maintenance OPEL GT-R 1973 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 281 of 625

5C- 221973 OPEL SERVICE MANUAL

DRUM BRAKES

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description of Brake Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OperationofHydraulicServiceBrake

. . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

BrakeTrouble

Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

BrakeAdjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Filling, Bleeding and Flushing Brake

Hydraulic System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Replace or Reline Brake Shoes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Inspecting and Reconditioning Brake Drums

. . . . . . . . . .Brake Wheel Cylinder Overhaul

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ReplacingBrakePipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Brake Specifications

. . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTION AND OPERATION - DRUM

BRAKES

DESCRIPTION OF BRAKE MECHANISM

Wheel Brake Assemblies

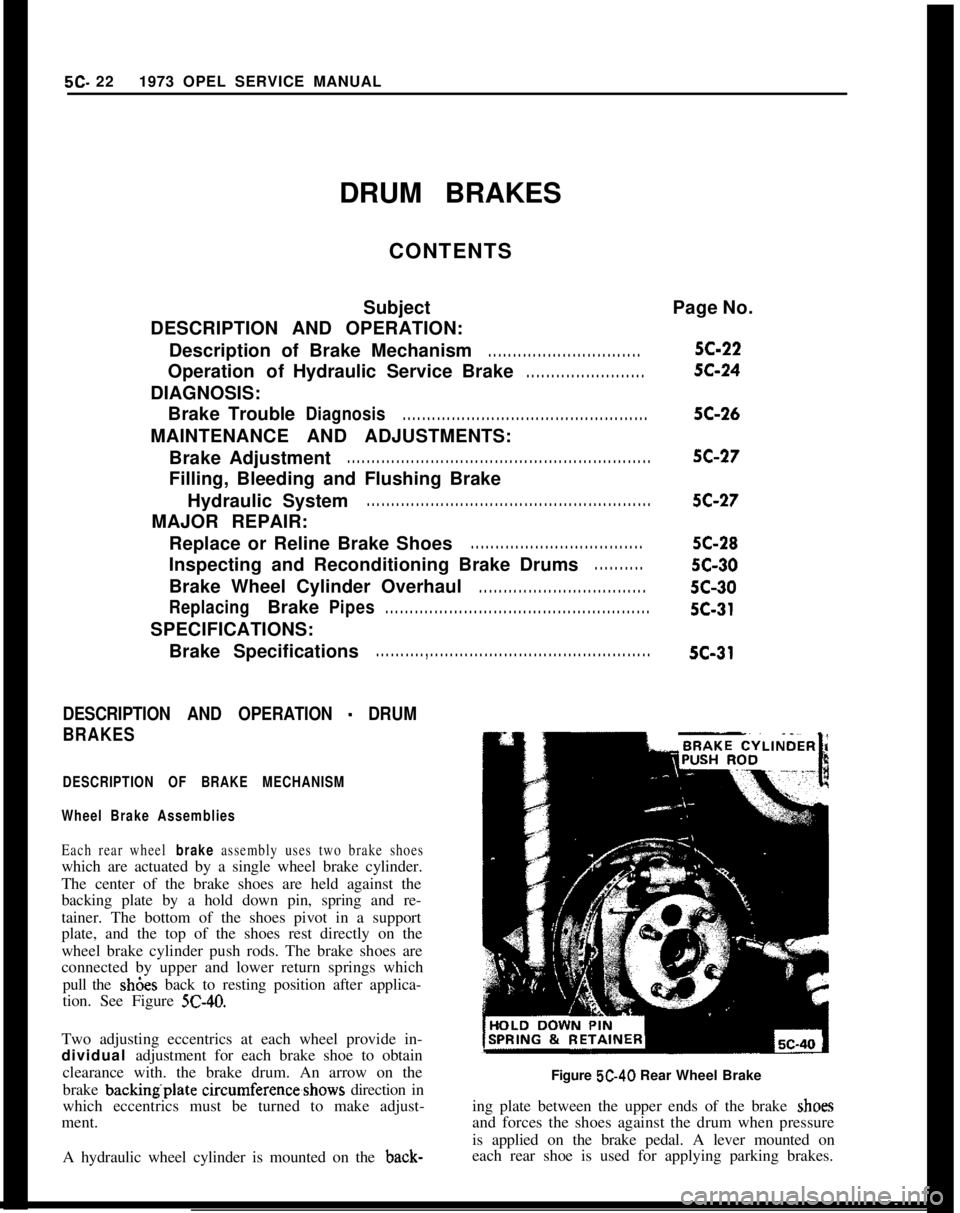

Each rear wheel brake assembly uses two brake shoeswhich are actuated by a single wheel brake cylinder.

The center of the brake shoes are held against the

backing plate by a hold down pin, spring and re-

tainer. The bottom of the shoes pivot in a support

plate, and the top of the shoes rest directly on the

wheel brake cylinder push rods. The brake shoes are

connected by upper and lower return springs which

pull the sh6es back to resting position after applica-

tion. See Figure

5C-40.Two adjusting eccentrics at each wheel provide in-

dividual adjustment for each brake shoe to obtain

clearance with. the brake drum. An arrow on the

brake backing.plate circumference,shows direction in

which eccentrics must be turned to make adjust-

ment.

A hydraulic wheel cylinder is mounted on the back-Page No.5C-225C-245C-26

5C-275C-275C-28

5c-30

5c-305c-315c-31

Figure 5C-40 Rear Wheel Brake

ing plate between the upper ends of the brake

shoeand forces the shoes against the drum when pressure

is applied on the brake pedal. A lever mounted on

each rear shoe is used for applying parking brakes.

Page 286 of 625

DRUM BRAKES5C- 27MAINTENANCE AND ADJUSTMENTSBRAKE ADJUSTMENT

Preliminary Checks

1. Depress brake pedal firmly. If pedal travels to

within two inches of toeboard and has a hard feel,

brake shoes require adjustment or relining. However,

if pedal has a spongy feel, brake system needs bleed-

ing.2. Remove one rear drum if lining is worn nearly to

rivets. Reline both rear brakes (drum brakes only).

3. Check fluid level in master cylinder reservoir and

add fluid if necessary.

4. Fully release parking brake lever and place trans-

mission in neutral.

5. Pull on both ends of rear brake cable a number of

times to make sure that cables operate rear brake

shoes freely and do not bind in conduits. Check for

free movement of cable in brake cable sheave and

check brake cable spring for tension. Replace a weak

or broken cable spring.

