OPEL KARL 2015 Owners Manual

Manufacturer: OPEL, Model Year: 2015, Model line: KARL, Model: OPEL KARL 2015Pages: 217, PDF Size: 4.16 MB

Page 181 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

180 Vehicle Care

Tyres age, even if they are not

used. We recommend tyre

replacement every 6 years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may

be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and to make other

vehicle modifications

After converting to a different tyre

size, have the label with tyre

pressures replaced.

{Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel Covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.If the wheel covers and tyres used

are not factory approved, the tyres

must not have a rim protection

ridge.

Wheel covers must not impair brake

cooling.

{Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre Chains

Tyre chains are only permitted on

the front wheels.

Always use fine mesh chains that

add no more than 10 mm to the tyre

tread and the inboard sides

(including chain lock).

{Warning

Damage may lead to tyre

blowout.

Tyre chains are only permitted on

tyres of size 165/65 R14.

Tyre chains are not permitted on

tyres of size 185/55 R15 and

195/45 R16.

The use of tyre chains is not

permitted on the temporary spare

wheel.

Tyre Repair Kit

Minor damage to the tyre tread can

be repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Page 182 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

Vehicle Care 181

Tyre damage exceeding 4 mm or

that is at tyre's side wall near the

rim cannot be repaired with the tyre

repair kit.

{Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre :

Apply the parking brake.

For manual gearbox, engage first

gear or reverse gear.

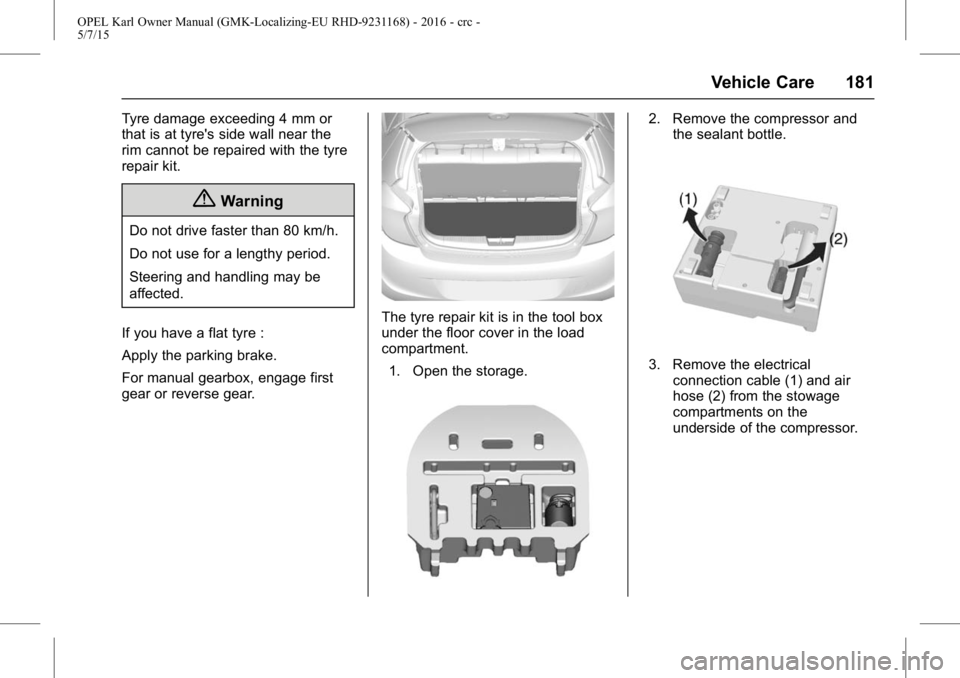

The tyre repair kit is in the tool box

under the floor cover in the load

compartment. 1. Open the storage.

