charging OPEL GT-R 1973 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 558 of 625

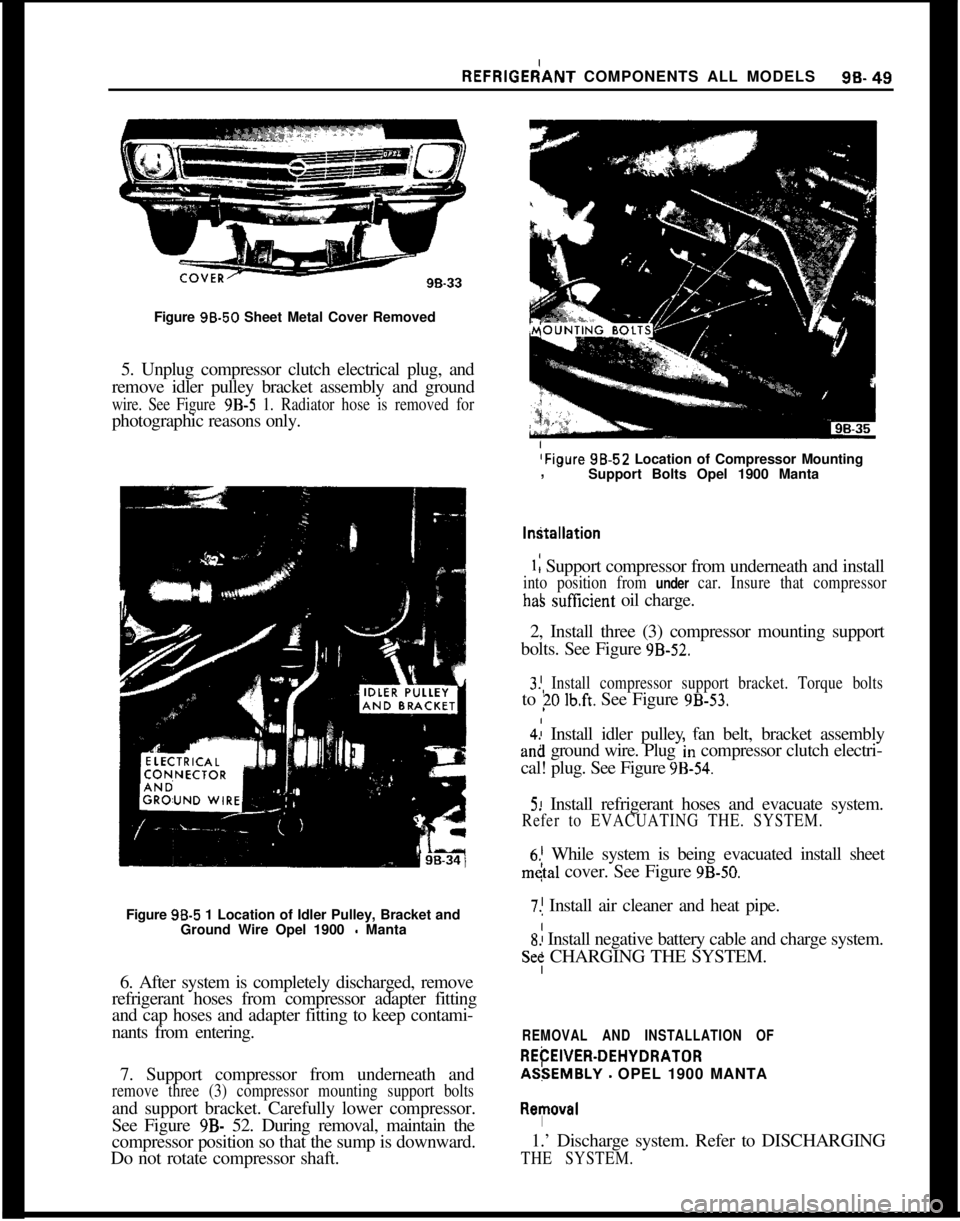

REFRlGEdANT COMPONENTS ALL MODELS96-49Figure 96.50 Sheet Metal Cover Removed

5. Unplug compressor clutch electrical plug, and

remove idler pulley bracket assembly and ground

wire. See Figure 9B-5 1. Radiator hose is removed forphotographic reasons only.

