OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 491 of 625

7C-130

1973 OPEL SERVICE MANUAL

Figure 7C-2 17

into case. See Figure 7C-218. Use liberal amount of

transmission fluid on oil seal rings.

GOVERNOR

HUBFigure

7C-2 183. Install snap ring over output shaft using snap ring

pliers such as J-8059. See Figure

7C-219.4. Install new governor body gasket.

5. Bolt governor body to governor hub. Torque to 6-8

lbs. ft. The two governor valves should move freely

after governor body is torqued.

6. Install speedometer drive gear retaining clip into

output shaft. See Figure

7C-220.Figure 7C-219

Figure 7C-220

7. While depressing retaining clip, slide speedometer

gear over output shaft and install gear and retaining

clip.

Installation of Extension Housing

1. Install new extension housing gasket.

2. Slide extension housing over output shaft and

align holes.

3. Align parking

paw1 shaft into extension housing.

Page 492 of 625

AUTOMATIC TRANSMISSION 7C-1314. Bolt extension housing to rear of case. Torque to

20-30 Ibs. ft. See Figure

7C-221.

Figure 7C-22

1

Installation of Speedometer Driven Gear1. Install speedometer driven gear and housing into

extension housing. See Figure

7C-222.Figure 7C-222

2. Install speedometer driven gear housing retainer

into slot provided in speedometer driven gear hous-

ing. Bolt retainer to extension housing. Torque to

6-Slbs. ft. See Figure

7C-223.

installation of Detent Valve, Modulator Valve,

Modulator Assembly1. inspect detent valve sleeve oil seal and replace if

necessary.Figure 7C-223

2. Install detent valve, sleeve, spring, and spring seat

into case bore using liberal amount of transmission

fluid.

3. Depress detent valve spring and insert spring pin

to secure detent valve assembly. Detent valve sleeve

must be installed with slots facing oil pan. Care

should be taken so that spring pin is inserted into the

groove provided in sleeve and not into one of the oil

passage slots in the sleeve.

4. Install modulator valve and sleeve into case with

small end of modulator valve first.

5. Using new modulator assembly gasket, install

plunger and thread modulator into case and tighten

to

12-15 Ibs. ft. using tool J-23100. See Figure 7C-

224.

Installation and Adjustment of ServoAdjustment of servo can be performed with trans-

mission in vehicle.

1. Install servo apply rod, spring and piston into case,

using liberal amount of transmission fluid.

2. Compress servo piston spring using compressor

tool J-23075, lightly tapping servo piston while com-

pressing until piston is seated to avoid damage to the

oil seal ring.

3. Install servo retaining ring. See Figure

7C-225.Remove compressor tool J-23075.

Page 493 of 625

7C-1321973 OPEL SERVICE MANUAL

Figure 7C-226

Figure 7C.224

Figure 7C-225

4. Using 3/16” hex head wrench on servo adjusting

bolt, adjust servo apply rod by tightening adjusting

bolt to 40 lbs. in. Back off bolt five (5) turns. exact/u.See Figure

7C-226.5. Tighten lock nut holding adjusting bolt and sleeve

firm with hex head wrench. See Figure

7C-227.

installation of Valve Body

1. I&all steel balls in oil passages in case. See Figure

7C-228.Figure 7C-227

2. Install new case to transfer plate gasket.

3. Locate guide pins in transmission case for correct

alignment of valve body and transfer plate. See Fig-

ure

7C-229.4. Install manual valve into valve body bore using

liberal amount of transmission fluid.

5. Install long side of manual valve link pin into

manual valve. See Figure

7C-230.

Page 494 of 625

AUTOMATIC TRANSMISSION 7C-1338/Figure 7C-228

Figure 7C-229

6. Install small end of manual valve link “A” into

selector lever and install valve body and transfer

plate assembly over guide pins. See Figure

7C-23 1.

7. Install selector lever roller spring and retainer.

Torque to

13-15 lbs. ft. The valve body bolts should

be torqued starting in the center of the valve body

and working outward. Torque to 13-15

lbs. Ft.

8. Install reinforcement plate to case. Torque to

13-15 lbs. ft.9. Inspect oil strainer. If foreign matter is present,

install new strainer.

-VALV; BODY

x-220

Figure 7C-230

Figure

7C-231

10. Install oil strainer assembly using new gasket.

Torque to 13-15 Ibs. ft.

11. Install new servo cover gasket.

12. Install servo cover. Torque to 17-19 lbs. ft.

Installation of Oil Pan and Gasket1. Install new oil pan gasket.

2. Bolt oil pan to transmission case. Torque to 7-9

lbs. ft.