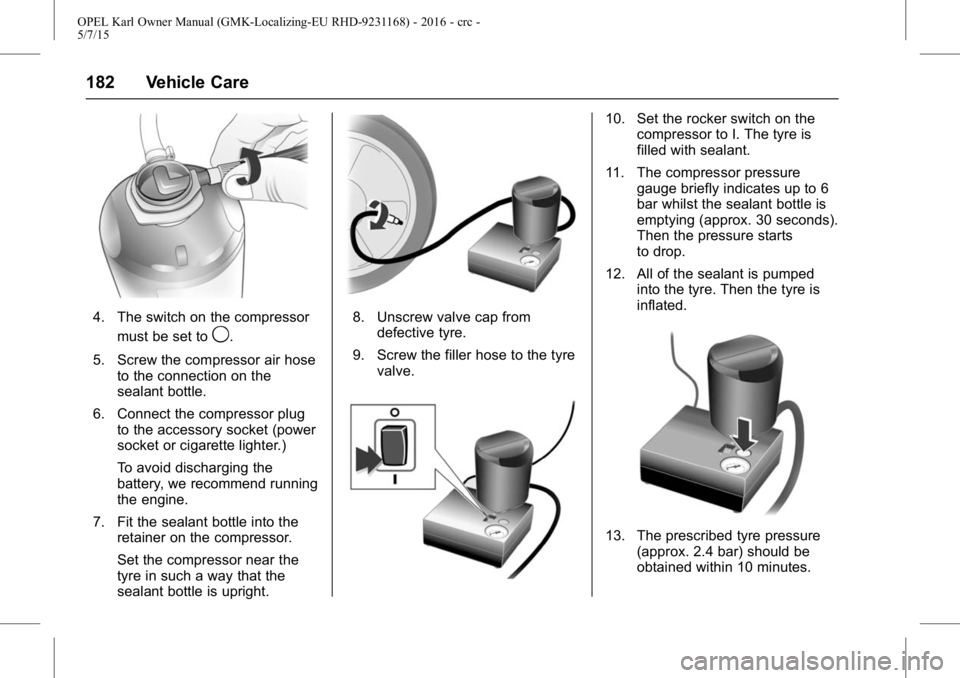

2. Remove the compressor and the sealant bottle.

3. Remove the electricalconnection cable (1) and air

hose (2) from the stowage

compartments on the

underside of the compressor.

Page 183 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

182 Vehicle Care

4. The switch on the compressormust be set to

9.

5. Screw the compressor air hose to the connection on the

sealant bottle.

6. Connect the compressor plug to the accessory socket (power

socket or cigarette lighter.)

To avoid discharging the

battery, we recommend running

the engine.

7. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the

tyre in such a way that the

sealant bottle is upright.

8. Unscrew valve cap from

defective tyre.

9. Screw the filler hose to the tyre valve.

10. Set the rocker switch on the compressor to I. The tyre is

filled with sealant.

11. The compressor pressure gauge briefly indicates up to 6

bar whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts

to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is

inflated.

13. The prescribed tyre pressure(approx. 2.4 bar) should be

obtained within 10 minutes.

Page 184 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

Vehicle Care 183

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure

is not obtained within

10 minutes, remove the tyre

repair kit. Move the vehicle one

tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure

for 10 minutes. If the

prescribed tyre pressure is still

not obtained, the tyre is too

badly damaged. Seek the

assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure

indicator.

Do not run the compressor

longer than 10 minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket.

Screw tyre inflation hose to

free connection of sealant

bottle. This prevents sealant

from escaping.

Stow tyre repair kit in tailgate. 15. Remove any excess sealant

using a cloth.

16. Take the label indicating maximum permitted speed

(approx. 80km/h) from the

sealant bottle and affix in the

driver's field of view.

17. Continue driving immediatelyso that sealant is evenly

distributed in the tyre. After

driving approx.

10 km (but no more than

10 minutes), stop and check

tyre pressure. Screw compressor air hose directly

onto tyre valve and compressor

when doing this.

If tyre pressure is more than

1.3 bar, set it to the correct

value (approx.2.4 bar).

Repeat the procedure until

there is no more loss of

pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the

assistance of a workshop.

18. Stow away tyre repair kit in tailgate.

Note

The driving characteristics of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Page 185 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

184 Vehicle Care

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle.

Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30°C ~ 70°C

(-22 ~ 158°F).

Tyre Changing

Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

Make the following preparations and

observe the following information :

.Park the vehicle on a level, firm

and non-skid surface. The front

wheels must be in the

straight-ahead position.

. Apply the parking brake.

For manual gearbox, engage

first gear or reverse gear.

. Remove the spare wheel. See "Temporary spare wheel"

under

Compact Spare

Tyre 0186.

. Never change more than one

wheel at once.

. Use the jack only to change

wheels in case of puncture, not

for seasonal winter or summer

tyre change. The jack is

maintenance-free.

. If the ground on which the

vehicle is standing is soft, a solid

board (max. 1cm (0.4 inches)

thick) should be placed under

the jack. Take heavy objects out

of the vehicle before jacking up.

