ESP Peugeot 508 2016 Workshop Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2016, Model line: 508, Model: Peugeot 508 2016Pages: 371, PDF Size: 12.12 MB

Page 207 of 371

205

508_en_Chap07_info-pratiques_ed01-2016

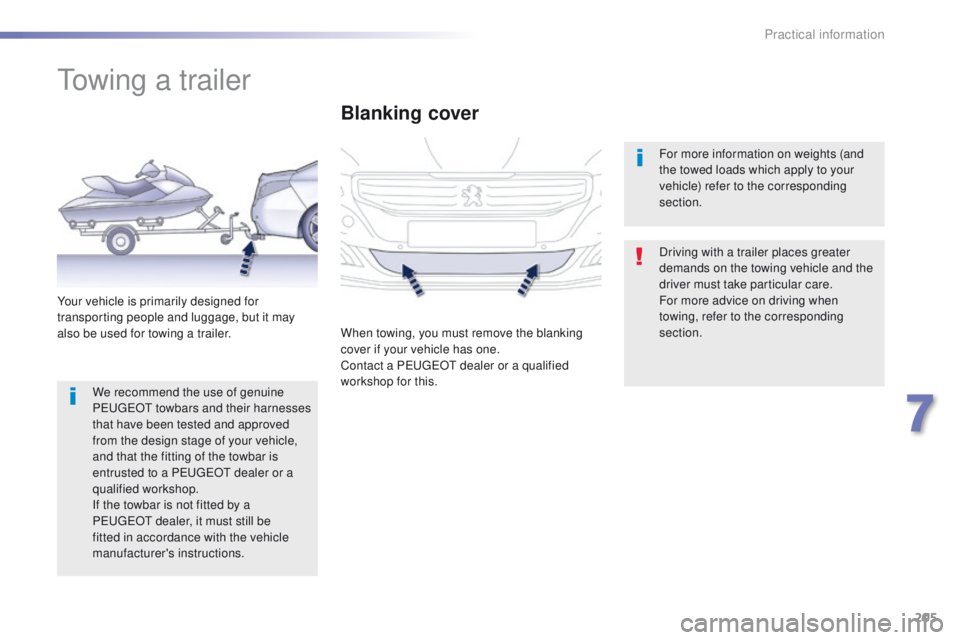

towing a trailer

Driving with a trailer places greater

demands on the towing vehicle and the

driver must take particular care.

For more advice on driving when

towing, refer to the corresponding

section.

Your vehicle is primarily designed for

transporting people and luggage, but it may

also be used for towing a trailer.

Blanking cover

When towing, you must remove the blanking

cover if your vehicle has one.

Contact a P

e

uge

Ot

dealer or a qualified

workshop for this. For more information on weights (and

the towed loads which apply to your

vehicle) refer to the corresponding

section.

We recommend the use of genuine

P

e

uge

Ot

towbars and their harnesses

that have been tested and approved

from the design stage of your vehicle,

and that the fitting of the towbar is

entrusted to a P

e

uge

Ot

dealer or a

qualified workshop.

If the towbar is not fitted by a

P

e

uge

Ot

dealer, it must still be

fitted in accordance with the vehicle

manufacturer's instructions.

7

Practical information

Page 209 of 371

207

508_en_Chap07_info-pratiques_ed01-2016

Before each use

Check that the towball is correctly fitted by verifying the following points:

- t he towball is correctly locked in place (position A ),

-

t

he security key lock is on and the key removed; the locking wheel can no longer be

operated,

-

t

he towball must no longer move at all in its carrier; try to shake it by hand.

During use

Never unlock the towball when a trailer or load carrier is fitted.

Never exceed the maximum authorised weight for the vehicle plus trailer (gr oss tr ain

Weight -

gt

W

).

Before driving, check the adjustment of the headlamp beam height.

For more information on adjusting the headlamps, refer to the corresponding section.

