ser Peugeot Boxer 2018 Repair Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2018, Model line: Boxer, Model: Peugeot Boxer 2018Pages: 232, PDF Size: 9.09 MB

Page 145 of 232

143

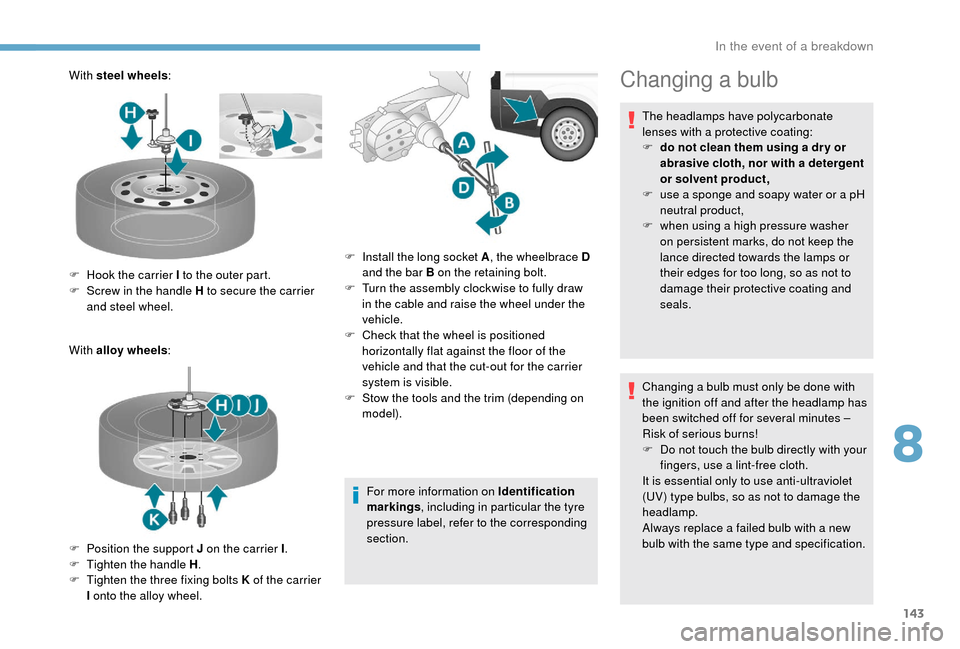

With steel wheels:

With alloy wheels :

For more information on Identification

markings, including in particular the tyre

pressure label, refer to the corresponding

section.

F

H

ook the carrier I to the outer part.

F

S

crew in the handle H to secure the carrier

and steel wheel.

F

P

osition the support J on the carrier I .

F

T

ighten the handle H .

F

T

ighten the three fixing bolts K of the carrier

I onto the alloy wheel. F

I

nstall the long socket A, the wheelbrace D

and the bar B on the retaining bolt.

F

T

urn the assembly clockwise to fully draw

in the cable and raise the wheel under the

vehicle.

F

C

heck that the wheel is positioned

horizontally flat against the floor of the

vehicle and that the cut-out for the carrier

system is visible.

F

S

tow the tools and the trim (depending on

model).Changing a bulb

The headlamps have polycarbonate

lenses with a

protective coating:

F

d

o not clean them using a dr y or

abrasive cloth, nor with a

detergent

or solvent product,

F

u

se a sponge and soapy water or a pH

neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep the

lance directed towards the lamps or

their edges for too long, so as not to

damage their protective coating and

seals.

Changing a

bulb must only be done with

the ignition off and after the headlamp has

been switched off for several minutes –

Risk of serious burns!

F

D

o not touch the bulb directly with your

fingers, use a

lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a

failed bulb with a new

bulb with the same type and specification.

