Replace Peugeot Boxer 2020 Owner's Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: Boxer, Model: Peugeot Boxer 2020Pages: 196, PDF Size: 5.1 MB

Page 107 of 196

105

In the event of a breakdown

8► Disconnect hose I and directly connect it

to the tyre valve; the cartridge will thereby be

connected to the compressor and the sealant will

not be injected.

If the tyre needs to be deflated, connect hose

I to the tyre valve and press the yellow button

located in the centre of the compressor switch.

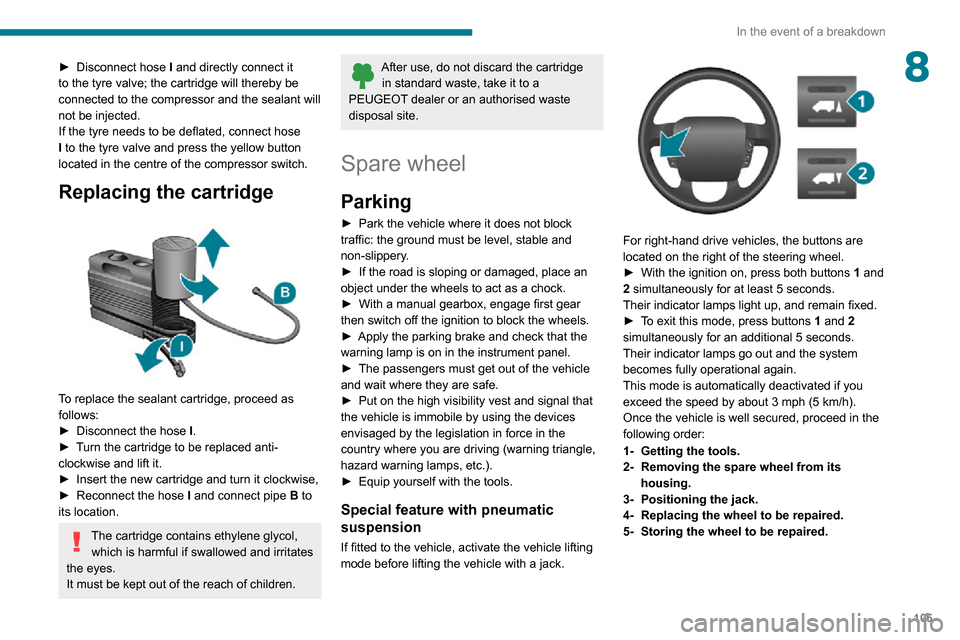

Replacing the cartridge

To replace the sealant cartridge, proceed as

follows:

► Disconnect the hose I.► Turn the cartridge to be replaced anti-clockwise and lift it.► Insert the new cartridge and turn it clockwise,► Reconnect the hose I and connect pipe B to

its location.

The cartridge contains ethylene glycol, which is harmful if swallowed and irritates

the eyes.

It must be kept out of the reach of children.

After use, do not discard the cartridge in standard waste, take it to a

PEUGEOT dealer or an authorised waste

disposal site.

Spare wheel

Parking

► Park the vehicle where it does not block traffic: the ground must be level, stable and

non-slippery.

► If the road is sloping or damaged, place an object under the wheels to act as a chock.► With a manual gearbox, engage first gear then switch off the ignition to block the wheels.► Apply the parking brake and check that the warning lamp is on in the instrument panel.► The passengers must get out of the vehicle and wait where they are safe.► Put on the high visibility vest and signal that the vehicle is immobile by using the devices

envisaged by the legislation in force in the

country where you are driving (warning triangle,

hazard warning lamps, etc.).

► Equip yourself with the tools.

Special feature with pneumatic

suspension

If fitted to the vehicle, activate the vehicle lifting

mode before lifting the vehicle with a jack.

For right-hand drive vehicles, the buttons are

located on the right of the steering wheel.

► With the ignition on, press both buttons 1 and

2 simultaneously for at least 5 seconds.

