OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 571 of 625

98-62 1973 OPEL SERVICE MANUAL

Figure 98.99 Refrigerant Hoses Retainer Grommet

-Under Car - GT

8. From under car install four (4) nuts securing

evaporator mounting bracket to floor. See Figures9B- 92 and

9B-93.Figure 98.100 Refrigerant Hoses

- Under Car GT

9. Evacuate system. Refer to EVACUATING SYS-

TEM.

10. While system is being evacuated, connect drain

hoses underneath evaporator housing.

11. Plug in the resistor assembly electrical connector

plug and connect the blower motor connection and

install ground wire and 2 mounting brackets to case

screws using the rearward holes. See Figure

9B-90.12. Install the evaporator cover and all cover screws.

See Figure

9B-88.13. Install luggage tray and attaching screws. See

Figure

9B-87.14. Connect the negative battery cable.

15. Charge system. Refer to CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF CONDENSERRECIWER- DEHYDRATOR ASSEMBLY

- GT

Removal

1. Disconnect negative battery cable.

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While the system is discharging, remove the

charcoal cannister, washer jar, battery and battery

tray. Battery needs only to be set up out of the way

and not removed from the car.

4. Disconnect inlet and outlet pipes of condenser

receiver-dehydrator and tape closed the open ends of

refrigerant lines, and also the open ends of the inlet

and outlet pipes of the condenser. See Figure 9B-101.

5. Disconnect discharge line from condenser and

tape closed open ends of discharge pipe and con-

denser inlet.

6. Remove 4 condenser attaching screws and lift out

condenser. See Figure 9B-101.

7. Remove 2 screws retaining receiver-dehydrator

to condenser and remove.

Figure

9B-101 Receiver - Dehydrator. Condenser

Attaching Screws and Brackets

- GT

Installation

If refrigerant circuit or condenser has been exposed

to the atmosphere and moisture may be present in

the circuit, the system and/or component must be

flushed prior to installation. Refer to FLUSHING

THE SYSTEM.

1. Install receiver-dehydrator to condenser and fas-

ten with 2 clamps and 2 screws.

Page 572 of 625

REFRIGERANT COMPONENTS ALL MODELSSB-632. Install condenser into car and secure with 4 at-

taching screws. See Figure

9B-101.3. Untape discharge line and pipe and install using

new o-rings lubricated with No. 525 viscosity oil.

Figure

99.102 Condenser - Receiver - Dehydrator

O-Rings. GT

4. Untape and install inlet and outlet pipes into the

receiver-dehydrator using new o-rings lubricated

with No. 525 viscosity oil.

Figure

98-103 Condenser Assembly - GT

5. Evacuate system. Refer to EVACUATING SYS-

TEM.

6. While system is being evacuated, install the char-

coal cannistor, washer jar, battery tray and battery

and connect negative battery cable.

7. Charge system. Refer to CHARGING SYS-

TEM.

DISASSEMBLY AND REASSEMBLY OF CLUTCH

DRIVE PLATE AND SHAFT SEALIt is not necessary to remove the compressor or dis-connect refrigerant lines to remove or install clutch

parts on the GT, however, the compressor must be

removed from the Opel 1900

- Manta.

Disassembly

1. Firmly clamp holding fixture (J-9396) in a vise

and attach compressor assembly to fixture (see Figwe

9B-104).

-_ .s -Figure SE-104 Removing or Installing Shaft Nut

2. Hold hub of clutch drive plate with wrench

(J-9403). Using special thin wall 9/16 inch socket

(J-9399) and 3/g inch drive, remove shaft nut.

3. Install threaded hub puller (J-9401) onto hub of

clutch drive plate (see Figure

9B-105). Hold body of

hub puller with wrench, tighten center screw of hub

puller, and lift off clutch drive plate and woodruff

key.Figure SE-105 Removing Clutch Drive Plate

Page 573 of 625

9B-64 1973 OPEL SERVICE MANUAL

4. Using No. 21 Truarc pliers (J-5403) take out

retainer ring from hub of clutch drive plate (see Fig-

ure 9B-106). Lift our spacer.

Figure 95.106 Removing

or Installing Retainer Ring inClutch Drive Plate5. If compressor has an absorbent sleeve in the neck,

pry out the sleeve retainer and remove the sleeve.