After use

For journeys made without a trailer or load carrier, the trailer harness socket must be folded

away, the towball removed and the protective blanking plug inserted in the carrier. th is

measure applies particularly if the towball could hinder visibility of the number plate or

lighting.

7

Practical information

Page 213 of 371

211

508_en_Chap07_info-pratiques_ed01-2016

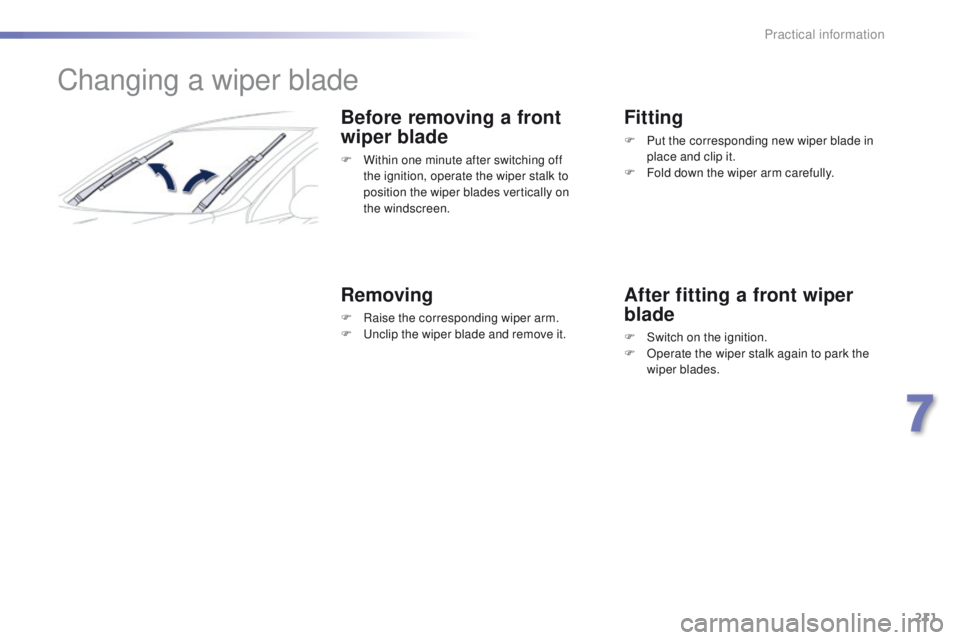

Changing a wiper blade

Before removing a front

wiper blade

F Within one minute after switching off the ignition, operate the wiper stalk to

position the wiper blades vertically on

the

windscreen.

Removing

F Raise the corresponding wiper arm.

F un clip the wiper blade and remove it.

Fitting

F Put the corresponding new wiper blade in place and clip it.

F

F

old down the wiper arm carefully.

After fitting a front wiper

blade

F Switch on the ignition.

F O perate the wiper stalk again to park the

wiper blades.