8

In the event of a breakdown

Page 151 of 232

149

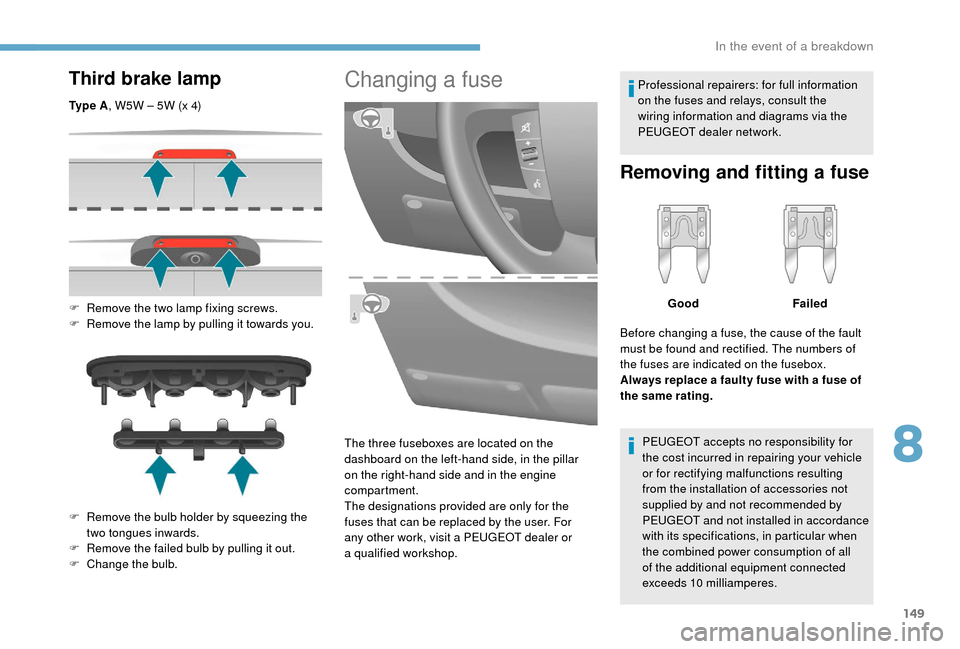

Third brake lamp

Ty p e A, W5W – 5W (x 4)

F

R

emove the two lamp fixing screws.

F

R

emove the lamp by pulling it towards you.

F

R

emove the bulb holder by squeezing the

two tongues inwards.

F

R

emove the failed bulb by pulling it out.

F

C

hange the bulb.

Changing a fuse

The three fuseboxes are located on the

dashboard on the left-hand side, in the pillar

on the right-hand side and in the engine

compartment.

The designations provided are only for the

fuses that can be replaced by the user. For

any other work, visit a

PEUGEOT dealer or

a

qualified workshop. Professional repairers: for full information

on the fuses and relays, consult the

wiring information and diagrams via the

PEUGEOT dealer network.

Removing and fitting a fuse

PEUGEOT accepts no responsibility for

the cost incurred in repairing your vehicle

or for rectifying malfunctions resulting

from the installation of accessories not

supplied by and not recommended by

PEUGEOT and not installed in accordance

with its specifications, in particular when

the combined power consumption of all

of the additional equipment connected

exceeds 10

milliamperes.

Good

Failed

Before changing a fuse, the cause of the fault

must be found and rectified. The numbers of

the fuses are indicated on the fusebox.

Always replace a faulty fuse with a fuse of

the same rating.