Their indicator lamps light up, and remain fixed.

► To exit this mode, press buttons 1 and 2

simultaneously for an additional 5 seconds.

Their indicator lamps go out and the system

becomes fully operational again.

This mode is automatically deactivated if you

exceed the speed by about 3 mph (5 km/h).

Once the vehicle is well secured, proceed in the

following order:

1- Getting the tools.

2- Removing the spare wheel from its

housing.

3- Positioning the jack.

4- Replacing the wheel to be repaired.

5- Storing the wheel to be repaired.

Page 109 of 196

107

In the event of a breakdown

8

► Install extended socket A, wheelbrace D and

wheel bar B on the retaining bolt.

► Turn the assembly anti-clockwise to lower the wheel.► Turn to the locking point of the winch, indicated by the hardening of the manoeuvre and

notch G not visible.

► After unrolling the cable completely , take the spare wheel out.

With steel wheels:

► Unscrew handle H.

► Remove caliper I from the outer part of the

steel wheel.

With alloy wheels:

► Unscrew the three fixing bolts K.► Unscrew handle H.► Remove bracket J from caliper I.► Remove the spare wheel and place it near the wheel to be replaced.► If possible, place a chock under the wheel diagonally opposite the wheel to be changed.

3 - Position the jack

Ensure that the jack is stable.

If the ground is slippery or loose, the jack

may collapse - Risk of injury!

Take care to place the jack strictly at jacking point 1 or 2 under the vehicle,

making sure that the jack head is centred at

the contact point on the vehicle. Otherwise,

there is a risk of damage to the vehicle and/or

the jack collapsing.

Make sure that any passengers are safe

(removed, away from the vehicle).

Never put your hands or your head in the

wheel arch.

Page 112 of 196

11 0

In the event of a breakdown

► Lightly tighten using wheelbrace D and wheel

bar B.

► Lower the vehicle using wheelbrace D and

wheel bar B, and then remove the jack.

► Tighten the bolts again using wheelbrace D

and wheel bar B.

Have the tightening of the bolts and the

pressure of the spare wheel checked by

the Manufacturer's dealer network or a

qualified workshop without delay.

Have the punctured wheel repaired and

refitted on the vehicle as soon as possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures and

reinitialise the system.

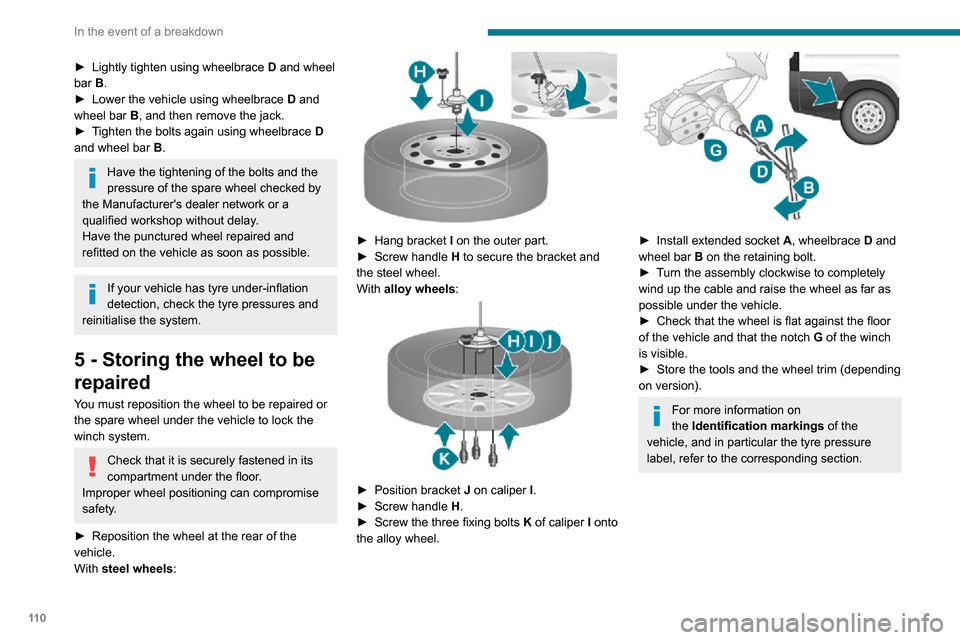

5 - Storing the wheel to be

repaired

You must reposition the wheel to be repaired or

the spare wheel under the vehicle to lock the

winch system.

