-26

Wheel Alignment Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3C-26

DESCRIPTION AND OPERATIONFRONT WHEEL ALIGNMENT

Wheel alignment is the mechanics of adjusting the

position of the front wheels in order to attain the

least steering effort with a minimal amount of tire

wear.handling, but require only reasonable accuracy to

provide normal tire life. With the type of front sus-

pension used, the toe-in adjustment is much more

important than caster and camber are as far as tire

wear is concerned.

Correct alignment of the chassis is essential to proper

alignment of front and rear wheels. Briefly, the es-

sentials are that the frame must be square in plain

view within specified limits, that the top and bottom

surfaces of the front cross member must be parallel

fore and aft, and that the upper and lower control

arm must be at correct location in respect to shafts

and the front cross member. All bushings, ball joints

and bolts must be of proper torque and in usable

condition.Caster and camber adjustments need not be consid-

ered unless visual inspection shows these settings to

be out, or unless the car gives poor handling on the

road. In the majority of cases, services consisting of

inflating tires to specified pressure and interchanging

tires at recommended intervals, balancing all wheels

and tires, adjusting steering gear and setting toe-in

correctly will provide more improvement in car han-

dling and tire wear than will other front end align-

ment adjustments.

Wheel and tire balance has an important effect on

steering and tire wear. If wheels and tires are out of

balance, “shimmy” or “tramp” may develop or tires

may wear unevenly and give the erroneous impres-

sion that the wheels are not in proper alignment. For

this reason, the wheel and tire assemblies should be

known to be in proper balance before assuming that

wheels are out of alignment.The correct use of accurate front end alignment

equipment is essential to determine whether front

suspension parts have been damaged by shock or

accident, and to obtain correct alignment settings

after new parts have been installed.

MAINTENANCE AND ADJUSTMENTS

Inspection Before Checking Front Wheel AlignmentClose limits on caster, front wheel camber, andBefore making any adjustment affecting caster, cam-

theoretical king pin inclination are beneficial to carber, toe-in, theoretical king pin inclination, or

steer-

Page 194 of 625

STEERING GEAR ASSEMBLY3D. 27

STEERING GEAR ASSEMBLY

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description and Operation of Steering Gear. . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

AdjustmentofSteeringGear

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal and Installation of Steering Gear

Assembly

andTieRods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly and Reassembly of Steering Gear

Assembly With Tie Rods

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

TighteningSpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No.

3D-27

3D-273D-28

3D-303D-33

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF

STEERING GEAR ASSEMBLYThe Opel 1900

- Manta and GT steering gear is the

rack and pinion type. The steering gear pinion shaft,

connected to the lower end of the steering column,

moves the rack to the left or right thereby transmit-

ting the turning motion of the steering wheel to the

tie rods and steering arms.

The steering gear housing is held to the cross mem-

ber by rubber bushings and clamps. The bushings

serve to prevent driving noises and vibrations from

being transmitted into the passenger compartment.

A pinion shaft is seated in the upper portion of the

steering gear housing and is supported by a needle

bearing in the upper housing, and a bushing in the

lower housing. The pinion is not adjustable.

A rubber “0” ring seal is provided for sealing needle

bearing, and a second “0” ring for sealing pinion

bushing. The rack and pinion shaft are held in mesh

by a thrust spring and shell. See Figure

3D-2.The pressure of the thrust spring may be varied by

means of an adjusting screw. The spring forces the

sintered bronze shell against the rack, which in turn

is held against the pinion shaft. Backlash in the steer-ing gear is avoided, and road shocks are effectively

absorbed.

The rack is seated in the long neck of the steering

gear housing in a self-lubricating sintered metal

bushing. It is laterally guided by the sintered bronze

shell in the adjusting screw opening, and in the short

gear housing neck by the rack guide bushing. See

Figure

3D-3.MAINTENANCE

AND ADJUSTMENTS

ADJUSTMENTS OF STEERING GEAR

Adjustment of Steering GearAdjustment of the steering gear assembly is accom-

plished by turning the adjusting screw in or out. See

Figure

3D-2.Positioning of the adjusting screw exerts a pressure

on the rack, thereby varying the backlash between

the pinion and rack.

1. Set steering gear to high point by positioning front

wheels straight ahead with steering wheel centered.

Flexible coupling bolt hole will be positioned hori-

zontal (or parallel) to the rack.