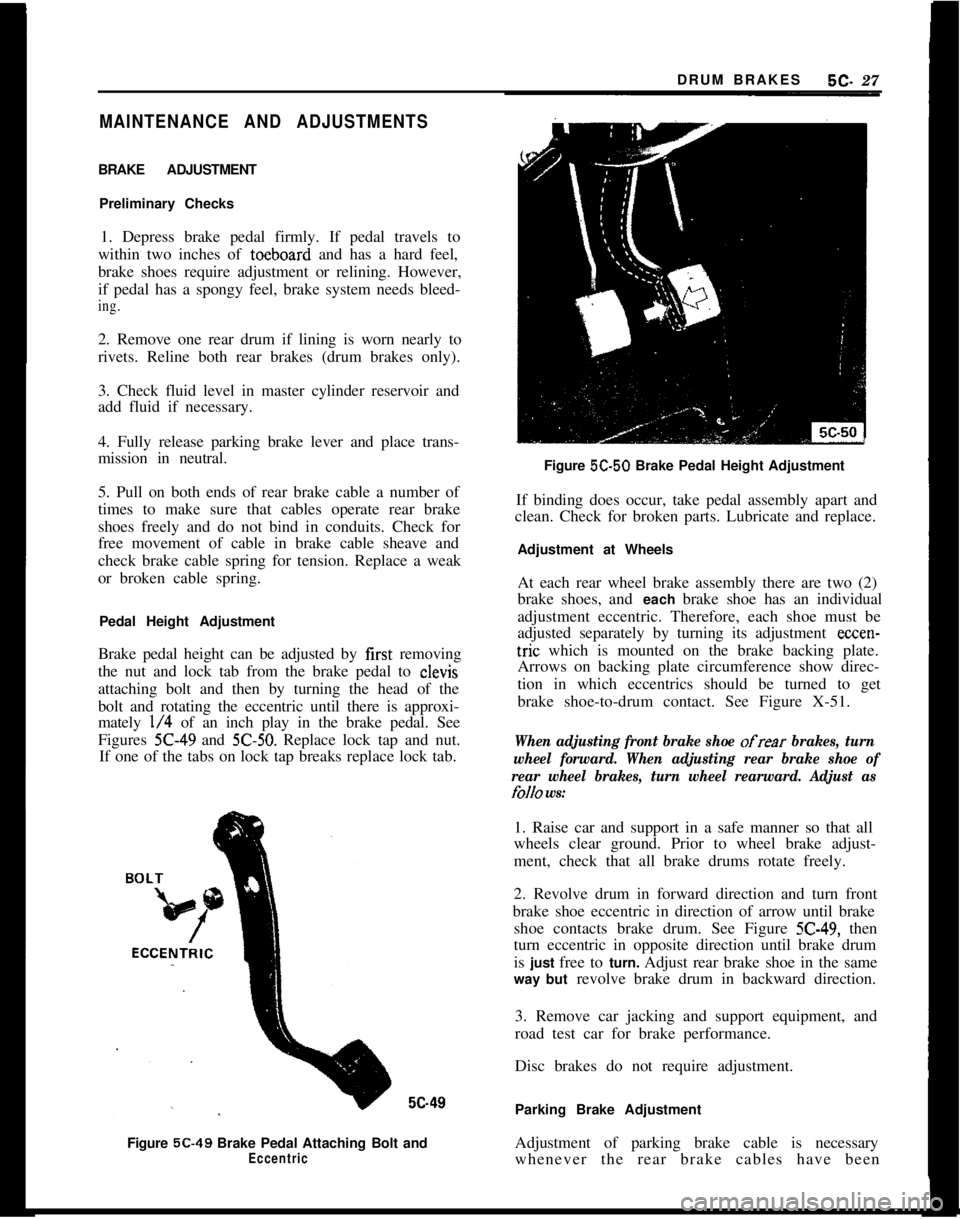

Pedal Height Adjustment

Brake pedal height can be adjusted by first removing

the nut and lock tab from the brake pedal to clevis

attaching bolt and then by turning the head of the

bolt and rotating the eccentric until there is approxi-

mately

l/4 of an inch play in the brake pedal. See

Figures

X-49 and 5C-50. Replace lock tap and nut.

If one of the tabs on lock tap breaks replace lock tab.5c49

Figure 5C-49 Brake Pedal Attaching Bolt and

EccentricFigure 5C-50 Brake Pedal Height Adjustment

If binding does occur, take pedal assembly apart and

clean. Check for broken parts. Lubricate and replace.

Adjustment at Wheels

At each rear wheel brake assembly there are two (2)

brake shoes, and each brake shoe has an individual

adjustment eccentric. Therefore, each shoe must be

adjusted separately by turning its adjustment

ccccn-tric which is mounted on the brake backing plate.

Arrows on backing plate circumference show direc-

tion in which eccentrics should be turned to get

brake shoe-to-drum contact. See Figure X-51.

When adjusting front brake shoe ofrear brakes, turn

wheel forward. When adjusting rear brake shoe of

rear wheel brakes, turn wheel rearward. Adjust as

folio ws:1. Raise car and support in a safe manner so that all

wheels clear ground. Prior to wheel brake adjust-

ment, check that all brake drums rotate freely.

2. Revolve drum in forward direction and turn front

brake shoe eccentric in direction of arrow until brake

shoe contacts brake drum. See Figure

5C-49, then

turn eccentric in opposite direction until brake drum

is just free to turn. Adjust rear brake shoe in the same

way but revolve brake drum in backward direction.

3. Remove car jacking and support equipment, and

road test car for brake performance.

Disc brakes do not require adjustment.

