OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 591 of 625

r98-82 1973 OPEL SERVICE MANUAL

SPECIFICATIONS

Tightening Specifications

Part

Location

NutDrivePlateNut toCompressorShaft..............................

NutRear Head to Shell................................................................

CaPSchraderServiceValve......................................................

Compressor Specifications

Torque

Lb. Ft.

15

21

5Type

..............................................................................................Six Cylinder Axial Opposed

Make

............................................................................................................................Frigidaire

Effective Displacement (Cu. In.)

..........................................................................................

9.2Oil

..........................................................................................................................525 Viscosity

Oil Content (New)

....................................................................................................10 Fl. Oz.

Air Gap Between Clutch Drive Plate and Pulley

......................................0.022 to 0.057 In.

Clutch Type

................................................................................................................h4agnetic

Belt Tension

..............................................................................................1 lo-125 Lbs. Irritial

....................................................................................................................80 Lbs. Retension

Pipe and Hose Connection Torque Chart

Metal TubeThread andSteel TubingAluminum orNominal Torque

I

Outside Dia.Fitting SizeTorqueCopper TubingWrench Span

Lb. Ft.Torque

Lb. tit.

5-7

General SpecificationsThermostat Opening Temperature

.._.....,,,...__....,,.............................................................. 189

Capacity of Cooling System With Air Conditioner (Quarls)

.,,..___....___............... 6 (Approx.)Type of Refrigerant

.___,,,._...,.,,,.__.....,,,.......,,,,.......,,,...................,,,......,,,............ Refrigerant 12

Refrigerant Capacity (Fully Charged)

Opel

1900-Manta,,._....,,,,._...._.,,,,.......,,,........,,............................................................2 Lbs.

GT

,..__..,..,..__..,,,.......,,,,.......,,,........,,,.,......,,,,,......,,.,,........,,.......,,..........,,............... 2 l/4 Lbs.

Functional Test Procedures1. Place transmission in park for automatics and in

neutral for manuals. Apply hand brake.

2. Turn blower switch to HI position,

3. Turn temperature switch to MAX position-.

4. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a commercial high volumn fan in front of condenser

if head pressure should exceed 250 psig.A commercial high volumn fan should be placed in

front of the condenser at high ambients to bring the

pressures to within the limits specified in the Func-

tional Charts. When testing the Opel 1900 and

Man& a thermometer should be placed in a position

to read the temperature of the air discharging from

the right-hand A/C outlet. When testing the GT, a

thermometer should be placed in a position to read

the temperature of the air discharging, from the left-

rear

,A /c outlet.

Page 592 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 83

FUNCTIONAL TEST - OPEL 1900.

MANTA

Temp. of Air Entering

Cond.

Engine RPM

Camp. Head Pressure*

Suction Press.’

Discharge Air Temperature*

*When compressor clutch disengages,

FUNCTIIONAL TEST - GT

Temp. of Air Entering Cond.

Engine RPM

Camp. Head Pressure”

Suction Press.”

Discharge~Air Temperature*

“When compressor clutch disengages70

8090100110

20002000200020002000

155.165195.205200-210

250.260270.280

1922222729

38-4340.4542-47

45-5047-52

708090100110

2000

2000200020002000

125.135145.155180-190

210-220150.260

1720202224

37-42

38.4339-4440-4545-50

Page 593 of 625

9B-84 1973 OPEL SERVICE MANUALtCOMPRESSOR

CONDENSEREVAPORATOR

q H.P. VAPORq H.P. LIQUIDq 1.p. LIQUIDq L.P. VAPORq H.P.T.X.V. POWER ELEMENTFigure 96-l 61 Cycle of Operation

Page 594 of 625

REFRIGERANT COMPONENTS ALL MODELSSB- 85

123 45 6 7a910 11 12 131415 lb1718 19

_202122232425 26 272a2930313233 34 35 3b

I. Rear Head13. Coil and Housing

Assemblv

2. Rear Head to Shell “0” Ring

3. Rear Discharge Valve Plate14. coil Housiq Retaining Ring25. Thrust Race

4. Rear Suction Reed Plate

15. Pulley and Bearing Assembly26. Thrust &zarin~27.16. Pulley BearingThrust Race

28.

5.