Remove the seal seat retainer ring, using No. 21

Truarc pliers, Tool J-5403, (see Figure

9B-107).

SEAL SEATFigure 98.107 Removing or Installing Shaft Seal Seat

Retaining Ring6. Thoroughly clean the area inside the compressor

neck surrounding the shaft, the

ezxposed portion of

the seal seat and the shaft itself of any dirt or foreign

material. This is absolutely necessary to prevent any

such material from getting into

t:he compressor.

7. Remove the seal seat (see Figure 9B-108) using

Tool J-23128. Insert Tool

J-2312E; into seal seat and

tighten, using a twisting motion remove the seal seat.96-82

Figure SE-108 Removing or Installing Ceramic Shaft

Seal seat

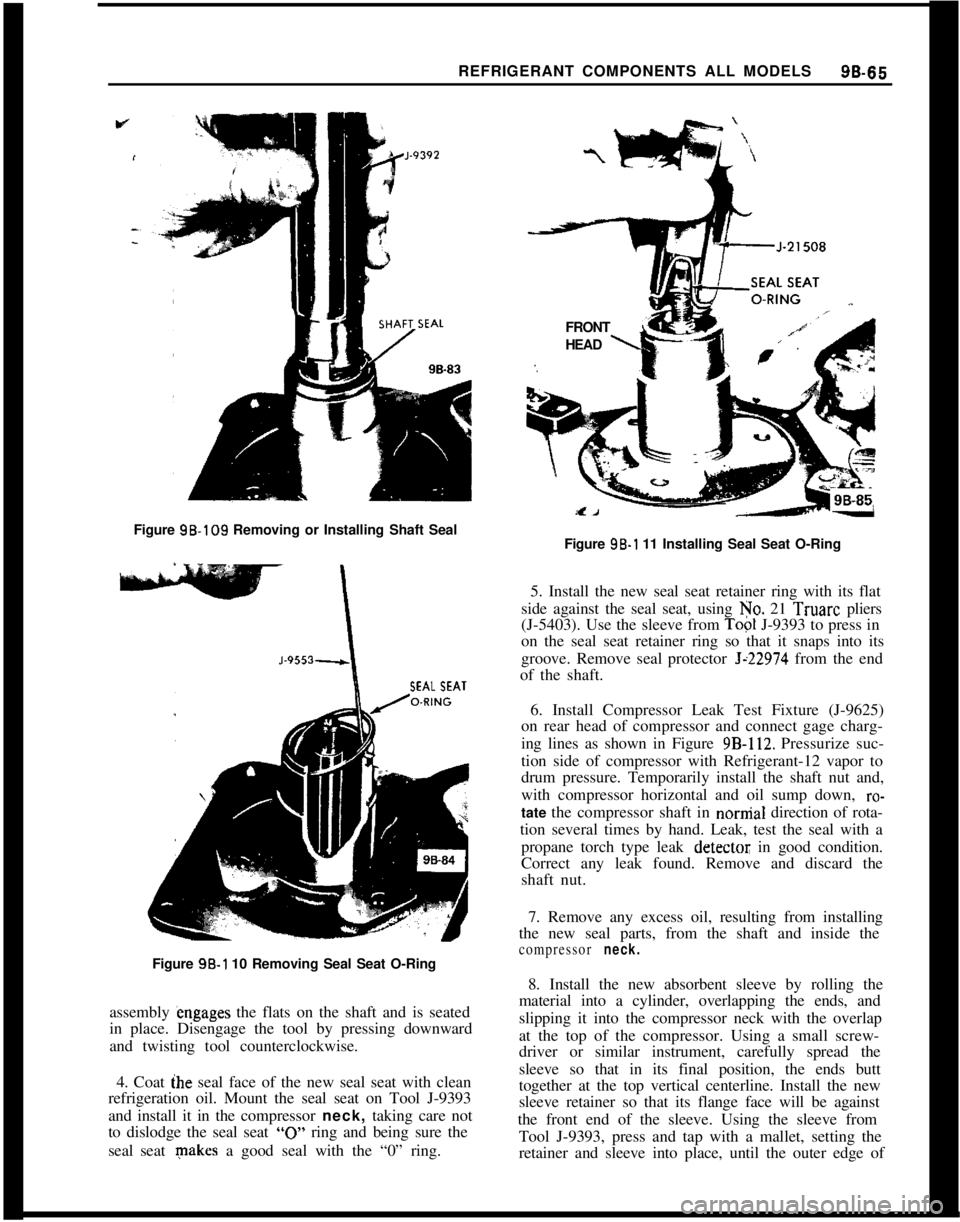

8. Remove the seal assembly, using Tool J-9392.

Press tool downward on seal while twisting it clock-

wise to engage the tabs of the seal assembly. Gently

but firmly, pull tool straight out (see Figure

9B-109).9. Remove the seal seat

“0” ring, using Tool J-9553

(see Figure

9B-110).10. Recheck the inside of the compressor neck and

the shaft. Be sure these areas are perfectly clean

before installing new parts.

Reassembly

1. Coat the new seal seat

“0” ring with clean refrig-

eration oil and install it in its groove in the compres-

sor neck. Tool J-21508 may be used to accomplish

this. (See Figure