Page 495 of 625

7C-1341973 OPEL SERVICE MANUAL

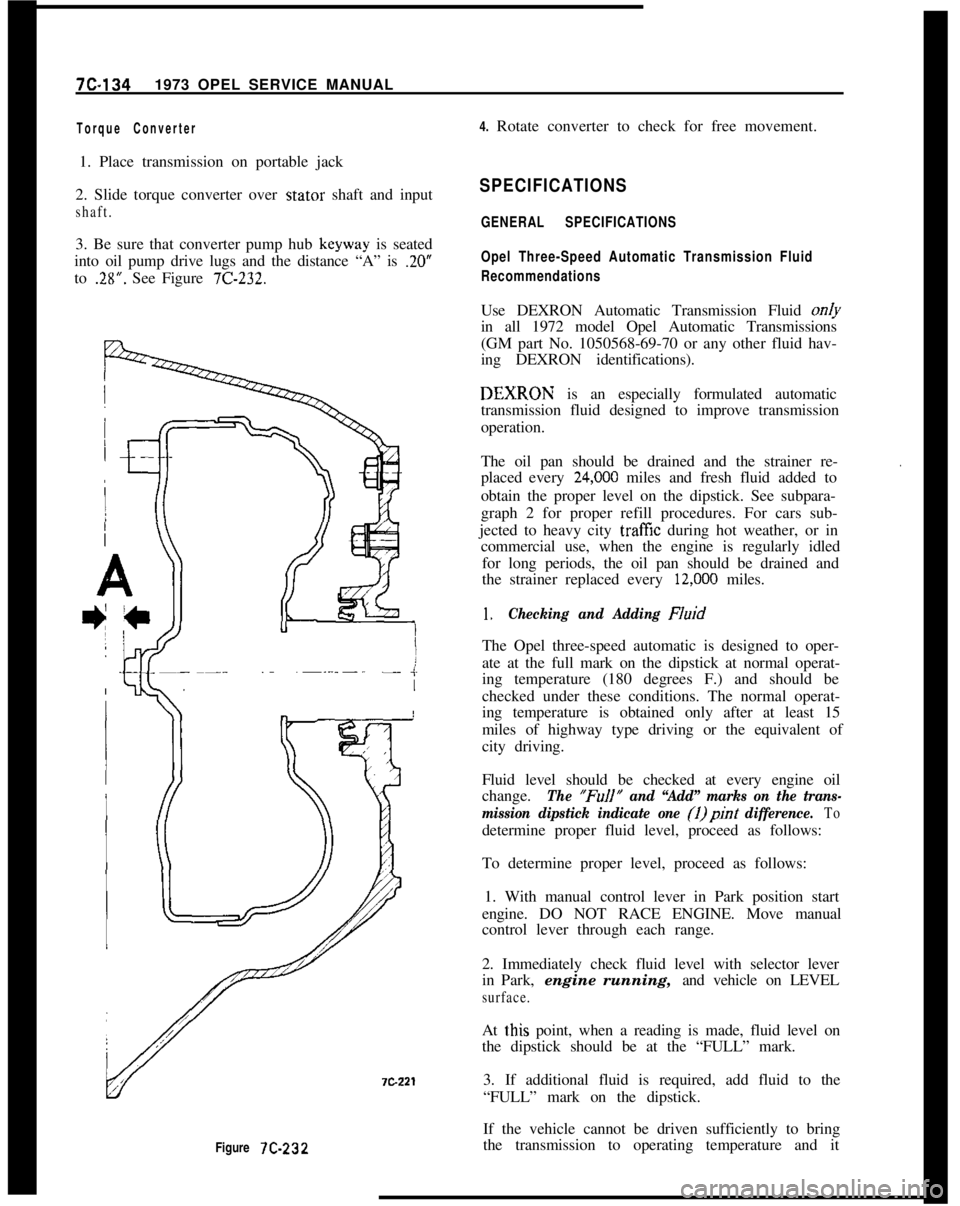

Figure 7C-232

Torque Converter4. Rotate converter to check for free movement.

1. Place transmission on portable jack

2. Slide torque converter over stator shaft and input

shaft.3. Be sure that converter pump hub keyway is seated

into oil pump drive lugs and the distance “A” is

.20”to

.28”. See Figure 7C-232.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Opel Three-Speed Automatic Transmission Fluid

RecommendationsUse DEXRON Automatic Transmission Fluid on/y

in all 1972 model Opel Automatic Transmissions

(GM part No. 1050568-69-70 or any other fluid hav-

ing DEXRON identifications).DEXIRON is an especially formulated automatic

transmission fluid designed to improve transmission

operation.