Check that it is securely fastened in its

compartment under the floor.

Improper wheel positioning can compromise

safety.

► Reposition the wheel at the rear of the vehicle.

With steel wheels:

► Hang bracket I on the outer part.► Screw handle H to secure the bracket and

the steel wheel.

With alloy wheels:

► Position bracket J on caliper I.► Screw handle H.► Screw the three fixing bolts K of caliper I onto

the alloy wheel.

► Install extended socket A, wheelbrace D and

wheel bar B on the retaining bolt.

► Turn the assembly clockwise to completely wind up the cable and raise the wheel as far as

possible under the vehicle.

► Check that the wheel is flat against the floor of the vehicle and that the notch G of the winch

is visible.

► Store the tools and the wheel trim (depending on version).

For more information on the Identification markings of the

vehicle, and in particular the tyre pressure

label, refer to the corresponding section.

Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

► do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

► use a sponge and soapy water or a pH neutral product,► when using a high pressure washer on persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

► Do not touch the bulb directly with your fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

Page 113 of 196

111

In the event of a breakdown

8Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

► do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

► use a sponge and soapy water or a pH neutral product,► when using a high pressure washer on persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

► Do not touch the bulb directly with your fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

disappears after the lamps have been on for a

few minutes.

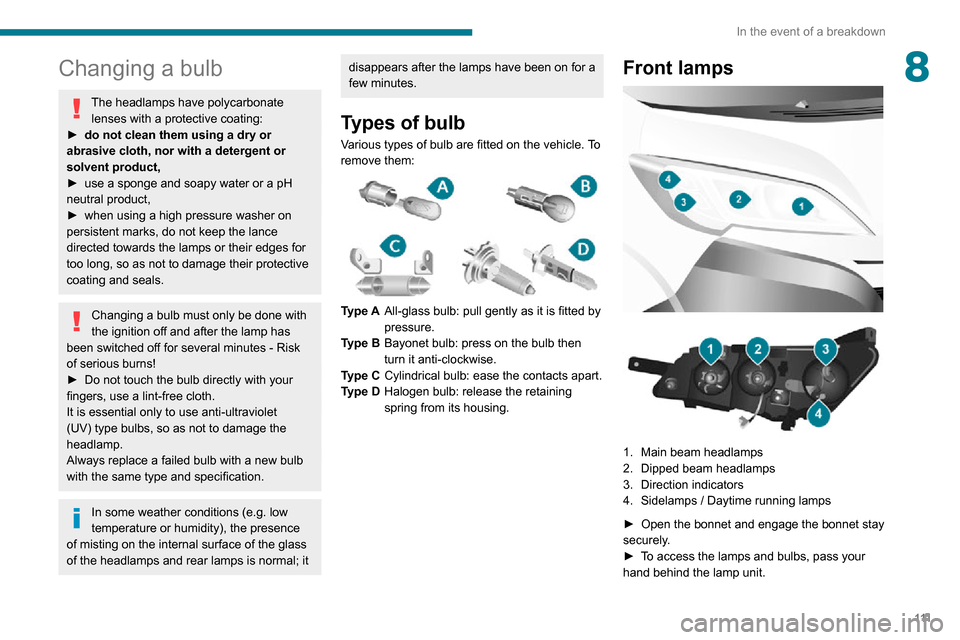

Types of bulb

Various types of bulb are fitted on the vehicle. To

remove them:

Type A All-glass bulb: pull gently as it is fitted by

pressure.

Type B Bayonet bulb: press on the bulb then

turn it anti-clockwise.