9B;,lll)2. Coat the

“0” ring and seal face of the new seal

assembly with clean refrigeration oil. Carefully

mount the seal assembly to Tool J-9392 by engaging

the tabs of the seal with the tangs of the tool.

3. Place seal protector, Tool J-22974, over end of

shaft and carefully slide the new seal assembly onto

the shaft. Gently twist the tool clockwise while push-

ing the seal assembly down the shaft until the seal

Page 574 of 625

REFRIGERANT COMPONENTS ALL MODELS96-66Figure 98.109 Removing or Installing Shaft Seal

SEAL SEAT

-Figure 98-l 10 Removing Seal Seat O-Ring

assembly engages the flats on the shaft and is seated

in place. Disengage the tool by pressing downward

and twisting tool counterclockwise.

4. Coat ihe seal face of the new seal seat with clean

refrigeration oil. Mount the seal seat on Tool J-9393

and install it in the compressor neck, taking care not

to dislodge the seal seat

“0” ring and being sure the

seal seat makes a good seal with the “0” ring.FRONT

L’HEAD

\Figure 96-l 11 Installing Seal Seat O-Ring

5. Install the new seal seat retainer ring with its flat

side against the seal seat, using No. 21 Truarc pliers

(J-5403). Use the sleeve from

Top1 J-9393 to press in

on the seal seat retainer ring so that it snaps into its

groove. Remove seal protector

Jz22974 from the end

of the shaft.