. No people or animals may be in

the vehicle when it is jacked-up.

. Never crawl under a jacked-up

vehicle.

. Do not start the vehicle when it

is raised on the jack.

. Clean wheel nuts and thread

before mounting the wheel.

Do not grease wheel bolt, wheel

nut and wheel nut cone.

Wheel changing

Make the following preparations and

observe the following information:

.Park the vehicle on a level, firm

and non-skid surface. The front

wheels must be in the

straight-ahead position.

. Apply the parking brake and

engage first gear, reverse gear

or P.

. Never change more than one

wheel at once.

. Use the jack only to change

wheels in case of puncture, not

for seasonal winter or summer

tyre change.

. The jack is maintenance-free.

. If the ground on which the

vehicle is standing is soft, a solid

board (max. 1 cm thick) should

be placed under the jack.

. Take heavy objects out of the

vehicle before jacking up.

. No people or animals may be in

the vehicle when it is jacked-up.

Page 186 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

Vehicle Care 185

.Never crawl under a jacked-up

vehicle.

. Do not start the vehicle when it

is raised on the jack.

. Clean wheel nuts and thread

with a clean cloth before

mounting the wheel.

{Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Steel wheels:

Pull off the wheel cover.

Alloy wheels with bolt caps:

Disengage wheel bolt caps

with a screwdriver and remove.

To protect the wheel, place a

soft cloth between the

screwdriver and the alloy

wheel.

Alloy wheels with centre cap:

Insert extractor in the open slot

of the centre cap and withdraw

the cap from the wheel. Vehicle

tools

0Tools 0173.

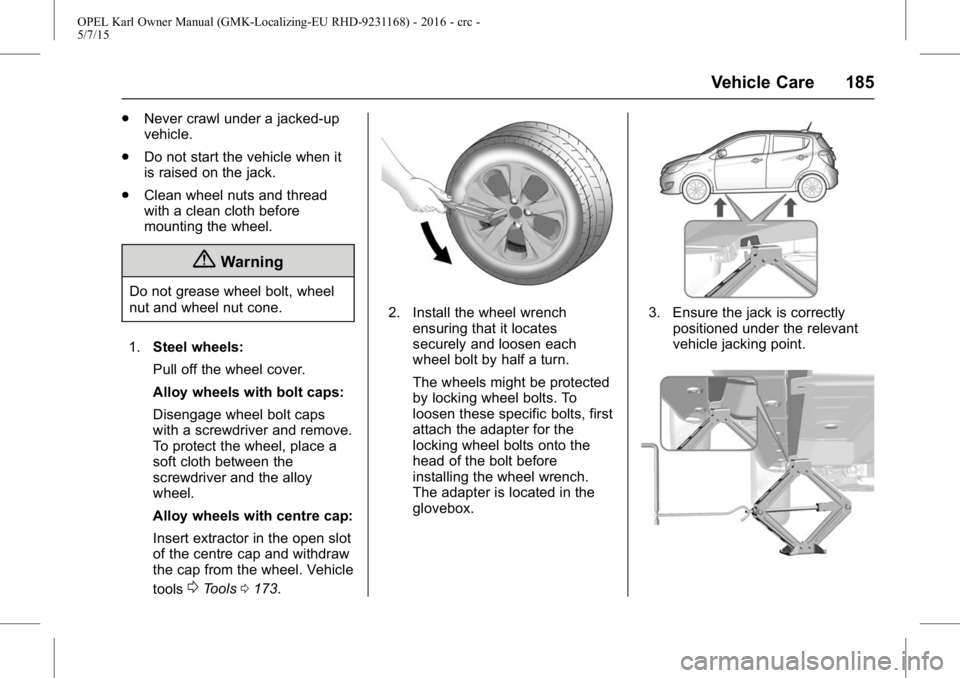

2. Install the wheel wrench

ensuring that it locates

securely and loosen each

wheel bolt by half a turn.

The wheels might be protected

by locking wheel bolts. To

loosen these specific bolts, first

attach the adapter for the

locking wheel bolts onto the

head of the bolt before

installing the wheel wrench.