(Figure 98.52 Location of Compressor Mounting

,

Support Bolts Opel 1900 Manta

I

Figure 98-5 1 Location of Idler Pulley, Bracket and

Ground Wire Opel 1900

- Manta

6. After system is completely discharged, remove

refrigerant hoses from compressor adapter fitting

and cap hoses and adapter fitting to keep contami-

nants from entering.

7. Support compressor from underneath and

remove three (3) compressor mounting support boltsand support bracket. Carefully lower compressor.

See Figure

9B- 52. During removal, maintain the

compressor position so that the sump is downward.

Do not rotate compressor shaft.

1: Support compressor from underneath and install

into position from under car. Insure that compressor

haS sutXcient oil charge.

2, Install three (3) compressor mounting support

bolts. See Figure

9B-52.I

3! Install compressor support bracket. Torque boltsto

?O lb.ft. See Figure 9B-53.

4.: Install idler pulley fan belt, bracket assemblyan8 ground wire. Plug

‘In compressor clutch electri-

cal! plug. See Figure

9B-54.

5! Install refrigerant hoses and evacuate system.

Refer to EVACUATING THE. SYSTEM.

6.’ While system is being evacuated install sheet

m&l cover. See Figure 9B-50.

7.1 Install air cleaner and heat pipe.

S! Install negative battery cable and charge system.

Se: CHARGING THE SYSTEM.

REMOVAL AND INSTALLATION OF

REtiEWEFt-DEHYDRATORAS:EMBLY

- OPEL 1900 MANTA

I

R~l!lOV~lI1.’ Discharge system. Refer to DISCHARGING

THE SYSTEM.

Page 560 of 625

REFRIGERANT COMPONENTS ALL MODELSSB- 51

3. Remove two (2) screws securing receiver-dehy-

drator within support bracket and lift out receiver-

dehydrator.

InstallationIf the receiver-dehydrator has been exposed to the

atmosphere for any amount of time, (more than five

(5) minutes), the receiver-dehydrator should be re-

placed, since the life of the dessicant is probably

expended.

1. Install receiver-dehydrator. Using new o-rings

during installation. Lubricate o-rings prior to instal-

lation using No. 525 viscosity oil.