Parking Brake Adjustment

Adjustment of parking brake cable is necessary

whenever the rear brake cables have been

Page 293 of 625

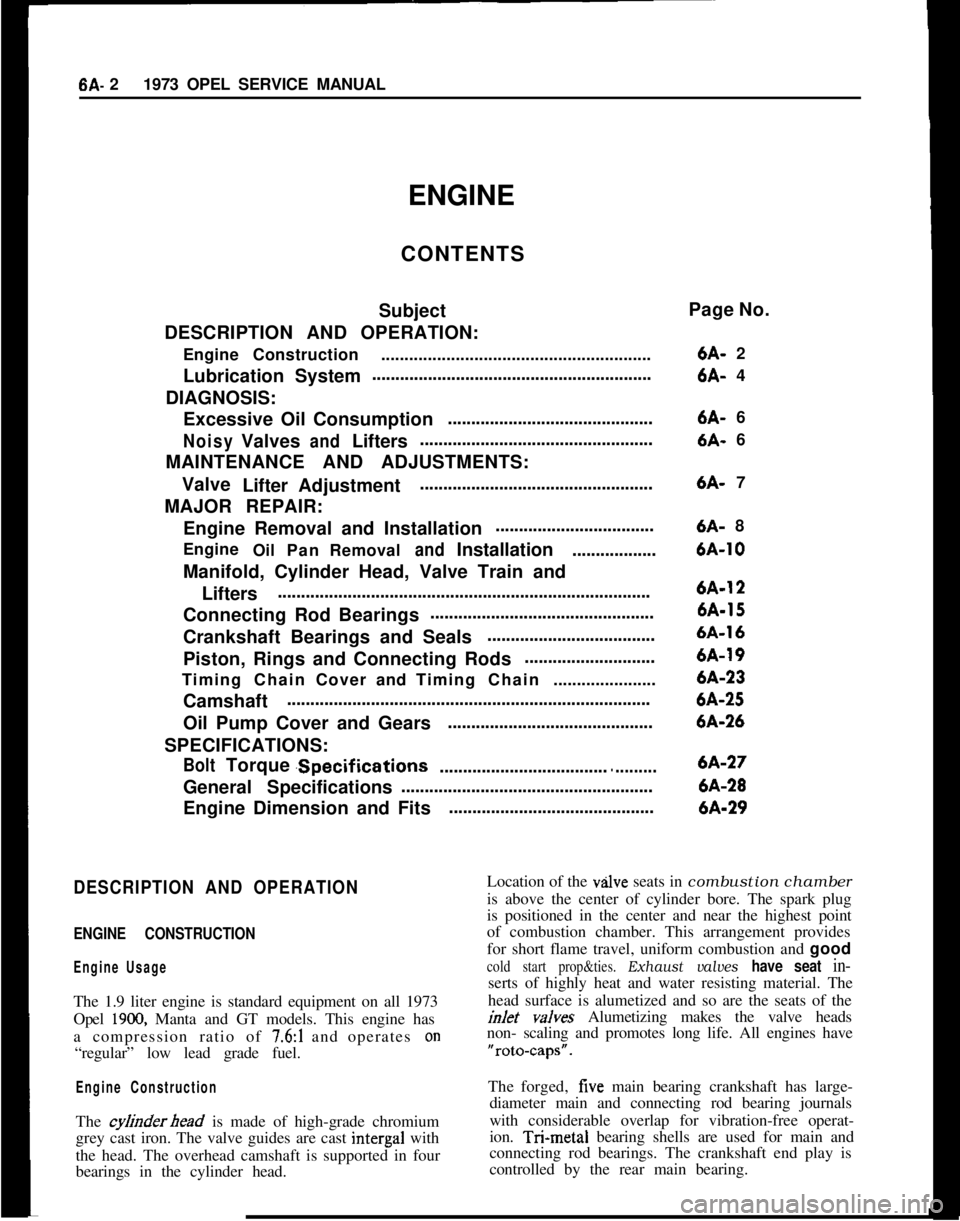

6A- 21973 OPEL SERVICE MANUAL

ENGINE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

EngineConstruction..........................................................

LubricationSystem............................................................

DIAGNOSIS:

Excessive Oil Consumption............................................NoisyValvesandLifters..................................................

MAINTENANCE AND ADJUSTMENTS:

Valve

LifterAdjustment..................................................

MAJOR REPAIR:

Engine Removal and Installation..................................

Engine

OilPanRemoval

andInstallation..................

Manifold, Cylinder Head, Valve Train and

Lifters................................................................................

Connecting Rod Bearings................................................

Crankshaft Bearings and Seals....................................

Piston, Rings and Connecting Rods............................

TimingChainCoverandTimingChain......................

Camshaft..............................................................................

Oil Pump Cover and Gears............................................

SPECIFICATIONS:

BoltTorque.Specifications

..............................................General Specifications......................................................

Engine Dimension and Fits............................................Page No.

6A- 2

6A- 4

6A- 6

6A- 6

6A- 7

6A- 86A-106A-126A-156A-166A-196A-236A-256A-266A-276A-286A-29

DESCRIPTION AND OPERATION

ENGINE CONSTRUCTION

Engine UsageThe 1.9 liter engine is standard equipment on all 1973

Opel

1900, Manta and GT models. This engine has

a compression ratio of

7.6:1 and operates on“regular” low lead grade fuel.

Engine ConstructionThe

cyfinderhead is made of high-grade chromium

grey cast iron. The valve guides are cast intergal with

the head. The overhead camshaft is supported in four

bearings in the cylinder head.Location of the

vzllve seats in combustion chamber

is above the center of cylinder bore. The spark plug

is positioned in the center and near the highest point

of combustion chamber. This arrangement provides

for short flame travel, uniform combustion and good

cold start prop&ties. Exhaust valves have seat in-serts of highly heat and water resisting material. The

head surface is alumetized and so are the seats of the

inlet v&es Alumetizing makes the valve heads

non- scaling and promotes long life. All engines have“rota-caps”.

The forged, five main bearing crankshaft has large-

diameter main and connecting rod bearing journals

with considerable overlap for vibration-free operat-

ion. T&metal bearing shells are used for main and

connecting rod bearings. The crankshaft end play is

controlled by the rear main bearing.

Page 298 of 625

ENGINE MECHANICAL AND MOUNTS6A- 7

Pour penetrating oil over the valve spring cap andengine off. It makes no difference whether the engine

allow it to drain down the valve stem. Apply pressureis cold or is at operating temperature. Set piston of

to the one side of the valve spring and then the other,the respective cylinder to upper top center on the

and then rotate the valve spring about l/2 turn. Iffiring stroke. This can be accomplished by removing

these operations affect the valve noise, it may bethe distributor cap and observing the rotor. Check

assumed that valves should be reconditioned.position of the rotor and follow spark path for the

