OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 561 of 625

96-52 1973 OPEL SERVICE MANUAL

REMOVAL AND INSTALLATION OF EVAPORATOR

AND EXPANSION VALVE. OPEL 1900 - MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove left side of distributor duct, and in line

fuse. See Figure

9B-61.3. Remove glove box. See Figure

9B-62.Figure 96-64 Delay Restrictor

and Check Valve Hose

Assembly Location

5. Disconnect the delay restrictor and check valve

hose assembly from the vacuum cut-off switch and

disconnect the electrical wiring. See Figures 9B-63

and 64.

6. Remove evaporator inlet and outlet pipes re-

tainer and rubber grommet. See Figure

9B-65.Figure

98.62 Glove Box Removed

4. Discharge refrigerant from system. (Refer to

DISCHARGING SYSTEM) and disconnect refrig-

erant hose from evaporator outlet and pipe from

evaporator inlet and tape the open ends of the refrig-

erant lines and evaporator pipes. See Figure

9B-63.Figure

98.65 Inlet and Outlet Pipes retainer and

Rubber Grommet-Opel 1900 - Manta

Figure

98.63 Location of Refrigerant Hoses, Pipes,

Vacuum Cut Off Switch and Evaporator Attaching Bolt

(Left Side) - Opel 1900

- Manta

Page 562 of 625

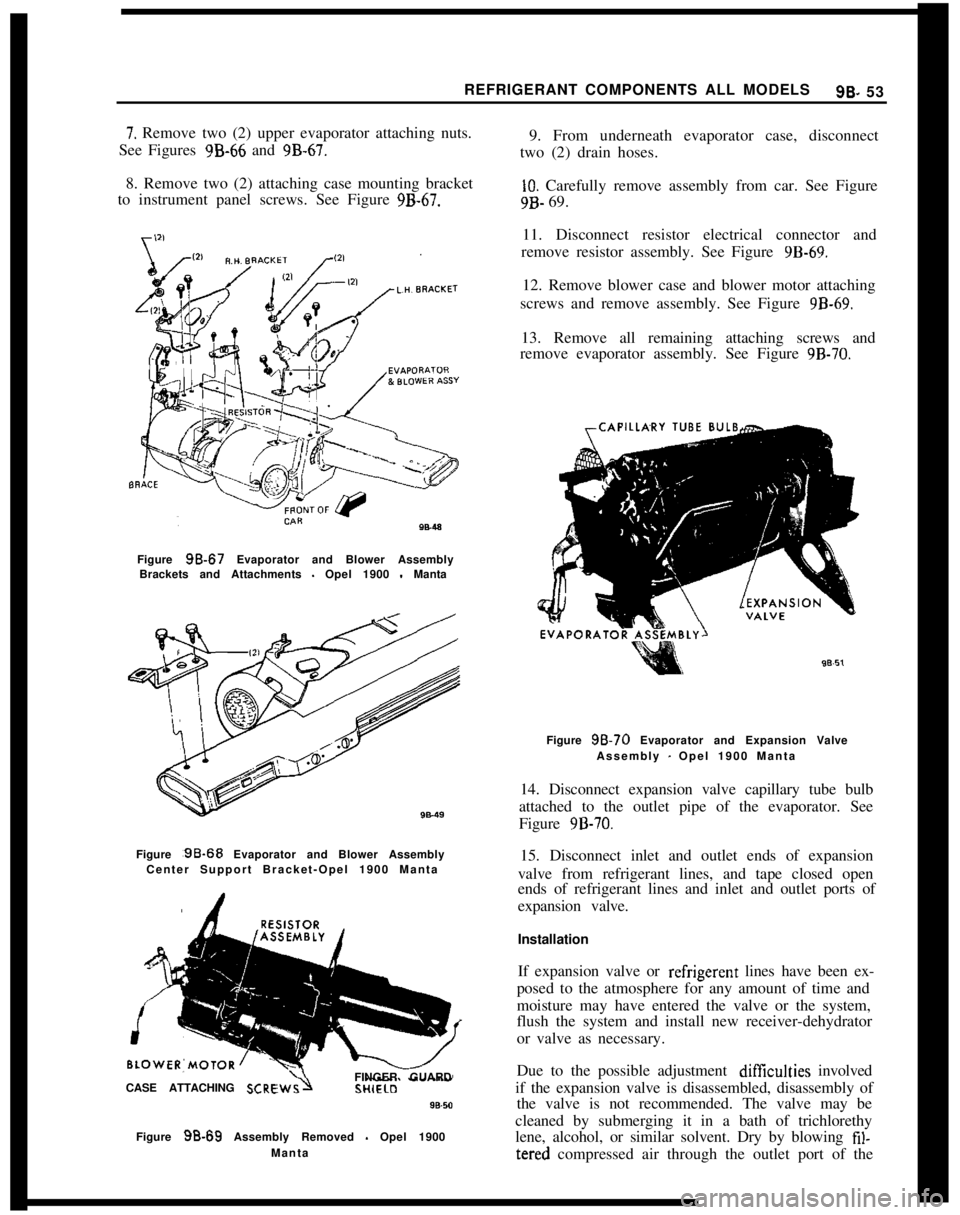

REFRIGERANT COMPONENTS ALL MODELS9B- 537. Remove two (2) upper evaporator attaching nuts.

See Figures 9B-66 and 9B-67.

8. Remove two (2) attaching case mounting bracket

to instrument panel screws. See Figure

9B-67.Figure

98.67 Evaporator and Blower Assembly

Brackets and Attachments - Opel 1900 - Manta

Figure :9B-68 Evaporator and Blower Assembly

Center Support Bracket-Opel 1900 Manta

CASE ATTACHING

SCREFINGER GUARD

Figure

98.69 Assembly Removed - Opel 1900

Manta9. From underneath evaporator case, disconnect

two (2) drain hoses.

10. Carefully remove assembly from car. See Figure9B- 69.

11. Disconnect resistor electrical connector and

remove resistor assembly. See Figure

9B-69.12. Remove blower case and blower motor attaching

screws and remove assembly. See Figure

9B-69.13. Remove all remaining attaching screws and

remove evaporator assembly. See Figure

9B-70.Figure

98.70 Evaporator and Expansion Valve

Assembly

- Opel 1900 Manta

14. Disconnect expansion valve capillary tube bulb

attached to the outlet pipe of the evaporator. See

Figure

9B-70.15. Disconnect inlet and outlet ends of expansion

valve from refrigerant lines, and tape closed open

ends of refrigerant lines and inlet and outlet ports of