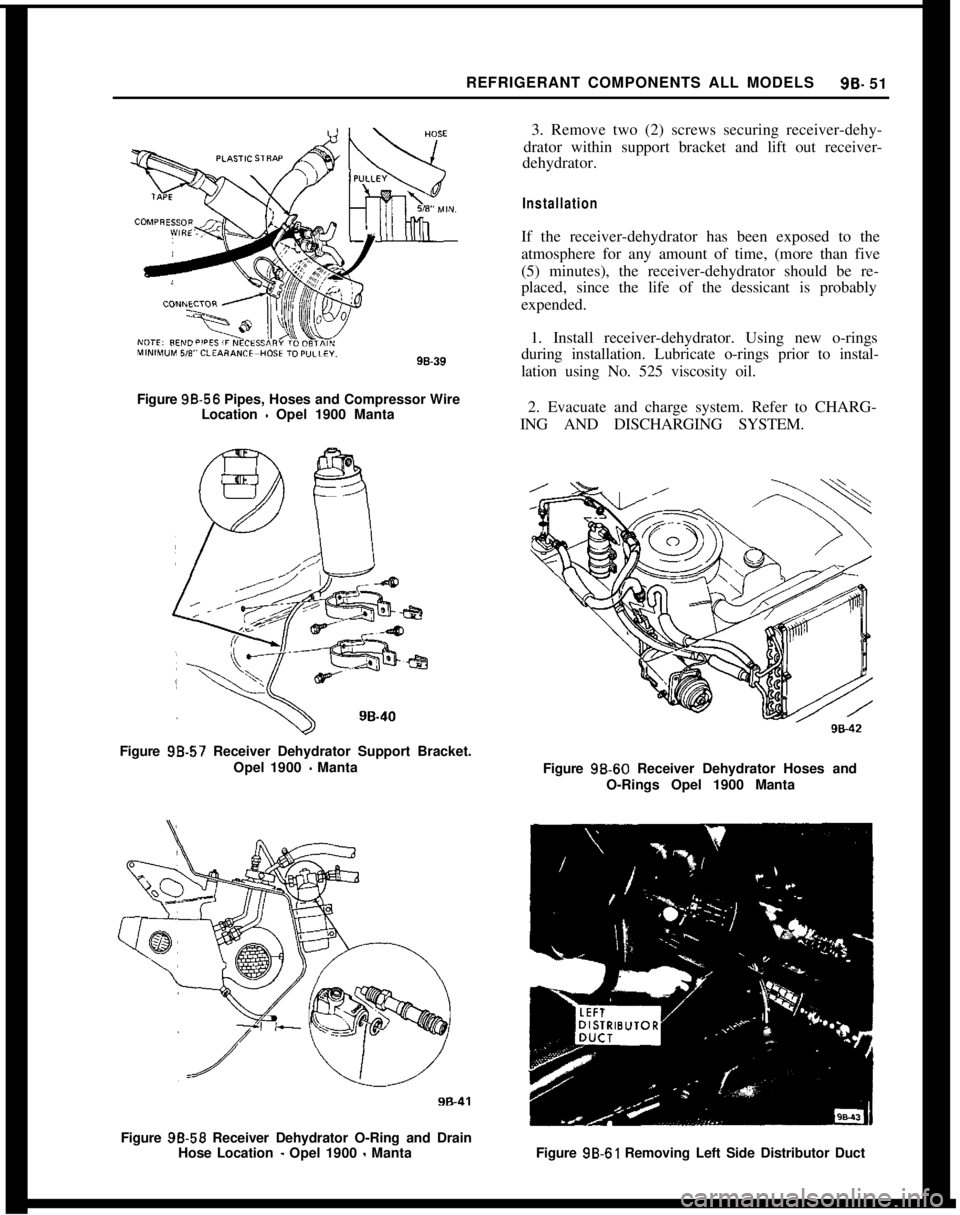

Figure 98.56 Pipes, Hoses and Compressor Wire

Location

- Opel 1900 Manta2. Evacuate and charge system. Refer to CHARG-

ING AND DISCHARGING SYSTEM.

Figure 98.57 Receiver Dehydrator Support Bracket.

Opel 1900

- Manta

Figure 98-59 Receiver Dehydrator O-Ring and Drain

Hose Location

- Opel 1900 - MantaFigure 9B-60 Receiver Dehydrator Hoses and

O-Rings Opel 1900 Manta

Figure 9B-61 Removing Left Side Distributor Duct

Page 561 of 625

96-52 1973 OPEL SERVICE MANUAL

REMOVAL AND INSTALLATION OF EVAPORATOR

AND EXPANSION VALVE. OPEL 1900 - MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove left side of distributor duct, and in line

fuse. See Figure

9B-61.3. Remove glove box. See Figure

9B-62.Figure 96-64 Delay Restrictor

and Check Valve Hose

Assembly Location

5. Disconnect the delay restrictor and check valve

hose assembly from the vacuum cut-off switch and

disconnect the electrical wiring. See Figures 9B-63

and 64.

6. Remove evaporator inlet and outlet pipes re-

tainer and rubber grommet. See Figure

9B-65.Figure

98.62 Glove Box Removed

4. Discharge refrigerant from system. (Refer to

DISCHARGING SYSTEM) and disconnect refrig-

erant hose from evaporator outlet and pipe from

evaporator inlet and tape the open ends of the refrig-

erant lines and evaporator pipes. See Figure

9B-63.Figure

98.65 Inlet and Outlet Pipes retainer and

Rubber Grommet-Opel 1900 - Manta

Figure

98.63 Location of Refrigerant Hoses, Pipes,

Vacuum Cut Off Switch and Evaporator Attaching Bolt

(Left Side) - Opel 1900

- Manta

Page 563 of 625

96-54 1973 OPEL SERVICE MANUAL

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw into old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws. See Figure 9B-70.3. Install blower motor assembly into case and se-

cure with attaching screws. See Figure

9B-69.4. Install finger guard shields and fan housing case.

See Figure

9B-69.5. Install resistor assembly and electrical connector.