2.Worn or Scored Parts in the Valve Train Inspectrotor tip through the distributor cap, high tension

rocker arms, push rod ends for scoring. Check pushwire to spark plug. This determines which cylinder

rods for bends, valve lifters, and camshaft surfacesis at upper top center on the firing stroke. Adjust the

for scoring. Replace faulty parts.hydraulic lifters of the two valves for that cylinder at

this time. When they are adjusted, turn engine so

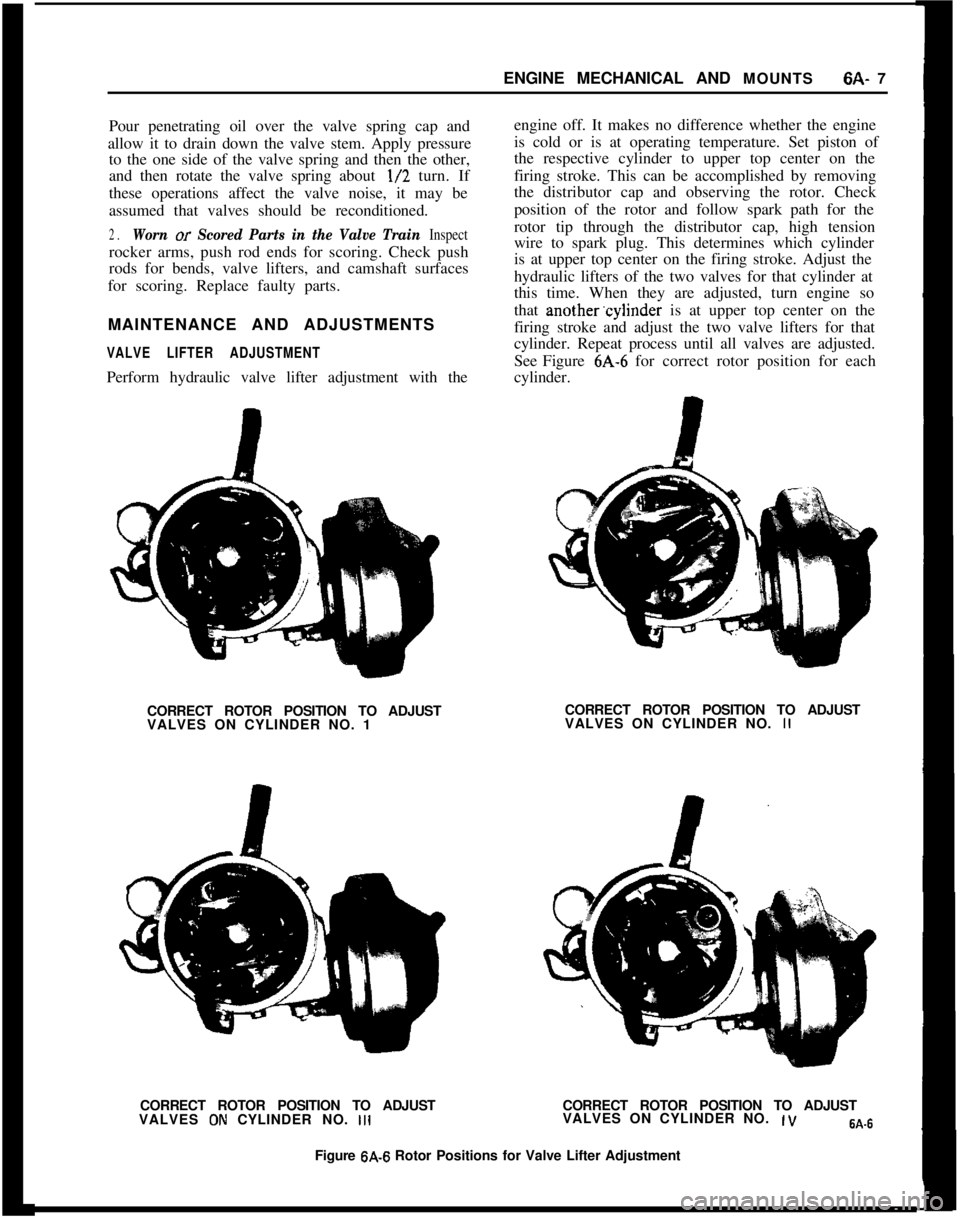

MAINTENANCE AND ADJUSTMENTSthat another.cylinder is at upper top center on the

firing stroke and adjust the two valve lifters for that

VALVE LIFTER ADJUSTMENTcylinder. Repeat process until all valves are adjusted.

See Figure 6A-6 for correct rotor position for each

Perform hydraulic valve lifter adjustment with thecylinder.

CORRECT ROTOR POSITION TO ADJUSTCORRECT ROTOR POSITION TO ADJUST

VALVES ON CYLINDER NO. 1VALVES ON CYLINDER NO. II

CORRECT ROTOR POSITION TO ADJUSTCORRECT ROTOR POSITION TO ADJUST

VALVES

ON CYLINDER NO. IllVALVES ON CYLINDER NO. ,VW-6Figure

6A-6 Rotor Positions for Valve Lifter Adjustment

Page 306 of 625

ENGINE MECHANICAL AND MOUNTS6A- 15New inlet valves must not be refaced or lapped with

grinding compound.The correct angle for the intake

and exhaust valve head is 44 degrees.10. Install cylinder head.

11. Adjust valve clearance. See MAINTENANCE

AND ADJUSTMENTS.

7. Inspect valve guides. Worn or pitted guides can be

reamed to accept valves with oversize stems. Over-

size valves are occasionally used in production.

Oversize valves are marked

’ 1 u “2” or “A” and are

stamped into the valve stem end and also stamped

near spark plug hole. See Figure 6A-22.

Replacing Rocker Arm Studs1. When replacing rocker arm studs become

neces-

sary, remove air cleaner, rocker arm cover and

rocker arm.

8. Reseat valve seats in cylinder head in the following

sequence:

Intake

NOTE:The rocker arm studs are screwed into the

cylinder head. A tapered part of the stem serves to

a void stud loosening.With 45 degrees cutter, remove burnt structure until

a metallic bright seat is obtained. Lightly coat valve

head with red lead, insert it into guide and turn it

under light pressure several times back and forth.

Thereby a contact pattern is obtained and the seat

width can be measured. If valve does not seat per-

fectly all around, lightly recut valve seat to the estab-

lished seat width of

,049” - .059” with 30 degrees

correction cutter.

ExhaustThe directions for reconditioning intake valve seats

apply in principle also to exhaust valve seat recondi-

tioning with the exception that the valve seat width

should be

.063-,073 in. and different cutters are em-

ployed.