8

In the event of a breakdown

Page 157 of 232

155

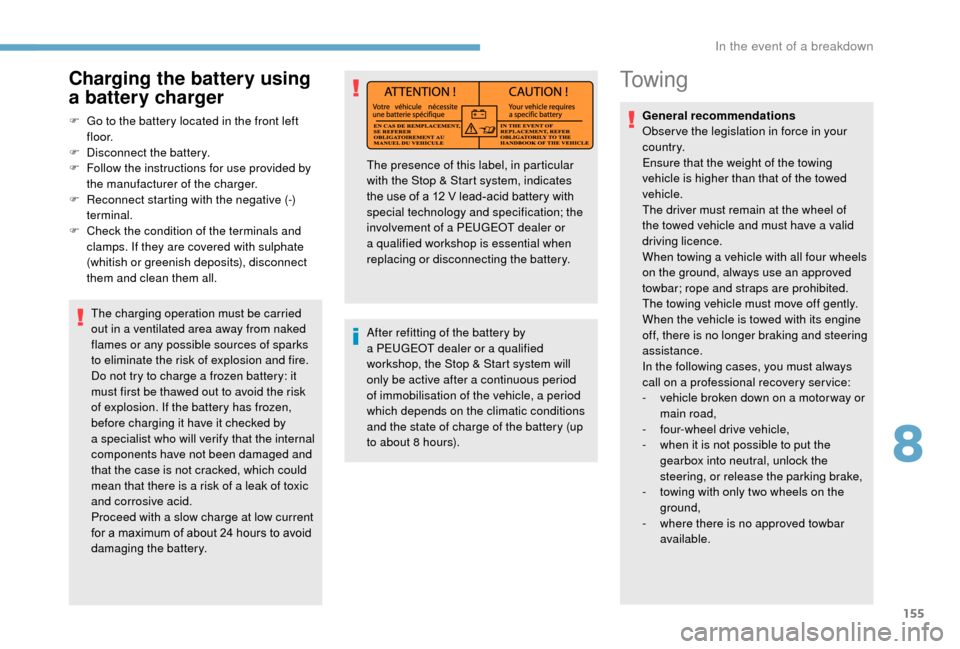

To w i n g

General recommendations

Obser ve the legislation in force in your

c o u nt r y.

Ensure that the weight of the towing

vehicle is higher than that of the towed

vehicle.

The driver must remain at the wheel of

the towed vehicle and must have a valid

driving licence.

When towing a

vehicle with all four wheels

on the ground, always use an approved

towbar; rope and straps are prohibited.

The towing vehicle must move off gently.

When the vehicle is towed with its engine

off, there is no longer braking and steering

assistance.

In the following cases, you must always

call on a

professional recovery ser vice:

-

v

ehicle broken down on a motor way or

main road,

-

f

our-wheel drive vehicle,

-

w

hen it is not possible to put the

gearbox into neutral, unlock the

steering, or release the parking brake,

-

t

owing with only two wheels on the

ground,

-

w

here there is no approved towbar

available.

The charging operation must be carried

out in a

ventilated area away from naked

flames or any possible sources of sparks

to eliminate the risk of explosion and fire.

Do not try to charge a

frozen battery: it

must first be thawed out to avoid the risk

of explosion. If the battery has frozen,

before charging it have it checked by

a

specialist who will verify that the internal

components have not been damaged and

that the case is not cracked, which could

mean that there is a

risk of a

leak of toxic

and corrosive acid.

Proceed with a

slow charge at low current

for a

maximum of about 24

hours to avoid

damaging the battery.

Charging the battery using

a battery charger

F Go to the battery located in the front left

f l o o r.

F

D

isconnect the battery.

F

F

ollow the instructions for use provided by

the manufacturer of the charger.

F

R

econnect starting with the negative (-)

terminal.

F

C

heck the condition of the terminals and

clamps. If they are covered with sulphate

(whitish or greenish deposits), disconnect

them and clean them all.

After refitting of the battery by

a

PEUGEOT dealer or a qualified

workshop, the Stop & Start system will

only be active after a

continuous period

of immobilisation of the vehicle, a period

which depends on the climatic conditions

and the state of charge of the battery (up

to about 8

hours).

The presence of this label, in particular

with the Stop & Start system, indicates

the use of a

12 V lead-acid battery with

special technology and specification; the

involvement of a

PEUGEOT dealer or

a

qualified workshop is essential when

replacing or disconnecting the battery.