PistonRingCompressor Shell6. Piston Drive Ball17. Pulley Bearing Retainer Ring

18. Pulley and

Bearing Retainer Ring29. Cylinder Assembh30.Shaft Seal

7. Ball Seat (Shae Disc)

8. Piston

19. Clutch Hub and Drive Plate Assembly 31. Shaft Seal Seat “0” Rjn820. Oil Pump Gears

32. Shaft Seal sear

9. Front Suction Reed Plate

10. Front Discharge Valve Plate21. Mainshaft

Bearing (Rear)

22. Oil inlet Tube “0” Ring33. Shaft Seal Seat Rrrainer Ring

11. Fr&t Head to Shell “0” Rin8 23. Oil Inlet Tube34. Spacer

12. Front Head24. Wobble

(Skash) Plate and Mainshaft35. Clutch flub Retainer Ring36:Shaft Nut

Assembly98.131Figure 98.162 Compressor Section View

Page 595 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 87

SUCTION,011 INLET T”BE

REAR CYLINDER

’ REAR NEEDtE”q.PRESSURE RELIEF VALVE

THRUST BEARlNG

/IT DISCHARGE VALVE PLATE

fFRONT HEAD

,-SEAL SEAT O-RING

I,-SHAFT SEAL

~&SHELL TOHEAD O-RING

I,IPORTFRONT

CYLINDE<\., -I\,VALVE PLATE[SERVICE ONLYI(SERVICE ONLY1.TION VALVE REED DISC

Figure 96-l 64 Compressor Exploded View

Page 596 of 625

98-88 1973 OPEL SERVICE MANUAL

Figure gB-165 Special Tools

Page 597 of 625

AIR CONDITIONER SYSTEM -OPEL 1900 - MANTASB- 89

cJ 6084

J

14OVSJ

5428.03

,J 23390

J 23600 BELT IENSION GAUGE

J 6212.01 #4 MlJLTI.OPtNtR . 4 CAN RtFRIGtRANT OPENER

J 23400

tlKlRONIC LEAK DETECTOR

J 23575 COMPLHE MANIFOLD ASSfYBLY

J 6034 LEAK WtClORJ 5418-03 VACUUM PUMP

! ?!!~O~!~~~..~I~poIIRL~ REFRIGERANT CAN CONIROL VALVEI WI" 6A"Gt ADAPTEK

J 5453 GOGGLES

J 24095 COMPRESSOR OIL INJECTOR

J 6742.03 IHtRMOMETER

- DIAL TYPE (2S”.lZ5~)J 22132.02

I

J 9459

1J 5410

J 23500J 6171

141%360 GAUGt CHARGING LINE 36” BLUEi418 -36R ” ” ” -36” RED, J!I I, .J 5418.48W ””” 48” WHIIEJ5418.728

” ” ” 72” BLUI

J 5418.72s ”” I’ . 11” RtD

J 5418.7ZW ””” . 72” WWllt

J 23500 PORlARLt AIR ~ONDIlIONtR SERVlCt STAllON

J 22132.D2 SCWRADER VALVE

J 6271 FIlS.ALL VALVE98136I

IFigure 96-l 66 Special Tools

Page 598 of 625

System controls are the AIR knob controlling the

three speed blower motor switch and the TEMP

knob which controls the setting of the thermostatic

switch. When operating this system, the heater must

be off for maximum cooling.DIAGNOSIS

TROUBLE DIAGNOSIS GUIDE

Air Knob

Insufficient CoolingTurning the AIR knob clockwise operates the three-

speed blower motor.CHECK AIR FLOW9B-90 1973 OPEL SERVICE MANUAL

AIR CONDITIONER SYSTEM

OPEL 1900

- MANTA

CONTENTS

Subject

DESCRIPTION AND OPERATION:

General Description of System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...”Operation of Controls

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .DIAGNOSIS:

DiagnosisGuide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..“................... . . . . . . . . .MAINTENANCE AND ADJUSTMENT:

Adjustment of Thermostatic Switch

. . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal81InstallationBlowerSwitch. . . . . . . . . . . . . . . . . . . . . .Page No.

9B-90

9B-90

9B-90

9B-91

98-92Removal

& Installation Temperature Control Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal

& Installation Resistor Assembly. . . . . . . . . . . . . .Removal

& Installation Blower Motor Assembly . .

SPECIFICATIONS:

Specifications

.,...,,.,,..~.,.,..,,......,.,....,.,........,......,........ ,, . . . . . . .

98-92

98-92

98-92

98-96

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION OF SYSTEMThe air conditioner is intended to give maximum

cooling comfort within the vehicle. To do this, care-

ful attention must be given to the following Sections.