NOTE:

: OTse new valve seals whenever

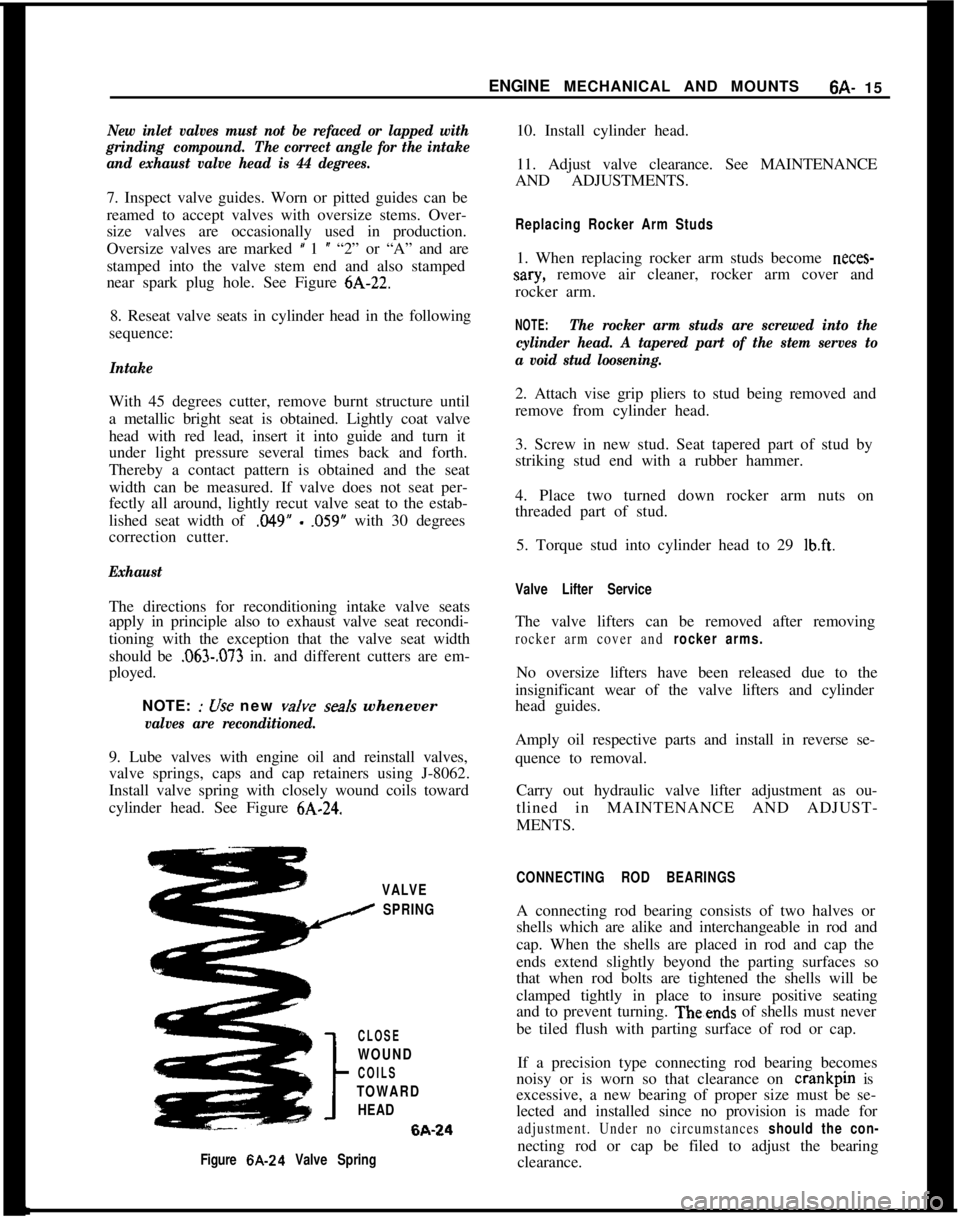

valves are reconditioned.9. Lube valves with engine oil and reinstall valves,

valve springs, caps and cap retainers using J-8062.

Install valve spring with closely wound coils toward

cylinder head. See Figure

6A-24.2. Attach vise grip pliers to stud being removed and

remove from cylinder head.

3. Screw in new stud. Seat tapered part of stud by

striking stud end with a rubber hammer.

4. Place two turned down rocker arm nuts on

threaded part of stud.

5. Torque stud into cylinder head to 29

lb.ft.

Valve Lifter ServiceThe valve lifters can be removed after removing

rocker arm cover and rocker arms.No oversize lifters have been released due to the

insignificant wear of the valve lifters and cylinder

head guides.

Amply oil respective parts and install in reverse se-

quence to removal.

Carry out hydraulic valve lifter adjustment as ou-

tlined in MAINTENANCE AND ADJUST-

MENTS.

VALVE

I SPRING

CLOSE

WOUND

COILS

TOWARD

HEAD6A-24

Figure 6A-24 Valve SpringCONNECTING ROD BEARINGSA connecting rod bearing consists of two halves or

shells which are alike and interchangeable in rod and

cap. When the shells are placed in rod and cap the

ends extend slightly beyond the parting surfaces so

that when rod bolts are tightened the shells will be

clamped tightly in place to insure positive seating

and to prevent turning. Theends of shells must never

be tiled flush with parting surface of rod or cap.

If a precision type connecting rod bearing becomes

noisy or is worn so that clearance on crankpin is

excessive, a new bearing of proper size must be se-

lected and installed since no provision is made for

adjustment. Under no circumstances should the con-necting rod or cap be filed to adjust the bearing

clearance.

Page 323 of 625

66.321973 OPEL SERVICE MANUAL

COOLING SYSTEM

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Cooling System and Water Pump

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Checking and Filling Cooling System

. . . . . . . . . . . . . . . . . . . . . . . .Draining

andFlushingCoolingSystem. . . . . . . . . . . . . . . . . . . . . .Conditioning the Cooling System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Using and Testing Anti-Freeze Solutions

. . . . . . . . . . . . . . . . . .Fan Belt Adjustment or Replacement

. . . . . . . . . . . . . . . . . . . . . . . .Radiator Thermostat Inspection and Test

. . . . . . . . . . . . . . . .MAJOR REPAIR:

Water Pump Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Radiator

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Cooling System Capacities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

68-32

6B-32

68-32

68-33

68-33

68-33

68-33

68-34

68-34

6B-35

DESCRIPTION AND OPERATION

COOLING SYSTEM AND WATER PUMPThe coiling system is of the conventional pressurized

type. A centrifugal pump arranged in timing case

serves to circulate the coolant.

When the thermostat is closed, the coolant will re-

turn to the pump via a by-pass for swift and uniform

warming up of the engine the coolant circulates

through the radiator, only when the engine has

reached normal operating temperature.

The heater system branches off the cooling system

ahead of thermostat in flow direction so that the

heater is in operation before engine has reached full

operating temperature.

MAINTENANCE AND ADJUSTMENTS

Checking and Filling Cooling SystemThe coolant level should be checked only when the

engine is cold and only enough coolant should be

added to bring the level halfway between core andtank top. It is unnecessary and undesirable to remove

the radiator cap and check the coolant level each

time the car stops at a filling station for gasoline or

oil, since the engine is usually hot at such times.