expansion valve.

Installation

If expansion valve or refrigerent lines have been ex-

posed to the atmosphere for any amount of time and

moisture may have entered the valve or the system,

flush the system and install new receiver-dehydrator

or valve as necessary.

Due to the possible adjustment difficulties involved

if the expansion valve is disassembled, disassembly of

the valve is not recommended. The valve may be

cleaned by submerging it in a bath of trichlorethy

lene, alcohol, or similar solvent. Dry by blowing fil-tered compressed air through the outlet port of the

Page 563 of 625

96-54 1973 OPEL SERVICE MANUAL

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw into old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws. See Figure 9B-70.3. Install blower motor assembly into case and se-

cure with attaching screws. See Figure

9B-69.4. Install finger guard shields and fan housing case.

See Figure

9B-69.5. Install resistor assembly and electrical connector.

Install blower motor connector. See Figure

9B-69.6. Install assembly into car carefully guiding

evaporator pipes up through cowl opening. See Fig-

ure

9B-71.Figure 93-7 1 Inlet and Outlet Pipes and O-Rings

-Opel 1900 Manta

7. Install two (2) upper attaching evaporator at-

taching nuts. See Figures 9B-66 and

9B-67.8. Install two (2) attaching case mounting bracket

to instrument panel screws. See Figure

9B-67.9. Connect two (2) drain hoses underneath evapora-

tor.10. Install evaporator inlet and outlet pipes retainer

and rubber grommet. See Figure

9B-65.11. Connect vacuum cut-off switch and electrical

wiring, making sure the delay restrictor and checkvalve hoses are installed correctly. See Figures

9B-63and 64.

.gB-72 Delay Restrictor and Check Valve Hose.Assembly

12. Install refrigerant hoses and pipes using new

o-rings on line fittings and evacuate system. Refer to

EVACUATING SYSTEM.

13. While system is being evacuated, install in-line

fuse and left side of distributor duct. See Figure 9B-

61.14. Install glove box.

15. Install negative battery cable and charge system.

Refer to CHARGING SYSTEM.

REMOVAL AND INSTALLATION OF CONDENSER

ASSEMBLY -OPEL 1900. MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove air cleaner.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

4. While system is discharging, remove lower radia-

tor hose from radiator and drain coolant into a suita-

ble container.