7

Practical information

Page 220 of 371

218

508_en_Chap07_info-pratiques_ed01-2016

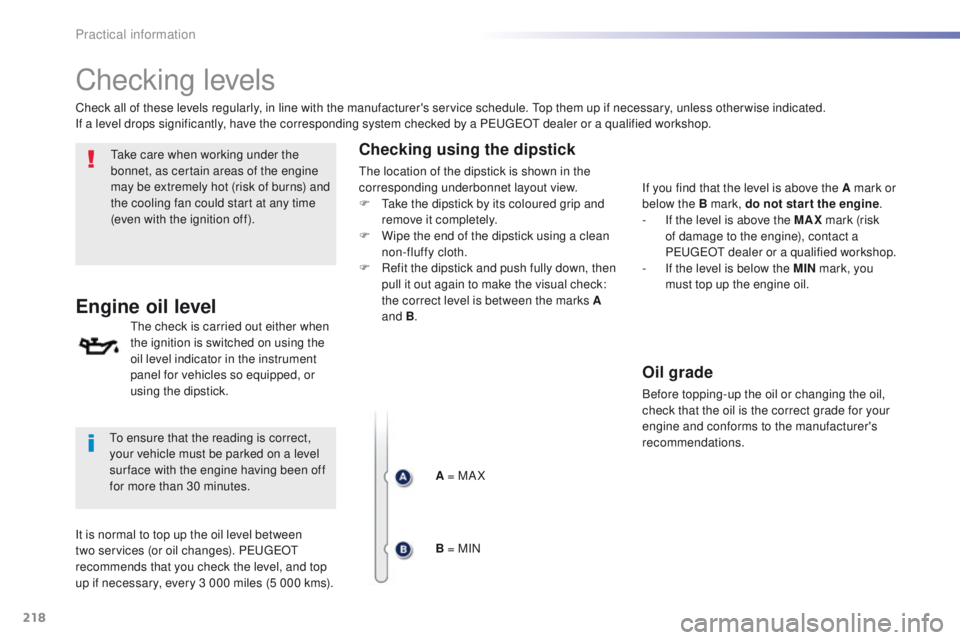

Checking levels

take care when working under the

bonnet, as certain areas of the engine

may be extremely hot (risk of burns) and

the cooling fan could start at any time

(even with the ignition off).

Engine oil level

the check is carried out either when

the ignition is switched on using the

oil level indicator in the instrument

panel for vehicles so equipped, or

using the dipstick.

to e

nsure that the reading is correct,

your vehicle must be parked on a level

sur face with the engine having been off

for more than 30 minutes.

It is normal to top up the oil level between

two services (or oil changes). P

e

uge

Ot

recommends that you check the level, and top

up if necessary, every 3 000 miles (5 000 kms). Check all of these levels regularly, in line with the manufacturer's service schedule. t

o

p them up if necessary, unless other wise indicated.

If a level drops significantly, have the corresponding system checked by a P

e

uge

Ot

dealer or a qualified workshop.

Checking using the dipstick

the location of the dipstick is shown in the

corresponding underbonnet layout view.

F

t

a

ke the dipstick by its coloured grip and

remove it completely.

F

W

ipe the end of the dipstick using a clean

non-fluffy cloth.

F

R

efit the dipstick and push fully down, then

pull it out again to make the visual check:

the correct level is between the marks A

and B .

A = MA X

B = MIN If you find that the level is above the A mark or

below the B mark, do not star t the engine

.

-

I

f the level is above the MAX mark (risk

of damage to the engine), contact a

P

e

uge

Ot

dealer or a qualified workshop.

-

I

f the level is below the MIN mark, you

must top up the engine oil.

Oil grade

Before topping-up the oil or changing the oil,

check that the oil is the correct grade for your

engine and conforms to the manufacturer's

recommendations.

Practical information

Page 221 of 371

219

508_en_Chap07_info-pratiques_ed01-2016

Power steering fluid level

the power steering fluid level should

be close to the "MA X" mark. With

the engine cold, unscrew the cap to

check the level.

th

e brake fluid level should be close

to the "MA X" mark. If it is not, check

the brake pad wear.

Brake fluid level

Changing the fluid

Refer to the manufacturer's service schedule

for details of the interval for this operation.

Fluid specification

the brake fluid must conform to the

manufacturer's recommendations.

Topping-up the engine oil level

the location of the oil filler cap is shown in the

corresponding underbonnet layout view.

F

u

n

screw the oil filler cap to reveal the filler

aperture.

F

A

dd oil in small quantities, avoiding any

spills on engine components (risk of fire).

F

W

ait a few minutes before checking the

level again using the dipstick.

F

A

dd more oil if necessary.

F

A

fter checking the level, carefully refit the

oil filler cap and the dipstick in its tube.

After topping-up the oil, the check when

switching on the ignition with the oil level

indicator in the instrument panel is not valid

during the 30 minutes after topping up.

Engine oil change

Refer to the manufacturer's service schedule

for details of the interval for this operation.

In order to maintain the reliability of the engine

and emission control system, never use

additives in the engine oil.