Install blower motor connector. See Figure

9B-69.6. Install assembly into car carefully guiding

evaporator pipes up through cowl opening. See Fig-

ure

9B-71.Figure 93-7 1 Inlet and Outlet Pipes and O-Rings

-Opel 1900 Manta

7. Install two (2) upper attaching evaporator at-

taching nuts. See Figures 9B-66 and

9B-67.8. Install two (2) attaching case mounting bracket

to instrument panel screws. See Figure

9B-67.9. Connect two (2) drain hoses underneath evapora-

tor.10. Install evaporator inlet and outlet pipes retainer

and rubber grommet. See Figure

9B-65.11. Connect vacuum cut-off switch and electrical

wiring, making sure the delay restrictor and checkvalve hoses are installed correctly. See Figures

9B-63and 64.

.gB-72 Delay Restrictor and Check Valve Hose.Assembly

12. Install refrigerant hoses and pipes using new

o-rings on line fittings and evacuate system. Refer to

EVACUATING SYSTEM.

13. While system is being evacuated, install in-line

fuse and left side of distributor duct. See Figure 9B-

61.14. Install glove box.

15. Install negative battery cable and charge system.

Refer to CHARGING SYSTEM.

REMOVAL AND INSTALLATION OF CONDENSER

ASSEMBLY -OPEL 1900. MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove air cleaner.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

4. While system is discharging, remove lower radia-

tor hose from radiator and drain coolant into a suita-

ble container.

5. Remove fan shroud.

6. On vehicles with automatic transmission, un-

screw oil lines from connectors on lower radiator

tank and plug lines. It is essential that no dirt enters

the oil lines. When unscrewing oil lines, hold connec-

tors on lower radiator tank with pliers to avoid leak-

ages. Ensure that no dirt enters oil cooler.

7. Remove upper radiator hose from radiator.

8. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

9. Remove inlet and outlet hoses from condenser

Page 565 of 625

98-56 1973 OPEL SERVICE MANUAL

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 11-15 Ibs. ft.

7. Install fan shroud.

8. Install upper radiator hose.

9. Install lower radiator hose and add collected coo-

lant.

All Opel

1900’s and Manta’s are provided with a

radiator initial fill of an anti-freeze solution contain-

ing corrosion inhibitor. The anti-freeze has either a

glycol or glycerin base and protects the engine

against freezing, down to minus 22 degrees F. (minus

30 degrees C.). Before the start of the cold season,

coolant must be checked with a hydrometer and if

necessary, brought to the necessary specific gravity

by adding anti-freeze. Anti-freeze added, must have

a glycol or glycerin base. As the specific gravities of

all anti-freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.).

IO. Install negative battery cable and air cleaner.

11. Charge system. Refer to CHARGING SYS-

TEM.