The oil pan should be drained and the strainer re-

placed every

24,ooO miles and fresh fluid added to

obtain the proper level on the dipstick. See subpara-

graph 2 for proper refill procedures. For cars sub-

jected to heavy city

traff%z during hot weather, or in

commercial use, when the engine is regularly idled

for long periods, the oil pan should be drained and

the strainer replaced every

12,ooO miles.

.

1.Checking and Adding FluidThe Opel three-speed automatic is designed to oper-

ate at the full mark on the dipstick at normal operat-

ing temperature (180 degrees F.) and should be

checked under these conditions. The normal operat-

ing temperature is obtained only after at least 15

miles of highway type driving or the equivalent of

city driving.

Fluid level should be checked at every engine oil

change.

The “FuIl” and “Add” marks on the trans-

mission dipstick indicate one (1)pint

difference. Todetermine proper fluid level, proceed as follows:

To determine proper level, proceed as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

surface.At

t,his point, when a reading is made, fluid level on

the dipstick should be at the “FULL” mark.

3. If additional fluid is required, add fluid to the

“FULL” mark on the dipstick.

If the vehicle cannot be driven sufficiently to bring

the transmission to operating temperature and it

Page 496 of 625

AUTOMATIC TRANSMISSION 7C-135

becomes necessary to check the fluid level, the trans-

mission may be checked at room temperature (70

degrees F.) as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. lmmediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL sur-

face.At this point, when a reading is made, fluid level on

the dipstick should be I/4” below the “ADD” mark.

3. If additional fluid is required add fluid to bring

level to

l/4” below the “ADD” mark on the dip-

stick.If transmission fluid level is correctly established at

70 degrees F. it will appear at the “FULL” mark on

the dipstick when the transmission reaches normal

operating temperature (180 degrees F.) The fluid

level is set

l/4” below the “ADD” mark on the

dipstick to allow for expansion of the fluid which

occurs as transmission temperatures rise to normal

operating temperature of 180 degrees F.

Do not overfill, as foaming and loss of fluid through

the vent pipe might occur as fluid heats up. If fluid

is too low especially when cold, complete loss

of’drive may result which can cause transmission fail-

ure.

2.Draining oilpan and rep/a&g strainer assembly.

(a) Raise car on hoist or p/ace OnJxk stands, and

provide container to collect draining fluid.

(b) Remove oil pan and gasket. Discard gasket.

(c) Drain fluid from oil pan. Clean pan with solvent

and dry thoroughly with clean compressed air.

(d) Remove strainer assembly, strainer gasket and

discard.

(e) Install new oil strainer gasket. Install new strainer

assembly.

(f) Install new gasket on oil pan and install pan.

Tighten attaching bolts to 7-10 lb. ft.

(g) Lower car and add approximately three (3) pints

of transmission fluid through filler tube.

(h) With manual control lever in Park position, start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

(i) Immediately check fluid level with selector leverin Park, engine running, and vehicle on LEVEL

sur-

face.(i) Add additional fluid to bring level to

l/4” below

the “ADD” mark on the dipstick. Do not overfill.

3.Adding Fluid to Fill Dry Transmission and Con-

verter Assembly

The fluid capacity of the Opel Three Speed Auto-

matic transmission and converter assembly is ap-

proximately IO-l/2 pints, but correct level is

determined by the mark on the dipstick rather than

by amount added. In cases of transmission overhaul,

when a complete fill is required, including a new

converter proceed as follows:

(a) Add approximately 10-l/2 pints of transmission

fluid through tiller tube.

The converter should be replaced on any major fail-

ure, such as a clutch or gearset, and an excessive

amount of foreign material is indicated in the pan. If

installation of a new converter is not required add

approximately five (5) pints of transmission fluid.

(b) With manual control lever in Park position start

engine and run at 1000 RPM. DO NOT RACE EN-

GINE. Move manual control lever through each

range.

(c) Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

sur-

face.(d) Add additional fluid to bring level to

l/4” below

the “ADD” mark on the dipstick. Do not overfill.

Opel Three Speed Automatic Transmission Towing

Instructions

If an Opel equipped with an automatic transmission

must be towed, the following precautions must be

observed:

The car may be towed safely on its rear wheels with

the shift lever in neutral position at speeds of 35 miles

per hour or less under most conditions.

However, the drive shaft must be disconnected or the

car towed on its front wheels if:

a. Tow speeds in excess of 35 mph are necessary.

b. Car must be towed for extended distances (over 50

miles).

c. Transmission is not operating properly.

