wheel bolts PEUGEOT 5008 2018 Owners Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2018, Model line: 5008, Model: PEUGEOT 5008 2018Pages: 364, PDF Size: 13.03 MB

Page 243 of 364

241

With 2.0 HDi engines

F Fill the fuel tank with at least five litres of Diesel.

F

O

pen the bonnet.

F

I

f necessary, unclip the cover to access the

priming pump.

F

L

oosen the degassing screw.

F

U

se the priming pump until fuel appears in

the transparent tube.

F

R

etighten the degassing screw.

F

O

perate the starter until the engine starts (if

the engine does not start at the first attempt,

wait around 15

seconds before trying

again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

P

ut it back in place, clip in the cover and

ensure it is clipped in.

F

C

lose the bonnet.

Tool kit

This is a set of tools provided with the vehicle.

I ts content depends on your vehicle's

equipment:

-

t

emporary puncture repair kit,

-

spar

e wheel.

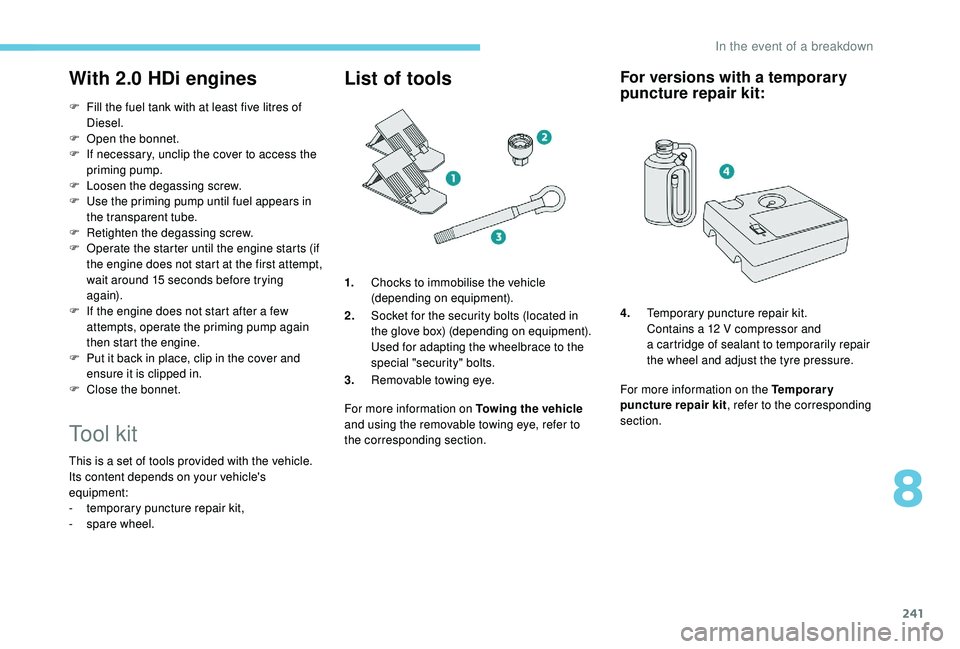

List of tools

1.Chocks to immobilise the vehicle

(depending on equipment).

2. Socket for the security bolts (located in

the glove box) (depending on equipment).

Used for adapting the wheelbrace to the

special "security" bolts.

3. Removable towing eye.

For more information on Towing the vehicle

and using the removable towing eye, refer to

the corresponding section.