The adapter is located in the

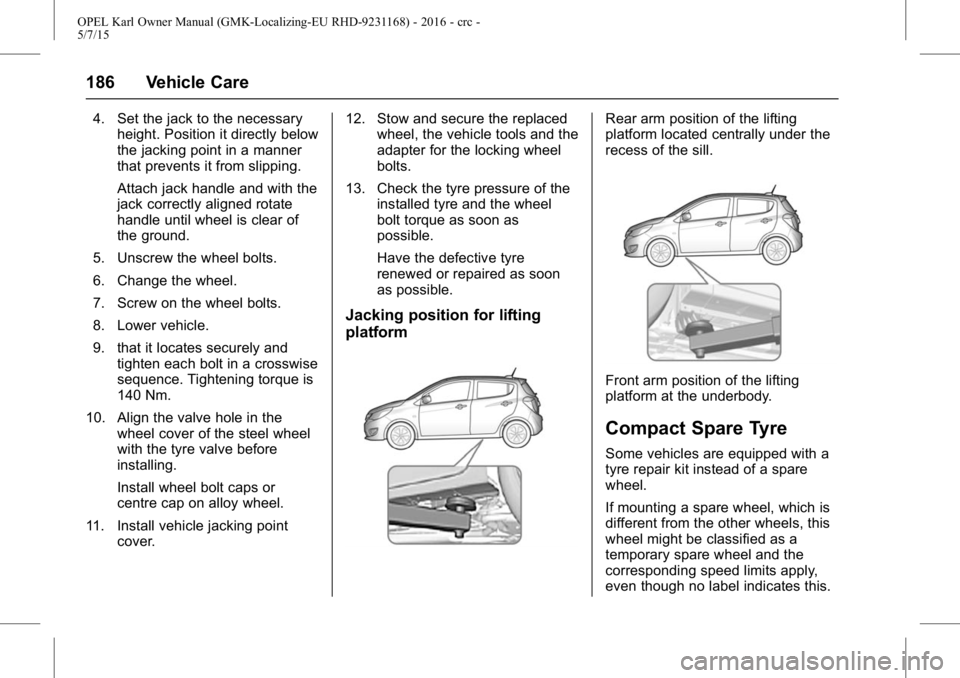

glovebox.3. Ensure the jack is correctlypositioned under the relevant

vehicle jacking point.

Page 187 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

186 Vehicle Care

4. Set the jack to the necessaryheight. Position it directly below

the jacking point in a manner

that prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate

handle until wheel is clear of

the ground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. that it locates securely and tighten each bolt in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover of the steel wheel

with the tyre valve before

installing.

Install wheel bolt caps or

centre cap on alloy wheel.

11. Install vehicle jacking point cover. 12. Stow and secure the replaced

wheel, the vehicle tools and the

adapter for the locking wheel

bolts.

13. Check the tyre pressure of the installed tyre and the wheel

bolt torque as soon as

possible.

Have the defective tyre

renewed or repaired as soon

as possible.

Jacking position for lifting

platform

Rear arm position of the lifting

platform located centrally under the

recess of the sill.

Front arm position of the lifting

platform at the underbody.

Compact Spare Tyre

Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Page 188 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

Vehicle Care 187

Seek the assistance of a workshop

to check the applicable speed limit.

The spare wheel has a steel rim.

Caution

Use of a spare wheel that is

smaller than the other wheels or

together with winter tyres could

affect drive ability. Have the

defective tyre replaced as soon

as possible.