7

Practical information

Page 223 of 371

221

508_en_Chap07_info-pratiques_ed01-2016

Checks

12 V battery

the battery does not require any

maintenance.

However, check regularly that the

terminals are correctly tightened (versions

without quick release terminals) and that

the connections are clean.Refer to the manufacturer's

service schedule for details of the

replacement intervals for these

components.

Air filter and passenger compartment filter

Replace the oil filter each time the

engine oil is changed.

Refer to the manufacturer's

service schedule for details of

the replacement interval for this

component.

Oil filter

Versions equipped with Stop & Start are

fitted with a 12 V lead-acid battery of specific

technology and specification.

Its replacement should be carried out only by a

P

e

uge

Ot

dealer or a qualified workshop.

Particle filter (Diesel)

the start of saturation of the particle

filter is indicated by the temporary

As soon as the traffic conditions permit,

regenerate the filter by driving at a speed

of at least 40 mph (60 km/h) until the

warning lamp goes off.

If the warning lamp stays on, this

indicates a low additive level.

For more information on checking levels,

refer to the corresponding section.

On a new vehicle, the first particle

filter regeneration operations may be

accompanied by a "burning" smell,

which is per fectly normal.

Following prolonged operation of the

vehicle at very low speed or at idle,

you may, in exceptional circumstances,

notice the emission of water vapour at

the exhaust on acceleration.

t

h

is does

not affect the behaviour of the vehicle

or the environment.

un

less otherwise indicated, check these components in accordance with the manufacturer's service schedule and according to your engine.

Other wise, have them checked by a P

e

uge

Ot

dealer or a qualified workshop.

When carrying out any operation on the 12 V

battery, refer to the corresponding section for

details of the precautions to be taken before

starting work. Depending on the environment (e.g. dusty

atmosphere) and the use of the vehicle

(e.g.

city driving), replace them twice as often

if necessary .

A clogged passenger compartment filter may

have an adverse effect on the per formance

of the air conditioning system and generate

undesirable odours. illumination of this warning lamp accompanied

by a message in the multifunction screen.

7

Practical information

Page 224 of 371

222

508_en_Chap07_info-pratiques_ed01-2016

Manual gearbox

the gearbox does not require any

maintenance (no oil change).

Refer to the manufacturer's service

schedule for the checking interval

for this component.

Automatic gearbox

the gearbox does not require any

maintenance (no oil change).

Refer to the manufacturer's

service schedule for details of

the level checking interval for this

component.

Brake wear depends on the style

of driving, particularly in the case

of vehicles used in town, over short

distances. It may be necessary to

have the condition of the brakes checked, even

between vehicle services.

un

less there is a leak in the circuit, a drop in

the brake fluid level indicates that the brake

pads are worn.

Brake pads

For information on checking brake

disc wear, contact a Pe ugeOt

dealer or a qualified workshop.

Brake disc wear Electric parking brake

this system does not require any

routine servicing. However, in

the event of a problem, have the

system checked by a P

e

uge

Ot

dealer or a qualified workshop.

Only use products recommended by

P

e

uge

Ot

or products of equivalent

quality and specification.

In order to optimise the operation of

units as important as those in the

braking system, P

e

uge

Ot

selects and

offers very specific products.

After washing the vehicle, dampness,

or in wintry conditions, ice can form

on the brake discs and pads: braking

efficiency may be reduced. Make light

brake applications to dry and defrost

the brakes.

Parking brake

If excessive travel or a loss of

effectiveness of this system is

noticed, the parking brake must

be checked, even between

two

services.

Checking this system must be done by a

P

e

uge

Ot

dealer or a qualified workshop. For more information on the electric parking

brake, refer to the corresponding section.