WARNING: Never remove the radiator cap quickly

when engine is HOT Sudden release of cooling

sys-

tern pressure may cause the coolant to boil and some

of it may be ejected from the radiator

filler neck,

resulting in

inl’ury to persons or damage to the car

finish.If it is necessary at any time to remove the radiator

cap when engine is hot, rotate the cap counterclock-

wise until first stop is reached. Leave cap in this

position until all pressure in cooling system has been

released, then turn cap past the first stop and remove

it.

Draining and Flushing

Cooling SystemThe cooling system should be completely drained

and the recommended coolant installed every two (2)

years.To drain the cooling system, remove radiator cap,

remove lower radiator hose from the lower tank and

Page 327 of 625

6C- 361973 OPEL SERVICE MANUAL

FUEL SYSTEM

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Fuel Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .Evaporation Control System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

(Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Cleaning Fuel Pump Strainer.,....................................

*.Evaporation Control System

. . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Fuel Tank

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fuel Lines and Fuel Tank Gauge Units

. . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Fuel System Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.6C-366C-376C-376C-386C-396C-416C-41

DESCRIPTION AND OPERATION

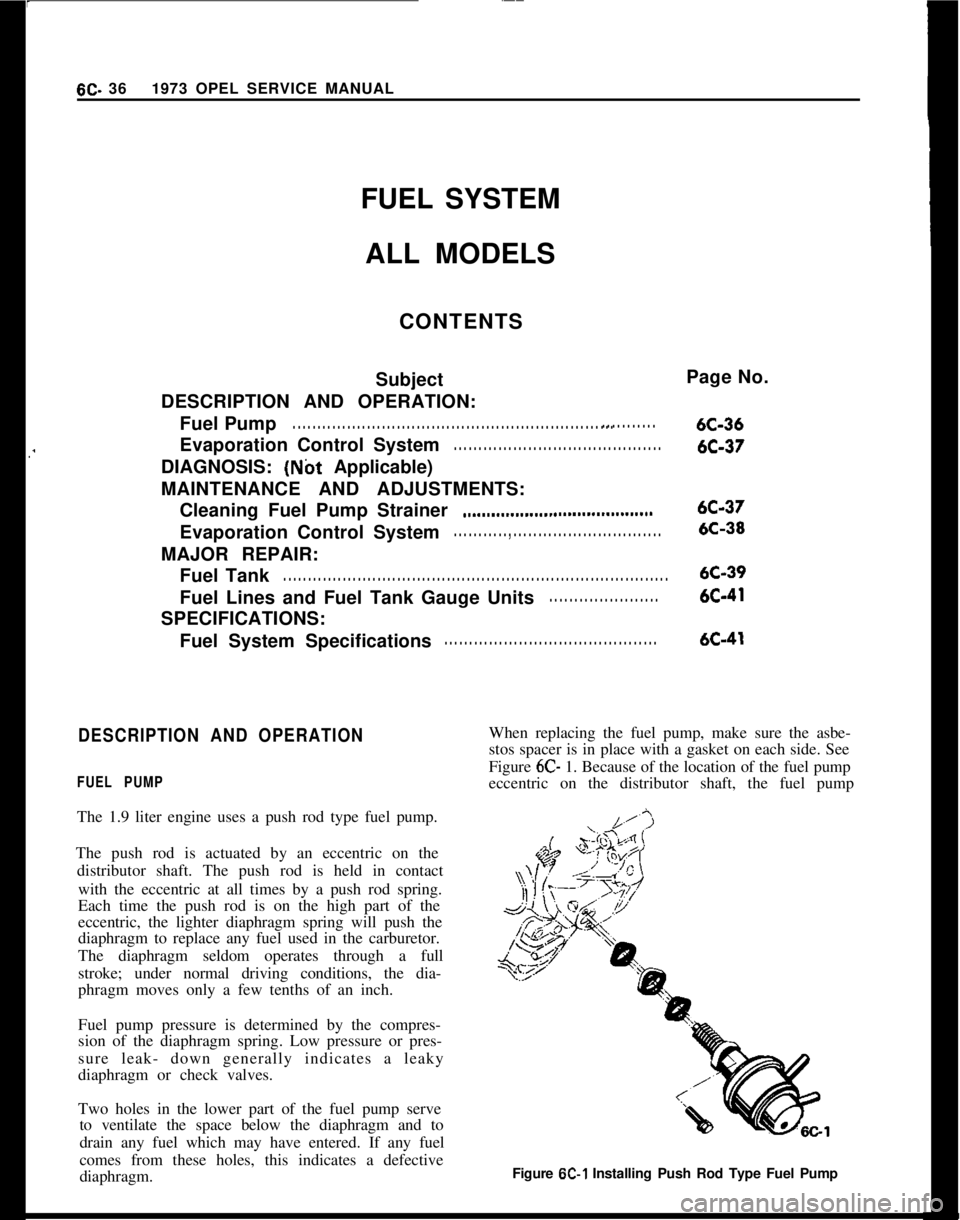

FUEL PUMPThe 1.9 liter engine uses a push rod type fuel pump.

The push rod is actuated by an eccentric on the

distributor shaft. The push rod is held in contact

with the eccentric at all times by a push rod spring.

Each time the push rod is on the high part of the

eccentric, the lighter diaphragm spring will push the

diaphragm to replace any fuel used in the carburetor.

The diaphragm seldom operates through a full

stroke; under normal driving conditions, the dia-

phragm moves only a few tenths of an inch.

Fuel pump pressure is determined by the compres-

sion of the diaphragm spring. Low pressure or pres-

sure leak- down generally indicates a leaky

diaphragm or check valves.

Two holes in the lower part of the fuel pump serve

to ventilate the space below the diaphragm and to

drain any fuel which may have entered. If any fuel

comes from these holes, this indicates a defective

diaphragm.When replacing the fuel pump, make sure the asbe-

stos spacer is in place with a gasket on each side. See

Figure 6C- 1. Because of the location of the fuel pump

eccentric on the distributor shaft, the fuel pump

Figure

6C-1 Installing Push Rod Type Fuel Pump

Page 328 of 625

FUEL SYSTEMSC- 37

must always be removed before the distributor can be

removed.