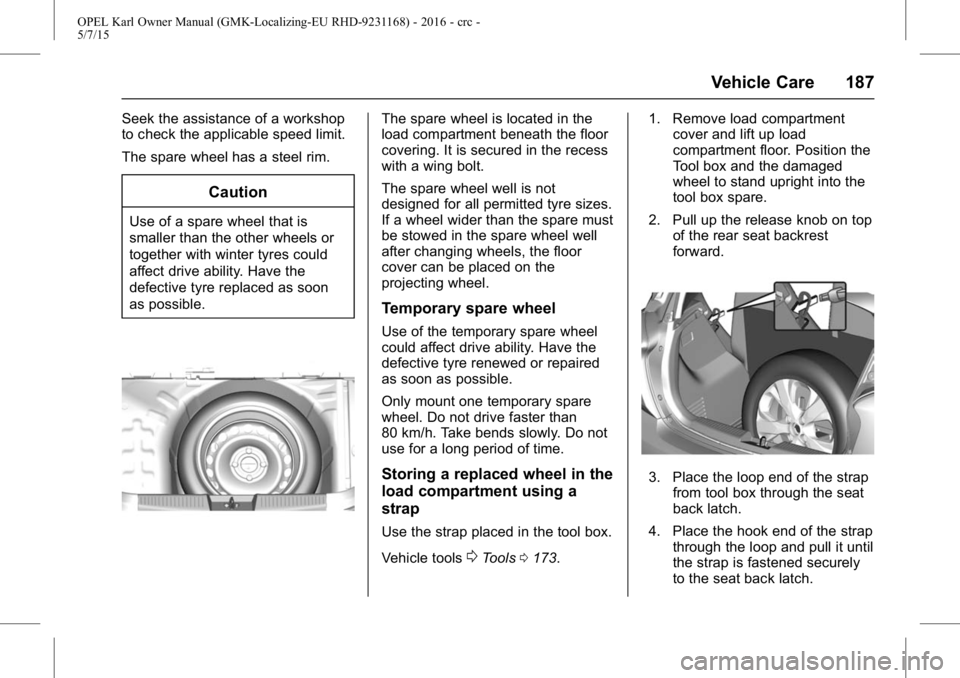

The spare wheel is located in the

load compartment beneath the floor

covering. It is secured in the recess

with a wing bolt.

The spare wheel well is not

designed for all permitted tyre sizes.

If a wheel wider than the spare must

be stowed in the spare wheel well

after changing wheels, the floor

cover can be placed on the

projecting wheel.

Temporary spare wheel

Use of the temporary spare wheel

could affect drive ability. Have the

defective tyre renewed or repaired

as soon as possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take bends slowly. Do not

use for a long period of time.

Storing a replaced wheel in the

load compartment using a

strap

Use the strap placed in the tool box.

Vehicle tools

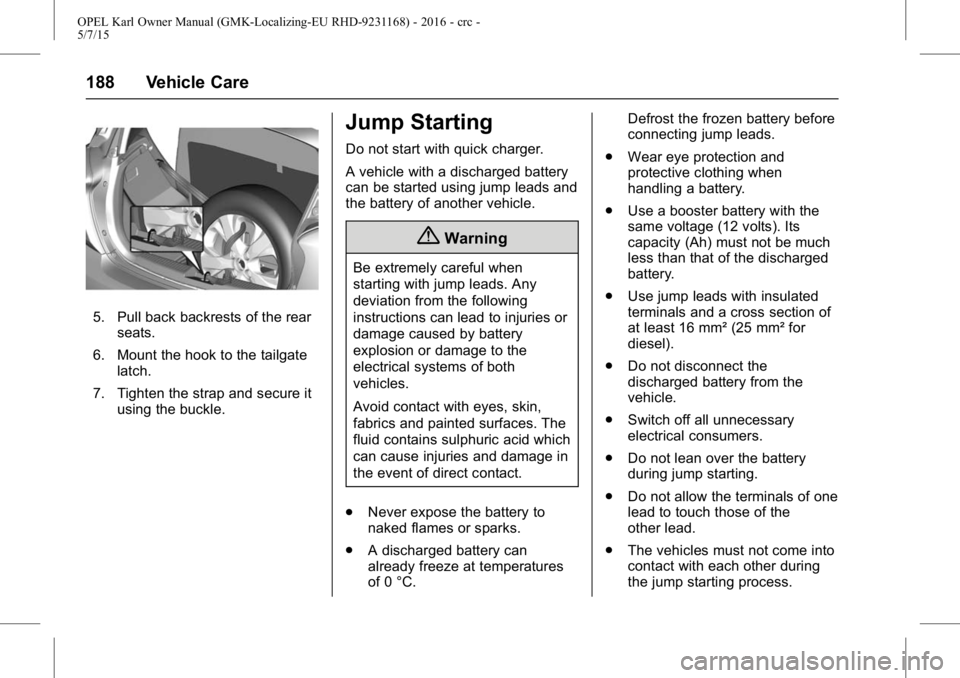

0Tools0173. 1. Remove load compartment

cover and lift up load

compartment floor. Position the

Tool box and the damaged

wheel to stand upright into the

tool box spare.

2. Pull up the release knob on top of the rear seat backrest

forward.

3. Place the loop end of the strapfrom tool box through the seat

back latch.

4. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely

to the seat back latch.

