OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 471 of 625

7C-1101973 OPEL SERVICE MANUALHSEAL

REVERSE CLUTCH

Figure

7C-151Figure 7C-153Figure

7C-15230. Install new oil seals on reverse clutch piston. See

Figure

7C-153.31. Install reverse clutch piston onto rear face of oil

pump using liberal amount of transmission fluid. See

Figure

7C-154.32. Inspect reverse clutch piston springs. Evidence of

extreme heat or burning in the area of the clutch may

have caused the springs to take a heat set and would

justify replacement of the springs.

33. Install the twenty-four reverse clutch piston re-

turn springs.Figure

7C-15434. Install retaining seat.

35. Compress return springs using second and re-

verse clutch piston spring compressor tool J-2590-12

with adapter J-21420-1. Care should be taken not to

damage retainer should retainer catch in snap ring

groove. See Figure 7C-155.

36. Install snap ring using snap ring pliers such as

J-8059. See Figure 7C-155. Do not air check reverse

clutch as the clutch is not complete and damage to

the return spring retaining seat may occur.

Page 472 of 625

AUTOMATIC TRANSMISSION 7C-111

OIL PUMP /’ASSEMBLY

ASPklNG

I(ETAINERSNAP RING

PLIERS

h7C146

Figure 7C.15537. Turn oil pump and reverse clutch assembly so

that oil pump face is facing up.

38. Install oil pump gears using the location mark

made before disassembly.

39. Check the end clearance of both gears to the oil

pump face. Clearance should be between

.0005 to

.0035. See Figure 7C-156.Disassembly, Inspection and Reassembly of Second

Clutch

1. Remove ring gear retaining ring from second

clutch drum. See Figure X-157.

GEAR

Figure

7C-1572. Remove ring gear. See Figure

7C-158.

SECOND CLUTCH DRUM

:-157Figure

7C-15641. Replace the oil pump assembly if the end clear-

ance is not within specifications.Figure 76.158

3. Remove second clutch spacer plate retaining ring.

4. Remove second clutch spacer plate. See Figure7c- 159.

Page 473 of 625

7C-1121973 OPEL SERVICE MANUALSECOND CLUTCHSPACER

----IFigure 7C-159

5. Remove second clutch steel and composition

plates. The plates should be kept in the same se-

quence as they were installed in the clutch. See Fig-

ure 7C- 160.

Figure 7C-160

6. Remove second clutch assembly to third clutch

assembly bronze thrust washer. See Figure

7C-161.7. Install second and reverse clutch spring

cotnpres-sor tool J-2590-12 with adapter J-21420-1 on second

clutch piston return spring retainer and compress

second clutch piston return springs.

SECOND TO THIRD CLUTCHFigure

7C-1618. Remove snap ring using snap ring pliers such as

J- 8059. See Figure

7C-162.Figure 7C-162

9. Remove second clutch retaining seat and 22 return

springs.

10. Remove second clutch piston.

11. Inspect second clutch piston. See Figure

7C-163.If piston is damaged or if check ball falls out upon

inspection, replace piston. Install two new piston lip

seals.

Page 474 of 625

AUTOMATIC TRANSMISSION 7C-113

12. Inspect the piston return springs. Evidence of

extreme heat or burning in the area of the clutch may

have caused the springs to take a heat set and would

justify replacement of the springs.

Figure 7C-16313. Inspect second clutch hub bushing for scoring or

wear.14. If necessary, remove second clutch hub bushing

using remover and installer J-23130-6 with driver

handle J-8092. See Figure 7C-164.

P-J-6092

SECOND CLUTCH

DRUM

iJ:23130-6Figure

7C-16415. Clean in solvent to remove any foreign matter.

Install new second clutch hub bushing using tool

J-23 130-6 and driver handle J-8092. Bushing must be

driven in until tool bottoms on bench. See Figure 7C-

164.16. To install second clutch piston into second clutch

drum, use installer tool J-23080 so as not to damage

lip seal. See Figure 7C-165. Use liberal amount of

transmission fluid for ease of installation and to pre-

vent seal damage.

SECOND CLUTCHDRUM

J-23,060Figure

7C-16517. Remove second clutch piston and seal installer

J-23080.18. Install 22 springs and retaining seat on second

clutch piston.