If car is towed on its front wheels, the steering wheel

Page 497 of 625

7C-1361973 OPEL SERVICE MANUALshould be secured to keep the front wheels in a

straight-ahead position.sand,. mud, or snow, move the selector lever from

“D” to “R” in a repeat pattern while simultaneously

applying moderate pressure to the accelerator. DoRocking Carnot race engine. Avoid spinning wheels when trying

If it becomes necessary to rock the car to free it fromto free the car.

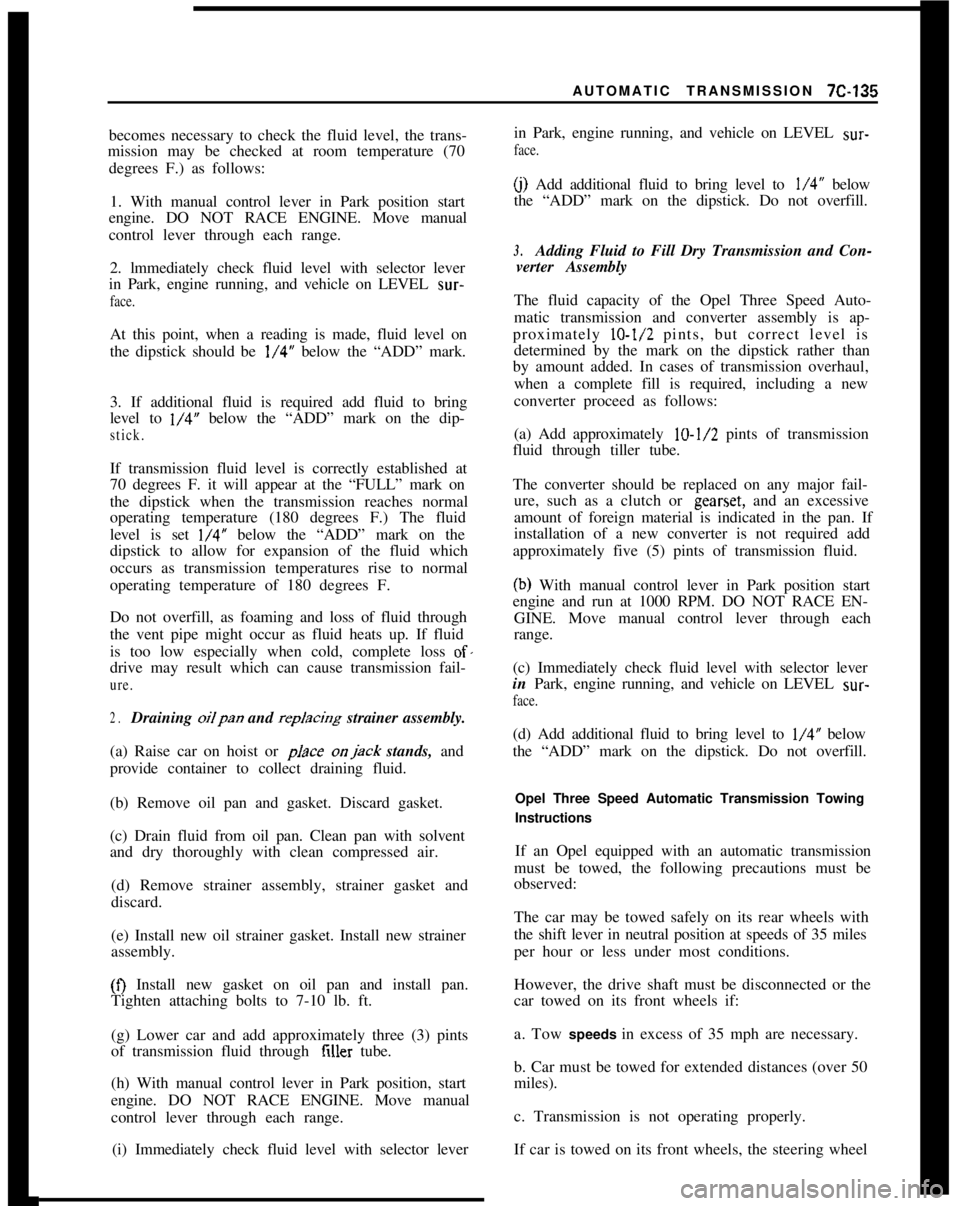

Model DesignationsTrans.

converterReverse Clutch

ModelAssemblyPlates Required2nd Gear

Clutch3rd Gear Clutch

Plates Required

Plates RequiredOpel

1900

OG

GT

CIHInformation

Drive

(Composition Faced:

Drive3Drive3

Green

(Composition

Faced)(CompositionFaced)

Dot ofDriven (Steel)4Driven (Steel) 4

Driven (Steel) 4

PaintWaved1Waved1Waved.1Pressure1Pressure1Pressure1-.