8

In the event of a breakdown

Page 159 of 232

157

Engine technical data and

towed loads

Engines

The engine characteristics are given in the

vehicle's registration document, as well as in

sales brochures.The maximum power corresponds to the

value type-approved on a

test bed, under

conditions defined in European legislation

(Directive 1999/99/EC).

For more information, contact a

PEUGEOT

dealer or a

qualified workshop.

Weights and towed loads

The maximum weights and towed loads for

your vehicle are given in the registration

document, as well as in sales brochures.

These values are also given on the

manufacturer's plate or label.

For more information, contact a PEUGEOT

dealer or a

qualified workshop. The GTW and towed load values indicated are

valid up to a

maximum altitude of 1,000 metres.

The towed load value must be reduced by 10%

for each additional 1,000 metres of altitude.

The maximum authorised nose weight

corresponds to the weight permitted on the

towbar (which can be dismantled with or

without a tool).

GT W: Gross train weight.

High exterior temperatures may result

in a reduction in the per formance of

the vehicle to protect the engine. If the

exterior temperature is above 37°C, limit

the towed load.

Towing with a towing vehicle which is only

slightly laden may negatively affect its

handling.

Towing a

trailer increases the braking

distance.

When towing, never exceed the speed

of 62

mph (100 km/h) (obser ve the local

legislation in force). If the exterior temperature is high, it is

recommended that the engine be allowed

to idle for 1

to 2 minutes after the vehicle

comes to a stop, to facilitate its cooling.

9

Technical data

Page 169 of 232

167

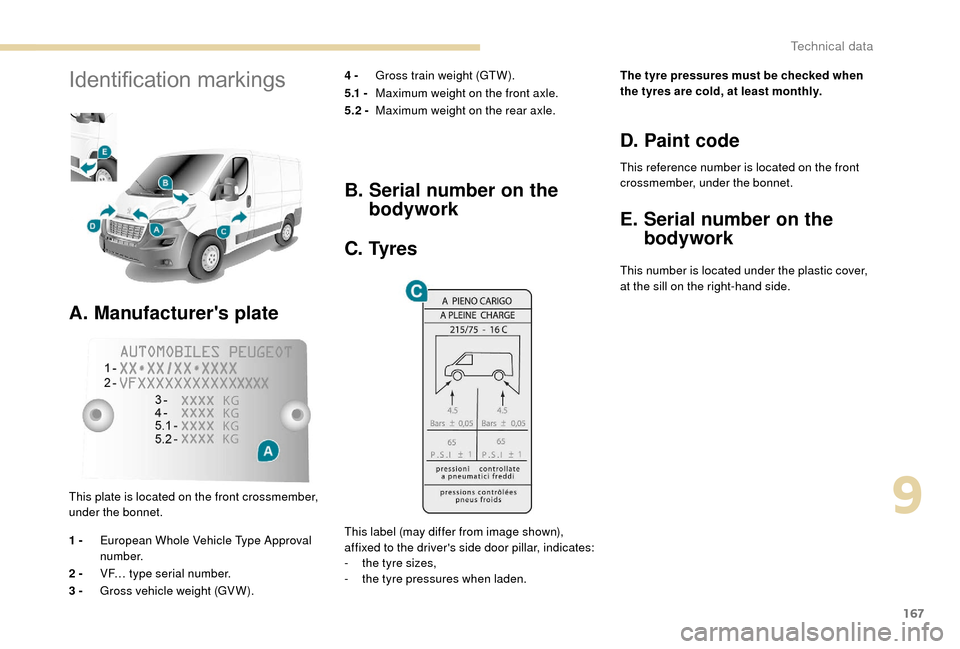

Identification markings

A. Manufacturer's plate

4 - Gross train weight (GTW).

5.1 - Maximum weight on the front axle.

5.2 - Maximum weight on the rear axle.

This plate is located on the front crossmember,

under the bonnet.

1 - European Whole Vehicle Type Approval

number.