Practical information

Page 225 of 371

223

508_en_Chap07_info-pratiques_ed01-2016

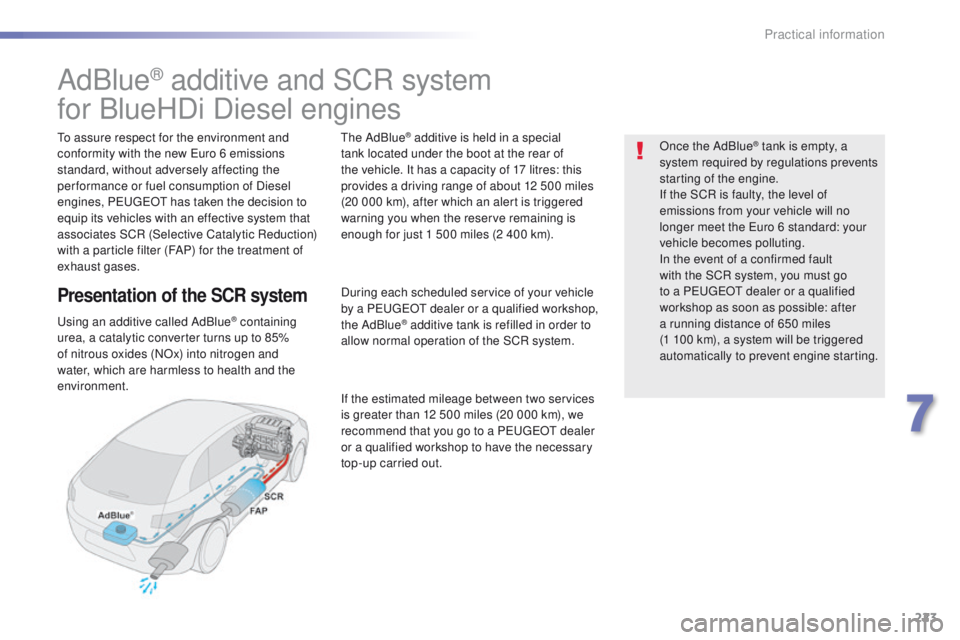

AdBlue® additive and SCR system

for BlueHDi Diesel engines

to assure respect for the environment and

conformity with the new

eu ro 6 emissions

standard, without adversely affecting the

per formance or fuel consumption of Diesel

engines, P

e

uge

Ot

has taken the decision to

equip its vehicles with an effective system that

associates SCR (Selective Catalytic Reduction)

with a particle filter (FAP) for the treatment of

exhaust gases.

Presentation of the SCR system

using an additive called AdBlue® containing

urea, a catalytic converter turns up to 85%

of nitrous oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

th

e AdBlue

® additive is held in a special

tank located under the boot at the rear of

the vehicle. It has a capacity of 17 litres: this

provides a driving range of about 12 500 miles

(20 000 km), after which an alert is triggered

warning you when the reserve remaining is

enough for just 1 500 miles (2 400 km).

During each scheduled service of your vehicle

by a P

e

uge

Ot

dealer or a qualified workshop,

the AdBlue

® additive tank is refilled in order to

allow normal operation of the SCR system.

If the estimated mileage between two services

is greater than 12 500 miles (20 000 km), we

recommend that you go to a P

e

uge

Ot

dealer

or a qualified workshop to have the necessary

top-up carried out. Once the AdBlue

® tank is empty, a

s

ystem required by regulations prevents

starting of the engine.

If the SCR is faulty, the level of

emissions from your vehicle will no

longer meet the

e

u

ro 6 standard: your

vehicle becomes polluting.

In the event of a confirmed fault

with the SCR system, you must go

to a P

e

uge

Ot

dealer or a qualified

workshop as soon as possible: after

a running distance of 650 miles

(1 100 km), a system will be triggered

automatically to prevent engine starting.

7

Practical information

Page 230 of 371

228

508_en_Chap08_en-cas-de-pannes_ed01-2016

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel.

For all versions other than BlueHDi, refer to the

corresponding engine compartment view.

Running out of fuel (Diesel)

For more information on the Diesel

misfuel prevention device, refer to the

corresponding section.F

F

ill the fuel tank with at least five litres of

diesel.

F

O

pen the bonnet.