Type C Cylindrical bulb: ease the contacts apart.

Type D Halogen bulb: release the retaining

spring from its housing.

Front lamps

1.Main beam headlamps

2. Dipped beam headlamps

3. Direction indicators

4. Sidelamps / Daytime running lamps

► Open the bonnet and engage the bonnet stay securely.► To access the lamps and bulbs, pass your hand behind the lamp unit.

Page 115 of 196

11 3

In the event of a breakdown

8

► Remove the screw, located in the wheel arch.► Remove the protective flap.

► Remove the fixing clip and disconnect the electrical connector.► Turn and remove the bulb holder.► Change the bulb taking care to align the metal part with the grooves on the lamp.

The replacement of halogen bulbs must

be done with the headlamps switched off

a few minutes beforehand (risk of serious

burns). Do not touch the bulb directly with

your fingers; use a lint-free cloth.

When each operation has been completed,

check the operation of the lighting.

Direction indicator side

repeaters

Type A, W16WF - 16W

► Move the glass of the mirror to access the screws.► Remove the two fixing screws.► Pull the bulb holder to release it from the pins.► Pull the bulb out and change it.

Left-hand and right-hand

sidelamps

Type A, W5W - 5W

► If fitted on the vehicle (dimension L4), remove the two fixing screws.► Pull the bulb holder to release it from the pins.► Pull the bulb out and change it.

Courtesy lamps

Type C, 12V 10W - 10W

Page 117 of 196

11 5

In the event of a breakdown

8

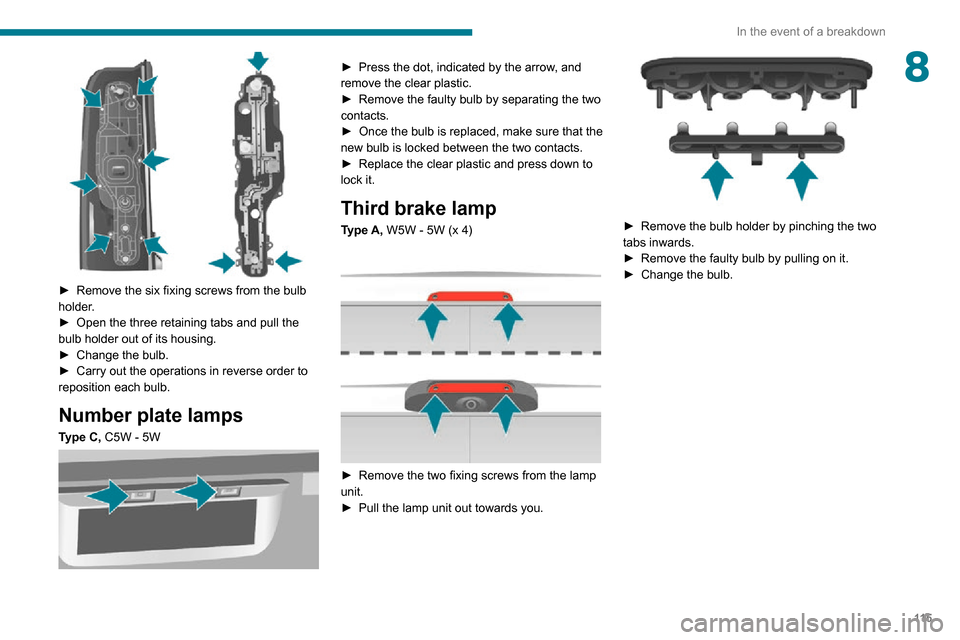

► Remove the six fixing screws from the bulb holder.► Open the three retaining tabs and pull the bulb holder out of its housing.► Change the bulb.► Carry out the operations in reverse order to reposition each bulb.

Number plate lamps

Type C, C5W - 5W

► Press the dot, indicated by the arrow, and remove the clear plastic.► Remove the faulty bulb by separating the two contacts.► Once the bulb is replaced, make sure that the new bulb is locked between the two contacts.► Replace the clear plastic and press down to lock it.