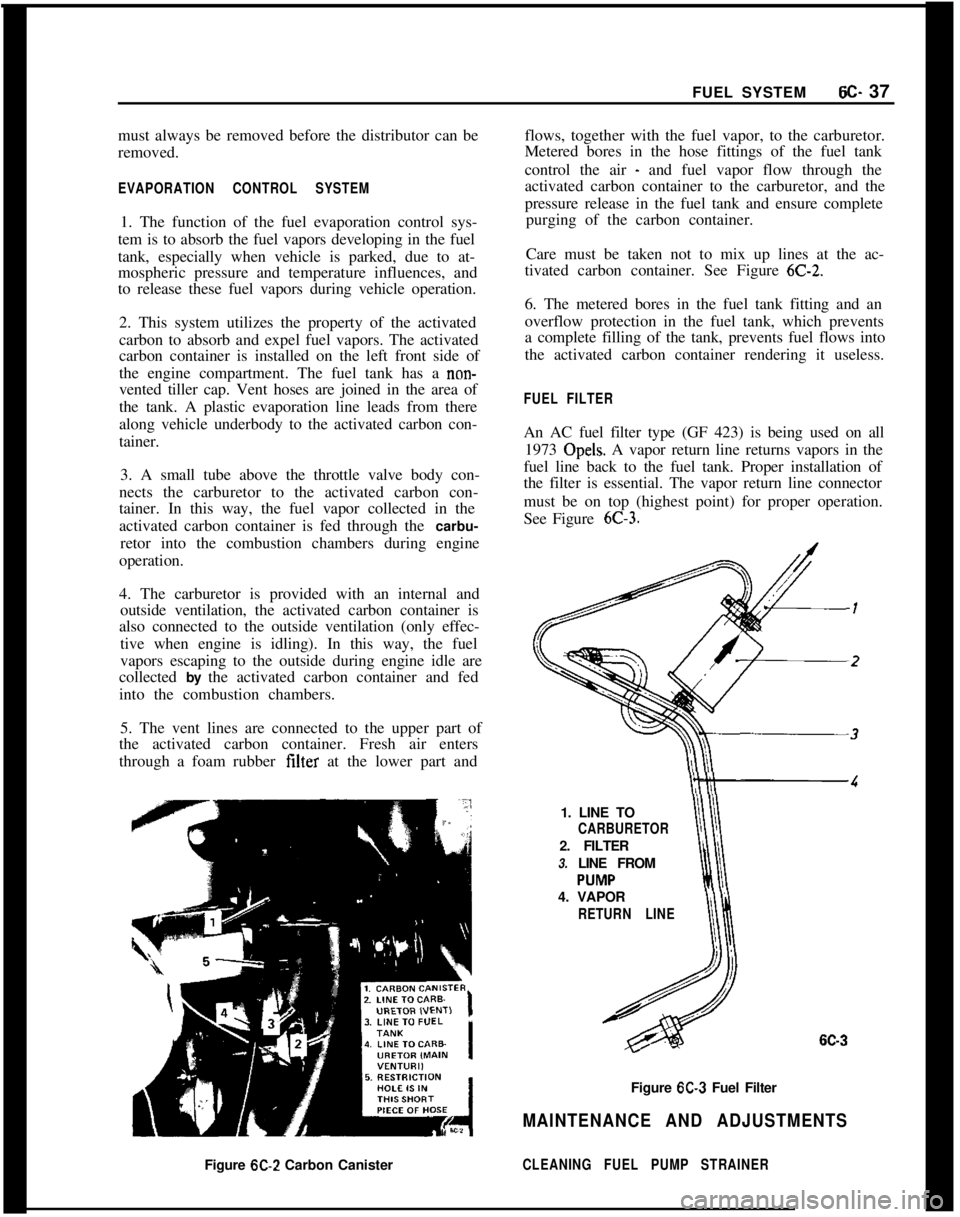

EVAPORATION CONTROL SYSTEM1. The function of the fuel evaporation control sys-

tem is to absorb the fuel vapors developing in the fuel

tank, especially when vehicle is parked, due to at-

mospheric pressure and temperature influences, and

to release these fuel vapors during vehicle operation.

2. This system utilizes the property of the activated

carbon to absorb and expel fuel vapors. The activated

carbon container is installed on the left front side of

the engine compartment. The fuel tank has a

non-vented tiller cap. Vent hoses are joined in the area of

the tank. A plastic evaporation line leads from there

along vehicle underbody to the activated carbon con-

tainer.

3. A small tube above the throttle valve body con-

nects the carburetor to the activated carbon con-

tainer. In this way, the fuel vapor collected in the

activated carbon container is fed through the carbu-

retor into the combustion chambers during engine

operation.

4. The carburetor is provided with an internal and

outside ventilation, the activated carbon container is

also connected to the outside ventilation (only effec-

tive when engine is idling). In this way, the fuel

vapors escaping to the outside during engine idle are

collected by the activated carbon container and fed

into the combustion chambers.

5. The vent lines are connected to the upper part of

the activated carbon container. Fresh air enters

through a foam rubber filter at the lower part andflows, together with the fuel vapor, to the carburetor.

Metered bores in the hose fittings of the fuel tank

control the air

- and fuel vapor flow through the

activated carbon container to the carburetor, and the

pressure release in the fuel tank and ensure complete

purging of the carbon container.

Care must be taken not to mix up lines at the ac-

tivated carbon container. See Figure

6C-2.6. The metered bores in the fuel tank fitting and an

overflow protection in the fuel tank, which prevents

a complete filling of the tank, prevents fuel flows into

the activated carbon container rendering it useless.

FUEL FILTERAn AC fuel filter type (GF 423) is being used on all

1973 Opels. A vapor return line returns vapors in the

fuel line back to the fuel tank. Proper installation of

the filter is essential. The vapor return line connector

must be on top (highest point) for proper operation.