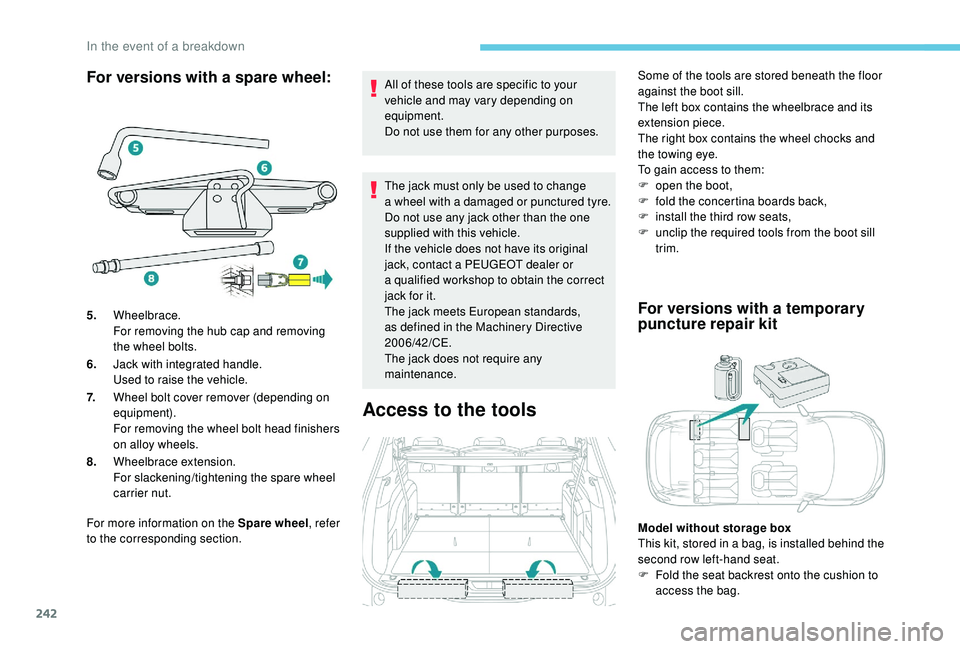

For versions with a temporary

p uncture repair kit:

4. Temporary puncture repair kit.

Contains a

12 V compressor and

a

cartridge of sealant to temporarily repair

the wheel and adjust the tyre pressure.

For more information on the Temporary

puncture repair kit , refer to the corresponding

section.

8

In the event of a breakdown

Page 244 of 364

242

For versions with a spare wheel:

For more information on the Spare wheel, refer

to the corresponding section. All of these tools are specific to your

vehicle and may vary depending on

equipment.

Do not use them for any other purposes.

The jack must only be used to change

a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original

jack, contact a PEUGEOT dealer or

a qualified workshop to obtain the correct

jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/CE.

The jack does not require any

maintenance.

Access to the tools

Some of the tools are stored beneath the floor

against the boot sill.

The left box contains the wheelbrace and its

extension piece.

The right box contains the wheel chocks and

the towing eye.

To gain access to them:

F

o

pen the boot,

F

fo

ld the concertina boards back,

F

i

nstall the third row seats,

F

u

nclip the required tools from the boot sill

trim.

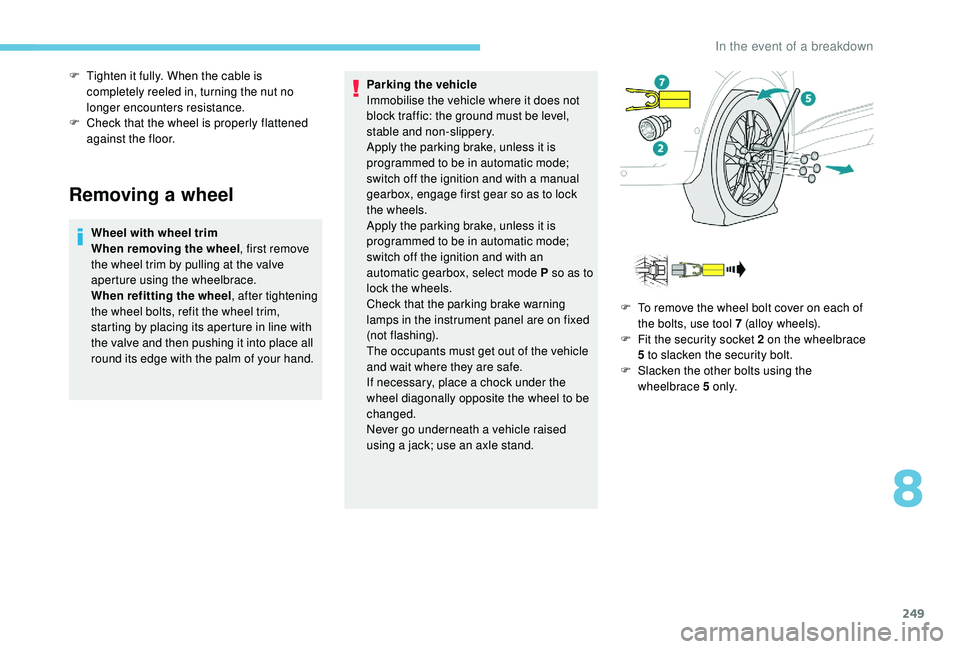

5. Wheelbrace.

For removing the hub cap and removing

the wheel bolts.