2 - VF… type serial number.

3 - Gross vehicle weight (GV W).

B. Serial number on the

bodywork

C. Tyres

This label (may differ from image shown),

affixed to the driver's side door pillar, indicates:

-

t

he tyre sizes,

-

t

he tyre pressures when laden. The tyre pressures must be checked when

the tyres are cold, at least monthly.

D. Paint code

This reference number is located on the front

crossmember, under the bonnet.

E. Serial number on the

bodywork

This number is located under the plastic cover,

at the sill on the right-hand side.

9

Technical data

Page 182 of 232

180

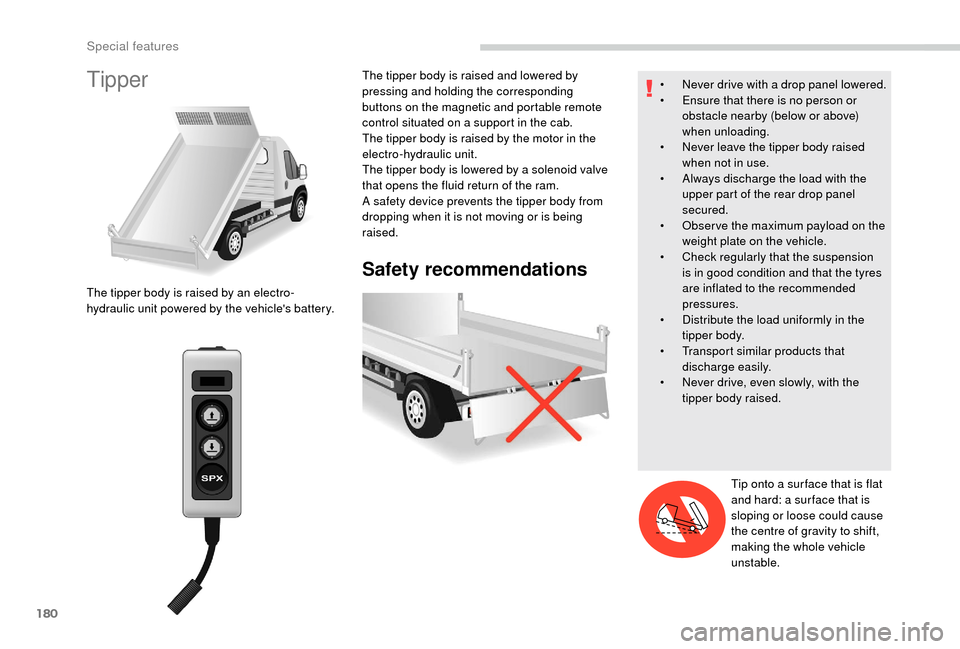

Tipper

Safety recommendations

The tipper body is raised by an electro-

hydraulic unit powered by the vehicle's battery.The tipper body is raised and lowered by

pressing and holding the corresponding

buttons on the magnetic and portable remote

control situated on a

support in the cab.

The tipper body is raised by the motor in the

electro-hydraulic unit.

The tipper body is lowered by a solenoid valve

that opens the fluid return of the ram.

A safety device prevents the tipper body from

dropping when it is not moving or is being

raised. •

N

ever drive with a drop panel lowered.

•

E

nsure that there is no person or

obstacle nearby (below or above)

when unloading.

•

N

ever leave the tipper body raised

when not in use.

•

A

lways discharge the load with the

upper part of the rear drop panel

secured.

•

O

bser ve the maximum payload on the

weight plate on the vehicle.

•

C

heck regularly that the suspension

is in good condition and that the tyres

are inflated to the recommended

pressures.

•

D

istribute the load uniformly in the

tipper body.

•

T

ransport similar products that

discharge easily.

•

N

ever drive, even slowly, with the

tipper body raised.

Tip onto a

sur face that is flat

and hard: a sur face that is

sloping or loose could cause

the centre of gravity to shift,

making the whole vehicle

unstable.