Page 189 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

188 Vehicle Care

5. Pull back backrests of the rearseats.

6. Mount the hook to the tailgate latch.

7. Tighten the strap and secure it using the buckle.

Jump Starting

Do not start with quick charger.

A vehicle with a discharged battery

can be started using jump leads and

the battery of another vehicle.

{Warning

Be extremely careful when

starting with jump leads. Any

deviation from the following

instructions can lead to injuries or

damage caused by battery

explosion or damage to the

electrical systems of both

vehicles.

Avoid contact with eyes, skin,

fabrics and painted surfaces. The

fluid contains sulphuric acid which

can cause injuries and damage in

the event of direct contact.

. Never expose the battery to

naked flames or sparks.

. A discharged battery can

already freeze at temperatures

of 0 °C. Defrost the frozen battery before

connecting jump leads.

. Wear eye protection and

protective clothing when

handling a battery.

. Use a booster battery with the

same voltage (12 volts). Its

capacity (Ah) must not be much

less than that of the discharged

battery.

. Use jump leads with insulated

terminals and a cross section of

at least 16 mm² (25 mm² for

diesel).

. Do not disconnect the

discharged battery from the

vehicle.

. Switch off all unnecessary

electrical consumers.

. Do not lean over the battery

during jump starting.

. Do not allow the terminals of one

lead to touch those of the

other lead.

. The vehicles must not come into

contact with each other during

the jump starting process.

Page 190 of 217

OPEL Karl Owner Manual (GMK-Localizing-EU RHD-9231168) - 2016 - crc -

5/7/15

Vehicle Care 189

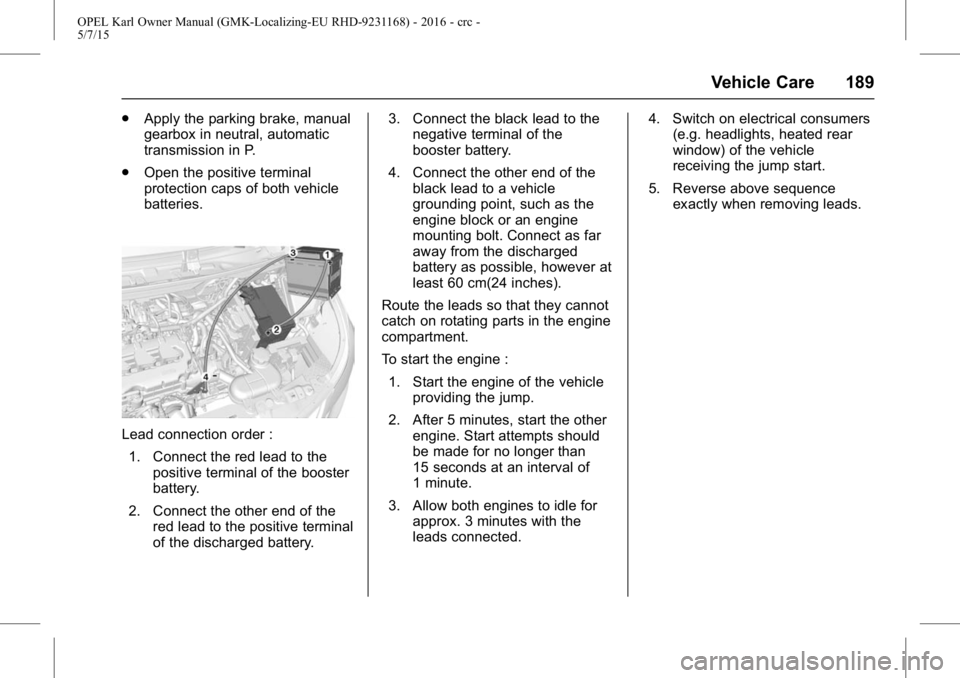

.Apply the parking brake, manual

gearbox in neutral, automatic

transmission in P.

. Open the positive terminal

protection caps of both vehicle

batteries.

Lead connection order :

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal

of the discharged battery. 3. Connect the black lead to the

negative terminal of the

booster battery.

4. Connect the other end of the black lead to a vehicle

grounding point, such as the

engine block or an engine

mounting bolt. Connect as far

away from the discharged

battery as possible, however at

least 60 cm(24 inches).

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine : 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should

be made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the

leads connected. 4. Switch on electrical consumers

(e.g. headlights, heated rear

window) of the vehicle

receiving the jump start.

5. Reverse above sequence exactly when removing leads.