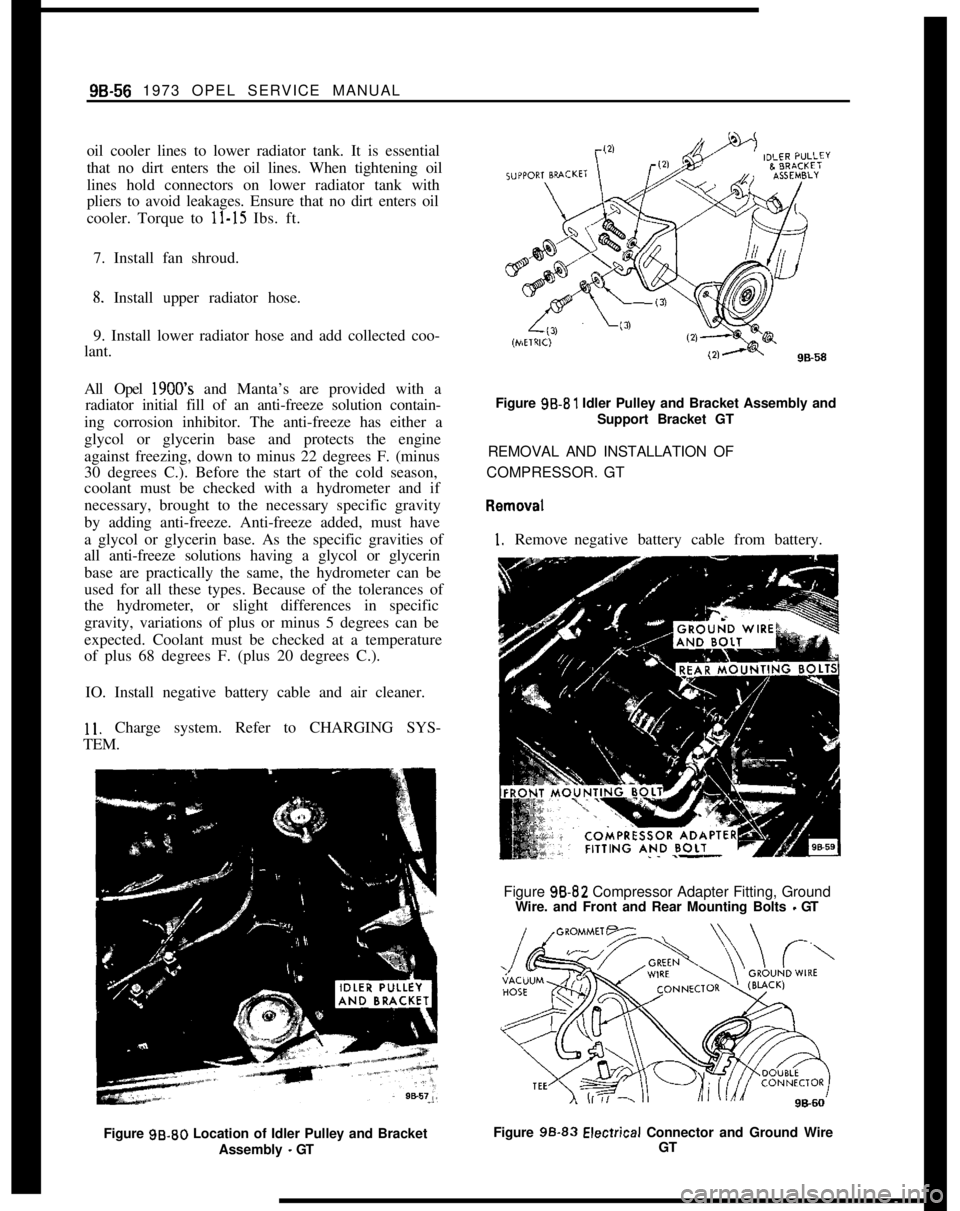

Figure 99.80 Location of Idler Pulley and Bracket

Assembly

- GTFigure 99.81 Idler Pulley and Bracket Assembly and

Support Bracket GT

REMOVAL AND INSTALLATION OF

COMPRESSOR. GT

I. Removenegative battery cable from battery.

Figure 98-82 Compressor Adapter Fitting, Ground

Wire. and Front and Rear Mounting Bolts

- GT

Figure 99.83

Elecirical Connector and Ground Wire

GT

Page 567 of 625

98-58 1973 OPEL SERVICE MANUAL

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While system is discharging remove air cleaner

and loosen idler pulley and bracket assembly. See

Figure 98-80.

4. Remove bolt holding compressor adapter fitting

into rear head. Disengage from compressor and tape

closed openings in both lines and ports in rear head.

It is important to seal compressor ports to avoid a

loss of refrigeration oil and also to prevent foreign

material and moisture from entering compressor. See

Figure 9B-82.

5. Remove bolt and ground wire, unplug electrical

connector, and remove 2 rear compressor mounting

bolts. See Figure 98-82.

6. Remove 2 front compressor mounting bolts,

clutch drive belt, and lift out compressor. During

removal, maintain the compressor position so that

the sump is downward. Do not’rotate compressor

shaft. See Figure 9B-84.

Installation1. Install compressor into mounting brackets and

secure with 4 mounting bolts. See Figure

9B-84.2. Untape lines and ports, and install compressor

adapter fitting and bolt using new o-rings. See Figure

9B-82.3. Evacuate system. Refer to, EVACUATING

SYSTEM.

4. While system is being evacuated, install drive belt

and tighten idler pulley. See Figure

9B-80.5. Install bolt and ground wire and plug in electrical

connector. See Figure

9B-83.6. Install air cleaner and negative battery cable.