19. Using spring compressor tool J-2590-12 with

adapter J-21420-1 on retaining seat, compress sec-

ond clutch piston return springs. Care should be

taken so that retainer does not catch in snap ring

groove and damage retainer.

20. Install snap ring with snap ring pliers such as

J-

8059.21. Install bronze thrust washer so that the tang seats

in the slot of the second clutch hub. Secure with

petroleum jelly (unmedicated).

22. Inspect condition of composition and steel plates.

Do not diagnose a composition drive plate by co/or.

A. Dry composition plates with compressed air and

inspect the composition surface for:

1. Pitting and flaking

2. Wear

3. Glazing

Page 475 of 625

7C-1141973 OPEL SERVICE MANUAL

4. Cracking

5. Charring

6. Chips or metal particles imbedded in lining

If a composition drive plates exhibits any of the

above conditions, replacement is required.

B. Wipe steel plates dry and check for heat discolora-

tion. If the surface is smooth and an even color smear

is indicated, the plates should be reused. If severe

heat spot discoloration or surface scufftng is in-

dicated, the plates must be replaced.

23. Install second clutch plates into second clutch

drum with cushion plate (wave washer) first, then

steel plate, composition plate, steel plate, etc. Use

liberal amount of transmission fluid. See Figure 7C-

166.

-I

DRUM

7c-167Figure 7C-167

Disassembly, Inspection and Reassembly of Third

Clutch1. Compress third clutch sprag race and retainer

assembly retaining ring, and remove assembly from

third clutch drum. See Figure

7C-168. Third clutch

hub and input sun gear assembly will be removed at

the same time.

Figure 7C-16624. Install second clutch spacer plate into second

clutch drum. If necessary, expand spacer plate with

screw driver until ends of spacer are evenly butted

together seating tightly into drum. See Figure 7C-

159.

25. Install second clutch spacer retaining ring

26. Install ring gear into second clutch drum.

Figure 7C-168

27. Install ring gear retaining ring.

28. Air check second clutch assembly. See Figure7C- 167.2. Remove input sprag race and retainer assembly

from third clutch hub and input sun gear assembly.

See Figure

7C-169.

Page 476 of 625

AUTOMATIC TRANSMISSION 7C-115INPUT SPRAG RACE

8 RETAINER ASSEMBLY/

GEAR

CLUTCH HUBFigure

7C-1693. Push sprag assembly and retaining rings from

sprag race and retainer. See Figure

7C-170.Figure

7C.17 I7. Remove snap ring using snap ring pliers such as

J- 8059. See Figure 7C-172.SPRAG RACE

-AND RETAINER

,, SPRAG ASSEMBLY

\Figure

7C-1704. Remove third clutch plates from third clutch

drum. See Figure

7C-171. The plates should be kept

in the same sequence as they were installed in the

clutch.

5. Remove input shaft thrust washer and needle

thrust bearing. See Figure

7C-171.6. Using compressor tool J-23075 on third clutch

piston retaining seat, compress third clutch piston

return springs using arbor press.Figure 7C.172

8. Remove the retaining seat and 12 return springs.

9. Remove third clutch piston from third clutch

drum. See Figure

7C-174.

10. Inspect third clutch piston return springs. have

caused the springs to take a heat set and would jus-

tify replacement of the springs.

11. Inspect check ball in third clutch piston. If ball

is missing or falls out upon inspection or piston is

Page 477 of 625

7C.1161973 OPEL SERVICE MANUALDRUM

THIRD CLUTCH

PISTON

70174Figure 7C-174

damaged, replace piston. Install new lip seal on pis-

ton. See Figure

7C-175.

CHECKTHI

Figure 7C-175

12. Install new oil lip seal on input shaft inside of

third clutch drum. See Figure

7C-176.13. Inspect steel thrust washer on front face of third

clutch drum. Replace if scored or damaged. See Fig-

ure 7c-177.

14. Install third clutch piston into third clutch drum

using a

.020 music wire crimped into a piece of cop-

per tubing and a liberal amount of transmission fluidFigure 7C-176

Figure 7C-177

so that lip seal is not damaged upon installation. See

Figure

7C-178.15. Install the 12 third clutch piston return springs

onto piston.

16. Install retaining seat.

17. Using compressor tool J-23075 on retaining seat,

compress piston return springs. Care must be taken

so that retaining seat does not catch in snap ring

groove and damage retainer.