Bolt Torque Specifications

Location

Oil Pan to Case......................................................................Transfer Plate to Valve Body............................................

ReinforcementPlatetoCase..............................................

ValveBodytoCase..............................................................

ServoCovertoCase............................................................

Modulator Assembly............................................................

ConverterHousingtoOilPump........................................

Converter Housing to Case................................................

Selector Lever Jam Nut......................................................

Governor Body to Governor..............................................

ExtensionHousing to Case................................................

Servo AdjustingBolt Lock Nut..........................................

Planetary Carrier Lock Plate..............................................

OilPressureCheckPlug......................................................

Flex Plate to Crankshaft......................................................

Converter to Flex Plate........................................................

ConverterHousingtoCylinderBlock..............................

intermediate Selector Lever to Console

Selector Lever Shaft........................................................

Rear Engine Support to Transmission

CaseExtension..................................................................

Outer Transmission Selector Lever to

TransmissionSelectorLeverShaft..............................

Oil Cooler Line Connector..................................................

Oil Cooler Line to Connector............................................

Oil Cooler Line to Oil Cooler Hose..................................

Oil Cooler Hose to Oil Cooler............................................

Torque

Lb.Ft.7-10

6-8

13.15

13.1516-1812.15

13.17

22.26

8-l 1

6-8

20.30

12.15

20.35

5-736.5

138.42

38.42

Thread

Size

5/16-18

l/6-20

5/16-18

5/16-18

5/16-18

5/16-18

5/16-18

l/4-20

3/8-l 6

18.20

18.22

13.1610-13

1 l-15

1 l-15

11.15

Page 498 of 625

AUTOMATIC TRANSMISSION X-137F. OPEL AUTOMATIC TRANSMISSION LINKAGE ADJUSTMENTP

1. REMOVE LOCK CLIP

-‘\R

l2. PLACE SELECTOR LEVER IN

“r’ 0~ “1” POSITION

23. PLACE TRANSMISSION SHIFT LEVER IN “L” OR “1” POSITION

4. ADJUST CONTROL ROD (ALLOWING IT TO FIT OVER

PIN IN LOWER SELECTOR LEVER FREELY)

5. INSTALL LOCK CLIP

--_--_-SELECTORi--_-~-- GATE

\

\---

-x---i -__‘LACE SHIFT------

LEVER IN

“L” OR “I”

-.-

\/\SHIFT LEVER

L--________--7C-222Figure 7C-233 Adjusting Selector

Level

Page 499 of 625

7C.1381973 OPEL SERVICE MANUAL4

5

IFigure

7C-234 Special Tools. Automatic Transmission7C223

Page 500 of 625

AUTOMATIC TRANSMISSION 75139

SPECIAL TOOLSJ-8763-01

:: J-21369

3.J-8400-1

4.J-3289-20

5.J-23130-3

6.J-8092

7.J-21359

8.J-21426

9.J-2312910. J-7004

11. J-2590-12

12. J-21420-1

13. J-23130-7

14. J-23075

15. J-23 130-S16. J-231306

17. J-23130-1

18. J-21424-9

19.J-21465-17

20.J-23080

21.J-23 130-2

22.J-23082

23.J-23085

24.J-23 100Transmission Holding Fixture

Converter Leak Test Fixture

Cape ChiselHolding Fixture Base

Rear Case Bushing Remover and Installer

Driver Handle

Converter Housing Oil Seal Installer

Extension Housing Oil Seal Installer

Converter Housing Seal Remover

- Without Disassembling Transmission

(Use With J-7004)Slide Hammer

2nd and Reverse Clutch Piston Spring Compressor

Clutch Piston Compressor Adapter

Reaction Sun Gear Drum Bushing Sleeve Installer

Servo and 3rd Clutch Piston Spring Compressor

Oil Pump Bushing Remover

2nd Clutch Drum Bushing Remover and Installer

Oil Pump Bushing Installer

Extension Housing Bushing Remover and Installer (Use with J-8092

Driver Handle)

Converter Housing Bushing Remover and Installer (Use With J-8092)

2nd Clutch Piston Seal Installer

Reaction Sun Gear Drum Bushing Installer

Converter to Oil Pump Alignment Tool

Oil Pump to 2nd Clutch Drum Gauging Tool

Vacuum Modulator Wrench