5. Remove fan shroud.

6. On vehicles with automatic transmission, un-

screw oil lines from connectors on lower radiator

tank and plug lines. It is essential that no dirt enters

the oil lines. When unscrewing oil lines, hold connec-

tors on lower radiator tank with pliers to avoid leak-

ages. Ensure that no dirt enters oil cooler.

7. Remove upper radiator hose from radiator.

8. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

9. Remove inlet and outlet hoses from condenser

Page 564 of 625

REFRIGERANT COMPONENTS ALL MODELS99.55pipes and tape closed the open ends of refrigerant

lines, and also the open ends of the inlet and outlet

pipes of the condenser.

10. Remove two (2) top retaining screws.

Figure

9,S-73 Condenser Retaining Screws - Opel

1900

- Manta

11. Remove radiator grille and two (2) condenser to

body mounting screws. See Figure 98.74.

Figure 98-74 Condenser Assembly and Attachments.

Opel 1900

- Manta

12. Remove condenser.

Installation

If refrigerarit circuit or condenser has been exposed

to the atmosphere and moisture may be present in

the circuit, the system and/or component must beFigure 98-75 Condenser Assembly Mounting Brackets

Opel 1900 Manta

flushed prior to installation. Refer to FLUSHING

THE SYSTEM.

1. Install comjenser into car and install 2 condenser

to body mounting screws. See Figure 98-74. Install

radiator grill.

2. Install 2 top retaining screws.

3. Remove tape from the condenser pipes and re-

frigerant hoses and install hoses using new o-rings on

lines lubricated with No.

525 viscosity oil.

4. Evacuate system. Refer to EVACUATING SYS-

TEM.

5. While system is being evacuated, install radiator

into engine compartment and secure lower attaching

nut.