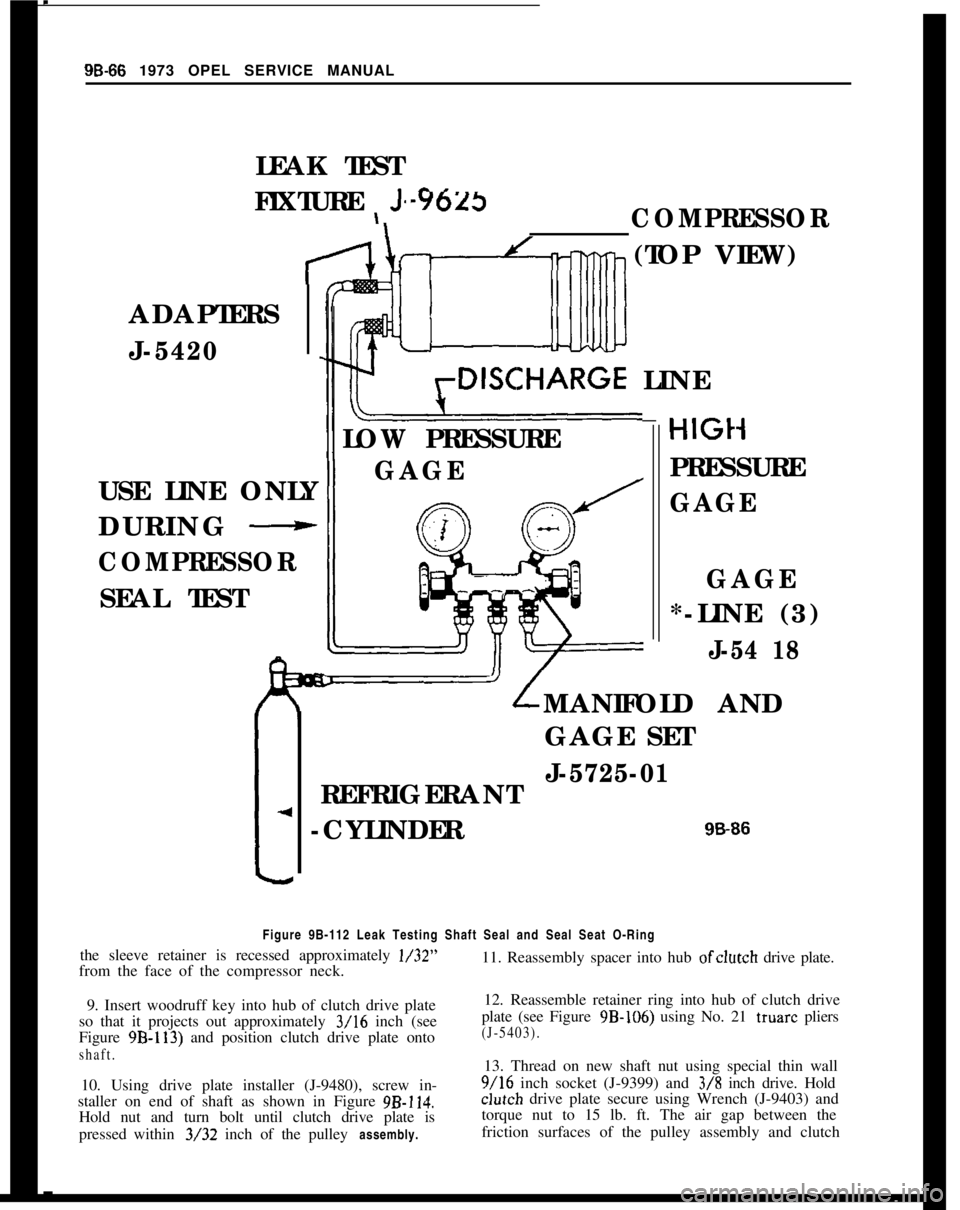

6. Install Compressor Leak Test Fixture (J-9625)

on rear head of compressor and connect gage charg-

ing lines as shown in Figure

9B-112. Pressurize suc-

tion side of compressor with Refrigerant-12 vapor to

drum pressure. Temporarily install the shaft nut and,

with compressor horizontal and oil sump down,

ro-tate the compressor shaft in nornial direction of rota-

tion several times by hand. Leak, test the seal with a

propane torch type leak

detectot; in good condition.

Correct any leak found. Remove and discard the

shaft nut.

7. Remove any excess oil, resulting from installing

the new seal parts, from the shaft and inside the

compressor neck.8. Install the new absorbent sleeve by rolling the

material into a cylinder, overlapping the ends, and

slipping it into the compressor neck with the overlap

at the top of the compressor. Using a small screw-

driver or similar instrument, carefully spread the

sleeve so that in its final position, the ends butt

together at the top vertical centerline. Install the new

sleeve retainer so that its flange face will be against

the front end of the sleeve. Using the sleeve from

Tool J-9393, press and tap with a mallet, setting the

retainer and sleeve into place, until the outer edge of

Page 575 of 625

9B-66 1973 OPEL SERVICE MANUAL

LEAK TEST

FIXTURE

\ Js - s ---Y623

\COMPRESSOR

ADAPTERS

J-5420

USE LINE ONLY

DURING

-

COMPRESSOR

SEAL TEST

-4

-

It-’rDISCHARGE LINE

-

LOW PRESSUREHIGt

GAGE

4

PRESSURE

GAGE

(TOP VIEW)

GAGE

*-LINE (3)

J-54 18

GAGE SET

REFRIGERANT

J-5725-01

-CYLINDER

LMANIFOLD AND

9&86

Figure 9B-112 Leak Testing Shaft Seal and Seal Seat O-Ring

the sleeve retainer is recessed approximately l/32”

from the face of the compressor neck. 11. Reassembly spacer into hub ofclutch

drive plate.