Third brake lamp

Type A, W5W - 5W (x 4)

► Remove the two fixing screws from the lamp unit.► Pull the lamp unit out towards you.

► Remove the bulb holder by pinching the two tabs inwards.► Remove the faulty bulb by pulling on it.► Change the bulb.

Page 118 of 196

11 6

In the event of a breakdown

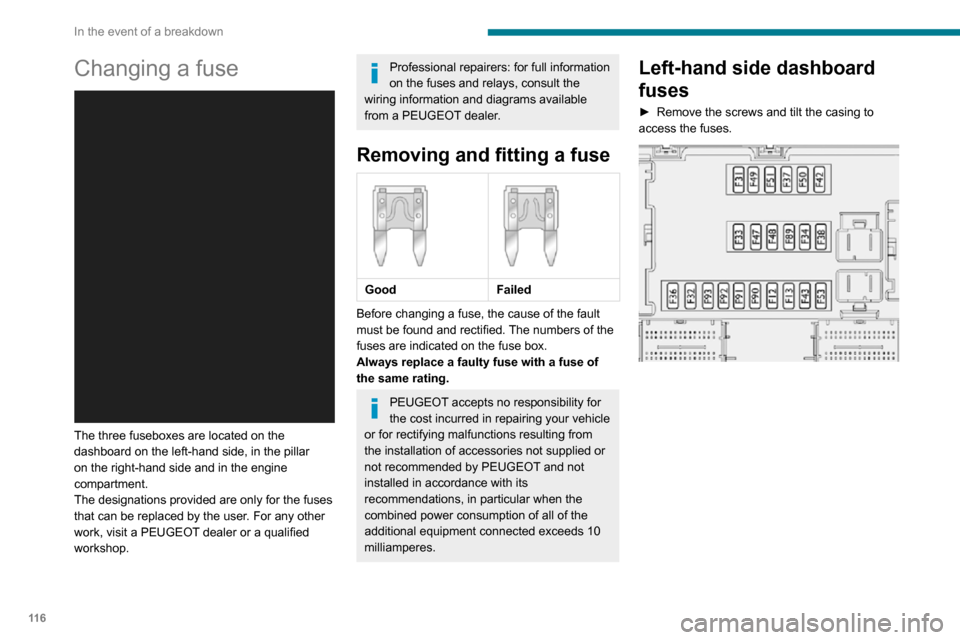

Changing a fuse

The three fuseboxes are located on the

dashboard on the left-hand side, in the pillar

on the right-hand side and in the engine

compartment.

The designations provided are only for the fuses

that can be replaced by the user. For any other

work, visit a PEUGEOT dealer or a qualified

workshop.

Professional repairers: for full information

on the fuses and relays, consult the

wiring information and diagrams available

from a PEUGEOT dealer.