Figure 98.76 Clearance Between Lower Radiator

Tank and Fan Blades

- Opel 1900 Manta

6. On vehicles with automatic transmissions, fasten

Page 565 of 625

98-56 1973 OPEL SERVICE MANUAL

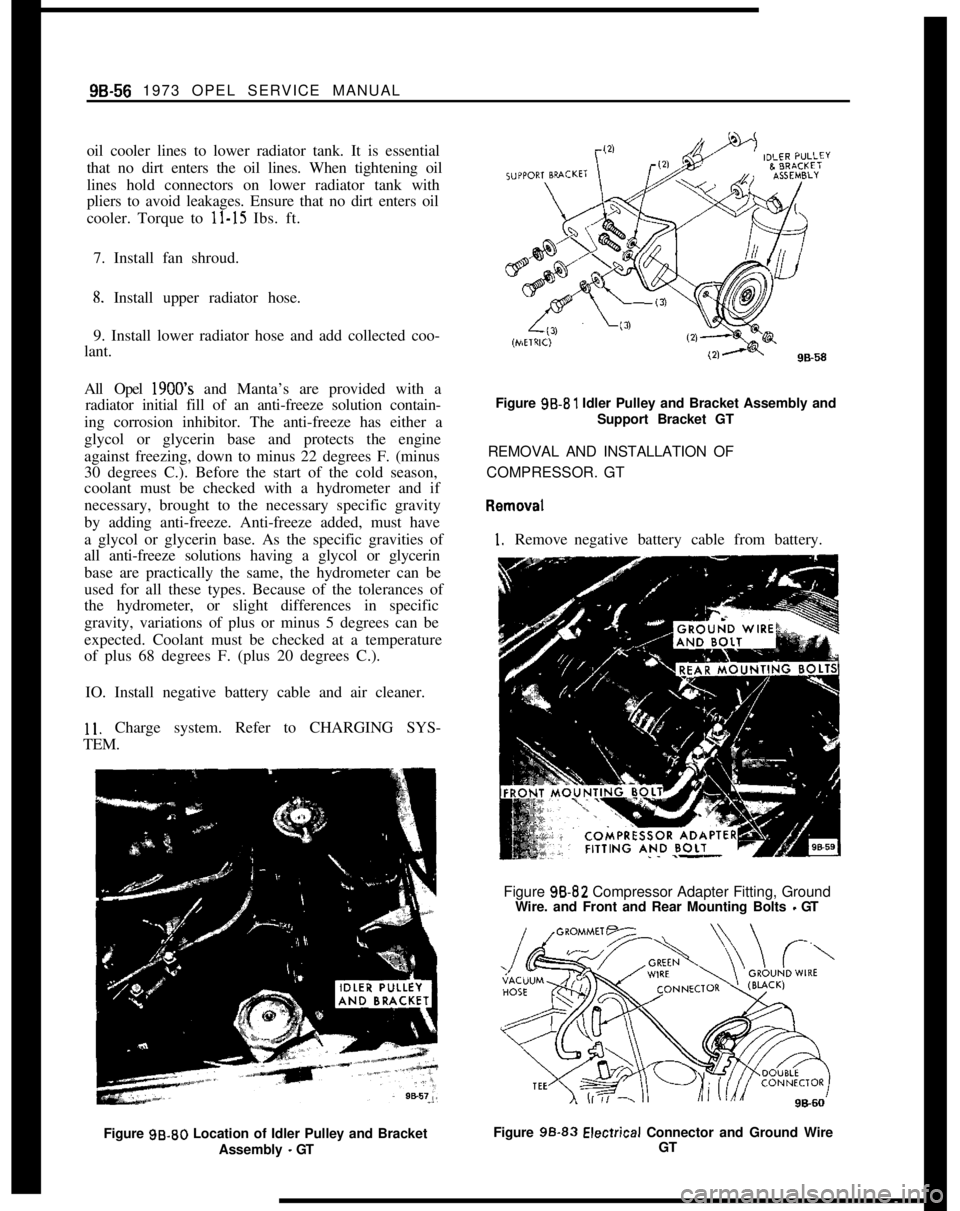

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 11-15 Ibs. ft.

7. Install fan shroud.

8. Install upper radiator hose.

9. Install lower radiator hose and add collected coo-

lant.

All Opel

1900’s and Manta’s are provided with a

radiator initial fill of an anti-freeze solution contain-

ing corrosion inhibitor. The anti-freeze has either a

glycol or glycerin base and protects the engine

against freezing, down to minus 22 degrees F. (minus

30 degrees C.). Before the start of the cold season,

coolant must be checked with a hydrometer and if

necessary, brought to the necessary specific gravity

by adding anti-freeze. Anti-freeze added, must have

a glycol or glycerin base. As the specific gravities of

all anti-freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.).

IO. Install negative battery cable and air cleaner.

11. Charge system. Refer to CHARGING SYS-

TEM.

Figure 99.80 Location of Idler Pulley and Bracket

Assembly

- GTFigure 99.81 Idler Pulley and Bracket Assembly and

Support Bracket GT

REMOVAL AND INSTALLATION OF

COMPRESSOR. GT

I. Removenegative battery cable from battery.

Figure 98-82 Compressor Adapter Fitting, Ground

Wire. and Front and Rear Mounting Bolts

- GT

Figure 99.83

Elecirical Connector and Ground Wire

GT

Page 566 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 57SUPPORT BRACE (LARGE)Figure 98-84 Compressor Installation GT

Page 567 of 625

98-58 1973 OPEL SERVICE MANUAL

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While system is discharging remove air cleaner

and loosen idler pulley and bracket assembly. See

Figure 98-80.

4. Remove bolt holding compressor adapter fitting

into rear head. Disengage from compressor and tape

closed openings in both lines and ports in rear head.

It is important to seal compressor ports to avoid a

loss of refrigeration oil and also to prevent foreign

material and moisture from entering compressor. See

Figure 9B-82.

5. Remove bolt and ground wire, unplug electrical

connector, and remove 2 rear compressor mounting

bolts. See Figure 98-82.

6. Remove 2 front compressor mounting bolts,

clutch drive belt, and lift out compressor. During

removal, maintain the compressor position so that

the sump is downward. Do not’rotate compressor

shaft. See Figure 9B-84.

Installation1. Install compressor into mounting brackets and

secure with 4 mounting bolts. See Figure

9B-84.2. Untape lines and ports, and install compressor

adapter fitting and bolt using new o-rings. See Figure

9B-82.3. Evacuate system. Refer to, EVACUATING

SYSTEM.

4. While system is being evacuated, install drive belt

and tighten idler pulley. See Figure

9B-80.5. Install bolt and ground wire and plug in electrical

connector. See Figure

9B-83.6. Install air cleaner and negative battery cable.

7. Charge system. Refer to, CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF

RECEIVER.DEHYDRATOR

ASSEMBLY. GT

Removal1. Discharge system. Refer to DISCHARGING

SYSTEM.