2. Thread adjusting screw into steering gear housing

Page 198 of 625

STEERING GEAR ASSEMBLY3D- 31

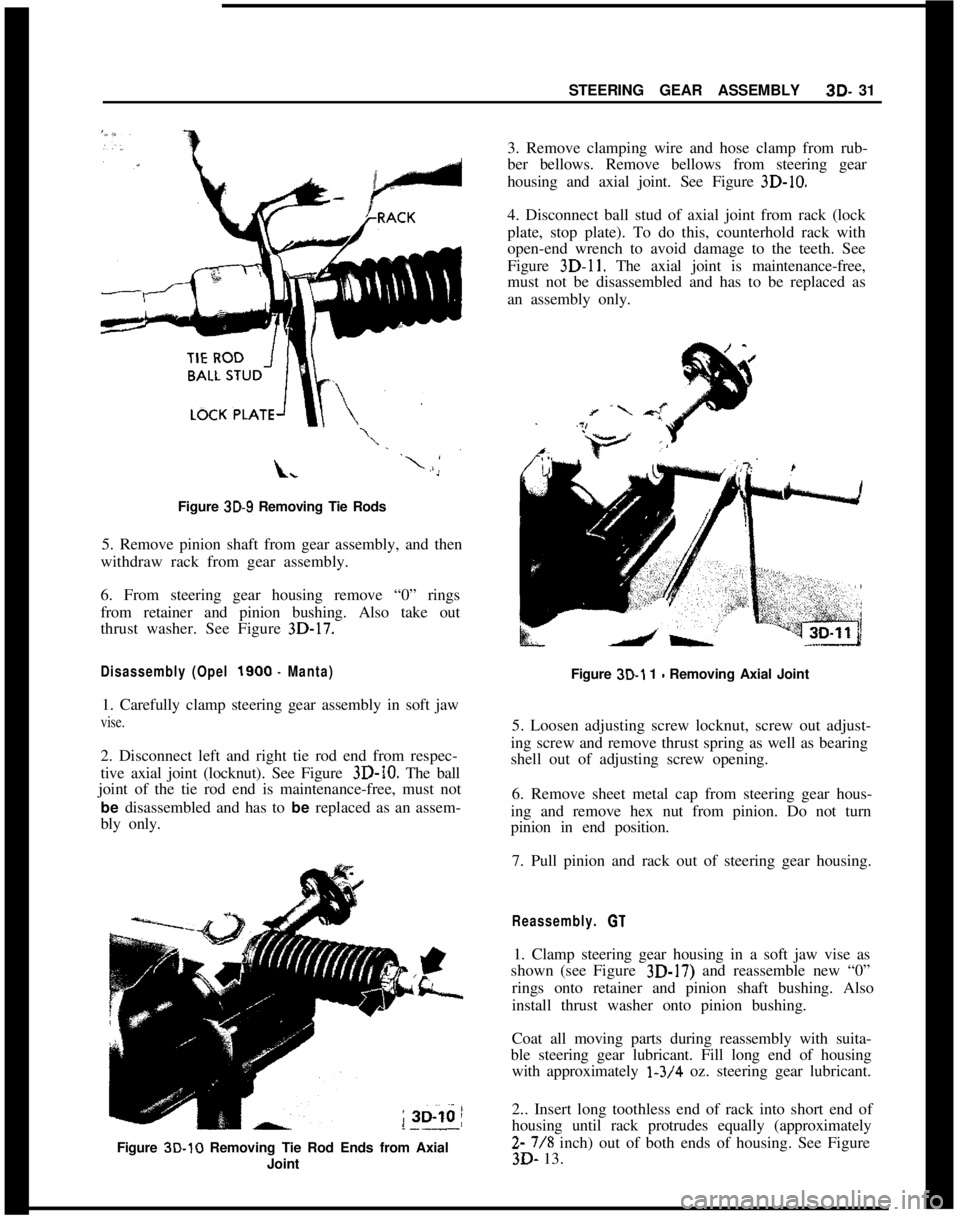

Figure 3D-9 Removing Tie Rods

5. Remove pinion shaft from gear assembly, and then

withdraw rack from gear assembly.

6. From steering gear housing remove “0” rings

from retainer and pinion bushing. Also take out

thrust washer. See Figure

3D-17.

Disassembly (Opel

1900. Manta)1. Carefully clamp steering gear assembly in soft jaw

vise.2. Disconnect left and right tie rod end from respec-

tive axial joint (locknut). See Figure

3D-10. The ball

joint of the tie rod end is maintenance-free, must not

be disassembled and has to be replaced as an assem-

bly only.

Figure 3D-10 Removing Tie Rod Ends from Axial

Joint3. Remove clamping wire and hose clamp from rub-

ber bellows. Remove bellows from steering gear

housing and axial joint. See Figure

3D-10.4. Disconnect ball stud of axial joint from rack (lock

plate, stop plate). To do this, counterhold rack with

open-end wrench to avoid damage to the teeth. See

Figure

3D-11. The axial joint is maintenance-free,

must not be disassembled and has to be replaced as

an assembly only.