The system operates on recirculated air only and is

entirely independent of the vehicle heater.

Temp KnobThis knob may be regulated to control the degree of

cooling desired. Fully clockwise provides maximum

cooling; however, turning the knob to the center de-

tent position provides adequate cooling for highway

operation.

When maximum cooling is required, outside air

should not be admitted to the car.

Recirculated inside air is drawn into the unit, passed

through the evaporator core and into the car through

the adjustable outlets in the evaporator case.

Operation of ControlsWhen the unit is set for maximum cooling and the

vehicle is being driven continuously at highway

speeds or at elevations of

4,OOC!ft. or more, there is

a possibility of the formation of ice on the evaporator

core fins.

Page 599 of 625

AIR CONDITIONER SYSTEM -OPEL 1900 - MANTA9B- 91FAN DOES NOT RUN Correct electrical fault.

FAN RUNS

- Check air velocity.

NOT OK Clean evaporator inlets.

Clean evaporator core.

Clean evaporator outlets.

OK Check refrigeration (refer to Refrigeration

Diagnosis Guide).

MAINTENANCE AND ADJUSTMENTS

ADJUSTMENT OF THERMOSTATIC SWITCHThe system makes use of a thermostatic switch with

a self-supporting air sensing capillary. This capillary

controls the switch by sensing the temperature of the

air leaving the evaporator fins.

Checking for Proper Operation

I. Install the gauge set and set up the vehicle as

described under FUNCTIONAL TESTING SYS-

TEM iti Refrigerant Components Section.

2. Movement of the temperature control knob

should result in a definite change in suction pressure

and cycling of the compressor clutch.

3. If compressor continues to operate regardless of

the knob adjustment, it indicates that the switch

points are fused, which will lead to evaporator

freeze- up. The switch should be replaced.

Adjusting Switch

If, after ihe foregoing checks, the switch seems to be

operating correctly, adjust for proper setting if neces-

sary, as

~follows:1. Set up car as described in FUNCTIONAL

TESTING SYSTEM in Refrigerant Components

Section.2. The suction side of the system, read on the low

pressure gauge, should pull down to the pressure

shown in the chart in SPECIFICATIONS in Refrig-

erant Components Section.