Special features

Page 183 of 232

181

Characteristics

EquipmentDetails

Tipper Tipper base made of 2

strips of 2.5 mm thick zinc-coated high tensile

steel, joined by central and longitudinal laser welding.

Tipper body painted vehicle body colour.

Tipper structure 2

main longerons in galvanised high tensile steel.

1

tubular steel ram head cross member.

Cross members in galvanised high tensile steel. Protected against

corrosion by application of a

powder coating.

Sub-frame 2 "C" section longerons made of 2.5

mm thick high tensile steel, interior

strengthening by enlarged lower wings.

Fixing to the base vehicle by high tensile steel brackets.

1

machine-welded tubular steel ram foot cross member, hot galvanised.

1

rear articulation cross member in galvanised steel.

Stop brackets at the ends of the longerons.

Rear lamp protection grille.

Cycle guard and wing supports in galvanised steel.

Body sides Body sides in high tensile steel, 15/10

thickness, cold formed, assembled

by continuous laser welding.

Anti-corrosion protection assured by a

powder coating paint finish.

Catches with reinforced zinc protection integrated into the form of the

sides.

Ladder carrier Galvanised steel uprights. Panels and cross members in painted steel

with clinched bolts.

Electro-pump unit 12

Volts/2 kW.

Operating temperature range: -20

to +70°C.

Hydraulic ram Expansion type, nitride ram, 3 -section, dia.: 107

mm

Maximum pressure: 20

bar.

Hydraulic fluid Mineral type ISO HV 46

or equivalent.

Dimensions

This conversion is only available on the

L2 single cab; refer to the table below for the

characteristics of the tipper.

Tipper (in mm)

Load length 3,200

Overall length 3,248

Load width 2,000

Overall width 2 ,1 0 0

Height of body sides 350

Conversion weight (in kg) 550

For information on the characteristics

of the L2

chassis cab, refer to the

"Dimensions" section for the floor cab

model.

10

Special features

Page 185 of 232

183

Check and top up the fluid level regularly.

Replace the fluid annually. Replace the fluid if it

contains water.

Check the condition of the hydraulic hose and

the sealing of the hydraulic system regularly.

Pump and motor

Requires no ser vicing; the ball bearings are

lubricated for life and the pump bearings by the

pumped fluid.

Lubrication

The tipper body and ram pivots do not have

grease nipples. Lubricate the hinges and

retainers for the tipper body sides regularly,

as well as the catches for the rear tipper body

side.

Sub-chassis and tipper body

For maximum life, we recommend that you

clean your tipper body by washing it down

regularly with a hose.

Touch up paint chips quickly to avoid rust

spreading.After 8

months of use, check the

tightening torque of the fixings of the

underbody to the chassis (following the

recommendations of the body converter).

Cleaning the valve slider

F Loosen the cap 244A paying attention to

the ball and retrieving it.

F

U

sing a wide screwdriver, unscrew the

bore/piston bolt assembly.

F

C

heck that the piston slides smoothly and

remove any impurities. Pass a

magnet over

if there is any swar f present.

F

R

efit the assembly and ensure that the

piston slides smoothly. Retain the ball with

some grease on the plug for reassembly.

F

B

leed the hydraulic unit.