9. Insert woodruff key into hub of clutch drive plate

so that it projects out approximately

3/16 inch (see

Figure

9B-113) and position clutch drive plate onto

shaft.

10. Using drive plate installer (J-9480), screw in-

staller on end of shaft as shown in Figure

9B-114.

Hold nut and turn bolt until clutch drive plate is

pressed within

3/32 inch of the pulley assembly.

12. Reassemble retainer ring into hub of clutch drive

plate (see Figure

9B-106) using No. 21 truarc pliers

(J-5403).

13. Thread on new shaft nut using special thin wall

9/16 inch socket (J-9399) and 3/8 inch drive. Hold

clut~ch drive plate secure using Wrench (J-9403) and

torque nut to 15 lb. ft. The air gap between the

friction surfaces of the pulley assembly and clutch

Page 576 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 67

Figure 9B-1 13 Positioning Clutch Drive Plate on Shaft

PLATE ON UNTlL THERE

IS APPROXIMATELY

3/32”-

. l m l GAP BETWEEN SURFACE

OF

PLATFigure

98-1 14 Installing Clutch Drive Plate

drive plate should be approximately l/32 to l/16

inch (see Figure

9B-115).

Flgure 98-1 16 Torquing Shaft Nut

BE98.89

DISASSEMBLY OF PULLEY ASSEMBLY, AND

COIL AND HOUSING ASSEMBLY

It is not necessary to remove the compressor or dis-connect refrigerant lines to remove or install clutch

parts on the GT, however, the compressor must be

removed from the Opel 1900

- Manta.

Disassembly

1. Disassemble clutch drive plate.

2. Using No. 26 Truarc pliers (J-6435) remove bear-ing to head retainer ring (see Figure

9B-116).Figure

9B-1 16 Removing or Installing Bearing to

Head Retainer Ring3. Place puller pilot (J-9395) on,hub of front head

and take off pulley assembly (see Figure

9B-117),using pulley puller (J-8433).

Puller pilot (J-9395) must be used. If force is exertedon shaft, damage will result to the internal parts of

the compressor.4. Remove bearing to pulley retaining ring with a

small screwdriver (see Figure

9B-118).5. Drive out bearing (see Figure

9B-119) by use of

puller Pilot (J-9398) and Handle (J-8092).

Do not take out pulley bearing unless it is going to

be replaced as removal may damage bearing.6. Mark position of coil and housing assembly in

relationship to shell of compressor, remove coil and

housing retainer ring (see Figure

9B-120) using No.

Page 577 of 625

98-68 1973 OPEL SERVICE MANUAL

J-9395:

Figure 9B-1 17 Removing Pulley Assembly

Figure

9B-1 10 Removing Pulley Bearing Retainer

26 truarc pliers (J-6435), and lift out coil and housing

assembly.

Reassembly

1. Reassemble coil and housing assembly reverse of

disassembly.

2. Drive new bearing into pulley assembly (see Fig-

ure 9B-121) with installer (J-9481) and handle

(J-

8092).3. Lock bearing in position with bearing to pulley

retainer ring (see Figure 9B-118).

4. Drive pulley assembly onto hub of front head (seeFigure 99-l 19 Removing Bearing From Pulley

AssemblyFigure 9B-120 Removing or Installing Coil and

Housing Retainer Ring

Figure 9B-122) using installer (J-9481) and handle

(J- 8092).

If the pulley assembly is going to be reused, clean thefriction surface with trichlorethylene, alcohol, or a

similar solvent.

5. Lock pulley assembly in position with bearing to

head retainer ring (flat side of retainer ring down-

ward) using No. 26 Truarc pliers (J-6435). (See Fig-

ure

9B-116).

Page 578 of 625

REFRIGERANT COMPONENTS ALL MODELS96.69

J-9481\J-8092

/BEARING

Disassembly of Rear Head, Oil Pump, Rear

Discharge Valve Plate, and Rear Suction Valve

Reed Disc

If compressor is not going to be disassembled any

further than removal of rear head, oil pump, rear

discharge valve plate, or rear suction valve reed disc,

omit Steps “1, 2 and

4”.