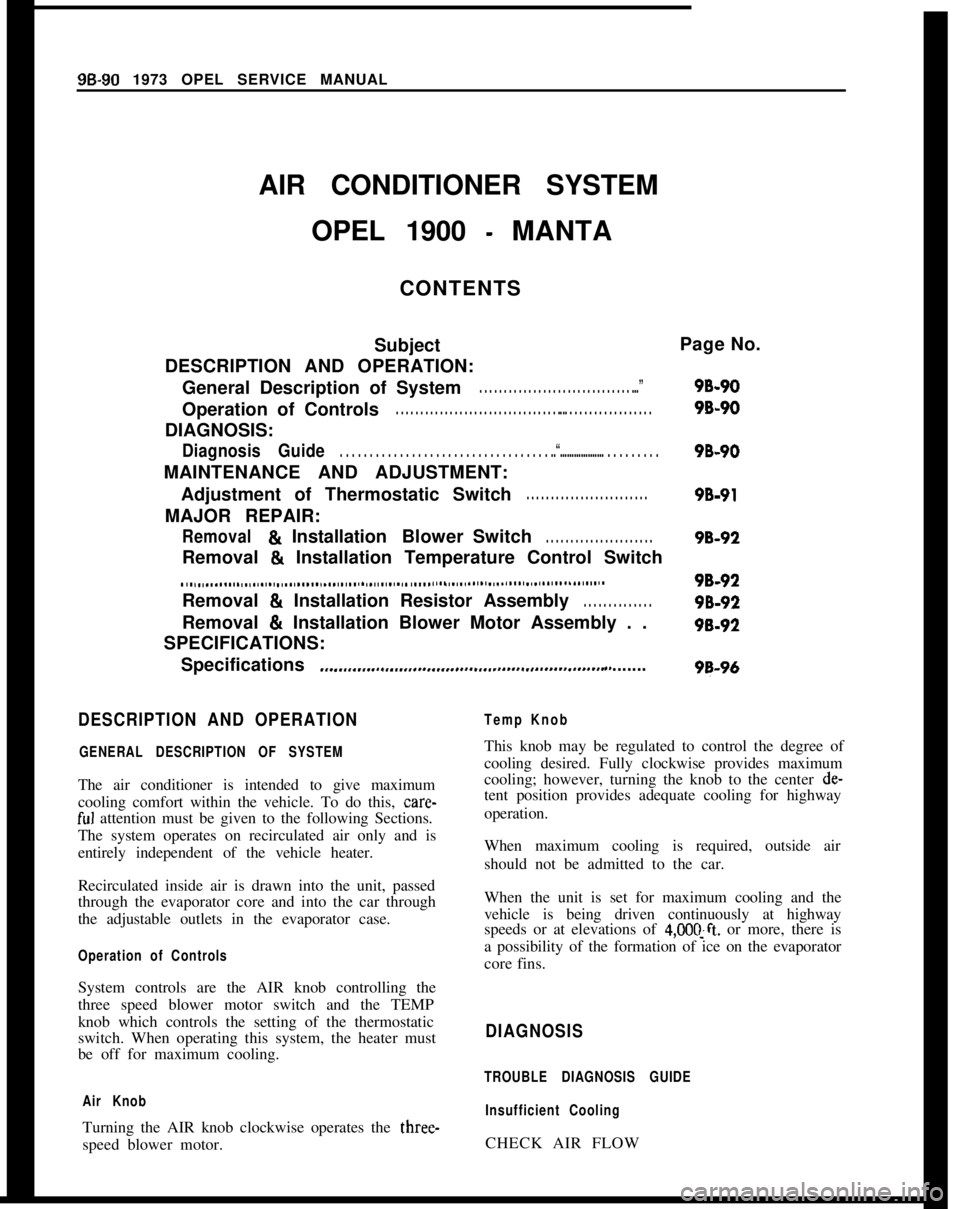

3. Remove the face plate retaining screws and

remove face plate assembly noting the position of the

air sensipg capillary so that it can be reinstalled in

the same location as when removed. See Figure 98.170. ,:Figure

98.170 Location of Air Sensing Capillary

4. Remove the thermostatic switch retaining screws

and remove switch. Remove the non-metal end plate

from the switch to gain access tq the switch adjusting

screw. Check the screw for stripped or otherwise

damaged threads.