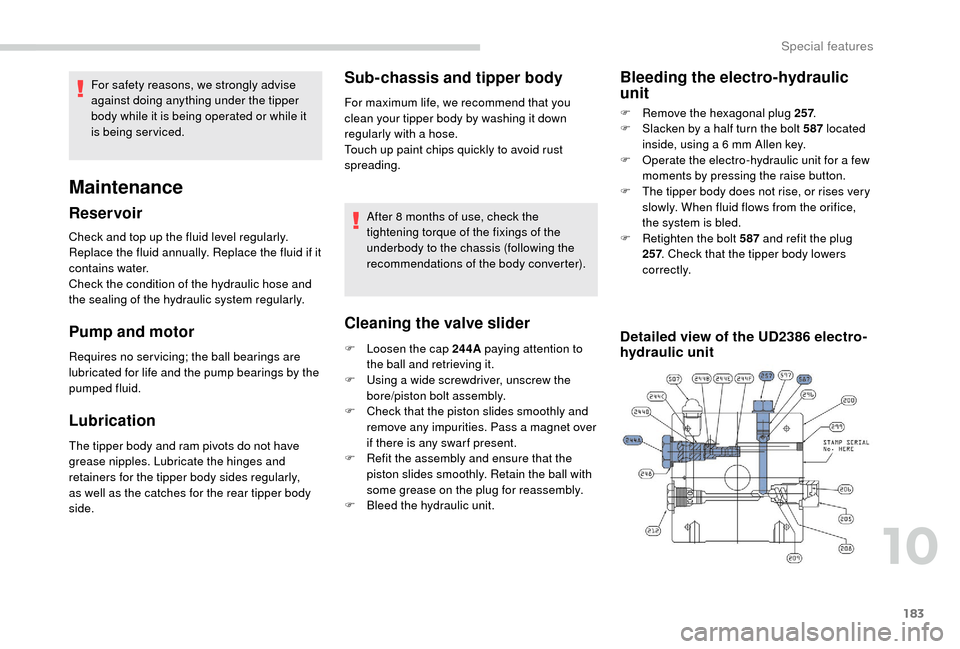

Bleeding the electro-hydraulic

unit

F Remove the hexagonal plug 257 .

F S lacken by a half turn the bolt 587 located

inside, using a

6 mm Allen key.

F

O

perate the electro-hydraulic unit for a few

moments by pressing the raise button.

F

T

he tipper body does not rise, or rises very

slowly. When fluid flows from the orifice,

the system is bled.

F

R

etighten the bolt 587

and refit the plug

257 . Check that the tipper body lowers

c o r r e c t l y.

Detailed view of the UD2386 electro-

h ydraulic unit

Maintenance

Reser voir

For safety reasons, we strongly advise

against doing anything under the tipper

body while it is being operated or while it

is being serviced.