2. Disconnect refrigerant lines to both ends of re-

ceiver-dehydrator and tape closed open ends of

re-

9862Figure 98.85 Refrigeration Hose Clamps Installation

GT

frigerant lines, and also the open

e:nds of the inlet and

outlet pipes of the receiver-dehydrator. See Figure

9B-86.Figure 98.86 Receiver-Dehydrator GT

3. Remove 2 screws securing receiver-dehydrator

and clamps to support bracket and lift out receiver

dehydrator. See Figure

9B-86.

Installation1. Install receiver-dehydrator using new o-rings

during installation. Lubricate o-rings prior to instal-

lation using No. 525 viscosity oil.

.

Page 568 of 625

REFRIGERANT COMPONENTS ALL MODELS9s. 59

2. If the receiver-dehydrator has been exposed to

the atmosphere for any amount of time, (more than

5 minutes), the receiver-dehydrator should be re-

placed, since the life of the dessicant is probably

expended.

3. Evacuate and charge system. Refer to CHARG-ING AND DISCHARGING SYSTEM.

REMOVAL AND INSTALLATION OF EVAPORATOR

AND EXPANSION VALVE. GTRemoval

1. Disconnect negative battery cable.

2. Discharge system. Refer to, DISCHARGING

SYSTEM.3. While system is discharging, remove attaching

screws and lift out luggage tray. See Figure

9B-87.Figure 98.88 Evaporator Cover Assembly and

Attaching Screws GT

Figure 98.87 Luggage Tray

4. Remove all evaporator cover screws and removecover. See Figure

9B-88.

5. Remove electrical plug connector from the resis-tor assembly and unplug blower motor connection

and remove ground wire. See Figure

9B-90.6. From underneath evaporator housing, discon-

nect two (2) drain hoses. See Figure

9B-91.

7. From under car remove 4 nuts securing

evapora-Figure 96.90 Electrical Connections, Ground Wire

GTtar mounting bracket to floor. See Figures

9B- 92

and

9B-93.8. Remove inlet and outlet pipes from evaporator

and tape closed the refrigerant lines and also the

open ends of the inlet and outlet pipes of the evapora-tor. See Figure

9B-94.

Page 569 of 625

9B-60 1973 OPEL SERVICE MANUAL

EVAPORATOR EVAPORATOR

DRAIN HOSE DRAIN HOSE

Figure 96-91 Drain Hose GT

Figure 98.92 Evaporator Mounting Bracket Bolts

Driver Side GT

9. Lift off the mounting bracket and remove the

evaporator assembly from the car.

10. Remove the resistor assembly. See Figure

9B-90.Figure 98-93 Evaporator Mounting Bracket Bolts

Passenger Side

- GT“0” RING-----

OUTLET TUBE

SEAL

9870Figure 98-94 Inlet and Outlet Pipes and O-Rings GT

11. Remove blower case and blower motor attaching

screws and remove assembly.

12. Remove all remaining attaching screws and

remove evaporator assembly. See Figure

9B-95.13. Disconnect expansion valve capillary tube bulb

attached to the outlet pipe of the evaporator. See

Figure 9B-95.

14. Disconnect inlet and outlet ends of expansion

Page 570 of 625

REFRIGERANT COMPONENTS ALL MODELS96.61

CAPILLARY T”BEFigure 98.95 Evaporator and Expansion Valve

Assembly GT

valve from refrigerant lines, and tape closed open

ends of lines and inlet and outlet ports of expansion

valve.

Installation5. Install resistor assembly.

6. Install evaporator assembly into car and install

mounting bracket. See Figure

9B-96.Figure 98.96 Evaporator and Blower Assembly

- GT

If expansion valve or refrigerant lines have been ex-

posed to

,the atmosphere for any amount of time and

moisture may have entered the valve or the system,

flush the system and install new receiver-dehydrator

or valve as necessary.7. Untape the refrigerant lines and the inlet and

outlet pipes from the evaporator and install using

new o-rings on line fittings.

Due to the possible adjustment difficulties involved

if the expansion valve is disassembled, disaisembly of

the valve is not recommended. The valve may be

cleaned by submerging it in a bath of trichlorethy-

lene, alcohol, or similar solvent. Dry by blowing iil-tered compressed air through the outlet port of the

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw intp old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws.

3. Install blower motor assembly into case and se-

cure with attaching screws.

4. Install finger guard shields and fan housing case.Figure 98-97 Refrigerant Hoses and Hose Clamps

Under Car

- GT