6. Jack with integrated handle.

Used to raise the vehicle.

7. Wheel bolt cover remover (depending on

equipment).

For removing the wheel bolt head finishers

on alloy wheels.

8. Wheelbrace extension.

For slackening/tightening the spare wheel

carrier nut.

For versions with a temporary

p uncture repair kit

Model without storage box

This kit, stored in a

bag, is installed behind the

second row left-hand seat.

F

F

old the seat backrest onto the cushion to

access the bag.

In the event of a breakdown

Page 251 of 364

249

Removing a wheel

Wheel with wheel trim

When removing the wheel, first remove

the wheel trim by pulling at the valve

aperture using the wheelbrace.

When refitting the wheel , after tightening

the wheel bolts, refit the wheel trim,

starting by placing its aperture in line with

the valve and then pushing it into place all

round its edge with the palm of your hand. Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and non-slippery.

Apply the parking brake, unless it is

programmed to be in automatic mode;

switch off the ignition and with a

manual

gearbox, engage first gear so as to lock

the wheels.

Apply the parking brake, unless it is

programmed to be in automatic mode;

switch off the ignition and with an

automatic gearbox, select mode P so as to

lock the wheels.

Check that the parking brake warning

lamps in the instrument panel are on fixed

(not flashing).

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a

chock under the

wheel diagonally opposite the wheel to be

changed.

Never go underneath a

vehicle raised

using a

jack; use an axle stand.

F

T

ighten it fully. When the cable is

completely reeled in, turning the nut no

longer encounters resistance.

F

C

heck that the wheel is properly flattened

against the floor.

F

T

o remove the wheel bolt cover on each of

the bolts, use tool 7 (alloy wheels).

F

F

it the security socket 2 on the wheelbrace

5

to slacken the security bolt.

F

S

lacken the other bolts using the

wheelbrace 5

o n l y.

8

In the event of a breakdown

Page 252 of 364

250

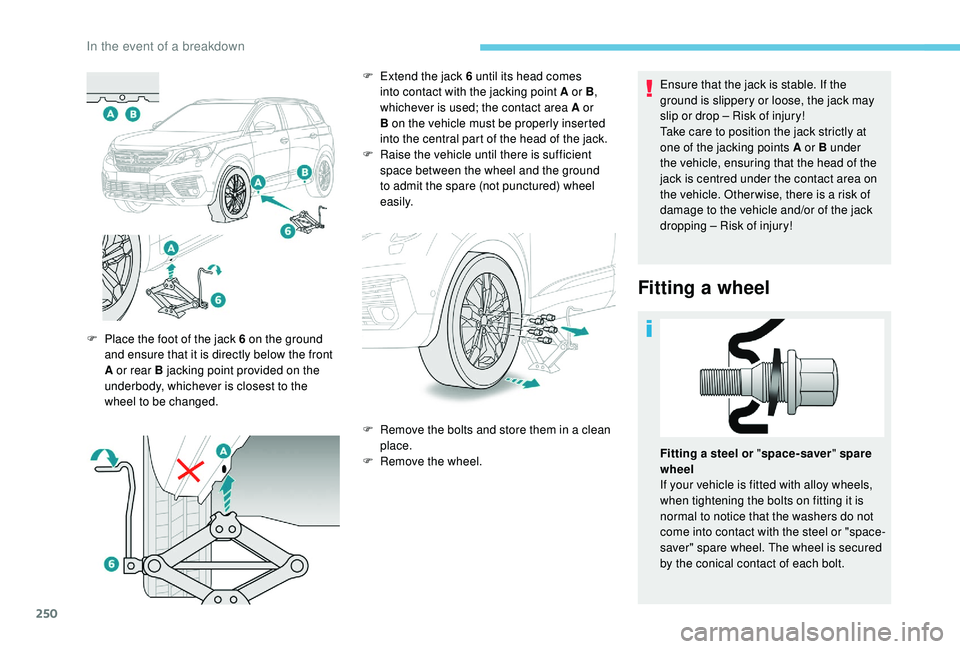

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or drop – Risk of injury!