F

I

f necessary, unclip the styling cover for

access to the priming pump.

F

S

queeze and release the priming pump

repeatedly until resistance is felt (there

may be resistance at the first press).

F

O

perate the starter until the engine starts

(if the engine does not start at the first

attempt, wait around 15 seconds before

trying again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

C

lip the styling cover back in place.

F

C

lose the bonnet.

1.6 litre HDi engine

F Fill the fuel tank with at least five litres of Diesel.

F

O

pen the bonnet.

F

I

f necessary, unclip the styling cover for

access to the priming pump.

F

S

queeze and release the priming pump

repeatedly until fuel appears in the

transparent pipe.

F

O

perate the starter until the engine starts

(if the engine does not start at the first

attempt, wait around 15 seconds before

trying again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

P

ut the styling cover back in position and

clip it in place.

F

C

lose the bonnet.

2 litre HDi engines

If the engine does not start first time,

don't keep trying but start the procedure

again from the beginning.

BlueHDi engines

F Fill the fuel tank with at least five litres of Diesel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10 times.

F

O

perate the starter to run the engine.

In the event of a breakdown

Page 231 of 371

229

508_en_Chap08_en-cas-de-pannes_ed01-2016

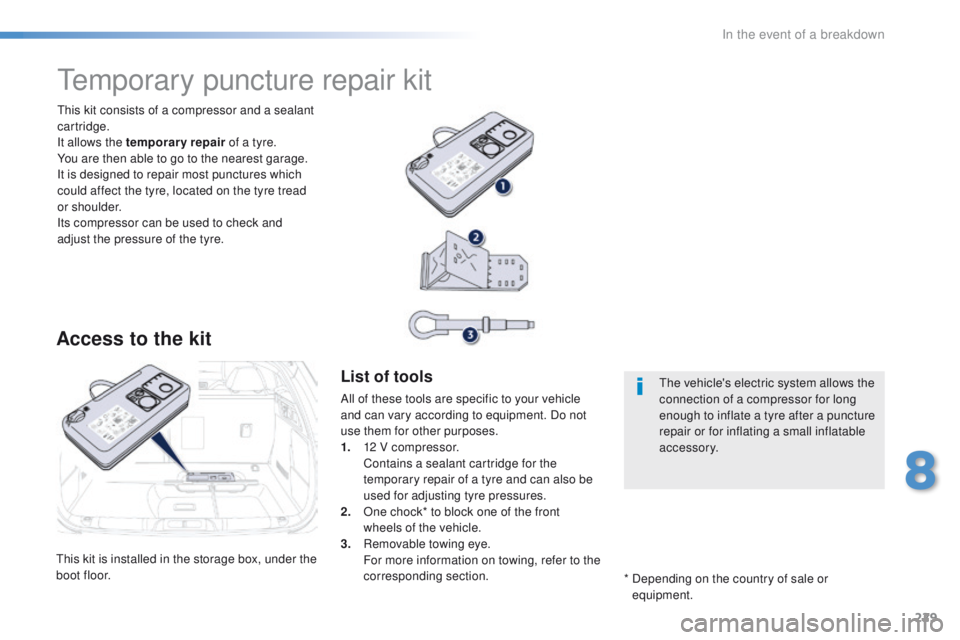

this kit is installed in the storage box, under the

boot floor.

th

is kit consists of a compressor and a sealant

cartridge.

It allows the temporary repair of a tyre.

You are then able to go to the nearest garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Its compressor can be used to check and

adjust the pressure of the tyre.

temporary puncture repair kit

Access to the kit

List of tools

All of these tools are specific to your vehicle

and can vary according to equipment. Do not

use them for other purposes.

1.

1

2 V compressor.

C

ontains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2.

O

ne chock* to block one of the front

wheels of the vehicle.

3.

R

emovable towing eye.

F

or more information on towing, refer to the

corresponding section. *

D

epending on the country of sale or

equipment.th e vehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

8

In the event of a breakdown