1. Disassemble clutch drive plate and shaft seal.

2. Disassemble pulley assembly, and coil and hous-

ing assembly.

3. Clean surface of compressor shell and dry with

compressed air.

4. Remove compressor from holding fixture

(J-

9396), unscrew drain screw. Drain, measure and re-

cord amount of oil in compressor.

Figure

98-121 Installing Bearing into Pulley Assembly 5. Reinstall compressor in holding fixture (J-9396)

positioned as shown in Figure 9B-123.

Figure SB-122 Installing Pulley Assembly

6. Reassemble clutch drive plate.

DISASSEMBLY AND REASSEMBLY OF INTERNAL

PARTS OF COMPRESSOR AND LEAK TESTING

COMPRESSOR

A clean work area and a place for each part removed

is required to properly disassemble and reassemble compressor. The internal parts of the compressor

must be kept free of dirt or foreign material.

When working with compressor, under no circum-

stances should compressor be rested on pulley end.

PRESSURE

Figure 96.123 Compressor Installed in Holding

Fixture

6. Unscrew and discard four lock nuts from rear of

compressor, and lift off rear head by tapping it with

a mallet. If Teflon sealing surface is damaged (see

Figure

9B-124), replace rear head. Clean or replace

suction screen as necessary.

7. Pencil mark top side of both oil pump rotors and

lift out rotors. Replace both oil pump inner and outer

rotors if one or both are damaged or worn.

Page 579 of 625

9B-70 1973 OPEL SERVICE MANUAL

SUCTION

SCREENTEFLON Iut 98-98

Figure 96-l 24 Rear Head Removal

8. Take out and discard shell to head

“0” ring.

9. Carefully pry out rear discharge valve plate and

rear suction valve reed disc with screwdrivers (seeFigures 9B-125 and

9B-126). Check both pieces and

replace as necessary.During disassembly, the disc generally adheres to the

plate and both pieces lift out together.