10

Special features

Page 186 of 232

184

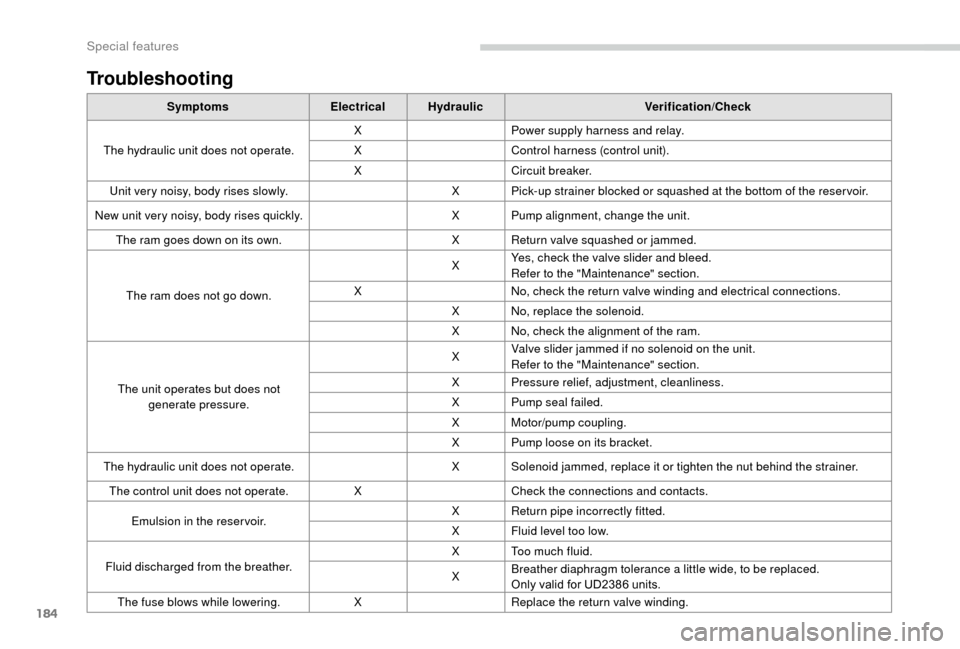

Troubleshooting

SymptomsElectricalHydraulic Verification/Check

The hydraulic unit does not operate. X

Power supply harness and relay.

X Control harness (control unit).

X Circuit breaker.

Unit very noisy, body rises slowly. X Pick-up strainer blocked or squashed at the bottom of the reser voir.

New unit very noisy, body rises quickly. X Pump alignment, change the unit.

The ram goes down on its own. X Return valve squashed or jammed.

The ram does not go down. X

Yes, check the valve slider and bleed.

Refer to the "Maintenance" section.

X No, check the return valve winding and electrical connections.

X No, replace the solenoid.

X No, check the alignment of the ram.

The unit operates but does not generate pressure. X

Valve slider jammed if no solenoid on the unit.

Refer to the "Maintenance" section.

X Pressure relief, adjustment, cleanliness.

X Pump seal failed.

X Motor/pump coupling.

X Pump loose on its bracket.

The hydraulic unit does not operate. X Solenoid jammed, replace it or tighten the nut behind the strainer.

The control unit does not operate. XCheck the connections and contacts.

Emulsion in the reser voir. X

Return pipe incorrectly fitted.

X Fluid level too low.

Fluid discharged from the breather. X Too much fluid.

X

Breather diaphragm tolerance a

little wide, to be replaced.

Only valid for UD2386

units.

The fuse blows while lowering. XReplace the return valve winding.

Special features

Page 191 of 232

5

Adjustment

- D irect adjustment .

The screen virtual keypad can be used to

enter a

single number corresponding to

a

station.

-

T

he "more" or "less" graphic symbols allow

precise adjustment of the frequency.

Info

-

I

nformation .

Display information on the current radio

station.

Audio

-

E

qualiser .

Adjust the bass, mid-range and treble.

-

B

alance/Fade .

Adjust the balance of the speakers, front

and rear, left and right.

Press the button in the middle of the arrows

to balance the adjustments.

-

V

olume/Speed .

Select the desired setting, the option is

highlighted.

-

L

oudness .

Optimise audio quality at low volume.

-

A

utomatic radio .

Adjust the radio on startup or restore the

active state the last time the ignition was

switched to STOP.

-

R

adio off delay .

Adjust the setting.

-

A

UX vol. adjustment .

Adjust the settings.DAB (Digital Audio

Broadcasting) radio

Digital Radio

Digital radio provides higher quality

reception and also the graphical display

of current information on the radio station

being listened to.

The different "multiplex/ensembles" offer

a

choice of radio stations in alphabetical

o r d e r.

Press repeatedly on " RADIO" to

display the "DAB Radio".

Select the " Navigate" tab.

Select a

list from the filters

proposed: " All", "Genres ",

" Ensembles " and then select

a

radio station.

Press the " Update" button to update

the list of "DAB Radio" stations

received.

DAB/FM tracking

"DAB" does not cover 100% of the

te r r i to r y.

When the digital radio signal is weak,

the " AF" (alternative frequencies) option

allows you to continue listening to the

same station, by automatically switching to

the corresponding "FM" analogue station

(if there is one).

When the system switches to analogue

radio, there is a

difference of a few

seconds with sometimes a

change in

volume.

When the digital signal is restored, the

system automatically changes back to

" DA B ".

If the "DAB" station being listened to is

not available, the sound will cut out while

the digital signal is too weak and the

alternative "AF" frequency will be greyed

out.

.

Touch screen Audio-Telematic system