7. Charge system. Refer to, CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF

RECEIVER.DEHYDRATOR

ASSEMBLY. GT

Removal1. Discharge system. Refer to DISCHARGING

SYSTEM.

2. Disconnect refrigerant lines to both ends of re-

ceiver-dehydrator and tape closed open ends of

re-

9862Figure 98.85 Refrigeration Hose Clamps Installation

GT

frigerant lines, and also the open

e:nds of the inlet and

outlet pipes of the receiver-dehydrator. See Figure

9B-86.Figure 98.86 Receiver-Dehydrator GT

3. Remove 2 screws securing receiver-dehydrator

and clamps to support bracket and lift out receiver

dehydrator. See Figure

9B-86.

Installation1. Install receiver-dehydrator using new o-rings

during installation. Lubricate o-rings prior to instal-

lation using No. 525 viscosity oil.

.

Page 568 of 625

REFRIGERANT COMPONENTS ALL MODELS9s. 59

2. If the receiver-dehydrator has been exposed to

the atmosphere for any amount of time, (more than

5 minutes), the receiver-dehydrator should be re-

placed, since the life of the dessicant is probably

expended.

3. Evacuate and charge system. Refer to CHARG-ING AND DISCHARGING SYSTEM.

REMOVAL AND INSTALLATION OF EVAPORATOR

AND EXPANSION VALVE. GTRemoval

1. Disconnect negative battery cable.

2. Discharge system. Refer to, DISCHARGING

SYSTEM.3. While system is discharging, remove attaching

screws and lift out luggage tray. See Figure

9B-87.Figure 98.88 Evaporator Cover Assembly and

Attaching Screws GT

Figure 98.87 Luggage Tray

4. Remove all evaporator cover screws and removecover. See Figure

9B-88.

5. Remove electrical plug connector from the resis-tor assembly and unplug blower motor connection

and remove ground wire. See Figure

9B-90.6. From underneath evaporator housing, discon-

nect two (2) drain hoses. See Figure

9B-91.

7. From under car remove 4 nuts securing

evapora-Figure 96.90 Electrical Connections, Ground Wire

GTtar mounting bracket to floor. See Figures

9B- 92

and

9B-93.8. Remove inlet and outlet pipes from evaporator

and tape closed the refrigerant lines and also the

open ends of the inlet and outlet pipes of the evapora-tor. See Figure

9B-94.

Page 571 of 625

98-62 1973 OPEL SERVICE MANUAL

Figure 98.99 Refrigerant Hoses Retainer Grommet

-Under Car - GT

8. From under car install four (4) nuts securing

evaporator mounting bracket to floor. See Figures9B- 92 and

9B-93.Figure 98.100 Refrigerant Hoses

- Under Car GT

9. Evacuate system. Refer to EVACUATING SYS-

TEM.

10. While system is being evacuated, connect drain

hoses underneath evaporator housing.

11. Plug in the resistor assembly electrical connector

plug and connect the blower motor connection and

install ground wire and 2 mounting brackets to case

screws using the rearward holes. See Figure

9B-90.12. Install the evaporator cover and all cover screws.

See Figure

9B-88.13. Install luggage tray and attaching screws. See

Figure

9B-87.14. Connect the negative battery cable.

15. Charge system. Refer to CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF CONDENSERRECIWER- DEHYDRATOR ASSEMBLY

- GT

Removal

1. Disconnect negative battery cable.

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While the system is discharging, remove the

charcoal cannister, washer jar, battery and battery

tray. Battery needs only to be set up out of the way

and not removed from the car.

4. Disconnect inlet and outlet pipes of condenser

receiver-dehydrator and tape closed the open ends of

refrigerant lines, and also the open ends of the inlet

and outlet pipes of the condenser. See Figure 9B-101.

5. Disconnect discharge line from condenser and

tape closed open ends of discharge pipe and con-

denser inlet.

6. Remove 4 condenser attaching screws and lift out

condenser. See Figure 9B-101.

7. Remove 2 screws retaining receiver-dehydrator

to condenser and remove.

Figure

9B-101 Receiver - Dehydrator. Condenser

Attaching Screws and Brackets

- GT

Installation

If refrigerant circuit or condenser has been exposed

to the atmosphere and moisture may be present in

the circuit, the system and/or component must be

flushed prior to installation. Refer to FLUSHING

THE SYSTEM.