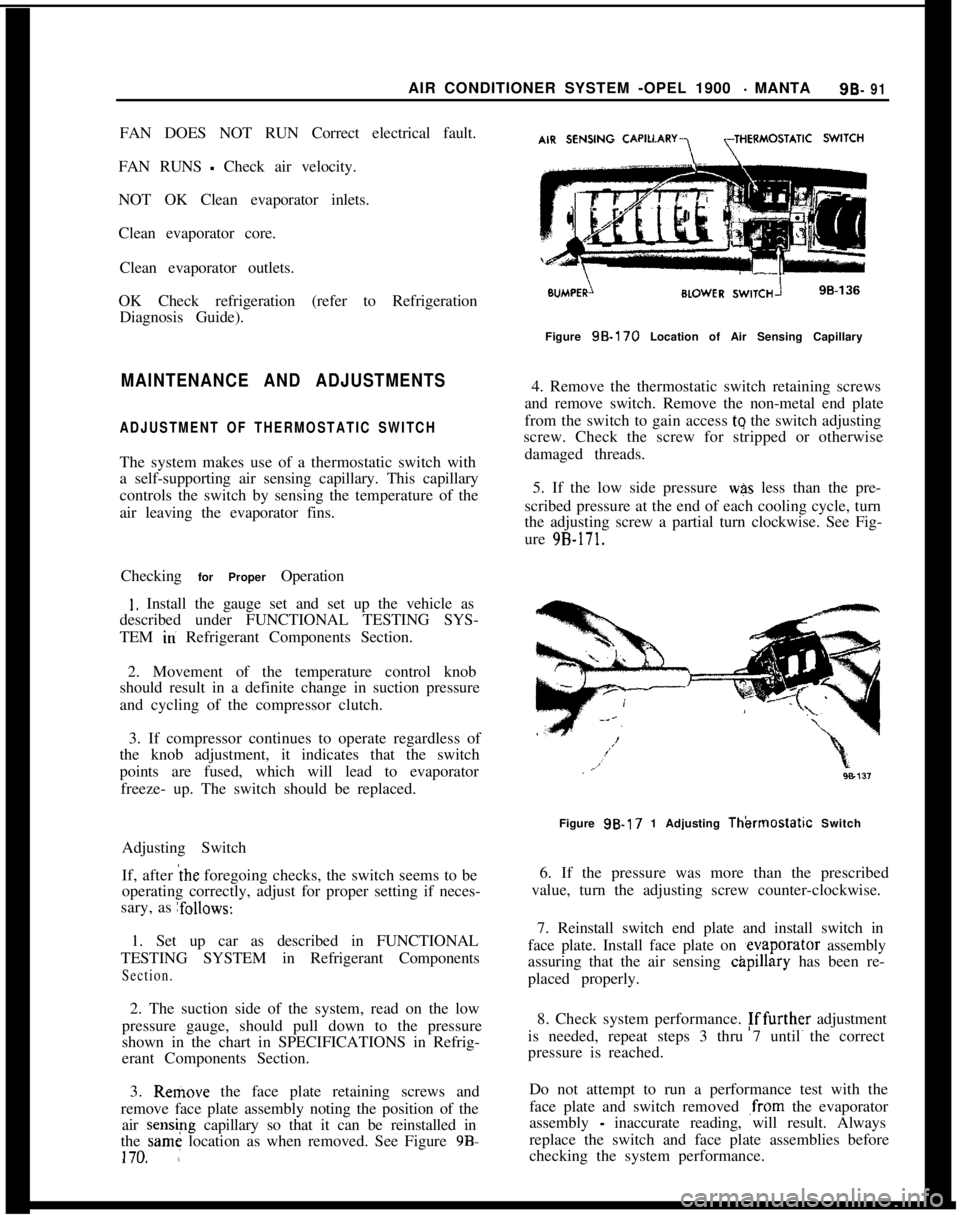

5. If the low side pressure

was less than the pre-

scribed pressure at the end of each cooling cycle, turn

the adjusting screw a partial turn clockwise. See Fig-

ure

9B-171.Figure 9B-17 1 Adjusting

Thkmosfatic Switch

6. If the pressure was more than the prescribed

value, turn the adjusting screw counter-clockwise.

7. Reinstall switch end plate and install switch in

face plate. Install face plate on ,evaporator assembly

assuring that the air sensing

c&pillary has been re-

placed properly.

8. Check system performance. Fffurther adjustment

is needed, repeat steps 3 thru 7 until the correct

pressure is reached.

Do not attempt to run a performance test with the

face plate and switch removed

,from the evaporator

assembly

- inaccurate reading, will result. Always

replace the switch and face plate assemblies before

checking the system performance.

Page 600 of 625

98-92 1973 OPEL SERVICE MANUAL

MAJOR REPAIR

REMOVAL AND INSTALLATION OF BLOWER

SWITCH

Removal

I. Remove the face plate retaining screws and

remove the face plate assembly. See Figure 9B-172.

Figure SE-172 Face Plate Retaining Screws andcontrots

2. Remove the blower switch retaining screws and

remove switch.

Installation

1. Install the blower switch and retainer screws.

2. Install the face plate and secure with the retainer

screws. See Figure

9B-372.

REMOVAL AND INSTALLATION OF

TEMPERATURE CONTROL SWITCH

Removal

1. Remove the face plate retaining screws and

remove the face plate assembly noting the position of

the air sensing capillary so that it can be reinstalled

in the same location as when removed. See Figure

9B- 173.

2. Remove the temperature control switch retaining

screws and remove switch.

AIR SENSING CAPILLARY,yT,,ERMOSTATIC SWITCH

!IBUMPERBLOWER SWITCH98-136

Figure SB-173 Location of Air Sensing Capillary

Installation

1. Install the temperature control switch and secure

with the retaining screws.

2. Position the air sensing capillary in the exact

location as was noted when removing.

3. Install the face plate and secure with the retain-

ing screws. See Figure

9B-172.

REMOVAL AND INSTALLATION OF RESISTOR

ASSEMBLY

Removal

1. Disconnect the negative battery cable.

2. Remove the glove box assembly. 3. Disconnect the electrical plug from the resistor

assembly. See Figure

9B-176.

4. Remove two (2) screws and remove resistor as-

sembly.

Installation

1. Install the resistor assembly and secure with two

(2) screws.

2. Install the electrical plug onto the resistor assem-

bly. See Figure

9B-176.

3. Install the glove box assembly.

4. Connect the negative battery cable.

REMOVAL AND INSTALLATION OF BLOWER

MOTOR ASSEMBLY

REMOVAL

1. Remove the negative battery cable from the bat-

tery.