Figure 96-l 25 Removing Rear Discharge Valve Plate

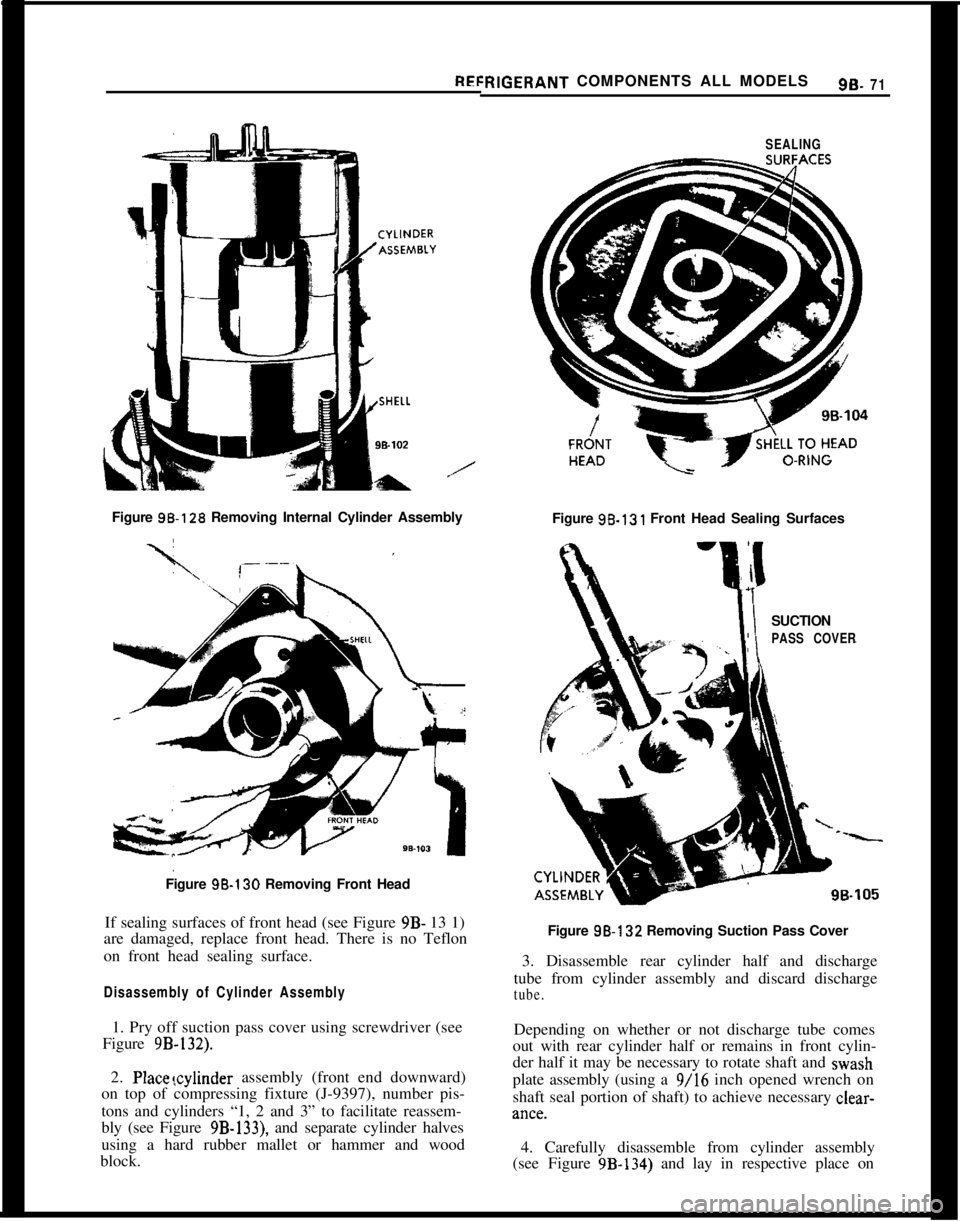

Removing Cylinder Assembly, and Disassembly of

Front Suction Valve Reed Disc, Front Discharge

Valve Plate, and Front Head1. Pull out oil inlet tube (see Figure 9B-127) and oil

inlet tube

“0” ring using Remover (J-6586).Figure 96-l 26 Removing Rear

SfJction Valve ReedDiscFigure 98-127 Removing Oil Inlet Tube

2. Push shaft upward from front head and lift out

cylinder assembly (see Figure 9B-128), front suction

valve reed disc, and front discharge valve plate.

When lifting out the cylinder assembly, the front

suction valve reed disc and the front discharge valve

plate generally adhere to the cylinder assembly and

lift out with it. Check and replace if necessary.

Depending on wear or damage to cylinder assembly,

it may be advisable to replace complete cylinder as-

sembly. If service replacement cylinder is used omit

following steps and continue on with subparagraph

entitled “FINAL REASSEMBLY OF CYLINDER

ASSEMBLY”.

3. Disassemble front head from shell by tapping

front head with a mallet to unseat head, and lifting

straight out through rear of shell the front head and

shell to head

“0” ring (see Figure 9B-130). Discard

“0” ring.

Page 580 of 625

REI:RIGERANT COMPONENTS ALL MODELS9s. 71

/Figure 9%128 Removing Internal Cylinder Assembly

Figure 9B-130 Removing Front Head

If sealing surfaces of front head (see Figure 9B- 13 1)

are damaged, replace front head. There is no Teflon

on front head sealing surface.

Disassembly of Cylinder Assembly1. Pry off suction pass cover using screwdriver (see

Figure

9B-132).2. Placevzylinder assembly (front end downward)

on top of compressing fixture (J-9397), number pis-

tons and cylinders “1, 2 and 3” to facilitate reassem-

bly (see Figure

9B-133), and separate cylinder halves

using a hard rubber mallet or hammer and wood

block.

SEALINGFigure 96.131 Front Head Sealing Surfaces

SUCTION

PASS COVERFigure 98-132 Removing Suction Pass Cover

3. Disassemble rear cylinder half and discharge

tube from cylinder assembly and discard discharge

tube.Depending on whether or not discharge tube comes

out with rear cylinder half or remains in front cylin-

der half it may be necessary to rotate shaft and wash

plate assembly (using a 9/16 inch opened wrench on

shaft seal portion of shaft) to achieve necessary clear-kl”Ct?.

4. Carefully disassemble from cylinder assembly

(see Figure 9B-134) and lay in respective place on