1. Install receiver-dehydrator to condenser and fas-

ten with 2 clamps and 2 screws.

Page 572 of 625

REFRIGERANT COMPONENTS ALL MODELSSB-632. Install condenser into car and secure with 4 at-

taching screws. See Figure

9B-101.3. Untape discharge line and pipe and install using

new o-rings lubricated with No. 525 viscosity oil.

Figure

99.102 Condenser - Receiver - Dehydrator

O-Rings. GT

4. Untape and install inlet and outlet pipes into the

receiver-dehydrator using new o-rings lubricated

with No. 525 viscosity oil.

Figure

98-103 Condenser Assembly - GT

5. Evacuate system. Refer to EVACUATING SYS-

TEM.

6. While system is being evacuated, install the char-

coal cannistor, washer jar, battery tray and battery

and connect negative battery cable.

7. Charge system. Refer to CHARGING SYS-

TEM.

DISASSEMBLY AND REASSEMBLY OF CLUTCH

DRIVE PLATE AND SHAFT SEALIt is not necessary to remove the compressor or dis-connect refrigerant lines to remove or install clutch

parts on the GT, however, the compressor must be

removed from the Opel 1900

- Manta.

Disassembly

1. Firmly clamp holding fixture (J-9396) in a vise

and attach compressor assembly to fixture (see Figwe

9B-104).

-_ .s -Figure SE-104 Removing or Installing Shaft Nut

2. Hold hub of clutch drive plate with wrench

(J-9403). Using special thin wall 9/16 inch socket

(J-9399) and 3/g inch drive, remove shaft nut.