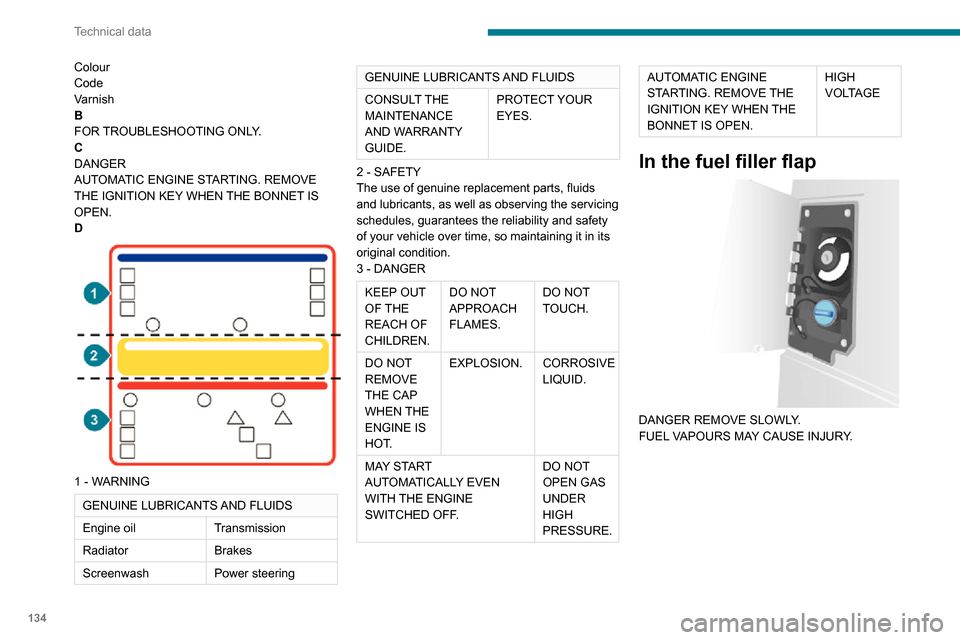

Removing and fitting a fuse

Good

Failed

Before changing a fuse, the cause of the fault

must be found and rectified. The numbers of the

fuses are indicated on the fuse box.

Always replace a faulty fuse with a fuse of

the same rating.

PEUGEOT accepts no responsibility for

the cost incurred in repairing your vehicle

or for rectifying malfunctions resulting from

the installation of accessories not supplied or

not recommended by PEUGEOT and not

installed in accordance with its

recommendations, in particular when the

combined power consumption of all of the

additional equipment connected exceeds 10

milliamperes.

Left-hand side dashboard

fuses

► Remove the screws and tilt the casing to access the fuses.

Page 136 of 196

134

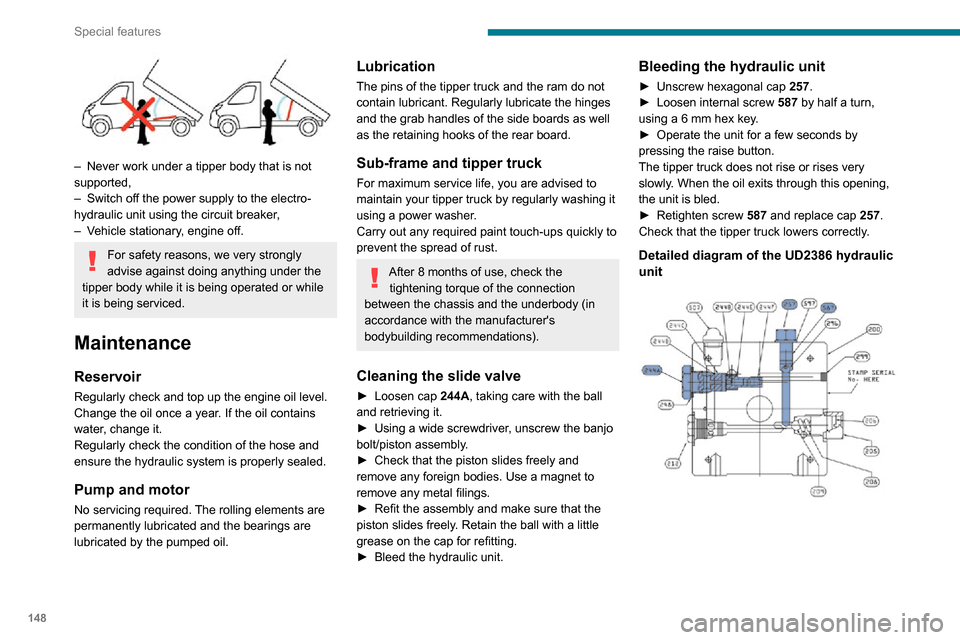

Technical data

Colour

Code

Varnish

B

FOR TROUBLESHOOTING ONLY.

C

DANGER

AUTOMATIC ENGINE STARTING. REMOVE

THE IGNITION KEY WHEN THE BONNET IS

OPEN.