Take care to position the jack strictly at

one of the jacking points A or B under

the vehicle, ensuring that the head of the

jack is centred under the contact area on

the vehicle. Other wise, there is a risk of

damage to the vehicle and/or of the jack

dropping – Risk of injury!

Fitting a wheel

F Place the foot of the jack 6 on the ground

and ensure that it is directly below the front

A or rear B jacking point provided on the

underbody, whichever is closest to the

wheel to be changed. F

E

xtend the jack 6 until its head comes

into contact with the jacking point A or B ,

whichever is used; the contact area A or

B on the vehicle must be properly inserted

into the central part of the head of the jack.

F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground

to admit the spare (not punctured) wheel

easily.

F

R

emove the bolts and store them in a clean

place.

F

R

emove the wheel.Fitting a

steel or "space-saver " spare

wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting it is

normal to notice that the washers do not

come into contact with the steel or "space-

saver" spare wheel. The wheel is secured

by the conical contact of each bolt.

In the event of a breakdown

Page 253 of 364

251

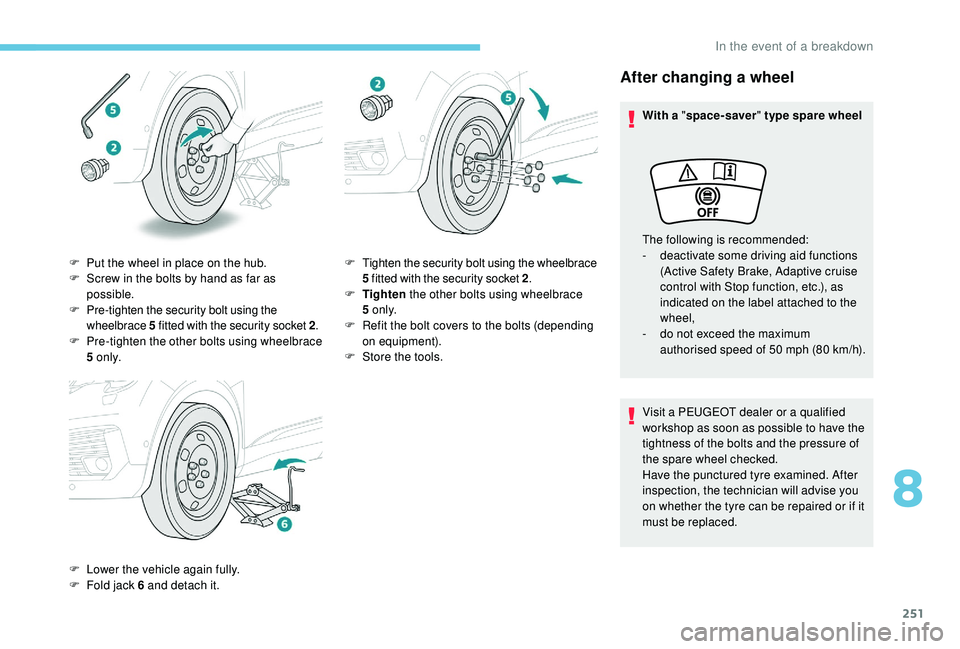

After changing a wheel

With a "space-saver " type spare wheel

Visit a PEUGEOT dealer or a qualified

workshop as soon as possible to have the

tightness of the bolts and the pressure of

the spare wheel checked.

Have the punctured tyre examined. After

inspection, the technician will advise you

on whether the tyre can be repaired or if it

must be replaced. The following is recommended:

-

d

eactivate some driving aid functions

(Active Safety Brake, Adaptive cruise

control with Stop function, etc.), as

indicated on the label attached to the

wheel,

-

d

o not exceed the maximum

authorised speed of 50

mph (80 km/h).

F

P

ut the wheel in place on the hub.

F

S

crew in the bolts by hand as far as

possible.

F

P

re-tighten the security bolt using the

wheelbrace 5

fitted with the security socket 2 .

F

P

re-tighten the other bolts using wheelbrace

5

o n l y.

F

L

ower the vehicle again fully.

F

F

old jack 6

and detach it. F

T

ighten the security bolt using the wheelbrace

5

fitted with the security socket 2 .

F

T

ighten the other bolts using wheelbrace

5

o n l y.

F

R

efit the bolt covers to the bolts (depending

on equipment).

F

S

tore the tools.

8

In the event of a breakdown