18. Install snap ring using snap ring pliers such as J-

8059.

Page 478 of 625

AUTOMATIC TRANSMISSION 7C-117WIRE CRIMPED

INTO COPPERTUBING

Figure 7C-178

19. Inspect condition of the third clutch composition

and steel plates. Do not diagnose a composition

drive plate by color,A. Dry composition plates with compressed air and

inspect the composition surface for:

1. Pitting and flaking

2. Wear

3. Glazing

4. Cracking

5. Charring

6. Chips or metal particles imbedded in lining

If a composition drive plate exhibits any of the above

conditions, replacement is required.

B. Wipe steel plates dry and check for heat discolora-

tion. If the surface is smooth and an even color smear

is indicated, the plates should be reused. If severe

heat spot discoloration or surface

scutXng is in-

dicated, the plates must be replaced.

20. Install third clutch plates into third clutch drum

beginning with a steel plate, composition plate, steel

plate, composition plate, etc. Use a liberal amount of

transmission fluid.

21. Inspect thrust washer and needle thrust bearing

for damage. Replace if necessary.

22. Install thrust washer and bearing onto input

shaft. Secure with petroleum jelly (unmedicated).23. Inspect sprag assembly for wear, damage orsprags that freely fall out of cage. Inspect input sun

gear for chipped or nicked teeth or abnormal wear.

Replace part if necessary.

24. Install sprag onto third clutch hub with groove

on sprag cage outer diameter toward input sun gear.