D

1 - WARNING

GENUINE LUBRICANTS AND FLUIDS

Engine oilTransmission

Radiator Brakes

Screenwash Power steering

GENUINE LUBRICANTS AND FLUIDS

CONSULT THE

MAINTENANCE

AND WARRANTY

GUIDE.PROTECT YOUR

EYES.

2 - SAFETY

The use of genuine replacement parts, fluids

and lubricants, as well as observing the servicing

schedules, guarantees the reliability and safety

of your vehicle over time, so maintaining it in its

original condition.

3 - DANGER

KEEP OUT

OF THE

REACH OF

CHILDREN. DO NOT

APPROACH

FLAMES.

DO NOT

TOUCH.

DO NOT

REMOVE

THE CAP

WHEN THE

ENGINE IS

HOT. EXPLOSION.

CORROSIVE

LIQUID.

MAY START

AUTOMATICALLY EVEN

WITH THE ENGINE

SWITCHED OFF. DO NOT

OPEN GAS

UNDER

HIGH

PRESSURE.

AUTOMATIC ENGINE

STARTING. REMOVE THE

IGNITION KEY WHEN THE

BONNET IS OPEN.HIGH

VOLTAGE

In the fuel filler flap

DANGER REMOVE SLOWLY.

FUEL VAPOURS MAY CAUSE INJURY.

On the rear bench seat

A

Push the backrest before folding it down.

B

PULL TO OPEN.

C

PULL LEVER 1 TO PARTIALLY TILT THE

BACKREST.

PULL LEVER 2 TO FOLD THE BACKREST

FULLY.

Page 150 of 196

148

Special features

– Never work under a tipper body that is not supported,– Switch off the power supply to the electro-hydraulic unit using the circuit breaker,– Vehicle stationary, engine off.

For safety reasons, we very strongly

advise against doing anything under the

tipper body while it is being operated or while

it is being serviced.

Maintenance

Reservoir

Regularly check and top up the engine oil level.

Change the oil once a year. If the oil contains

water, change it.

Regularly check the condition of the hose and

ensure the hydraulic system is properly sealed.

Pump and motor

No servicing required. The rolling elements are

permanently lubricated and the bearings are

lubricated by the pumped oil.

Lubrication

The pins of the tipper truck and the ram do not

contain lubricant. Regularly lubricate the hinges

and the grab handles of the side boards as well

as the retaining hooks of the rear board.

Sub-frame and tipper truck

For maximum service life, you are advised to

maintain your tipper truck by regularly washing it

using a power washer.

Carry out any required paint touch-ups quickly to

prevent the spread of rust.

After 8 months of use, check the tightening torque of the connection

between the chassis and the underbody (in

accordance with the manufacturer's

bodybuilding recommendations).

Cleaning the slide valve

► Loosen cap 244A , taking care with the ball

and retrieving it.

► Using a wide screwdriver , unscrew the banjo

bolt/piston assembly.► Check that the piston slides freely and remove any foreign bodies. Use a magnet to

remove any metal filings.

► Refit the assembly and make sure that the piston slides freely. Retain the ball with a little

grease on the cap for refitting.

► Bleed the hydraulic unit.

Bleeding the hydraulic unit

► Unscrew hexagonal cap 257.► Loosen internal screw 587 by half a turn,

using a 6 mm hex key.

► Operate the unit for a few seconds by pressing the raise button.

The tipper truck does not rise or rises very

slowly. When the oil exits through this opening,

the unit is bled.

► Retighten screw 587 and replace cap 257.

Check that the tipper truck lowers correctly.