See Figure

6C-3.1. LINE TO

CARBURETOR2. FILTER

3. LINE FROM

4. VAPOR

RETURN LINE

6C-3Figure

6C-3 Fuel Filter

MAINTENANCE AND ADJUSTMENTSFigure

6C-2 Carbon CanisterCLEANING FUEL PUMP STRAINER

Page 329 of 625

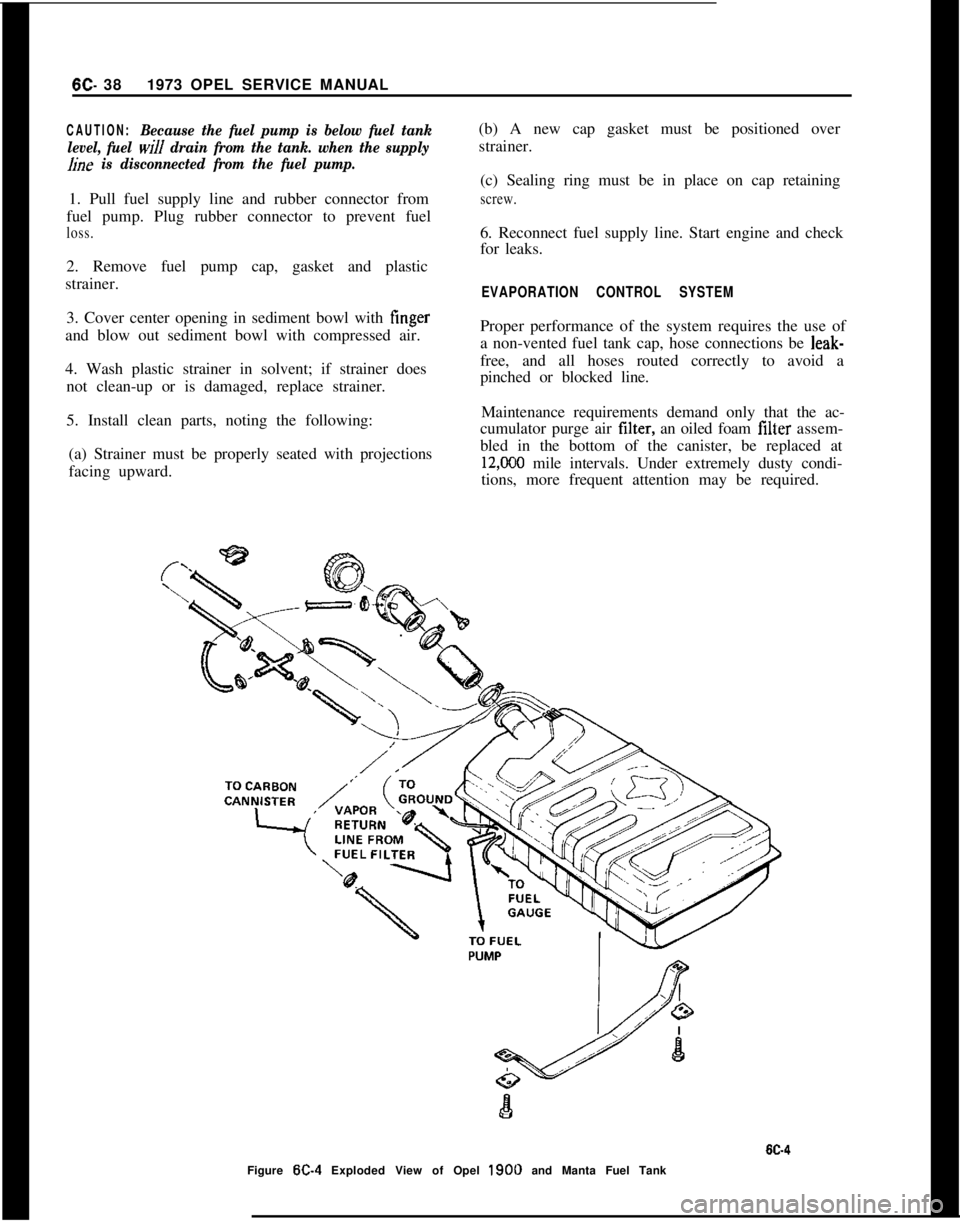

6C- 381973 OPEL SERVICE MANUALCAUTION:Because the fuel pump is below fuel tank

level, fuel

will drain from the tank. when the supply

hne is disconnected from the fuel pump.1. Pull fuel supply line and rubber connector from

fuel pump. Plug rubber connector to prevent fuel

loss.2. Remove fuel pump cap, gasket and plastic

strainer.

3. Cover center opening in sediment bowl with finger

and blow out sediment bowl with compressed air.

4. Wash plastic strainer in solvent; if strainer does

not clean-up or is damaged, replace strainer.

5. Install clean parts, noting the following:

(a) Strainer must be properly seated with projections

facing upward.(b) A new cap gasket must be positioned over

strainer.

(c) Sealing ring must be in place on cap retaining

screw.6. Reconnect fuel supply line. Start engine and check

for leaks.

EVAPORATION CONTROL SYSTEMProper performance of the system requires the use of

a non-vented fuel tank cap, hose connections be leak-

free, and all hoses routed correctly to avoid a

pinched or blocked line.

Maintenance requirements demand only that the ac-

cumulator purge air tilter, an oiled foam filter assem-

bled in the bottom of the canister, be replaced at

12,CKO mile intervals. Under extremely dusty condi-

tions, more frequent attention may be required.

Figure

W-4 Exploded View of Opel 1900 and Manta Fuel Tank

Page 333 of 625

6D. 421973 OPEL SERVICE MANUAL

EXHAUST SYSTEMS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION: (Not Applicable)

DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Page No.

Exhaust System (All Models). . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICA’TIONS:

Torque Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . .

6D-42

6D-42

MAJOR REPAIR

EXHAUST SYSTEM (ALL MODELS)

Removal1. Remove exhaust pipe from exhaust manifold.

2. Loosen front exhaust pipe to mufller clamp and

pull exhaust pipe out of muffler.

3. Remove muffler damper rings.

4. Remove center exhaust pipe clamp. Remove rearmut&r and tail pipe(s) as an assembly. See Figure

6D-1.5. Remove front exhaust pipe clamp, and remove

front muffler and center exhaust pipe as an assembly,then remove center exhaust pipe from front mufler.

The front mufIler and center exhaust pipe are one

piece on production-built cars but are separate itemsfor service, the tail pipe of the Rallye and GT, has

a dual pipe with one resonator.

InstallationCheck rubber damper rings for muffler and tail pipe

hanger and replace as necessary.

1. Coat I.D. of rear muffler inlet neck and O.D. of

center exhaust pipe outlet (rear of pipe) with exhaust

sealer compound (several brands are currently avail-able on the market).2. Insert center exhaust pipe into rear mufIler and

tighten clamp.

3. Coat I.D. of front muffler outlet neck and O.D. of

center exhaust pipe inlet (front of pipe) with exhaust

sealer compound.4. Insert center exhaust pipe into front mufiler and

tighten clamp.

5. Install muffler and tail pipe assembly on rubber

damper rings and tighten hangers. See Figures

6D-1and

6D-2.6. Install front exhaust pipe into muffler. Do not

tighten clamp.

7. Be sure to install gasket between exhaust manifoldand exhaust pipe. Using bolts with washers, attach

the exhaust pipe to the exhaust manifold. Torque to

15 lb.ft.8. Align exhaust system and tighten all clamps.

9. Check alignment of exhaust system; make sure

that the exhaust system components have at least

3/4” clearance from the floor pan to avoid possible

overheating of the floor pan.

SPECIFICATIONS

TORQUE SPECIFICATIONSExhaust Pipe to Exhaust Manifold

- 15 lb.ft.