Figure

3D-1 1 - Removing Axial Joint

5. Loosen adjusting screw locknut, screw out adjust-

ing screw and remove thrust spring as well as bearing

shell out of adjusting screw opening.

6. Remove sheet metal cap from steering gear hous-

ing and remove hex nut from pinion. Do not turn

pinion in end position.

7. Pull pinion and rack out of steering gear housing.

Reassembly. GT1. Clamp steering gear housing in a soft jaw vise as

shown (see Figure 3D-17) and reassemble new “0”

rings onto retainer and pinion shaft bushing. Also

install thrust washer onto pinion bushing.

Coat all moving parts during reassembly with suita-

ble steering gear lubricant. Fill long end of housing

with approximately

l-3/4 oz. steering gear lubricant.

2.. Insert long toothless end of rack into short end of

housing until rack protrudes equally (approximately

Z- 7/S inch) out of both ends of housing. See Figure3D- 13.

Page 199 of 625

3D- 321973 OPEL SERVICE MANUAL

Figure 3D-13 Steering Gear Housing With Rack

Check to insure that three air channels of sintered

metal bushing (See Figure 3D-17) are not obstructed

by lubricant. If air channels are blocked, a vacuum

condition in the bellows may result during operation

of the gear assembly. Under such circumstances, the

bellows will be drawn inward and jam into the rack

teeth.

3. Reassemble pinion shaft into gear assembly so that

spline in pinion shaft meshes with twelfth tooth of

the rack. Use pinion mounting sleeve J-21712 during

installation of pinion shaft to avoid damage to “0”

ring in pinion bushing. When reassembling pinion

shaft into gear housing, be sure that pinion is so

positioned that bolt hole in pinion shaft flexible cou-

pling is on top and parallel to the rack. See Figure3D- 14..~.. ~. ..~.IN FLEXIBLE

COUPLING PARALLEL ORRIZONTAL WITH R

._..-_ - -._..-

Figure 3D-14 Installing Pinion Shaft

4. Reassemble special washer, flat washer, and new

pinion nut onto pinion shaft. Torque pinion nut to 11

Ib.ft. Do not exceed torque due to possibility ofjam-

ming gear.

5. Place sintered bronze shell into steering gear hous-

ing and fill adjusting hole with Calcium Soap No. 2.

6. Reassemble thrust spring, adjuster screw and lock-

nut on gear assembly.

Final adjustment of adjuster screw is performed after

gear assembly and tie rods are installed in car. See

Maintenance and Adjustments in this section for ad-

justment of steering gear.

7. Place rubber bellows, clamps, and new lock plates

on ball stud portion of tie rods; and screw ball studs

into rack while holding bent tab of lock plate against

flat

ton rack. Torque ball studs 43 lb.ft. See Figure

3D-9. It is important that rack be held secure with

open end wrench to prevent damage to rack teeth.

8. Bend round edges of lock plate over flat on ball

stud to lock ball stud in position. See Figure

3D-15.Figure 3D-15 Bending Lock Plate Over Ball Stud

9. Properly position rubber bellows and clamps over

tie rod and gear housing and adjust clamps so that

ends are pointing same direction as adjusting screw.

Check that bellows is not twisted and will compress

and expand properly.

Reassembly (Opel 1900 - Manta)1. Clamp steering gear housing in a soft jaw vise and

reassemble new “0” rings onto retainer and pinion

shaft bushing. Also, install thrust washer onto pinion

bushing.

Coat all moving parts during reassembly with suita-

Page 202 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY 3E.35

II

OPEL 1900 AND MANTA STEERING COLUMN

ASSEMBLY

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

Description and Operation of Directional Signal

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description

andOperationofHorn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description of Steering Column Assembly

. . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

3E-353E-363E-36

Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Disassembly and Reassembly of Direction Signal

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly and Reassembly of Steering and

Ignition Lock Cylinder, and Electrical Switch

from Mast Jacket Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering

ColumnSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3E-363E-383E-393E-403E-41

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF

DIRECTIONAL SIGNAL LEVERhigh to low beam or vice versa. On all

19M) Rallye

cars, when switching from low to high beam posi-

tion, with the fog lamp instrument panel switch ON

The direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal and

headlight high and low beams. See Figure

3E-2.The dire&M signal lever is provided with a two-

step mechanism for operation of headlight high and

low beams, and passing signal (not in N.J.). With

headlights off, moving the lever repeatedly towards

steering wheel flashes headlights as a passing signal.

With headlights on, moving the lever repeatedly to-

wards steering wheel up to first stop also flashes

passing signal regardless whether or not the direction

signals are switched on. When the lever is moved up

to the second stop, the headlights are changed from

SE.2Figure

3E-2 Directional Signal Lever Position for

Headlamp Operation