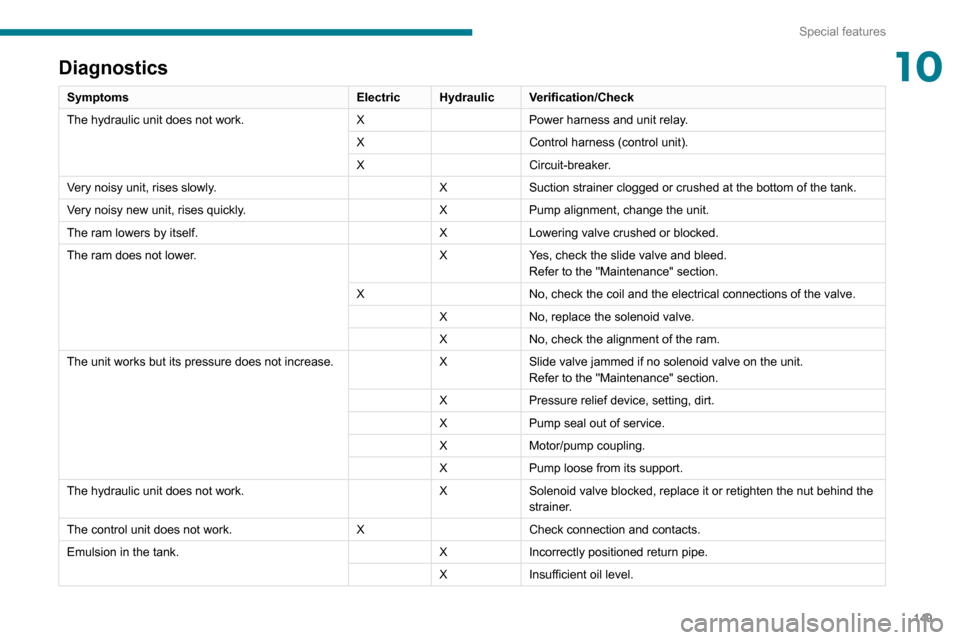

Detailed diagram of the UD2386 hydraulic unit

Diagnostics

Symptoms ElectricHydraulic Verification/Check

The hydraulic unit does not work. XPower harness and unit relay.

X Control harness (control unit).

X Circuit-breaker.

Very noisy unit, rises slowly. XSuction strainer clogged or crushed at the bottom of the tank.

Very noisy new unit, rises quickly. XPump alignment, change the unit.

The ram lowers by itself. XLowering valve crushed or blocked.

The ram does not lower. XYes, check the slide valve and bleed.

Refer to the "Maintenance" section.

X No, check the coil and the electrical connections of the valve.

X No, replace the solenoid valve.

X No, check the alignment of the ram.

The unit works but its pressure does not increase. XSlide valve jammed if no solenoid valve on the unit.

Refer to the "Maintenance" section.

X Pressure relief device, setting, dirt.

X Pump seal out of service.

X Motor/pump coupling.

X Pump loose from its support.

The hydraulic unit does not work. XSolenoid valve blocked, replace it or retighten the nut behind the

strainer.

The control unit does not work. XCheck connection and contacts.

Emulsion in the tank. XIncorrectly positioned return pipe.

X Insufficient oil level.

Page 151 of 196

149

Special features

10Diagnostics

SymptomsElectricHydraulic Verification/Check

The hydraulic unit does not work. XPower harness and unit relay.

X Control harness (control unit).

X Circuit-breaker.

Very noisy unit, rises slowly. XSuction strainer clogged or crushed at the bottom of the tank.

Very noisy new unit, rises quickly. XPump alignment, change the unit.

The ram lowers by itself. XLowering valve crushed or blocked.

The ram does not lower. XYes, check the slide valve and bleed.

Refer to the "Maintenance" section.

X No, check the coil and the electrical connections of the valve.

X No, replace the solenoid valve.

X No, check the alignment of the ram.

The unit works but its pressure does not increase. XSlide valve jammed if no solenoid valve on the unit.

Refer to the "Maintenance" section.

X Pressure relief device, setting, dirt.

X Pump seal out of service.

X Motor/pump coupling.

X Pump loose from its support.

The hydraulic unit does not work. XSolenoid valve blocked, replace it or retighten the nut behind the

strainer.

The control unit does not work. XCheck connection and contacts.

Emulsion in the tank. XIncorrectly positioned return pipe.

X Insufficient oil level.