3. Install threaded hub puller (J-9401) onto hub of

clutch drive plate (see Figure

9B-105). Hold body of

hub puller with wrench, tighten center screw of hub

puller, and lift off clutch drive plate and woodruff

key.Figure SE-105 Removing Clutch Drive Plate

Page 591 of 625

r98-82 1973 OPEL SERVICE MANUAL

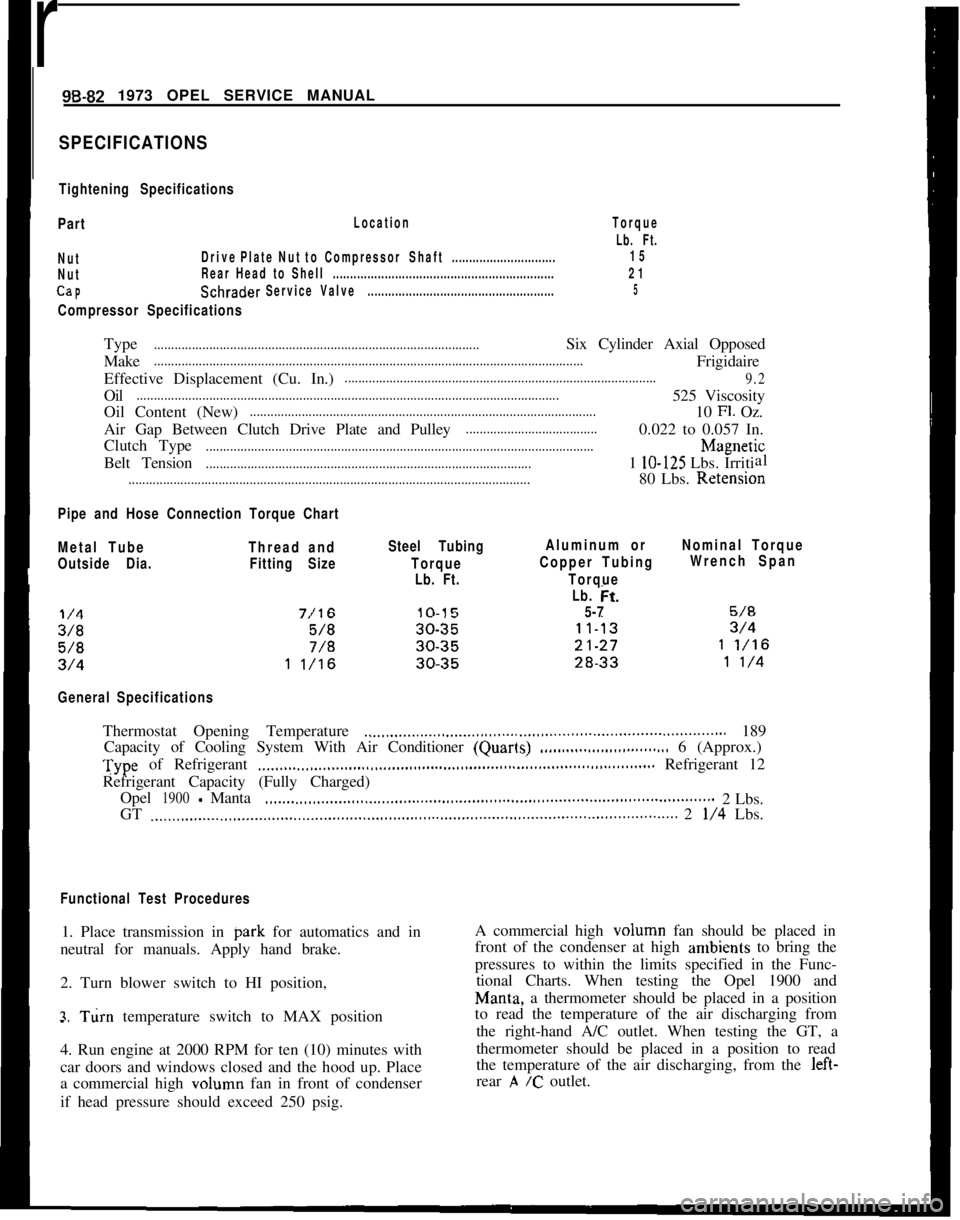

SPECIFICATIONS

Tightening Specifications

Part

Location

NutDrivePlateNut toCompressorShaft..............................

NutRear Head to Shell................................................................

CaPSchraderServiceValve......................................................

Compressor Specifications

Torque

Lb. Ft.

15

21

5Type

..............................................................................................Six Cylinder Axial Opposed

Make

............................................................................................................................Frigidaire

Effective Displacement (Cu. In.)

..........................................................................................

9.2Oil

..........................................................................................................................525 Viscosity

Oil Content (New)

....................................................................................................10 Fl. Oz.

Air Gap Between Clutch Drive Plate and Pulley

......................................0.022 to 0.057 In.

Clutch Type

................................................................................................................h4agnetic

Belt Tension

..............................................................................................1 lo-125 Lbs. Irritial

....................................................................................................................80 Lbs. Retension

Pipe and Hose Connection Torque Chart

Metal TubeThread andSteel TubingAluminum orNominal Torque

I

Outside Dia.Fitting SizeTorqueCopper TubingWrench Span

Lb. Ft.Torque

Lb. tit.

5-7

General SpecificationsThermostat Opening Temperature

.._.....,,,...__....,,.............................................................. 189

Capacity of Cooling System With Air Conditioner (Quarls)

.,,..___....___............... 6 (Approx.)Type of Refrigerant

.___,,,._...,.,,,.__.....,,,.......,,,,.......,,,...................,,,......,,,............ Refrigerant 12

Refrigerant Capacity (Fully Charged)

Opel

1900-Manta,,._....,,,,._...._.,,,,.......,,,........,,............................................................2 Lbs.

GT

,..__..,..,..__..,,,.......,,,,.......,,,........,,,.,......,,,,,......,,.,,........,,.......,,..........,,............... 2 l/4 Lbs.

Functional Test Procedures1. Place transmission in park for automatics and in

neutral for manuals. Apply hand brake.

2. Turn blower switch to HI position,

3. Turn temperature switch to MAX position-.

4. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a commercial high volumn fan in front of condenser

if head pressure should exceed 250 psig.A commercial high volumn fan should be placed in

front of the condenser at high ambients to bring the

pressures to within the limits specified in the Func-

tional Charts. When testing the Opel 1900 and

Man& a thermometer should be placed in a position

to read the temperature of the air discharging from

the right-hand A/C outlet. When testing the GT, a

thermometer should be placed in a position to read

the temperature of the air discharging, from the left-

rear

,A /c outlet.