See Figure

7C-179.Figure 7C-179

25. Install sprag race and retainer assembly over

sprag assembly. Holding input sun gear with left

hand, sprag race and retainer assembly should “lock

up” when turned with right hand in a clockwise

direction and should rotate freely when turned coun-

terclockwise. See Figure

7C-180.Figure 7C-180

Page 479 of 625

712.1191973 OPEL SERVICE MANUAL

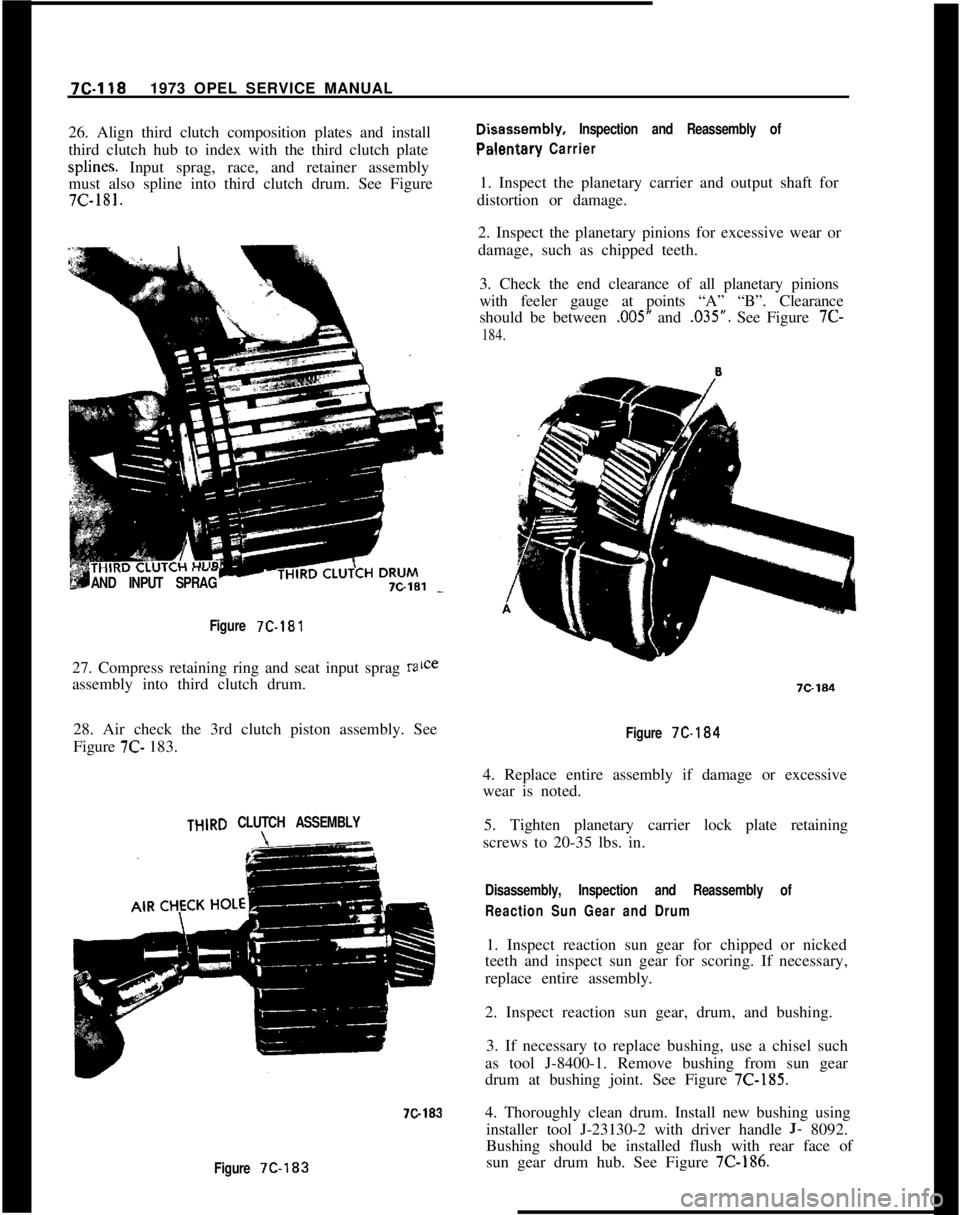

26. Align third clutch composition plates and install

third clutch hub to index with the third clutch platesplines. Input sprag, race, and retainer assembly

must also spline into third clutch drum. See Figure7c-181...-I-AND INPUT SPRAG

Disaseembly, Inspection and Reassembly of

Palentary Carrier1. Inspect the planetary carrier and output shaft for

distortion or damage.

2. Inspect the planetary pinions for excessive wear or

damage, such as chipped teeth.

3. Check the end clearance of all planetary pinions

with feeler gauge at points “A” “B”. Clearance

should be between

,005” and .035”. See Figure 7C-

184.

Figure

7C-18127. Compress retaining ring and seat input sprag

raassembly into third clutch drum.

28. Air check the 3rd clutch piston assembly. See

Figure 7C- 183.

THlRD CLUTCH ASSEMBLY

7C183

Figure 7C-183

Figure 7C-184

4. Replace entire assembly if damage or excessive

wear is noted.

5. Tighten planetary carrier lock plate retaining

screws to 20-35 lbs. in.

Disassembly, Inspection and Reassembly of

Reaction Sun Gear and Drum1. Inspect reaction sun gear for chipped or nicked

teeth and inspect sun gear for scoring. If necessary,

replace entire assembly.

2. Inspect reaction sun gear, drum, and bushing.

3. If necessary to replace bushing, use a chisel such

as tool J-8400-1. Remove bushing from sun gear

drum at bushing joint. See Figure

7C-185.4. Thoroughly clean drum. Install new bushing using

installer tool J-23130-2 with driver handle

J- 8092.

Bushing should be installed flush with rear face of

sun gear drum hub. See Figure

7C-186.

Page 480 of 625

driver and remove secondary valve spring retainer.

See Figure 7C-187.

S,ECONDARY’ VALVE SPRING

/SECONDARY VALVE

REACTIONSUN GEAR

DRUM

#ii

INERFigure 7C-1857G186

Figure 7C-186

Disassembly. Inspection and Reassembly of

Governor Body1. Depress secondary valve spring with small screw

$%OLL PIN

Figure 7C-187

2. Remove secondary valve spring, secondary valve,

primary valve, and roll pin from governor body. See

Figure

7C-188.

1. GOVERNOR SECONDARY VALVE SPRING RETAINER

2. GOVERNOR SECONDARY VALVE SPRING

3. GOVERNOR SECONDARY VALVE

4. GOVERNOR PRIMARY VALVE

5. GOVERNOR BODY7c.1886. ROLL PIN

Figure 7C-188 Governor Body Exploded View

3. Inspect the primary and secondary valve for nicks,

burrs, etc. If necessary, use crocus cloth to remove

small burrs. Do not remove the sharp edges of the

valve since these edges perform a cleaning action

with the valve bore.